Leaderboard

Popular Content

Showing content with the highest reputation on 04/15/22 in all areas

-

I think I wrote this elsewhere in this thread, but bear in mind that a hollow ground driver will fit exactly one size of slot. A little bigger slot and it will slip around and possibly cause dings, smaller slot and it won't fit. I have one (had two) of the special sharpeners, and tried out hollow ground, and, for the work involved, found that wedge shape is simply better for watch work, for me. But I have a friend who loves hollow ground- and since time is money, he has several sets of screwdrivers with varying thickness hollow ground blades, as well as a set with regular wedge shape. I gave him the spare hollow grind tool I had, he was happy to then have a spare, haha. When someone in the workshop starts pondering hollow ground drivers I pull out the tool and offer it to them. So far nobody has switched. It could work for you though, it's always good to try different things.3 points

-

There are many options, from single speed motors with countershaft to give a limited range of speeds, to variable speed AC/DC motors with or without countershaft, usually with a foot pedal rheostat to vary the speed, to more modern DC motors with variable speed, often with a knob to set the speed but could be with foot pedal or knob and foot pedal for on/off. In my early days most lathes I encountered in the U.S. had the AC/DC "universal motor", mounted on the famous Borel base,with foot pedal, which is familiar to most watchmakers, and which I despise (haha). I hate not having a fixed speed, and those motors hate being run slowly- no torque- so a countershaft is really necessary in my opinion to step down the speed from a fast spinning motor. DC with a proper control will give a very wide range of speed with plenty of torque at slow speeds. There are usually some DC motors with controler ready to mount up for sale on German Ebay, a friend got one and it is very nice. These tend to run very smoothly, and as stated, have plenty of power over their range, are quiet, and eliminate the need for a countershaft. Aside from the mentioned one that's offered as "for watch lathe", there are many industrial sewing machine motors available on Ebay, often marked as servo motor. A servo is just a DC motor that has a precision control. These tend to be overkill in size for a watch lathe, but there are smaller ones, and they tend to come complete with control. That would be far, far, better than the motor on your mother's sewing machine, which is usually a lower rpm "universal" motor, controlled by rheostat. As for belting, that's a matter of choice. There are many options, from miniature V belt, to leather (which is fine), to fusible plastic/rubber belt, which is the choice of most folks I know, myself, and industry. If you have an industrial belting supplier in your town or nearby, they likely carry Habasit belting, which comes in a number of varieties of flat and round shapes. The round stuff is called Polycord and is very good. 4mm would be perfect. It's fused by cutting it to length cleanly, then put a piece of 1 or 2mm sheet brass (or steel) in a vice, and heat with a torch until hot enough to melt the belt. Press the ends on opposing sides of the hot metal, face to face, let melt, and slowly slide it off so the ends meet up. Hold until cool, then trim off the bead around the joint. I have belts joined like this that have been in use for a decade, zero issues. In the pics you can see my primary lathe, the Leinen, with a 380v industrial 3 phase motor, with built in countershaft. That lathe had a motor integral to the base when bought, which was switched to a DC with control in the base, and finally I liked the industrial motor so much I pulled out all the DC stuff and have been running it this way for almost 20 years. The other lathe is a Favorite that my workshop mates use, it has a single speed (1400 rpm) motor, no countershaft, but 4 options on the pulleys, and they are very happy with it. The pic of the motor and controller is the one a friend bought off German Ebay (sells internationally). From the screwdriver stand you can get an idea of the size. Nice looking stuff, was under 200 bucks as I recall.3 points

-

Supposing he gets it apart, and cleans off the corrosion, yes, there will be metal missing where it once was. But the screw pitch remains 1mm and that pitch makes its own average over the number of threads engaged; if you were to measure and map the screw over its entire range you might see some diversion from one line/0.01mm, but for the short travel it might do to press in or even less adjust a jewel it will still be very accurate. The "push" is always down. Like using a lathe or milling machine with some play in the screws, you always take your cut coming up with the crank in the same direction. I had a bench lathe with screws so worn they had 3/4 turn of lash, and could still do accurate work, just always going the same direction (and over a short distance).3 points

-

The piece above the ratchet wheel is a nut. You need a tool to fit the two radial holes to unscrew it while holding the ratchet wheel, usually a stubby pair of tweezers will work but you may need fine round nose pliers. The ratchet then comes off and the rest is as usual.3 points

