Leaderboard

Popular Content

Showing content with the highest reputation on 04/20/22 in all areas

-

The ranfft site is incredibly useful but the balance staff (and stem) reference numbers are based on codes used by Flume Technik so not overly useful unless ordering parts from Germany via https://www.flume.de/ More universal for balance staff references are Ronda numbers and in this respect https://www.balancestaffs.com/ is a useful reference. This site tell us you need a 5053 balance staff. Clearly you could use this site to buy from but also with the Ronda number you can more likely find on a site like ebay. Also note that Cousins allows you to look up and order by Ronda number: https://www.cousinsuk.com/category/filter/ronda-staffs-by-ronda-number Note that anything involving the balance in some way is undoubtedly what fills most people's swear jars the quickest. Balance staff replacement is something valuable to learn ... but not straight away on something (sentimentally) valuable. I'd therefore certainly recommend practicing on something else first.4 points

-

No that's not what the stud is for. You can cause timekeeping in position if you have an amplitude change but otherwise that's not normally What it's used for. The first link below has a little information on adjusting. Then I have a PDF that you may find interesting the manufacturing information sheet for this watch. Unlike the technical communication which covers how to service the watch this has all the interesting technical specifications including the timing specifications. Then depending upon which grade you have it looks like you are Definitely out of timing specifications Is there any amplitude change in those positions? If for some unknown reason you had a severe amplitude change that might be a reason. Because this is an older watch is possible that somebody has re-staff the watch and you have a poise error. Normally wouldn't have that screwless balance wheel if somebody put the Roller back in a different location that would give you a small poise error. Or if somebody tried the statically poise or even dynamically poise the balance wheel when it really didn't need that to happen that would also give you poise error. But otherwise you should be within the specifications of the information sheet unless there's something else going on? So when you're in the positions on your timing machine of where you're giving the timing problem are there any changes on the timing machine like is that amplitude would do this do the lines still looked nice and clean extra noise etc. otherwise it still keeps coming back to poise error which normally wouldn't exist on a screwless balance wheel unless somebody's played with it. https://www.awci.com/watchmaking-excellen/hairsprings/ http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_2671 ETA_2671_info.pdf2 points

-

Perhaps a picture might be nice? The reason I ask is if you are assembling a 18 size Elgin pocket watch the answer might be a little bit different than if it was a 16 size or a 12 size watch.2 points

-

Here's a thought. Could you place a balance wheel/hairspring complete into the middle of it so that the staff goes into the hole and the impulse jewel sits in the radial slot. Use the swinging arm with the two downward pointing prongs to somehow clamp it in place and then you can rotate the H/S collet around the balance staff a measured amount to correct beat error. I'm not sure how the clamp would work or if you would hsave adequate access to the collet though.2 points

-

Heh, because curiosity killed the cat. I suspect there to be the cheapest of materials in there, with heavy handed oil application and spoons full of shellac on the pallet fork. And maybe, just maybe, we’re all being so **BLEEP** about oil amounts, down to the nano litre, being critical to how a watch works reliably - only to see that good enough is also perfect. Don’t get me wrong; being meticulous is a good thing. But spending 100% extra effort in one area to get 10% result is different than spending 10% extra effort elsewhere for 100% result. Understanding where the point of diminishing returns is. Anyway, part of any journey I guess. That was the long answer. Short answer is: Why not? Hahahahaa Yup, that wobbly crown is interesting. I don’t care for it, but it’s a case of function over form, like anything Russian. Simple, reliable fix for a complex problem. It’s the same kind of approach with an AK. Ugly and basic as you can get, but you can’t argue with results (firearms are another hobby of mine) Edit: I see **BLEEP** is a bad word. Well I guess using **BLEEP** in a sentence is only bad if you’re mind is in the gutter. **BLEEP** is a perfectly valid word to use in casual conversation. Unless you are **BLEEP** retentive2 points

