Leaderboard

Popular Content

Showing content with the highest reputation on 04/01/22 in all areas

-

It must have got so loose that is why it has been soldered. You will have to remove that solder and clean it up. Turn the collet back so you have a decent depth and rivet it as it should have been when new.2 points

-

Bergeon Protective Vinyl Sheets 7982 Pack of 3 https://a.aliexpress.com/_m0T8JtU I use these vinyl sheets with hand levers, exactly as seen in the photo. Even works on very small chrono hands.2 points

-

We’ve all been in that position. The sense of excitement is out of this world… as well as the feeling of dread when a part flies off and you spend hours on your knees searching for it on the floor.2 points

-

Wow! What a learning curve. 3 strip downs. Could not get the wheels to turn. Finally, after watching a video a number of times I realised that I was not getting the click to be operated on the crown wheel which is on the barrel spring. I had just been placing the crown wheel onto the barrel. No adjustment to make the click operate. Aagh! All the videos of this particular movement are accompanied with music. No verbal's. Got there. The main spring now winds. I can move the Pallet fork and the escapement operates. As a novice. It is such a sense of achievement. Felt I had to tell you all. Sorry to be a bore. Regards Ross2 points

-

Most likely that's because the minute hand is a bit lose, so it tends to move forward over time. The best approach is to tollerate that small detail, and if available, reset the the minute hand when needed. I don't know what you have seen, but no such device exist, and if it would exist it would be quite complicated and ver expensive, becuase it would need artificial vision to see where the hands are, and correspongly press buttons or make electrical contact to reset them. Indeed that is not how the hands of a quartz chronometer are reset. Since each hand is driven by a separate motor (there are exception, looked 'mecaquartz'), there is no need to mess with delicate items like pinion and tubes. Just advance the motor as per manual and let the IC deal with the rest.2 points

-

1 point

-

Disassembly sequence here (Please sort by name in ascending order) Assembly sequence here (Please sort by name in ascending order) The watch is an Enicar Star Jewels Ocean Pearl from the 1970s A bit of background I bought this watch on tradera.com (Swedish eBay) listed in the category "Klockor/Renoveringsobjekt" ("Watches / Renovation items"). It was listed as "working" despite lacking the winding stem. I bought it for three reasons. I wanted to try my hands on an inexpensive watch in visual need of renovation. I was curious of the Enicar brand and their in-house movements, and I thought the blue dial with its applied indices had potential. It was clear that the watch needed a new winding stem, crown, and armoured crystal. I found an original stem on eBay from Spain for less than €10 including shipping (a bit of a bargain I think). I bought a bunch of inexpensive waterproof crowns from CousinsUK.com so that I could select the most comfortable and at least somewhat nice looking. I also bought a couple of inexpensive Sternkreutz armoured glasses from CousinsUK.com Overall the movement looked pretty OK except for a third wheel pivot that was rusty. Removing the rust (using vinegar essence) the pivot became Coca Cola bottle shaped so I burnished it and in the process had to remove approx. 2 to 3/100 mm. This in turn created too much side-shake so I replaced the jewel as well. The mainspring looked pretty OK too so I kept it. The cannon pinion also needed a bit of tightening. I guess the friction between the centre wheel arbor and the cannon pinion really can't last forever when a watch is being used for many, many years, perhaps even for decades (looking at the case back of this watch it has seen massive use). Anyway, to tighten the cannon pinion I first tried with my Seitz jewelling pusher and stake for lanterning cannon pinions, but it feels like the edges of the pusher and stake are somehow too blunt or perhaps not designed for wrist watch movements?! So, I resorted to my cannon pinion tightening tool (Bergeon 4733) which is really a bit scary to use but works very well once you've destroyed your first two or three cannon pinions learning how to use it. The trick is not to alter the position of the screw (unscrew it) once it reaches the inside of the handle. As soon as the screw touches the inside of the handle it's time to press. That will usually tighten the cannon pinion the required 1-3/100 mm (I would guess). To give back some of the luster to the dial and hands I simply used a Dial & Hand Cleaning Pen from CousinsUK.com. It worked better than I had expected. The old lume was partly missing and what was left was completely crusty so I simply scratched the remains off and didn't bother to replace it (the blue colour shining through the hands looked pretty great and I don't care much for lume anyway) Despite throwing everything in my arsenal of collected knowledge and experience on the this watch I couldn't get it to run perfectly. The amplitude (as well as the rate) in the horizontal positions fluctuates between 260 and 280 degrees but mostly stays around 260 degrees. I did adjust the curb pin as the hairspring was pinched between the boot and the curb pin and made sure it bounced evenly between the two, but the effect was only marginal. I suspect that the hairspring touches the lower part of the boot. Anyway, I decided to wait with further investigations, put it together, wear it and enjoy it. Despite this shortcoming it performs very well as a daily wearer, only varying in rate between about +1 and -1 seconds per day.1 point