-

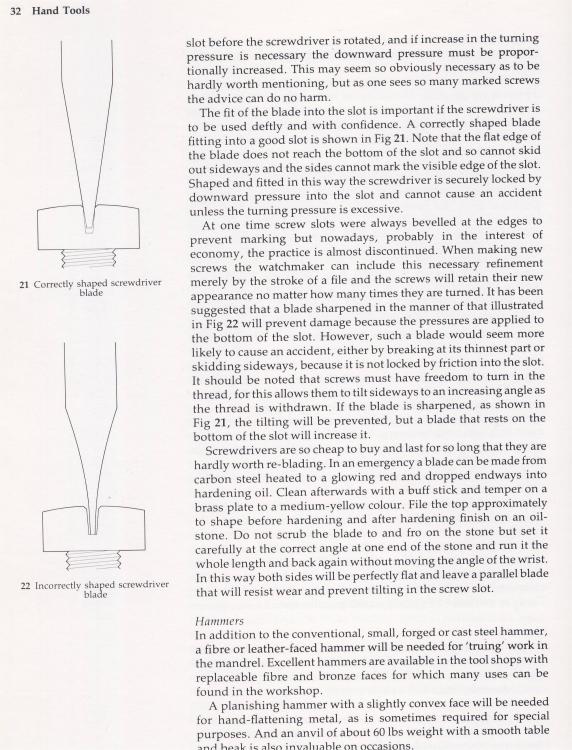

I'm definitely in agreement with this I think hollow ground screwdrivers is an accident waiting to happen. I scanned in a image of George Daniels book. You notice in his examples the second image while it's not actually a hollow ground I think would have the same effect of it's not a good idea. A correctly shaped screwdriver will work fine. Whether it's hollow ground or incorrectly shaped that will not work fine. If you're having a problem with the screw you have to change your screwdriver to fit the screw unfortunately. Then as there is no standard on what a screw slot should look like that means there's no real standard on shape of the blades you'll have to modify to fit the situation.2 points

-

So a lathe motor question was all it took to get to see @nickelsilver work space? Wish I had asked a year ago. I have a large roll of 3mm TPU filament for 3D printing. Makes a great belt.2 points

-

Supposedly, the zinc/aluminium whatever metal of your press expands its volume by corrosion, what makes the problems. It is different from the older steel body of Nibbler's tool. Unfortunately I have no better idea than lubricating & force. Frank2 points

-

I think Klassiker is on the money , some watches you have to press the crown down and hold and turn to set the hands Check out the attachment looks identical. 5325_Record 433.pdf2 points

-

Well, I am pretty sure that I can safely say that I have this. These screwdrivers, those screwdrivers. Should I buy a big set or individuals. Make my own base or buy screwdrivers that come with a base? Tweezers! Don't even start. Hand lifters? What size do I want? Movement holders? Spring winders? Clocks or watches. This cleaning fluid, that cleaning fluid. Do I buy an ultrasonic? Is it really necessary yet? Which oil? Which grease? Which polishing wheels do I get? Which timegrapher? Which desk light? Should I buy a microscope yet? Do I want a lathe? Do I need a lather yet? Do I want a mill? Do I need a mill yet? Do I get a lathe/mill combination? Would the Chinese machines be good enough to do precision work? Where in the hell am I even going to set things up as my house is already full of other stuff? Do I do Marks course? Do I do the BHI course? Will the watch companies succeed in their bid to basically shutdown access to parts? What would that mean to me, well any of us, that are looking to have a crack at all of this? Will I find people that have older clocks that need work or do people just not have that interest anymore? My head just doesn't stop. I hate it when it does this......... I know the answer is to just do something, but then I worry about what the other half will say. "You've got all these things that you want to do, now you want to add clocks and maybe watches? No-one is interested in them! Everyone has a smartwatch or a mobile phone." As I said, my head just doesn't stop.1 point

-

Its a lovely clock. Is the dial off center or is it the picture. You said the hour hand fell down to 6, The hands are usually a friction fit thing to do is take the dial off and check the fit of the hand onto the hour wheel if its a loose fit and sloppy it will need to be tightened up but no soldering or glueing.1 point

-

I've bought from this guy, a job lot of bits and pieces. Was ok. Not the cheapest for what I got tbf. But had no issues with him as a seller.1 point

-

1 point

-

I cannot see the type of pinions your movement has. Going by what I know most American movements have what are know as lantern pinions. The pivots do not need to be as well fitting in there pivot holes as much as the solid type of pinions because they can stand more wear, you might also find the pivots are more of a barrel shape and not straight from end to end as you might expect like with French or English movement from shall I say from the 1800's Here is a photo of the lantern type pinions the two wheels on the right. The left wheel shows the solid type pinions.1 point

-

1 point

-

1 point

-

Welcome to WRT forum. Chronograph complication is your Phd level in watch repair, your watch might have to wait until you acquire the experience to service it or should be entrusted in hands of a master repairman. Regs1 point

-

1 point

-

It looks very similar to swiss made Bulovas https://mybulova.com/bulova-movement/6ah-0 Karl1 point