-

2 points

-

1 point

-

Hi there, New to the hobby and have watched all of Mark's courses - absolutely brilliant. I have practiced breaking down and reassembling a few old pocket watch movements from eBay and feel ready to start my quest to repair my Grandfather's Olivia 17 jewel manual wind watch (an EB 8385-66). From the research I've completed, I understand that the EB 8385 is the model and the 66 denotes the year of manufacture - 1966 - a great year I'm sure many of you will agree! The model was stamped just under the balance wheel. It's a non runner and with my new found knowledge I inspected the balance fist to see a broken balance staff pinion. The good news is that there is still power coming through to the pallet fork which is flicking back and fourth nicely with my tweezers, so I'm hoping I just need a new balance staff. I have ordered a donor watch off of e-bay and plan to take the balance from that and hope that it fits in my Grandad's watch - I can't tell if it's an exact match until it arrives, but I'm hopeful. What I'd really like to do is replace the balance staff on the original parts, so the heart of his watch is mainly complete - hair spring, balance wheel, bridge etc. I have watched Mark's and others' tutorials on removing and replacing a balance staff, and whilst it looks very difficult, I feel I'd like to try. So that would mean me getting a staking set etc, but I really need to know which balance staff to order. One of the kind members (watchweasol) on here suggested I google the ranfft website and I found the article below: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&EB_8385& This describes the balance staff as a U3110. I have googled this and can't find it other than what is described on the link above. If the donor watch I have ordered is potentially the wrong model, I won't be able to nab the balance staff from that, so wanted to look at options to order one on it's own. So my question is does anyone know how I could order a U3110 balance staff? Here is the watch to give the whole thread some context. Thanks in advance for any help Rich1 point

-

Still waiting for my new/old motor to arrive. Cleaned the lathe so it’s ready to go1 point

-

Just so we're clear on the numbering schemes? A company selling you a watch will put their name on the dial. Oftentimes they put their name and/or number on the main plate in plain sight. Then many times they purchase basically an OEM movement from another company. That other company will put their Markings usually under the balance wheel but not always. Then sometimes the purchasing company will remove that or modify the watch. This means that you can end up with a lot of numbers on your watch that are all legitimate numbers. But possibly extremely unhelpful to figure out like if you're looking for parts because you need to figure out who action made the movement. Then sites such as ranfft Listing all those movements and that's only scratching the surface of the quantity of movements ever made. This is where reference books like bestfit comes in handy. At one time the makers conveniently made all of the setting parts unique and if you have the right book you can look up the setting components in figure out what you have. So if you to watch with no markings at all and you knew the size you could go to the book and possibly figure out what you have. Or in this case we can use the book to verify what you have or have not. Then if were really lucky we could get a parts list with pretty pictures like the PDF attached. I also have a link to a parts list we can look up which parts cross reference with what etc. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=PES_355 You'll also notice that I did include that in the images the setting parts don't match. 3180_Peseux 355,385.pdf1 point

-

Hi I haveattached the tech sheet for the peseux 355 so you can make a comparison with the balancs cock and plates not found on ton the phenix 355 yet. 3180_Peseux 355,385.pdf1 point

-

When you're assembling the wheels you don't need to have the mainspring in their that can come out. Then the unfortunate reality is it's just a lot of practice. There is something you do want to check is put the plate on without the wheels how tight is that? Sometimes there are way too tight for going together and that can definitely be an issue when you're trying to figure out how to get your pivots in place because you won't have a good feel for things at all. Otherwise unfortunately it just a practice technique thing. Usually helps to start at one side if there is a side or start with whichever wheel pivot manages to go in first and then work with the rest of them.1 point

-

Years ago I worked as a draftsman on a drawing board with a pencil (way before CAD/CAM). Our boards were covered with a light green colored material. I can attest to the fact that the color is easy on the eyes for 8 to 12 hours per day. I purchased a small mat for $11 USD from these guys. It's doing me just fine.1 point

-

Delicate little monkeys they are. This is when you will find out how steady your hands really are. Some very small tweezers and nerves of steel lol. Be as careful as you can, any distortion in the hairspring you create can be a real bugger to sort out later. Just a little tip with the hand shake, make sure your blood sugar is steady. It's so noticeable at this level. Blood sugar is always more stable in the afternoon, I'd be looking at an hour or so after dinner. Sometimes just a glass of good natural fruit juice will help raise it temporarily. Never thought what I knew about diet would be applied to watches.1 point

