Leaderboard

Popular Content

Showing content with the highest reputation on 10/10/22 in all areas

-

5 points

-

I have always and still do find hairspring manipulating a challenge. However for me working under a microscope with a pin and the Bergeon (7025-6) tweezers has given me the best results. Also study first before moving anything because making as few manipulations as possible is important because the spring will snap.3 points

-

sure thing bud. yep you're onto it now. just like a miniature egg crate at the bottom of your jars or as far as your imagination takes you. I should have mentioned that I only have one lead split T. so, i use one side of it in one jar, the other in the 2nd and the third is, yup you guessed it, a cookie cutter taken straight out of my wife's kitchen. She doesn't know it but she is short one six-pointed cookie cutter2 points

-

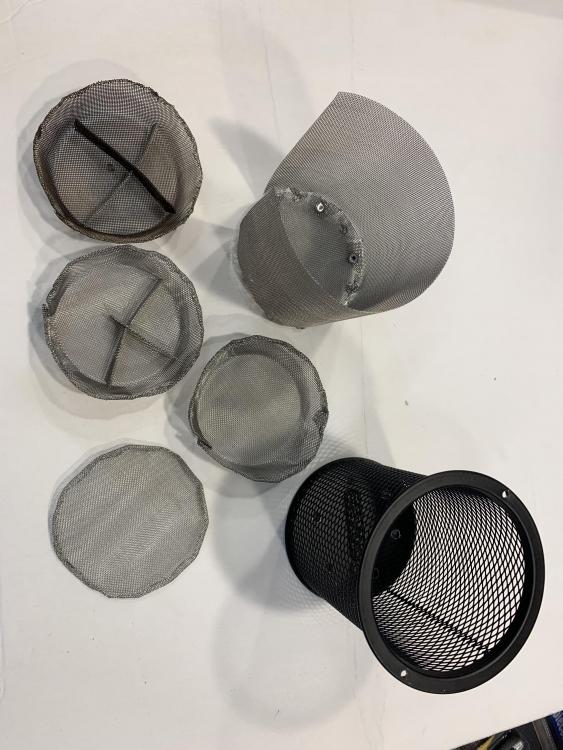

Hi Gerty think old fashioned "cookie cutters." you can find them just about anywhere. They're flexible, bendable and come in every shape and form known to man. you can also find the wavebreakers on Ebay from time to time. and the third option which I think you could easily handle is, make em yourself. my jars on my old bulky cranky Good-All watch parts washer(I've posted pics of on here somewhere)are thick lead split T-plates. rare to find and less attractive to make. may I present exhibit 'A' below -a fast and dirty napkin drawing I just meticulousy scribbled out. cut two pieces of 4-5mm x 85cm long(or depending on what dimensions work for you. these would fit in my jars) of stainless steel or something heavy and either slot saw or pierce saw a slot half way thru the center of each piece then turn em 90Degs. perpendicular to each other in an 'X' pattern, slide them together, one slot through the other and you have your wavebreakers. you can add as many as you want with more slots. hope I explained that ok. I like your DIY. I myself have been thinking about a homemade wash machine using air along with whatever cleaning agent. Ive even made another one of my famous napkin drawings of it. It's around here somewhere. I call it my "Bubbler." Just haven't started it yet. one of my many projects on the books. some of the commentors above have also spoke of air. in the machining/mechanic world, we've used air and chemicals for as long as I can remember to clean parts and had great results. One of my concerns tho, in a home shop setting, is fumes. I gotta work on that. keep us posted on your DIY washing maching. yes used it quite a bit during my career. works great. i have an idea for a DIY Bubbler machine I just haven't moved on it yet. vapor control is one of my issues and the usual dirty cleaning agent, in this case lighter fluid. for now when it gets dirty enough, I then put in a marked "dirty" jar and let it sit. when the jar is full enough the dirt and oil settles to the bottom, I take a turkey baster and siphon the "clean stuff" into yet another jar, with two coffee filters at the top. still get a few cycles from it later on before it finds its way proper disposal or the occasional bonfire starter.2 points

-

2 points

-

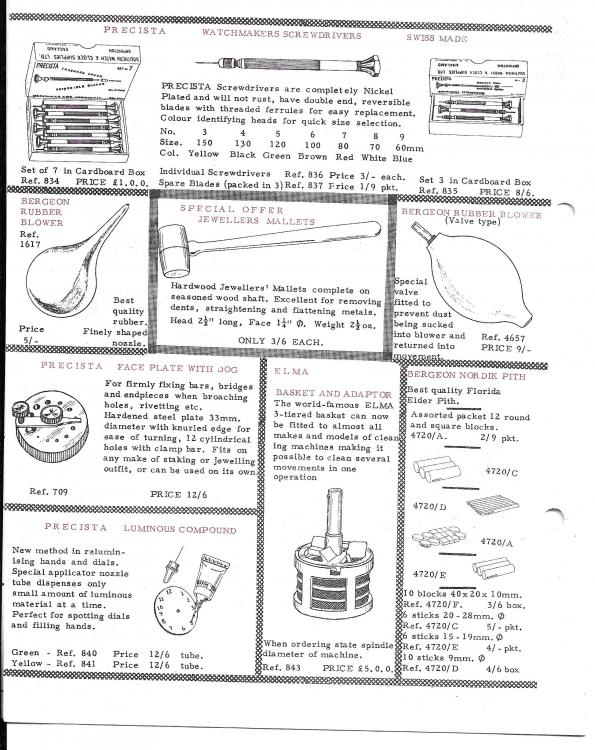

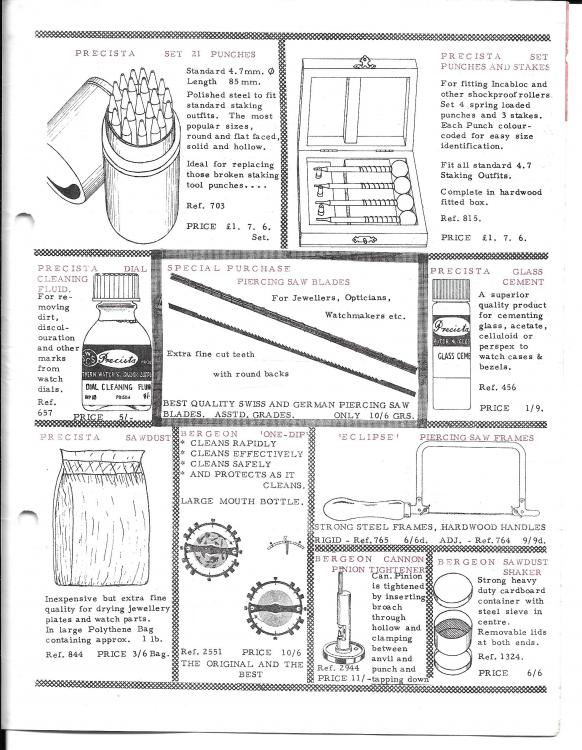

Hi Those ELMA basket are way too pricey for what they are, its just the "watchmaker"tag that does it. the Inserts are just pressed out of S/s wire mesh. and the basket holder is an injection moulded casing the cost in that being the tool/die but once done you can bat out hundreds no problem. I understand what you are trying to achieve as it would be bespoke tailored to your own spec. stick at it, any more ideas come up I will post them all the best.2 points

-

I just made me a little piece of thick white paper (1.5cm x 3cm) and fix that with photo stickers over the LED lamp of my iphone ( if it blinds you can reduce light power or use a second paper layer). This gives me a bright surface. With this setup I can exactly see what I m doing without irritating shadows.2 points

-

You’re gonna laugh at me but I’ve been using a staking block. I’ve been meaning to get a fancy hairspring holder but it slips my mind when I place orders. I’d imagine the collet of the HS goes over the hole? It’s for that reason I’ve cheated with a staking block because it’s full of holes2 points