-

Just a quickie When my dad died 7 years ago my mum gave me his old Riquartz watch that she gave him for their 25th wedding anniversary in 1981. It was in a sorry state. Dad had worn it solidly from that day to the day he died. The case and case were badly scratched, the original strap lost, the day date mechanism jammed (broken as it turned out). It had been left neglected for the last 7 years. With a bit of patience and good fortune I located new-old stock movements and crystals. For a well worn 41 year old watch I think it's come up rather well after a strip down, polish and careful rebuild and new movement. I think it's good for a few more years. Before and after photos below. I can't wait to show my mum. James.1 point

-

Hi There probably will be a replacement of the same size but it may not be a drop in, Measure the watch movement size 12 to 6 and 9 t0 3 probablt a 6 3/4 X 8 or close and then the height of the movement from the base to the top of the cannon pinion or center wheel is it has a center seconds, having got the measurements its then a case of doing what we all do and searching the net, I could not find anything on the 1400 but have enclosed a sheet on the 1421A which may be of the same family or a cloce cousin. What we maen by drop in is that the dial and hands from the original cross over unchanged, others may require dial feet shifting and new hands to suit the new movement. Seiko 1421A, 1428A.pdf1 point

-

Before calling it dead try restarting it with a line release or demagnatizer box.1 point

-

Hi Willow Old Hippy is right thats the only way to rectify the prolem, a P.I.A. but the only way.1 point

-

Hi they can be c;osed by nipping it up in a pin vise if the tube is long enough if not there are punches which are countersunk that to place over the hand from the back and tap down closing the small tube. there are also propriety btanded toold for the job.1 point

-

Even if the printing is on the outside, you could mask off the area with the text on it, and carefully polish the rest. Do you have a picture of the watch?1 point

-

1 point

-

In my post above, I also tested this, and yes, it dissolves rapidly https://www.watchrepairtalk.com/topic/3552-cleaning-fluids/?do=findComment&comment=1814781 point

-

1 point

-

I use 99.9% pure IPA. I also use flake shellac, but I don't have any issues at all with it dissolving- quite the opposite. I used some to fixture some parts for sandblasting a while back (I would normally use Loctite 480 black superglue and deglue in acetone) thinking it might be less fuss; it took forever to dissolve off all the shellac, finally in a separate bath in ethanol in the heated ultrasonic for a good 30 minutes. Perhaps there's differences in flake shellac. I know it sort of has an expiration date, though I have used very old stuff many times without issue. Maybe when it's very fresh it dissolves more easily- I would actually bet on it.1 point

-

Hi the "S" shaped wire is just a fairly hard wire bent to fit and hold the spring clutch together nothing special, brass wire I would say is a bit soft. Boiled linseed is best to feed the wood, I have used orange oil but seems hard to get now. If you apply the first few coars of wax with a000 grade wire wool it helps to flatten the surface and build up a nice surface.1 point