-

Hi Should you be unable to get a staff Have a look at the Jules Borel site under the JBC database the EB(bettelach) is listed and the balance complete is $21.60. The staff is listed in the balancestaffs.com catalogue as BS5596 @24.95 euros.1 point

-

Well it would be my first time, but I’ve watched many tutorials and will practice on something less important to me first.1 point

-

How much have you done on repairing. Do you feel confident removing hairsprings ?1 point

-

There would be fewer repetitive questions from newbies if WRT followed the commonly accepted/expected design language of internet forums, and they could A) find the information in the first place, B) not be unnecessarily burdened by lengthy and labyrinthine threads once they find it, and C) more experienced users had a way to direct them to that information. As is, a search for any specific set of terms (the first recourse) will lead to an incredibly long thread, the information being sought is not in the first page worth of posts, so they make the [i]correct[/i], if inaccurate, assumption that the information they're after has not been previously addressed, then ask. The people who know these junk drawer threads exist have two options; either wade through the junk drawer ourselves, or answer the question for the umpteen-billionth time. The junk drawer thread moderation strategy is and has been an objective failure and should be immediately abandoned. It makes accessing information more difficult for new users, makes helping new users more difficult for senior users, annoys senior users who are constantly bombarded with the same questions over and over, and makes more completely counterproductive work for mod(s). It should be immediately ceased in all cases as a practice, and concurrently replaced with "pinned" threads (per the forum software's terminology) created and curated by senior users with expertise in that given topic. The only pinable topic I feel like I could remotely make a dent in is stereo microscopes. I'm sure there are others who would be able to speak in a much more authoritative manner on the subject, but in the interest of putting my money where my mouth is, I'll be the first to step up and volunteer to write up the initial post and direction on that one.1 point

-

Hi Rich, didnt anyone pick up on the 1966 ? . Have a look at Marshall on wristwatch revival. He's a good amateur. There is one where he replaces a balance staff, only his second time. Sometimes good to watch an enthusiast on tenderhooks. This is the one reason I got a staking set, as broken balance pivots crop up regularly. I have a few to sort out. One on a lovely venus. Not yet had a go though, so I'm not your man for advice on the process, only on what I've watched. Definitely good advice to practice on something else less valuable. I practised over and over with mainsprings replacing by hand. My grandfather's had a few issues, my first repair. I worked through them and it got me into this hobby. If you have the same movement ordered then it's liable to be a fit. As a compromise how about just taking the balance staff roller and the balance wheel from the the donor, that way all you are doing is taking off the hairspring and cock. Only a few small procedures to work though, leaving out possibly th e most destructive and risky I had a similar dilemma with my first, what to change what not to. Obviously sentimental and want to retain as much as possible, but you might end up breaking your original balance wheel , roller ,impulse1 point

-

Haha. I know I'm shit at this . I am 55. Eyes are getting dim, brain is getting foggy. I like you, you have an attitude and a sense of humour. Two things that don't particularly fit in well here, especially as a newcomer. I think we will get on just fine, and hopefully between us **BLEEP** off a few of the # I'm up my own arse # members.1 point

-

You can test if the steel is "blue hard"; if a file will bite it, but you can't cut it with a jeweler's saw it's proper blue. If you have great collets, go ahead and flip it. Yes, do the upper side first as the balance diameter makes a good place to grip when you flip. When you flip, grip lightly in the collet, then checking at 10x or so turn the spindle by hand with the T rest up close to check for concentricity, nudge true as needed then tighten. If your collets (or the size needed for the flip) aren't that hot, best to do it in one go. Much harder to accurately measure the stuff collet side of the staff hub unless you have the right gear, haha. If it's blue steel no need to heat treat. I cut mine from soft steel using slide rest, leaving what will become the pivots a good 0.2mm oversize and the roller table diameter cylindrical, heat treat, then finish the pivots, rivet, hub, and roller table diameter by hand, holding bottom half first to finish hairspring side, then as above. Finish the pivots in a Jacot tool of course (leave them 0.01mm oversize for finishing)- but if you don't have one or know how to use it just concentrate on making a good staff. Crisp square shoulders, nice smooth cylinders, nice radius blending to the pivots. You only need about 0.01mm max interference for the roller fit- less if it's steel.1 point