-

No. I’ve set it so it will hide the post and an admin can review it later in case of mistake. Why it’s a bad idea for members to respond? Well I think it’s a bad idea because it lets the spammer know that their acts have been successful. Nope - just ANY advertising or self promotion done without permission of the site admin (me). The rules are very clear on our Rules page and Terms displayed when signing up. it’s worrying that you have to ask. If anyone has been involved with the internet for any small amount of time they simply must know what spam is, I shouldn’t have to explain it. However, in case of any confusion, a quick google search on the meaning of SPAM should clear any confusion. https://www.merriam-webster.com/dictionary/spam And to be clear, we are not talking about a heavily processed tin of dubious meat2 points

-

I'm a longtime member of another forum (non-watch related), and personally know several of the members. I have posted up some of my recent watch projects as a several of the people there have told me that they enjoy seeing that kind of work being done. One of the members (whom I haven't met previously) sent me a private message telling me that he had his grandfather's old watchmaking tools and asked me if I'd be interested in purchasing them. We started to talk and he sent me a few photos, which got me excited! He then proceeded to tell me that his grandfather was the official clock and watch repairer for Queen Juliana of Holland. He sent me a photo of a newspaper article his family has kept from the Tulsa World newspaper back from the 1970's, stating that his grandfather was one of the best watchmakers in Holland. After he repaired a special clock for Queen Juliana that was given to her as a gift from Prime Minister David Ben-Gurion of Israel, she was so pleased with his work that the queen became one of his clients! The story goes on to give a history on his grandfather, and was very interesting to read. I tried to upload a high quality photo of the newspaper article, so you can zoom in and read it if you'd like to. He told me that his family has kept his grandfathers tools since he passed away many years ago. They never had any intent of selling them, but after he read that I was getting started learning watchmaking and knew that I was local. They decided to offer them to me for sale with the strict provision that I do not sell any of them, but rather use his grandfathers tools as I continue to learn watchmaking. I was happy to agree to his terms. I finally got home this evening after meeting him on the other side of the state and began going through all of the items. There is a complete staking set with every single piece still in the box, all of which are in fantastic condition, a Jacot tool, a lathe, several sets of broaches and files, bags upon bags of parts, a poising tool, and some other tools that I honestly don't even know what they do at this point. I explained to him that some of the tools were beyond my current skill level. We both smiled when I said that because the whole idea was for me to use them to learn as I continue to move forward. Here are some photos: This last photo is of a few tools that I haven't yet figured out what they for. The bottom/middle tool I thought perhaps was what you use to hold hands if you need to use a broach to open up the eyelets, but it does not separate to allow you to install the hands, and the holes are quite large. I'm unsure what any of them do quite honestly. I think I got a really good deal. I purchased all of these items for a total of $600. I know the staking set is probably worth nearly that by itself. I'll need to find a motor to use for the lathe, but I'd imagine it'll be some time before I get to a point where I can use it. I have an immediate need for the staking set and Jacot tool, so I'm going to find some fishing line and restring the bow so I can spin the tool. If anyone can provide any insight on what the 4 tools are in the last photograph, I'd be very appreciative. I'm pretty excited to use these tools, and am extremely grateful that his family thought me worthy to continue on using his grandfather's tools. Hopefully I made a good investment!1 point

-

Hello, I just stumbled onto your site. I was looking for info on cleaning pallet forks & balance. I found the very good information here! My name is Benjamin. I am retired and live in San Marcos, California. I enjoy American pocket watches (mostly Hampden Watch Co.), just a small collection, I have. Also, many French clocks are in my home.1 point

-

1 point

-

1 point

-

Hi all, this is just a heads up for those who do not know… if you spot spam in the forum please do not respond with a post reply - it would be really helpful if you could click the ellipsis within that post and then choose “report” from the menu. Or in other words - report that post for spam. Now - the forum software we use automatically hides the post if just two members report that post, this is especially useful when I or other moderators are offline bearing in mind we’re all in different time zones. it will be impossible to eliminate spam but this is one tool we can all use to minimise it. BTW - Most spammers cannot even join as they’re already on a blacklist which I subscribe too. thanks for your help.1 point

-

typically with people who don't understand watches you will hear the term overwhelmed and that means for our discussion absolutely nothing. Fortunately you have a Hamilton 992B parts are readily available service information's available it's a really solid outstanding watch just very nicely made and it will keep really good time. Then yes it's an unfortunate classic that people get into watches and play with them I've seen worse. One of the watches I had in for repair was missing its hairspring and I think there was something else it was missing in addition to the hairspring. So it was missing the case back to need a new case and a few other things plus the balance staff is broken on some of the screws were wrong somebody was attempting amateur watch repair or playing with the screws so I've seen worse it looks to be visually intact I don't see anything missing it probably has a broken balance staff. Because it was probably dropped and that's an unfortunate problem a pocket watches they do not like to be dropped. Fortunately this is a relatively easy watch to change a staff it's a friction staff1 point

-

Thank you for the advice and for the link. That’s exactly what I needed, as it’s tough to find a vintage movement that works for under $100. I’ll order it right away! Also, here is a shot of the movement in my grandfather’s Hamilton. It looks to be in good shape, visually anyway. My mother actually told me yesterday that it was running fine until my sister got her hands on it when she was a little girl and over wound it. So that might be a good clue as to what is going on with the Hamilton. :)1 point

-

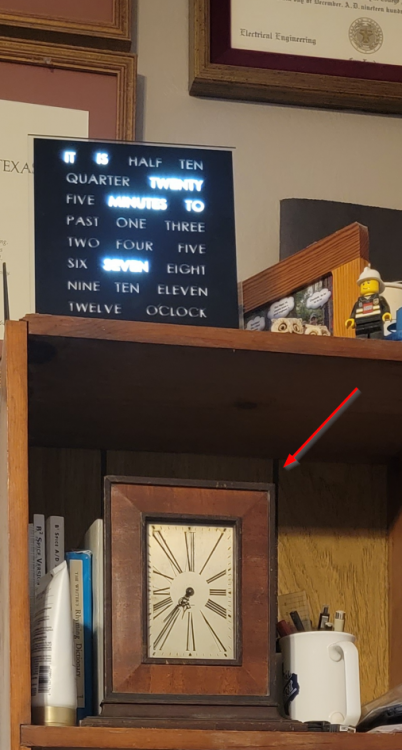

yes that's an interesting question. then you read my mind as I needed a picture but I also did a search in my computer and I found this. then you make out in that I did a search of my computer looks like I actually scanned this versus acquiring it from who knows where you get a service bulletin. Unfortunately you have to figure out some of the lubrication on your own as so much for lubrication standards throughout time of servicing watches. Omega 470 500.PDF1 point

-

out of curiosity when I was at work I asked where we send dials to and Kirk dial I may give you the only real link I have which will explain another problem. I remember what I was visiting Rolex in Geneva somebody asked about dials and they said Kirk dial. which I thought was odd that's a Seattle company now the catch is they do go through generations of people so now the other problem is like Kurt dial is operating like watch material houses do. A lot of them are not online they don't want to deal with online looking at the reviews for the company apparently only likes to deal with facts. I'm assuming if we deal with them they must physically go there something I didn't actually ask how we do dials with them. In any case a lot of the watch material houses and apparently dial companies are basically by word-of-mouth and you're in the trade and you know they exist otherwise they don't want to know that you exist https://www.yellowpages.com/kent-wa/mip/kirk-dial-of-seattle-inc-9303024 yes I know in this world of the Internet it seems impossible that everyone isn't on the Internet but in the watch material business and apparently the dial business is still exists.1 point

-

Thanks Gert, very kind of you. We've been together since we were 17 now 55, but was a while before we got married 16 years ago. Rome is an amazing place, very busy like Paris, you are taking your life in your hands just crossing the road, its a free for all. Your design is looking great, I build everything that way, a basic plan then make the rest up as you go along1 point