-

It looks very clean, not likely to be corrosion. Probably dried up 50 year old grease. Try WD40 sprayed into the locking screw hole. Dropping a couple of drops of benzine also helps. Have you tried pressing down on the 2 spring loaded index pointer pins?1 point

-

Yes, knock it out. If the center wheel is jeweled at the bridge you want the bridge off, and support the center wheel in a hole in a bench block, or better, a staking tool when knocking out the pin. If not jeweled you can leave the bridge on, but still support it on a block with a hole to pass the pin. The pin will go down as far as the top of the cannon pinion, which should be plenty to pull off the CP and the pin out the rest of the way from the center wheel. Going back, push in the pin, (this is with bridge on), support the large end of the pin on a block, and press down the cannon pinion. You may need to press quite hard, or use a staking tool with flat faced punch with hole to pass the pin to get the CP seated all the way.1 point

-

When you see something is right, don't hesitate to ask here, or pm one of us.1 point

-

Look for Allen Bradley foot pedal. They are continuous control vs. stepped.1 point

-

Wouldn’t corrosion in the micrometer stop cause some backlash/movement in precise measurements for jewel depth? You can imagine the micrometer dial/stop having “end-shake” due to a damaged screw thread of the micrometer.1 point

-

1 point

-

https://r.search.yahoo.com/_ylt=AwrIAX_.aVliKggAxwJ3Bwx.;_ylu=Y29sbwMEcG9zAzIEdnRpZAMEc2VjA3Ny/RV=2/RE=1650055806/RO=10/RU=https%3a%2f%2fabouttime-clockmaking.com%2f%3fC%3dD%3bO%3dA/RK=2/RS=uBUlg6aotCSGplaP9pGicJJd3_I- At this location there is an article on David La Bounty American ckock Guru and some animated descriptions of escapements that might be of some assistance.1 point

-

So the clock is in beat, and doesnt slow to a stop , It just stops. correct? Things to look for are bent .broken teeth or worn teeth in the mechanism, dirt in the pinions, escape wheel worn or a tooth out of shape causing a mis lock on the pallet/verge, the working surfaces of the pallet/verge worm these are but a few of the possible causes. Without diamantling cleaning and cheching everythin whilst re building its difficult to pin point an actual cause therefore the broad brush approach. One wat to verify the gear train is to take the power of the clock and remove the pallet/verge and then put 1/2 a turn on the spring if it runs down slowly and freely you are looking for a problem in the escapement and its action Cheers.1 point

-

1 point

-

I wasn't aware that the 7750 had a moon phase? You might want to look at this this is a 7751 maybe it's similar to yours1 point

-

1 point

-

The bankings pretty certainly didn't leave the factory like that. The escapement would need to be checked to find out why the entry banking is so bent. A guess from afar: the exit stone has been replaced with a stone too long or moved out for some reason, which means the escapement wouldn't fully escape from the exit side as the fork was against the banking on the entry side. Moving the entry banking pin will allow it to escape, but now in addition to the extra lock on the exit side from the jewel being out too far, there is additional drop and total lock on the entry side. The watch probably runs, but amplitude will suffer very much. I've been trying to find a clear description of the steps to checking and adjusting the lever escapement to share, but so far it's been old confusing texts or nothing. It's not that hard to understand or carry out the adjustments, but without a clear description very daunting. I actually know trained watchmakers from good schools who don't really understand it, so it's not just new/hobby folks who are in the dark. If I have time one of these days maybe I'll put something together. In the repair work I do I probably retouch the escapement on a third of the watches I see- it's an important thing to check and correct.1 point

-

1 point

-

So the autowinder might be the culprit and not wind full as its should, clean and inspect all parts of the winder module, epilame high speed arbours and reversers. I give the barrel a full manual wind and see how long it runs on bench, that gives you an idea how good the mainspring is, while winding the barrel might discharge power at some point (loud to hear) thats the barrel-mainpsring threshold, count how many turns of the crown it takes to get to the threshold (when power gets discharged) rewind just short of that threshold, how long it then runs on bench is your actual power reserve, comparing the actual power reserve to the nominal helps decide if a new mainspring is needed. Some folks just go ahead and renew the mainspring at each service. Good luck1 point

-

As clockboy has rightly said the clock need to be in beat. Put a small spirit level inside on the bottom of that case the clock, move the pendulum to start, if the clock doesn't give an even tick then the crutch should be bent so it does. If the clock still keeps stopping then you will need to check the whole movement. If the holes and pivots are all good, I would look at the pallets and the escape wheel. The pallets or the American term is verge should be smooth, the escape wheel teeth shouldn't have any burs on there tips, if so you could have problems, so check all that and when and if it stops mark the tooth of the escape wheel with something that you can wipe off when its been sorted, do this a few time to see if its the same place, if so check that tooth if it has burr then stone it very carefully to remove the burr but do not change the angle or shorten the tooth if you do the action of the escapement will be altered and the clock will not work. Check all that and let us know how things are going.1 point