-

1 point

-

I suspect you are correct. I'll let you know once it makes it to the bench. I found a similar example online (complete) that the seller appeared to think he could get >$1000 for. You have got to admire their optimism. There was a second version with a lever escapement movement in it. As I said, the case was what caught my attention (and of course the 404 club price).1 point

-

1 point

-

What makes Daniel's book interesting is he tells how to make things found in watches. In other words if you need to replace a missing component very likely he tells you how to make the component. Here's an interesting website and an interesting book on the website. You can either look at it or scroll down and downloaded in a variety of formats it's free. What makes it also interesting despite when it was written not really a lot has changed it's still a very useful book for learning watch repair. https://archive.org/details/TM9-1575 Then on the same website there is some other watch company stuff sometimes it's hard to find it looks like they have way more Waltham stuff. .https://archive.org/search.php?query=Waltham watch Then here's a really good book the older editions tend to be better because they cover doing more Like making things versus just replacing them but still each edition is good. The Swiss watch repairer's manual H. Jendritzki Here's a link to what happens when you get obsessed with George's book.Roger has a really interesting story is that a lecture once we talked about how he went to meet Georgia was quite amusing. Fortunately he was obsessed and he came back a year later. https://www.youtube.com/user/rwsmithwatches/featured1 point

-

I notice that the example featured here also has a radial arm which rotates around the central axis and has what appears to be a blade like tip. I wonder if this is maybe to poke into the split in the collet so that it can be turned.1 point

-

Haha. Well put my bleep friend, I like your style. I managed to get round the bleeping bleeps. My thoughts exactly on the watches a rugged industrial it does what it says on the tin approach to watch making. And paralysis by analysis, one of my favourite phrases, just get the bleeping job done and stop being so bleep about it haha1 point

-

1 point

-

The problem is this is a two-way street. What about the newbies showing a little tolerance? I have the vague feeling that last week I got scolded several times and where was the tolerance from the newbie?1 point

-

Welcome to one of the best watch/clock-work sites on the internet. As you'll find out, there are a great bunch of folks here that are always willing to offer experience-gained advice. Yes, it's sort of sad that the other two watches were sold, but you can't keep them all. Good luck with your Seikos. There are a few guys here who have a lot of Seiko experience that will surely be of help to you. Cheers.1 point

-

Some people have a high acid content in their perspiration that will basically eat away a thinner plating. My dad was like that. He couldn't wear the same gold-filled watch for very long before it would have the plating looking like that, and worse. The fact that the top of the case isn't discolored leads me to believe that you might have a higher acid content in your sweat. And in a foundry you may well have been sweating a lot, depending on what your job was. Just a thought. Have you worn other gold-filled watches for a long time where the plating hasn't been damaged like that? If so, then it may well be some sort of external, rather than internal influence. I think more than 1/2 of the ESA electronics of the time, especially the 9154's, had the battery hatch like yours, where you can change the battery without removing the back. I once wondered why so many parts movements were missing the battery clamp part. I thought people were breaking them during install. I now realize it's because they never had one. You can't tell by looking at the movement, as there are threaded posts in place whether the design uses the slotted hatch or not. It's certainly worth getting a #344/SR1136SW and trying it out. If the battery didn't leak in the movement then you'll probably be OK. If it did, well, you'll have to pull the back and take a look at what was damaged. Good luck.1 point