-

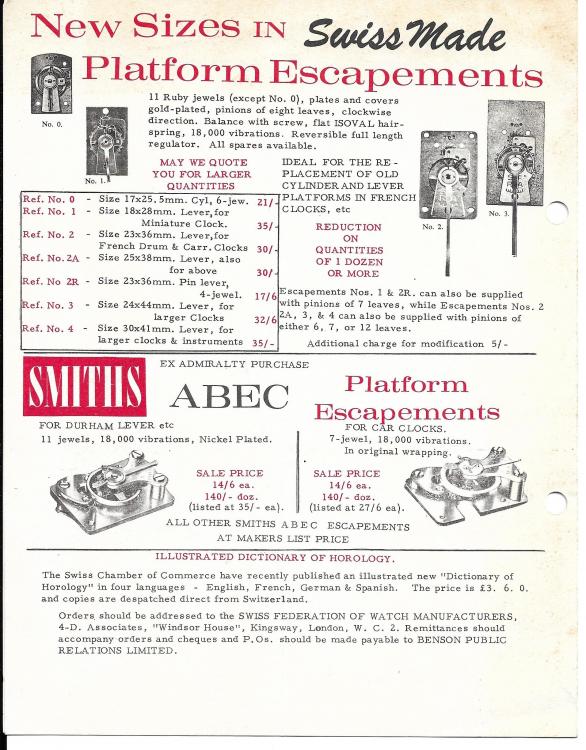

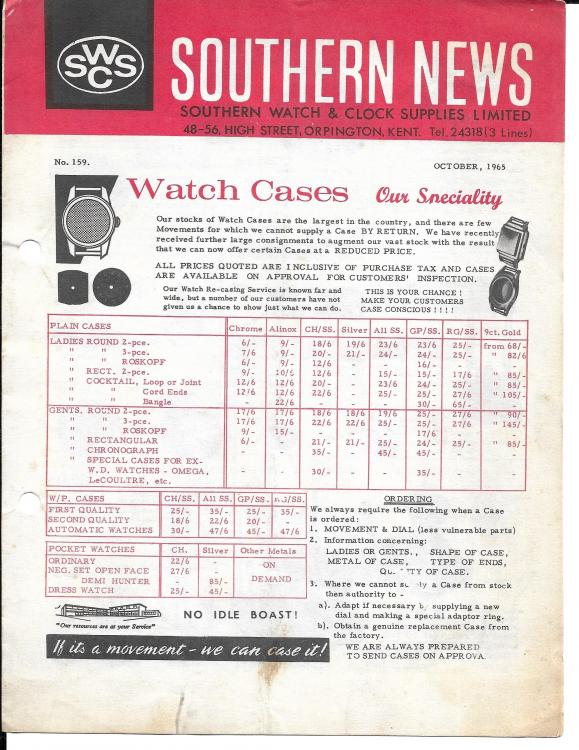

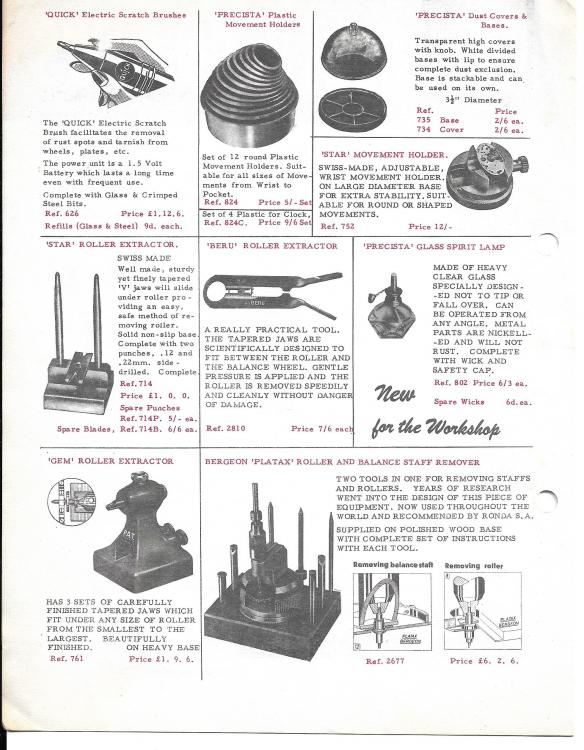

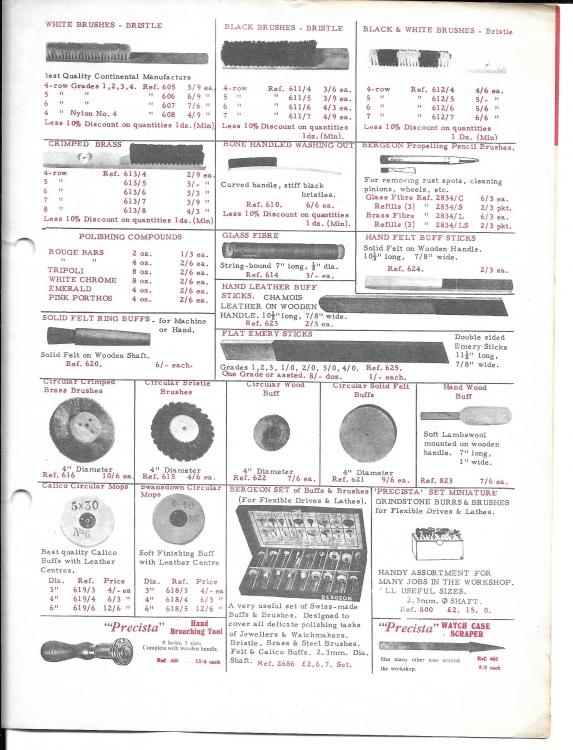

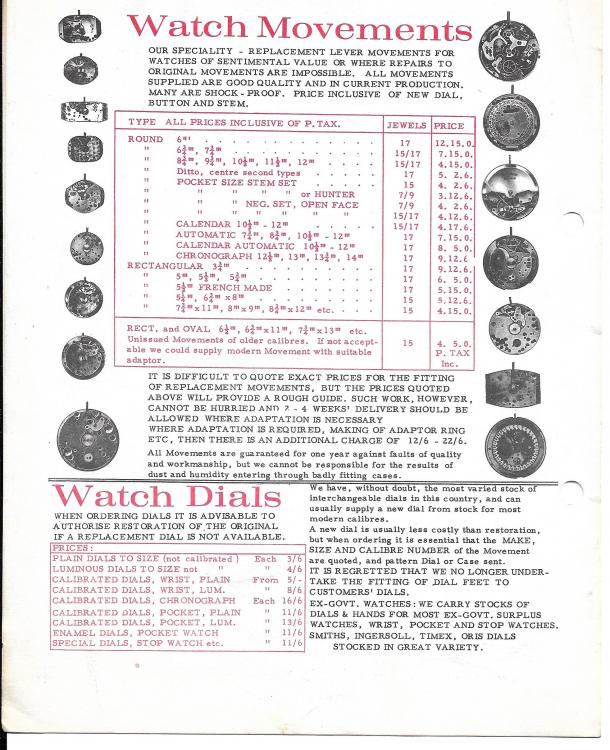

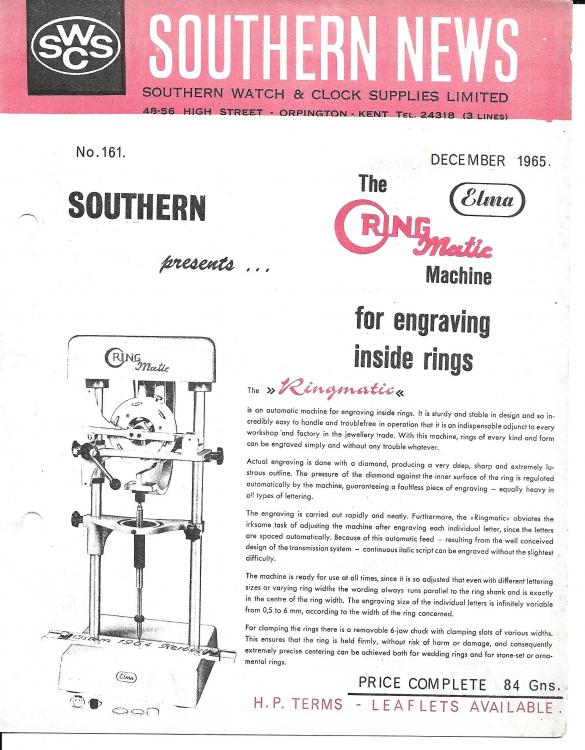

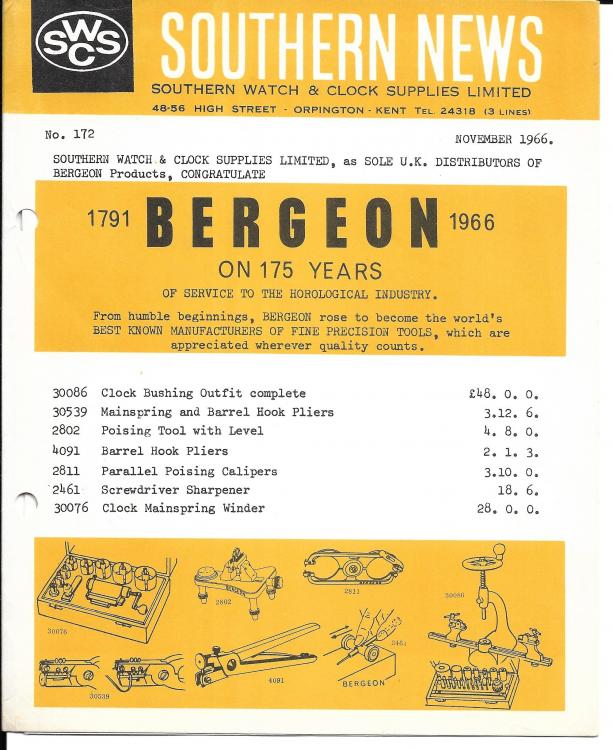

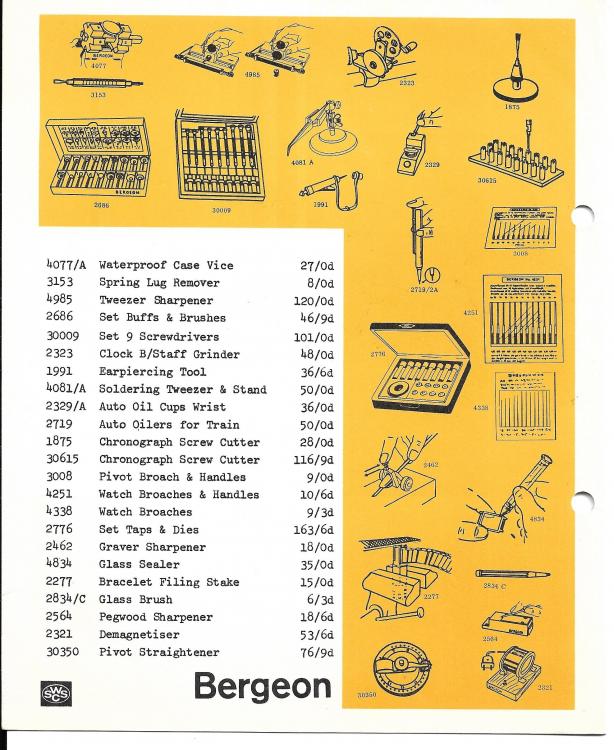

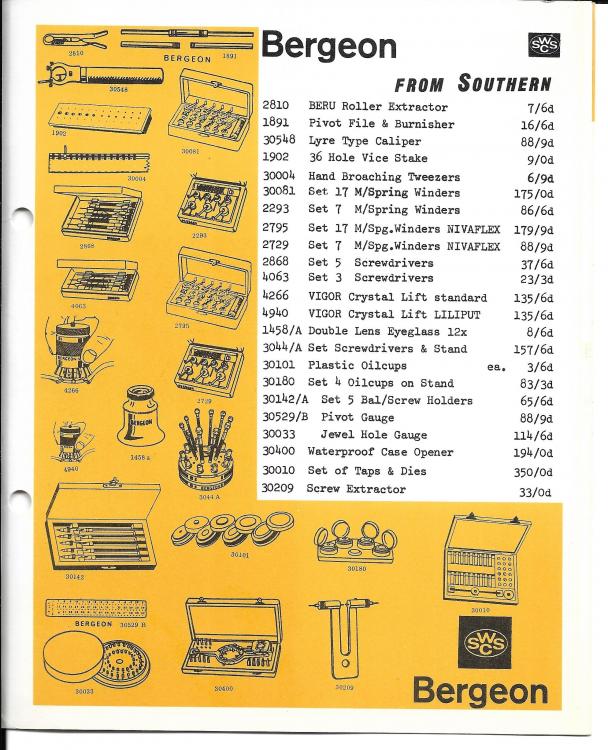

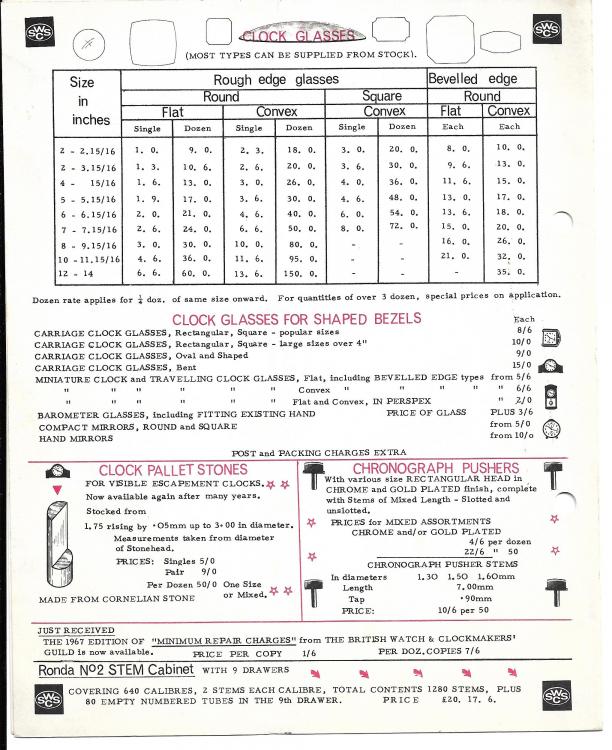

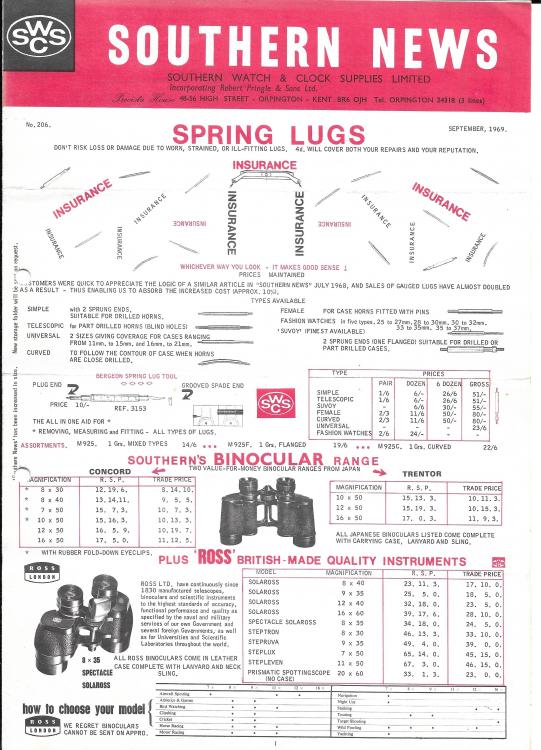

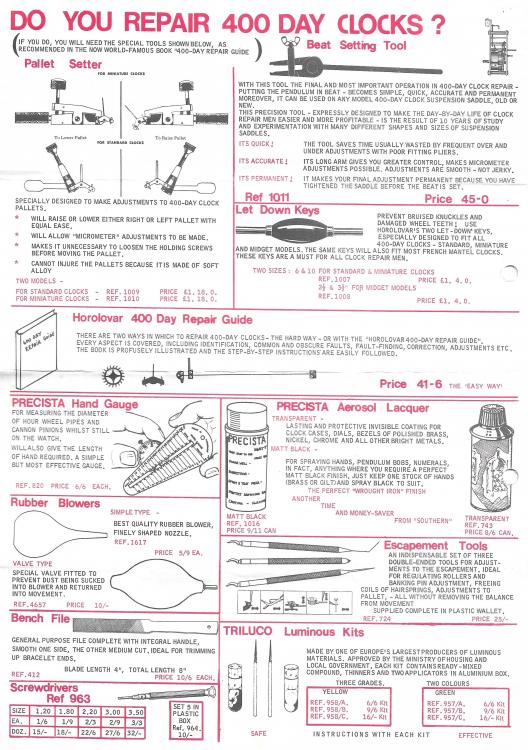

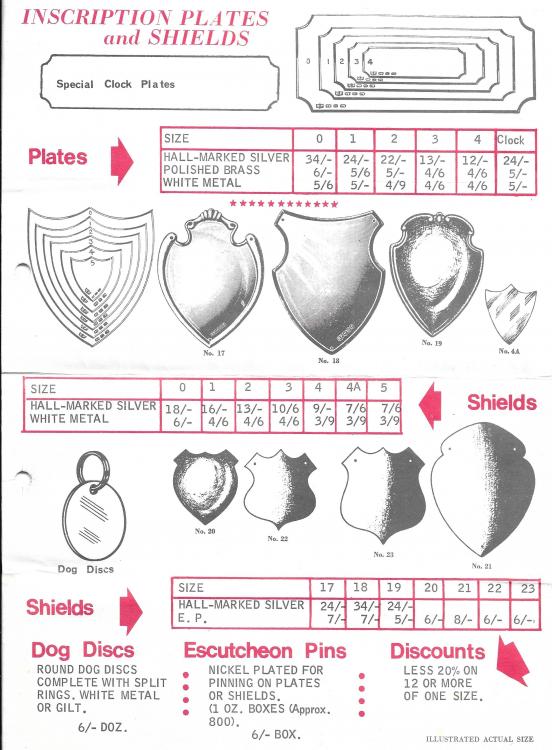

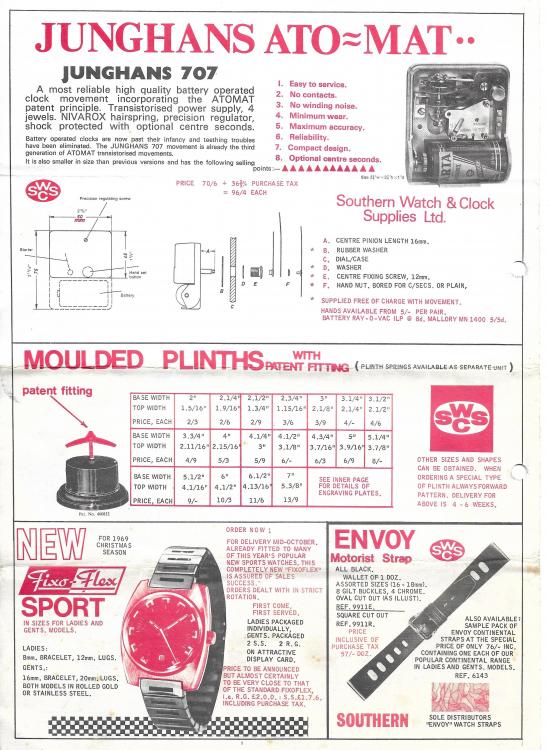

April 1963 Issue No 129 Why does the truing and posing tool eliminate the danger of distortion or damage to the Balance Staff Pivots or Balance Wheel Rivets? Smiths platform escapements. October 1965 Issue No 159 If its a movement we case it. December 1965 Issue No 161 November 1966 Issue No 172 One of those landmarks in yellow. February 1967 Issue No 175 September 1969 Issue No 2061 point

-

1 point

-

No Googling needed, if you watch Kalle Slaaps video (3 videos on hairspring reapair) on Chronoglide Watchmakers (very good channel), it confirms it.1 point

-

Hi I had the idea of using a mini sprayer (air brush) to clean watch parts as used in large engine cleaning machines where the fluid filters down into a tank and is re used untill its no use. This recycles the