-

1 point

-

Boiled helps it to dry out faster, apply raw and it could take months. Yes you can buy it boiled.1 point

-

EDIT: Oops, didn't realize I wasn't on the last page... Absolutely! The pivot has been broken off (sensitive little buggers, oftentimes only having a diameter of about 0.1 mm) You'll have to source an intact escape wheel.1 point

-

That it never is never done on quartz chronos unless an hand falls in between two indexes. Instead, as explained above, the independent motors can move each hand independently to zero, following the procedure in the manual. I never suggested to do that, never tried myself, and would not recommend it.1 point

-

The first day of my watch repair, this watch, I lost 2 items. My bride found them 2 days later. To overcome that problem, as a result from a comment from a member, I purchased a small plastic container from a local supermarket. Spent a few minutes cutting out the front, leaving a lip. I used an old laptop case as the base. Since install, I think I have have in excess of 20 'pings' on the side walls. A frantic look in the box has been successful on every occasion. Whew! I also place every item in small containers. I don't have much space as can be seen. Tools by the computer, watch box against the wall. I store the working box on the printer when not watch repairing. I can look at the computer when repairing. Thank goodness for YouTube. Thank you to all Regards Ross1 point

-

Check the balance pivots. Sounds like one may be slightly bent. Also make sure the balance cock screw is fully tightened. The hairspring is unlikely to cause the balance to wobble.1 point

-

1 point

-

If you use the dial protector with a cutout/slit for the hands, together with with a bergeon presto style hand remover, the thinner blades of the presto tool may be able to slide under the hands. Only thing is the hands won’t be protected by the plastic sheet since it will come in contact with the presto tool.1 point

-

Let me see if I got you correctly. You separated the movement plates without unpinning the hairspring. Was the balance wheel dangling by the hairspring when the plates were separated? If it was, then chances are the hairspring has deformed. Can you post some good close up photos of the hairspring?1 point

-

Finally the case. This was never going to be perfect. I started by gently cleaning it with white spirit and one of those green pan scourers. This removed the filth and didn't abrade the surface to harshly. I have seen a number of clocks where it looks like someones taken a belt sander to it. This was followed up by applying a 50/50 mix of white spirit/boiled linseed oil. Forgot how many coats I put on. Then finally applied the boiled linseed oil oil neat and wiped off any excess after allowing time to dry. Then is was two/three coats of clear wax and plenty of elbow grease. I'm no furniture restorer, but I think the results are pleasing on my humble little clock.1 point

-

Please post a picture. On the quartz chronographs I have worked on, there is a calibration procedure. Something like pull out stem to second or third position, then adjust the hands with the pushers, then return the stem to run position. no external tool is needed.1 point

-

1 point

-

You've done a nice job, it looks good, i'm sure it will bring back happy memories for both you and your mum, i recently joined for the same reason to repair an old watch i was given by mum, little things hold precious memories.1 point

-

At the link below you can download the tech sheets for All of lubrication including the HP and D5 oils. It's interesting when you look at the tech sheet for both of them the HP oil is definitely better. But then there's the chart at the top of the page your standard lubrication chart simplified versus the older ones. But the peculiar thing is found at the bottom of the page I snipped out an image and I've pasted the text below. This is where it be really nice if they would explain why? It looks like the superior synthetic oil must have some? Definitely annoying if you want to have all synthetic oils as now you can't. The Synt-HP oils (9101, 9102, 9103, 9104) are preferentially in use for ruby bearings. For brass bearings, we recommend Microgliss D-4 or D-5. https://www.moebius-lubricants.ch/en/products/oils1 point