-

1 point

-

One thing about optics: if you are very close to something it is very likely that your depth of field will be very thin. Macro lenses on cameras often offer great close-up capabilities but the depth of field can often be measured in millimeters. I'm planning to add a 100mm macro lens (I already have a 50mm macro). The main difference between the two will be that I will be able to position the 100mm farther away from the work (to allow room for better lighting). More light mean you can use a smaller aperture which will give you better depth of field. As I recall the cheapies that plug into your computer don't really allow for adjusting aperture so you're left with whatever the manufacturer decided. And while not a concern while "live viewing" be aware that published photographs showing some item in a "macro" view likely use a technique called "focus stacking" where many images are taken from the same view point with different focal depths and then all of those are "assembled" into a completely sharp image by using just the "in focus" part of each image stacked into a single image.1 point

-

A "Regulateur" pin set pocket watch (or some bits of one) is heading my way. I'll admit I bought this for the case, which appears to be in reasonably good shape. There is a pretty high likely hood that the worrying collection of bits in that tobacco tin should actually be in the watch. However since it only cost me 0.99p I think its worth the risk that it might be incomplete. Besides I have a fair number of homeless movements, so perhaps one of those might wind up in this case.1 point

-

I will add, if the gasket is old and hard it will probably come out in chunks. I use a curved dental pick to get them out but don't scratch the metal. Gently hook the gasket and fish it out. After you get the old gasket out, clean the gasket groove with solvent and Q-tips. Make sure there are no crumbs or goo left in there. The new gasket should be pliable enough to go in. I use a little silicone grease to help it in. VTA (Vintage Time Australia) gaskets are the best you can get and lucky for you, the seller is local. Your crown looks like a new replacement, maybe after market? If it is genuine Seiko, the gasket is surely old and hard by now, they haven't made them for 30 years. If it is one of the Philippine crowns, the gasket is crap. You are doing the right thing by replacing it with a good part. The rest of the crown is good in my experience. I've used a couple of them. I'm not a watchmaker but I have a collection of Seiko that use this crown and I like to keep them water tight because they are always in the water.1 point

-

Note where the o-ring is situated now. It is possible to insert it too far. Dig out the old o-ring. You have the male portion of the stem removed. That is good because it makes removal and installation of the o-ring much easier. Next issue. I don's see a seat washer between the spring and female end of the stem. I think the proper name for it is "spring seat", I'll have to dig out my notes. It may work without the washer but not correctly. It works much better with a washer in there. I had one without the washer that felt like it was cutting metal every time I screwed it in. Put a washer on it and it worked perfectly. I made a jig to hold the crown. It is very simple, a block of wood with a 7mm hole in it. I don't have a 7mm drill bit so it is probably the closest size bit from my index drill bit set. It holds the crown steady while mashing down the spring and seat washer. Lack of this simple jig is the number 1 cause of the missing washer. I also put a dab of thick sticky grease on the washer to hold it in place during assembly. I can't keep all the Loctite numbers straight in my mind. I use the purple, low strength stuff. It the end of the threaded portion properly prepared and is reasonably flat, i.e. no burrs, it will hold fine on its own. Loctite is just insurance.1 point

-

1 point

-

I've used "Loctite 222 Low Strength" with good results. The advantage is that it will be easier to remove the crown when it's time to replace it, of course. I guess "Loctite 290 Medium to High Strength" would be fine too. Other than that I'm afraid I can't help you with.1 point

-

Yes, my post was deemed to be political although it wasn't intended to be. I guess even mentioning the word Russia in a neutral or non hateful way these troublesome and sad times makes you a Putin collaborator. That's just wonderful! I have my grandfather's (born 1910) watch and my son is named after my grandfather. One day, perhaps when he turns 18, I'm going to give that watch to my son. I suppose you just misspelled Scuba (it's called "Scuba Dude"). Anyway, really nice, and I like the Komandirskies just as much as the Amphibians (amazing value for money!) Good to know I'm not alone in appreciating these Russian watches. I guess Russian watchmakers are human too, despite the horrible war.1 point

-

I think Hector covers all bases ," just keep calm and carry on ". I use the screw mothod as it retains the brigde and tappinf and shuffling usually works. The stubborn ones need a poke so I made some shaped tools from needles bent at various angles to get under the plate.1 point