fluid and when dirty is discarded. Abandonded it as it would be probably too large a construction and I have other things to do to devote the time to it. Just keep moving the cookie cutters around Mike she wont notice untill stock take.1 point

-

Perhaps you're on to something! It would be nice to know. Perhaps there's more to find out by Googling it intensely. Yes, that's my impression of how most people do it, so thanks for confirming. I try to think of delicate work as a kind of meditation. I always try to be aware of and guard my breathing and muscle tension (there's always more to do). If you stop breathing and get tense enough it can really turn into a mess, both the work and the joy of doing it.1 point

-

I always work with the stud facing up, so I don't see the point of the Bergeon tool having a hole - unless it's so that you can put the balance wheel pivot and roller in to the hole then work on the hairspring? - If you watch Kalle's excellent videos on hairspring repair, this is what he's doing https://www.youtube.com/watch?v=mUTvajqeX3U&t=5s , then when he's working on just the hairspring, he's working just on he flat surface. I've never used a hole. I just have the hairspring sat flat on the mat. Maybe I'm doing it wrong ! I always work under the microscope. I don't think I could do it otherwise - using a loupe with high enough magnification, your head gets in the way of lighting and tools. If I need to twist the spring, I used 2 pairs of pointed tweezers, and for adjusting the curve, one pair and the tip of an old sharpened oiler.1 point