-

They are 2 separate pieces. It has no screws, the upper wheel is pressed with the arbor of mainspring barrel. I recently found myself in the same situation. Somehow you have to try to separate both wheels. I don't know if there is any specific tool for this task. I'm sure someone with more experience will explain it better. Greetings.1 point

-

Blue wrench = torch. If all else fails you could try carefully heating up the main casting over the threads and then attempt to unscrew the insert. This would be a last resort option.1 point

-

Could it be this? http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Record_433 Looks like military issue (Broad Arrow on the case back) which makes it more collectable.1 point

-

1 point

-

Hi you migh find ths useful. this guy has just refurbished his press. https://r.search.yahoo.com/_ylt=AwrIDKSFXVhiWOgAsRJ3Bwx.;_ylu=Y29sbwMEcG9zAzEEdnRpZAMEc2VjA3Ny/RV=2/RE=1649987078/RO=10/RU=https%3a%2f%2f2makers.weebly.com%2fseitz-jeweling-tool.html/RK=2/RS=Dsvj5bB2msZavM_B6iA2rBS8Ja0-1 point

-

1 point

-

Hi An out of beat watch, depends on the error too far out and the watch will stop the further away from 0 will eventually affect the rate. Thats why when regulating a watch get the beat as near perfect as possinle then start the regultion.1 point

-

As the lift angle is calculated from the balance swing it may have a direct inpact the site below explains the lift angle https://r.search.yahoo.com/_ylt=AwrIS.WuUVhi5ycAIQJ3Bwx.;_ylu=Y29sbwMEcG9zAzIEdnRpZAMEc2VjA3Ny/RV=2/RE=1649984047/RO=10/RU=https%3a%2f%2fwahawatches.com%2fwatch-talk-whats-the-lift-angle-of-a-watch%2f/RK=2/RS=SbNfVIYyK1PbNAX_QABHYSRXOJ4-1 point

-

Hi Most watch crystals operate on a given frequency 32,768 Hz. bergeon had a tool which was a crystal embedded into a pen the method was to piggy back the suspect crystal and check. If you have a known working crystal you can make your own.1 point

-

Are you talking the power reserved by the selfwinder or manaual wind?1 point

-

Just a few points to note, as I have previously worked on this movements: the keyless work screws that hold the setting lever spring have a tendency to fly off when you unscrew them, because the setting lever spring is under tension. Hold with pegwood! Also, the pin at the end of the winding stem is rather long, and can break easily.1 point

-

Putting on my Deerstalker (sherlock Homes) I would bet it pinged on to your sleeve or chest and as you went for a coffee it fell off onto thr surface and repained there till you found it. case closed Watson/1 point

-

Hi sounds like a few problems there. but the watch needs dismantling carefully and the rotor bearings reversers etc inspecting and the watch given a good service. I have attached the service sheets for you 13_ETA2000,2000.1NEW.pdf 4107_ETA 2000.1, 2004.1 Ratchet Wheel.pdf 7878_ETA 2000.1 Reduction Wheels.pdf1 point

-

Denatured alcohol is ethanol mixed with a small amount (up to 5%) of methanol to make it undrinkable. Isopropyl alcohol is a kind of alcohol with a longer carbon chain than either methyl alcohol (methanol) or ethyl alcohol (ethanol). Since shellac is obtained from insects, the exact species it was isolated from, what they fed the insects, and even the season it was isolated from can affect the properties of the shellac that is obtained from the bugs. It seems that the higher the carbon chain of the alcohol, the less likely / longer time it takes for the shellac to dissolve in the alcohol, but this is still very variable. The length of time the shellac has been allowed to cure for (how old it is after heating/setting) also appears to play a part in whether it will dissolve.1 point

-

Hi djmcd, I use lighter fluid and a soft brush to clean the parts, and then 2 quick rinses in 99% alcohol, then air dry on a paper towel (the alcohol evaporates really quickly, leaving no residue behind). If needed, I soak the parts in lighter fluid for some time, but never in the alcohol (it will dissolve the shellac used on some parts). I need to get an ultrasonic cleaner too...1 point

-

Some posts about the supposed advantage of 'hollow ground' screwdrivers has been moved to our pinned topic on the subject below. Incidentally I'd like to inform fresh members that if they can undertake the not so big effort of reading into that or any other pinned topic, it's most likely that their questions and elucubrations have been covered there already in the past.0 points

-

0 points