-

Practice, practice, practice. There is no substitute for actual hands on practice. It took me 45 mins to get the train bridge on when I first started. After 4 years of practice, I can usually get a train bridge on in under a minute. There is no secret technique. Firstly, get all the bottom pivots into their respective holes and stand the wheels as upright as possible. Then take the top plate and orientate the holes to the pivots. Hover the plate just above the pivots and drop the plate on. If you are lucky, you'll get a "hole-in-one". If not, try using the back end of your tweezer to tap lightly on the movement holder. The vibration may jar the pivots into their holes. If all else fails, then you have to resort to the "poke and nudge" technique. Use your pegwood to apply gentle pressure on the top plate and use your tweezers to lightly upright the wheels and coax the pivots into their holes. Start with the bigger wheels first and work your way down to the escape wheel. Sometimes with really stubborn ones, you might have to place some of the screws back in, but do not tighten them. They are placed only to prevent the top plate from separating and allowing the bottom pivots to get out of their holes. Make sure you have good lighting, work at your shoulder level unless if you are using a microscope. Stay calm and breath slowly. Take breaks before you break something. Good luck and enjoy.1 point

-

Hi @JohnR725 yes, that was my photo (I also have way too many cameras and lenses). I was wondering what that lever was for - thanks! I have a Bergeon winder and handle on the way. I also have a 2nd grade 313 model 7 movement on the way. In the event that I fail to remember how things go, I can disassemble the 2nd one to that point. Thanks for your help on mainspring installation.1 point

-

One common error is using the wrong screw for the pallet fork bridge. The correct screw has a very flat head to clear the hairspring. Using a wrong screw will cause the arm of the balance to hit the screw head. The pallet bridge screw not being fully tightened will also have the same affect. rgds Anil1 point

-

I also ordered a mainspring since I don't have my own winder. I'll pop open the barrel and pop in the new spring. My next steps will be to run my parts through the wash (in small batches). I'm planning to keep like-with-like as (unlike you guys) I still have no confidence that I'll be able to figure out where they all go if they're just lumped in one big pile. Somewhere along the line I'm going to need to figure out winding it up outside of a case. My only goals with this are to: a) see if this is something I can do and b) get this un-running movement back to life. Thanks for watching...1 point

-

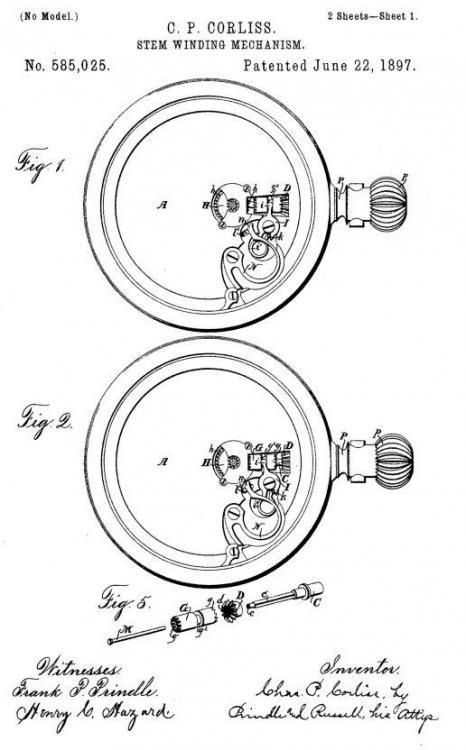

One of my concerns was that I was going to have trouble due to the situation with my left eye. Following a stroke last year, there is a gray cloud in the center of my left eye that I only notice if my right eye is closed. If I'm looking at you I can see all around but your head would be obscured by the damage to my optical nerve. Luckily it isn't getting worse but it's not getting better either. So, yesterday I removed the hands and dial, noticed some missing screws and removed the balance, bridges, train of wheels and other components from the dial side. I got to the keyless works and realized that these watches must have a winding stem that is part of the case? Anyway, there were some springs that I was reluctant to remove last night as I wasn't sure how I'd put them back. I solved that by finding a copy of the 1897 patent that describes the spring configuration.1 point

-

0 points