-

Getting quicker than me nowadays is not difficult. Getting older is just managed decline. Ps Mark still a great forum despite a few spammers.1 point

-

Unlikely watchie, I'm sure you are liked, I like you and that's all that matters Haha,I'm touched that you are worried about me Mark, thank you that makes me feel special. As if we would do such a thing .1 point

-

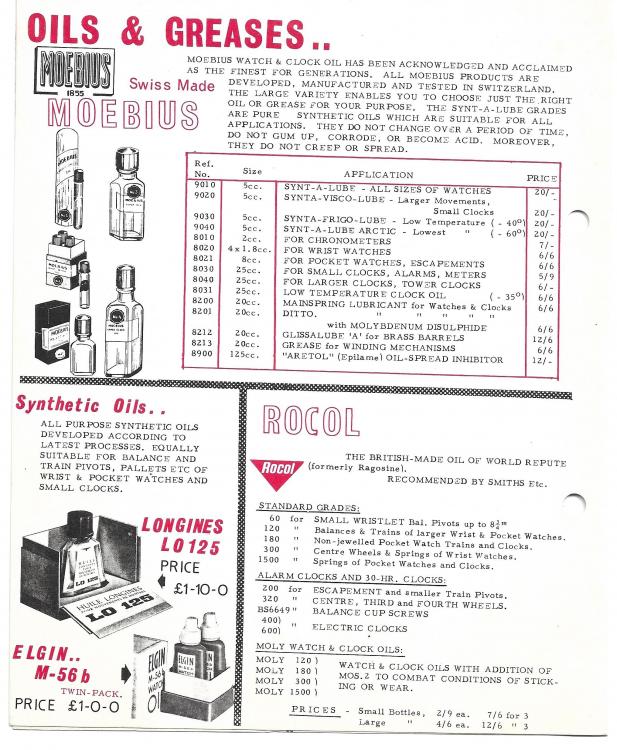

This might be common knowledge, but I found individually buying the Moebius synthetics was going to quickly make a single watch service not financially reasonable. The only solution I was reading about was compromising lubricants or running things dry that could probably get away with it so that not so many costly types of lubricants were needed. I ended up finding a seller on Ebay out of Sweden who is re-packaging Moebius into smaller quantities. Its taking a chance on the expiration date of these lubes, but in my mind a very small gamble to make if you are capable of doing your own service on your own watch. I don't have them in hand so if anything goes wrong I'll update the post. https://www.ebay.com/itm/295197592514?var=5934233810681 point