-

Hi there ! I would like to start sharing my small collection with two pieces that are really special to me. The Seiko SSA215J1 Caliber: 4R39 Date: 2015 Looks like this one is not really a popular Seiko. I barely find any related content online and the watch is litteraly selling half the price I've paid for it. But here is the thing, this is the first mechanical watch I've purchased for myself back in 2015. At that time I really wasn't that much into watches. But one day I entered a Seiko shop out of curiosity and it really was love at first sight :). I didn't buy it on the spot, but couldn't stop thinking about it until about 1 month later when I finally pulled the trigger. From that time I wear it almost daily ! The Rolex Datejust 1603 Caliber: 3035 Date: 1980 That one is a birthday present from my father. He actually bought it several month before my birth so technically it's my "older brother watch" :). He also wore it daily for so many years and in some borderline extreme conditions. The watch was still running great but started to show some degradation on the needles. So when he gave it to me I decided to have it serviced at a Rolex shop. Here is the result: That's it for now !1 point

-

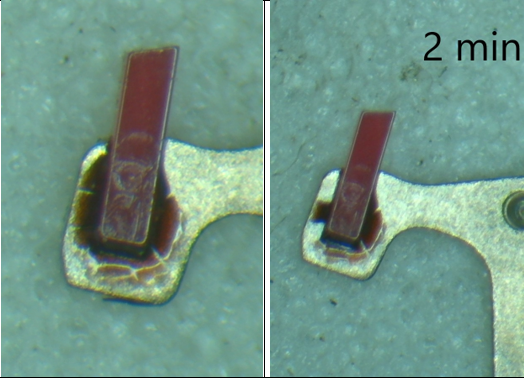

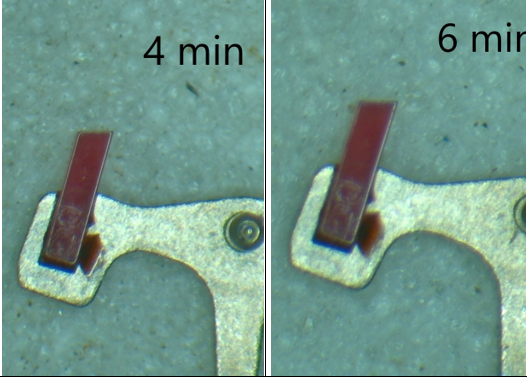

As a follow up, I thought I'd repeat my original experiment (because we all like an experiment ), as my new ultrasonic is twice the power (60W) and is heated (the test below was done at 40C). The only scrap part I could find was an old wristwatch pallet. The shellac was already badly cracked (you can't really see all the cracks in the first image) As you can see, after 2 mins, the loose shellac has been stripped - I wasn't surprised given the cracking. At 4 mins more of the loose shellac has come lose, but the remaining shellac is not noticeably smaller. At 6 mins it looks no different than at 4 min. The jewels are still firmly mounted. BUT ..... As I couldn't find a part with uncracked shellac, I took an old pocket watch pallet and added some big blobs of shellac. After 2 mins there was serious loss of shellac. So, Conclusions. Don't put parts with 'fresh' shellac in IPA in the ultrasonic. For more 'seasoned' parts, expect the ultrasonic to remove cracked bits of shellac - though I suspect it would be the same in any cleaning fluid - more vibrations than IPA doing the damage. From my test, it seems that, once the cracked bits are gone, the remaining shellac does not readily dissolve in IPA. As I mentioned, I rinse most parts for about 1 min in IPA, but parts with shellac - only about 30 secs.1 point

-

Makes for an interesting battery change, Is the sump drained and refilled on each chage.1 point

-

First of all do you know what calibre it is? I think it might be an AR1146 but I can be sure. These people may be able to help, also |Cousins do list some parts for the 1146, otherwise you may just have to keep searching eBay until something comes up.1 point

-

I have seen youtube videos on removal the only one I can find is this but I have seen another that had a better solution than this but cant find it now, Reinserting would be a reversal of the process above, I think in this video the screw he uses is too long and risks damaging the hairspring the other video I once found was a american guy who had used a similar method but he had made a tool for the purpose that looked better than this solution but I cant find it. I think you could do something along these lines with a bit of care.1 point