-

hay as a consumer of said processed tin of dubious meat that also happens to be process...er manufactured about 80 miles away from me, I resemble that!1 point

-

Those baskets are stupidly priced for what they are - I couldn’t agree more. But they are made to a high standard, where the Indian made alternative isn’t - just looking at the experiences over in the Pearl thread put me off cheap baskets. I have some of the cheaper small baskets here made in India and they appear to use a chrome plated steel as opposed to stainless. I’ve seen first hand where the chrome seems to be “dissolving” and where the mesh is welded poorly to solid areas. So yeah, £22 for a small lidded basket is stupid but here we are for lack of an alternative (I saw the cheaper Horotech mini baskets mentioned here, but I needed the complete package with basket holder and top adapter). I will certainly welcome more of your ideas as they come up! Thank you Mike! I get exactly what you saying and that is certainly something I’ll try. Like a X placed at the bottom and if I feel like going over the top, I can make a grid of these interconnected pieces. But as you say, a bendable cookie cutter might also work (and I suspect that design is what they used on the older L&R machines).1 point

-

I agree, and do. IMHO that expiration date is a ploy to get you to buy more. if that oil doesn't have "hair" growing on it like a moldy science project left in the fridge too long, them I'm using it.1 point

-

Coincidentally, I just purchased the Dumont version of those tweezers and have a bunch of hairspring work ahead of me. In addition to Mark's videos on the subject, I just found this Youtube video that I found super useful.1 point

-

No, a standard oiler won't generally fit, but it brings the oil drop to the hole. What actually goes through is the fine wire or broach, which does need to fit. I have a very fine strand taken from a wire brush that I keep in a cheap pin vise to use when oil needs to be fed/wicked/teased into the cap cavity. Some people use a very fine needle in the same way.1 point

-

And how! Stian posted a new video yesterday (10/8) where he makes short work of manipulating a hs back into useable shape.1 point

-

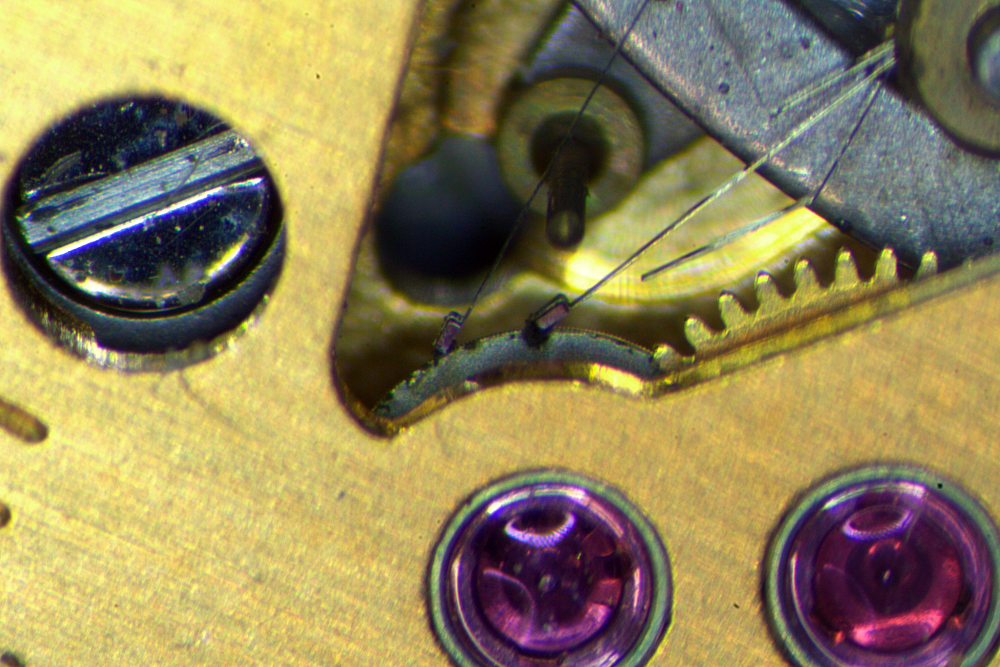

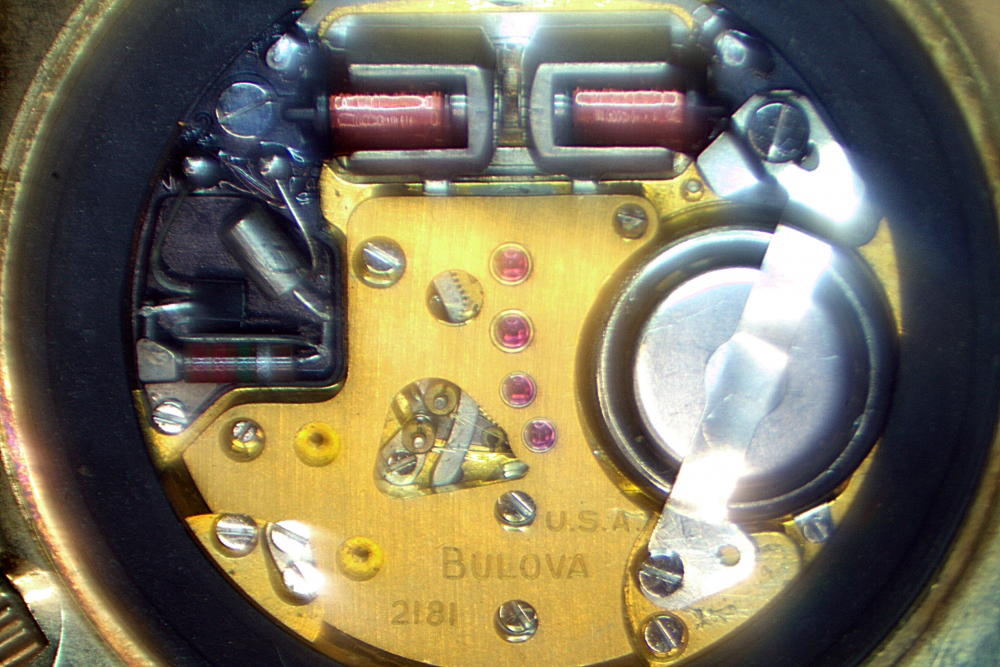

When I first started being interested in watches, mom passed on her dad's Accutron to me. He died back in 2004 and was a huge part of my life growing up, so this is a treasure to me. So I put it in a drawer and didn't touch it until I felt ready. I bought several other 218 movements to practice on, as well as the Accu-cell 1.35v battery. I've got the Model 700 test kit, the service manual, and watched all of Henry Frystack's videos, so I feel like I'm ready to dive in. Today I thought maybe start with putting a fresh battery in--looks like an old mercury cell is still in there--and see what happens. Then I put it under the microscope and found clouds of gunk on the index wheel and pawls and decided against it. Guess it's time for a cleaning!1 point

-

Can I see that my post has been hidden/marked as spam? I believe some social media platforms hide messages they wish to censor. That is, they can make the poster believe the message is public when in fact no one can read it. I certainly don't expect or suspect that happening on WRT. I was merely curious to know what it would look like from the spammer's perspective. Decisive and excellent! No room for interpretation! No, you are not! I feel most welcome at WRT, and if I may say so, it appears to me that many of my posts are appreciated As I said, I'm just being curious. Never, and I don't expect it either. The exception of course is @gbyleveldtand @Neverenoughwatches which can't be trusted but now that they are fully aware of the consequences I think and hope they will refrain from marking my posts as spam1 point

-

I can't imagine either @Neverenoughwatches or me playing a prank on you. Nope. Never crossed my mind. Till you planted that gem now of course.1 point

-

Rome? Geesh you're a baller - lucky man! And congrats in advance of your anniversary!! How long have you guys been married now? Well, this is how far I got the weekend. Still much to do as I'm designing it as I'm going (yeah, not a bright idea). I was going to sorta stop there, but then I realized that I'm going to need a 2nd gantry to make it more rigid. At 300 rpm (wash cycle) it's ok, but when I go to 1k rpm (drying spin cycle) then things come a little unglued. Why did I pick those numbers you may ask? Well that's how the modern Elma machines work (according to their spec sheets) so I figured I'd copy that. Then I figured, while I'm making another gantry, why not give it a z axis so it can lift itself out of the solution and then ramp up to the spin cycle. Automagically. Then all I need to do is push a button and it takes care of washing and spinning, then I change the jar to a rinsing solution and repeat. I hate that "while you're in there" thoughts... I also need to give some thought to what I'm going to do for wavebreakers. When it spins up even at low speeds the solution tends towards the outside of the jar, leaving the inner part of the basket with little solution. It may or may not be an issue though as I'm changing direction every 2 seconds in the wash cycle. On the older L&R machines there's a little 'star' bent plate that sits at the bottom, on the Elma machines it looks like they used a stretched weaved mesh that lines the inner walls of the jar. I'll have to experiment to see what works when I get to that point. I'm also going to have to give it some sort of heavy base to keep it stable and to centre the jar properly. The obvious choice would be a thick slab of steel but getting that machined is out of my wheelhouse, so I'll have to think up something else. Maybe thick perspex sheet with lead weights. I dunno...1 point

-

Just curious, let us say two members classify a post of mine as spam. Perhaps these two individuals don't like me or do it as a prank. Will I then somehow be notified of this?1 point

-

They mostly offer for sale or advertise a product. There was a case where a member had responded with a post , from Mark's instruction I gather the system would then not hide the thread even if it receives two spam reports.1 point

-

I am glad to see that my post on Reddit inspired Charette's version of the watch cleaner! I have since added a 3D printed L&R type holder for the baskets. I use a 200rpm DC gearmotor and I think the speed is just right. I did introduce myself back in March, I think. I have not posted very much because I am able to find most of what I need by searching.1 point

-

Hi all - here are some photos and description of my v1 diy watch cleaning machine. It is made of bits and bobs from the garage, dollar store, and amazon. I should first note that after much googling, what I made was directly inspired by a thread on reddit I came across by chance - here - https://www.reddit.com/r/watchrepair/comments/vk00i1/a_simple_watch_cleaning_machine/ Prices included below are in Canadian dollars. The frame of the machine is a lab support stand from Amazon. I was lucky to get this from warehouse deals for $18.89. Regular price is around $50, so a bit pricey. On the bottom of the stand I laser cut a holder from dollar store MDF (I think they call it 'craft board' to fit the jars I also got from the dollar store. I was hoping to use mason jars for the height and the nice sealing lids, as in the reddit thread, but the nice parts basket he used there was too expensive for me to order in Canada. I instead used wide mouth jars from the dollar store, I think they were $2.50 each. To load the parts, I have a pencil holder from the dollar store (~$1.50?) into which I have a bunch of pieces of stainless steel mesh ($20, amazon, for 5 sheets). I do not understand why formed products are so expensive (eg. the real baskets for watch cleaning machines). I cut a hole with a hole saw in a piece of wood and forced the mesh through with the cutout to make the rough 'baskets'. Not the nicest, but what I have at the moment for v1. Continued below as I think I can only attach 4 photos. Starting off here with the amazon stainless steel mesh product and the wood used to form the baskets. Some cut up pieces folded over inside to make compartments. I tried to solder these in place but that was a failure. So at the moment they are just set in there, and do move around. I think I will end up ordering some of those tiny little mesh baskets with lids - I have seen them for a reasonable price on etsy, of all places. Also I saw the parts basket used in the reddit thread on etsy for a more reasonable price as well, so may order to give it a try. The lab stand came with the clamp and gripper. In the gripper I have squeezed a 12v dc motor. Amazon, $15. It is 200 RPM. You can get these for extremely cheap on aliexpress, but I didn't want to wait for the shipping. I have subsequently ordered/received a 500 rpm motor from aliexpress - my thought was to use a potentiometer to slow it down, but have the extra speed to spin between wash/rinse/rinse. I think that the 200rpm is nice for cleaning but it doesn't do a good enough job with centrifugal force to get the first cleaner out, puts soap into my 1st rinse. Maybe my DIY solution just isn't the best. I have a flexible coupling, 4mm (on the motor side) to 5mm (approx diameter of the bolt I am using, I did have to add a bit of tape) to connect things up. At the bottom of the bolt there is a piece of aluminum, drilled so I can screw the pencil holder on, once loaded. A bit of a pain, but not like I am doing it all of the time. In a future version if I get that nice basket I may use little spring clips to grab its handle. Couple more photos of my current attachment method. I should note that I lost two parts from the basket when cleaning. One was the click spring - was at the bottom of 1st cleaner jar. So tiny it slipped through even the fine stainless mesh. The other was a spacer that Raketa uses on their balance bridge - it fell into where the pencil holder mesh meets the bottom and it was only luck that I happened to see it in there, shining a light. Another reason to switch to those little baskets with lids, I think. To control the machine, I have a pre-built controller, same as the redditor used ($20, amazon. I think it would have been close to the same price from aliexpress). It has multiple modes, but the one I found useful is where you can set time for direction one, stop time, time for reverse direction, and how many times this repeats. I have this on a little box I lasered, the redditor is just running it out in the open. It is dual power supply - a nice barrel plug for 5V, or can take up to 24v. When the DC motor stops to change direction, it is very sudden. I would like to get a litlte circuit for slow start/stop, but haven't been able to find if these exist. I don't have the know-how to build myself, only to wire up something someone else has built. I like how the mastermatic is nice and easy when it changes direction. I think that is all the detail I can think to note at this time. Hope this helps someone or gives some ideas.1 point

-

1 point

-

Hi Step two was to have a mesh base with a trap at the bottom and a filter (coffee filter paper) on top of the mesh to collect the dirt, that way with a second filter the fluid could be re used. These are still in the thinking stage and not been drawn up even, just food for thought.1 point

-

@Gramham This is an effective means of mixing and agitating a fluid. I have even used it for cleaning particulate contamination from oil's. I'll tell you because of your interest in cleaning. Put enough water in the bottom of a container of oil to cover your air stones. The container should have proportions more of a column then of a pan. Since the bubbles are formed in the water and then traverse into the oil, a thin membrane of water still exists. When the bubble pops at the surface the water droplets collect or adhere to particles, pulling them down on the return trip. This is better for organic particulates, as well as others gust above and below what is economically viable to filter. At some point the participants are to small to remove this way and are way to small to filter. The next and best step is gravity settling. Anything not removed by this point is probably a very fine mineral or metallic substance (or fine drop of water) and is denser then the oil. It will sink to the bottom over an extended period of time. That being said, without the trap at the bottom to hold the contamination, I think its addition to mechanical washer might keep more of the finer particles in suspension, not allowing gravity to remove them. If it's your only way of agitation, we do what we need to do but I don't think it's necessary to add to a mechanical cleaner. The proof is in the doing. If you try it, let us know how it works. @watchweasol I have used industrial rotating spray cleaning machines in the past. Your thoughts are intriguing. One of the very best way of degreasing something is physical vapor deposition with condensation recovery. Unfortunately there is no mechanical means of removing any leftover particulates afterwards. I'm wondering if this could be a second step within the same machine. Shane1 point

-

@Mark, I've seen you use manual air agitation in "one dip". What's your opinion on aeration in a static cleaning machine? 1) Fill reservoir with cleaning fluid 2) Place air stone at bottom of basket 3) Put parts in basket 4) Insert basket in fluid reservoir 5) Aerate for X minutes This might eliminate the need for a rotor...do you have any experience with aeration instead of agitation? Sorry if this has been asked 100M times already - if need be, just point me to the appropriate discussion. I have no "institutional memory" developed as yet. g. -----1 point

-

Jacot tools should have the runners marked in pivot size, some have arbitrary numbers but most will be marked in metric. So if you want a 0.12 pivot, you put the part in a 0.12 bed (bed is the grooved part of the runner). Unless- you are starting with a larger pivot, say 0.15, then work your way down, from bed to bed. Some tools will make exactly the size pivot marked, some will make a pivot that fits in that size jewel (a slightly smaller pivot). The size is dictated by the depth of the groove, so when the burnisher will no longer cut, the pivot is level with the top of the groove. Conical pivots should be set so that only the cylindrical portion is in the bed. Square shoulder pivots, bring the bed right up to the shoulder. On the pulley side, the runner is a simple female cone, and it works with the tip of the opposite pivot. As long as the tip gets in there it's ok. Yours looks fine to me. Most sets will do pivots up to around 0.35mm. Larger sets will go up to 1.00mm or so. In the pic you can see a typical small set (upper) and large set (lower). The larger set, with it's "center wheel runner", also has a corresponding pulley-side runner with larger female cones. Keep in mind that burnishers are "handed". Way back in the day when the designation came about, they were typically used in the right hand, on the underside of a pivot spinning in a lathe. For a Jacot, right hand, the burnisher is on top of the pivot, so the opposite burnisher is needed. So- for right handed Jacot use, you want a left-handed burnisher, which is French is gauche, or G. The most commonly used one is from Bergeon, the 2933-G. The burnisher is slightly parallelogram shaped, as you can see in the pic. If you have the wrong one, the side of the burnisher will hit the pivot shoulder, and the cutting face won't touch the whole length of the pivot. The Bergeon and many others from the past have one edge with a radius, the other straight for the pivots as needed.1 point

-

The tools for this job are offered by Seitz - Bergeon. Any jewelling press taking 4mm stakes can be used. Seitz - Bergeon 31000 Set of 4 Tools Sizes: Ø1.25, 1.75, 2.25 & 2.75mm For Seitz 31300 Jewelling Outfit (B59401) Tools for reducing hour hand holes. These make it possible to reduce hand holes very accurately, to within 0.005mm. It is essential to use the micrometer screw for this work.1 point

-

This project has been ongoing for about six months. Another specimen from the box-o-watches. It was a mess when I dug it out. The dial was a wreck. It had the alarm, minute, and hour hand but no second hand. At the time, I did not know it was supposed to have one. Found out later that the center wheel was busted. The first threshold was to see if I could get the dial refinished. I won't go into the ordeal, but it took about four months from start to finish! I had a crystal in my stock so that was not an issue. I bought a donor watch that had some of the parts I needed and the dial finally arrived. This week was the reassembly event! The last challenge was the second hand I got from the donor. When I snapped on the bezel/crystal, the second had would not clear and the watch stopped. This was extremely aggravating and tedious. At one point, the second hand took flight!!! I called the wife: "Help!!" She has a knack for finding things. I heard it hit the skin drawer. It was not there. It had bounced off and on to the floor. I found it!! Anyway...it is now running on the bench. Regression testing as they say in my business. I am showing two pictures because I turned off the LED lamp so I could bet better color balancing to illustrate that the watch is gold (gold plate).1 point

-

Part 3 is a sort of redemption, or at least some lessons learned. The donor arrived about six weeks later (thank you Covid) and I quickly transferred the balance complete. The wavy traces quickly returned. So I stripped the movement again, paying close attention to the barrel arbor bearings. Looking closely, I could see that the barrel had actually been scraping the bottom of the barrel bridge. Manipulating the barrel with the bridge on and the train removed, I could also see that, under torque, the barrel would foul both the bridge and possibly the mainplate. Swapping in the donor movement bridge, the wavy traces continued. The free running of the train was okay with the pallets removed, but, turning my attention to the mainplate barrel arbor bushing, I could see this was slightly out of round. Under torque, the barrel would still hit the bridge. So that was it. I could not close the barrel arbor bearing hole, so after repeated reassemblies and inspections, I became convinced that the original movement was a goner. Thankfully, I had the donor, which I decided to service and install in the watch. In truth, the donor looked to have very little wear - I am unsure what kielbosched it in the first place. I serviced the donor and prepared to install the balance complete. Here tragedy struck again, as it appears that one of the problems in the donor was that the regulator arm was improperly seated in the balance cock, or the pins were just too short. Closing the regulator pins, the hairspring caught the closing arm and became kinked in the terminal curve. Here I finally did Mark's video justice, carefully massaging the hairspring until it was again smooth throughout the curve. A final hurdle: the balance on the donor movement had no endshake - none at all. Having watched Mark's video on unexpected endshake problems, I looked for a shim under the balance cock. Sure enough, Minsk Watch Factory had indeed made a shim under the cock, near the screw, which I had flattened as I had rubbed the tarnished mainplate with pegwood. So I got my screwdriver, and made a painful jab into my newly-cleaned donor movement. Reinstalling the cock, it ran strongly! Hurrah. Here are the results, positive and negative. On the positive, the watch runs strongly and relatively straight in all positions. There is also relatively little positional error (maybe 5-10 seconds a day, but I can live with that). But here's the heartbreaking thing. This donor, this seemingly babied donor with no major signs of wear, has exactly the same problem of wavy traces and variable amplitude as the original movement! It's less pronounced, sure, but it's there - a 15-20 degree variability in amplitude at seemingly random intervals, with the associated wavy lines. A reflection on that below. Battle-ready once again, but not without difficulty. Another charm(?) of the Luch is that the dial does not sit flush with the movement, so you need to be extremely careful when seating the hands to make sure they won't hit the dial. And back on my wrist, at long last. So, a summary. Why should you, an absolute beginner, try to diagnose and fix a battered Russian watch that hasn't been opened since Gorbachev? Well, first, you won't break the bank. These are plentiful, and if you get a plain dial they are cheap as chips. Second, you will use a lot of Mark's lessons. Not just chapter 2, but 3 as well. I watched every single video repeatedly, and tried to apply them all. If not for his video on barrel arbor bearing wear, I would never have found the problem. Last, I practiced a lot - a lot - of skills. I'm still bad, but getting this Luch back on my wrist has made me feel like I'm on the road to being a real watchmaker, whatever that means. And why should you avoid articles like this? One reason: poor, inconsistent build quality. From the shim, to the regulator pins of incorrect length, to the badly-seated dial, it doesn't take a George Daniels to see that these things were absolutely slapped together. This makes them hard to work on and diagnose. And even when you find a good donor that was seemingly retired after only a few years in service, you may find that it has the same fundamental problems as the donor you thought was deeply, unusually defective. So just live with it, and know when good is good enough. Don't make perfect the enemy of the acceptable, because they sure didn't when they built these things in the first place. So that's it. If you're exceptionally patient or you didn't have anything better to do tonight, thanks for reading this far. And thanks to the people on this forum for helping me out with this project - I am very glad I joined. Cheers!1 point