Leaderboard

Popular Content

Showing content with the highest reputation on 01/15/22 in Posts

-

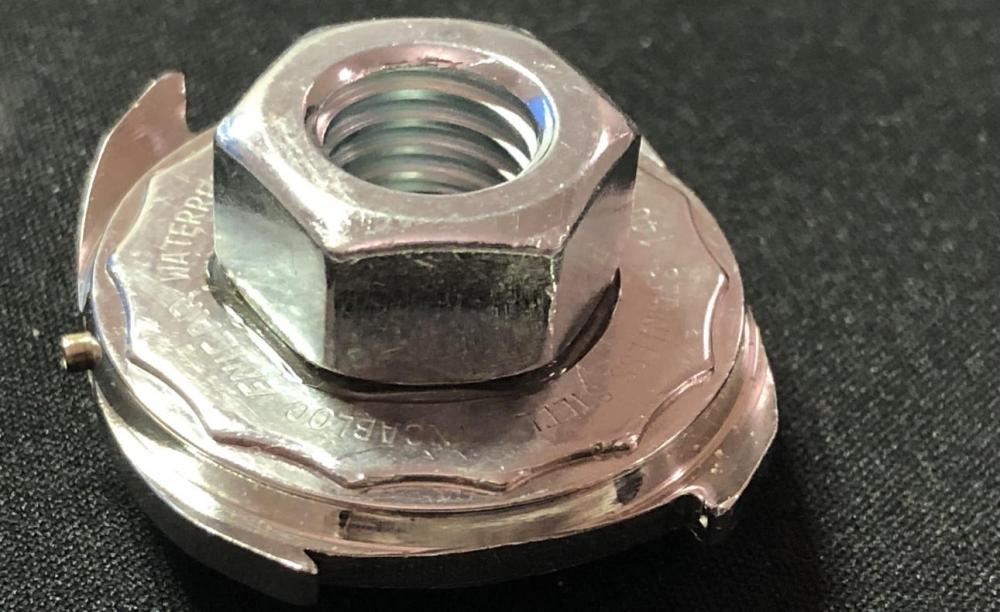

Hi all, Just got an old Favre Leuba and the caseback was well and truly stuck. Usually in this situation I would bring it to my mates shop and use his bench opener but as this Favre-Leuba has flats they usually don't work as well. Anyway, another solution is to glue a nut on the caseback and use a wrench on that. Well the superglue is pretty much a necessity for me and there are usually a few tubes in the freezer ...result! After 10minutes for the glue to set, a big adjustable wrench between the lugs and a 14mm spanner in the nut/caseback and it spun right off!. I must say the caseback did a good job keeping the movement clean! This trick has helped me out a few times. If you plan to do this just make sure you keep the superglue away from the caseback/case joint. If any superglue wicks into the joint then things get difficult! Anilv2 points

-

I just recently, and for the first time, used the same trick to get the case back off an Enicar Ocean Pearl having the same type of case back. It just wouldn't budge using my Jaxa tool and my sturdy case holder. Why anyone would screw on a case back that hard is beyond me, but perhaps it is necessary to preserve the water resistance!? I usually just use my suction grip ball to tighten the case back and then a final touch with my Jaxa tool to make sure. Anyway, I used Epoxy glue, and it probably was an overkill as it took many hours to dissolve it in acetone. Superglue is likely a better option. The case back just wouldn't budge using my Jaxa tool despite having a good grip. Using Epoxy glue was a probably an overkill. Using a wrench the case back still wouldn't budge but instead the jaws on my sturdy watch case holder started to give. Luckily the lugs fitted more or less precisely in my vise. It took many hours dissolve the Epoxy in acetone. Superglue is probably a better option.2 points

-

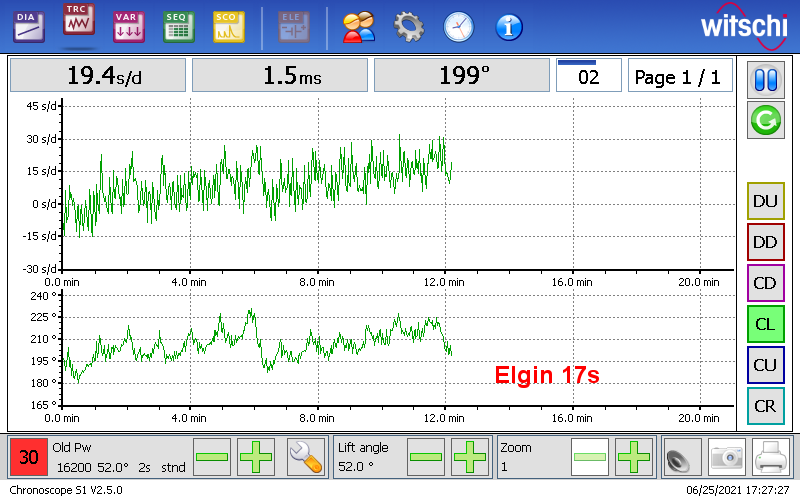

Lubrication is a problem in watch repair because watch repair has spanned a very long time. The technical sheets the books the bulletins whatever people look at have spanned a long time. People embrace a certain book author as their God and embrace whatever they said but that might've been written 50 or 100 years ago. The factories keep changing things continuously just because they can I guess. Then there is the missing documentation? Thinking of lubrication follow the link download number 40 and anything else that looks interesting https://www.cousinsuk.com/document/search?SearchString=Working So here's a nice lubrication guide and is at all in the guide no what's missing well number 67 is missing which is amusing document because it doesn't really cover lubricating the mainspring is not lubricated at all. But it's not in the lubrication guide it's in a separate guide titled recycling mainspring barrels. Then what about surface treatment is that necessary? That's also in another separate guide. Sometimes it's in the cleaning guide sometimes it's not. If you're ever at a lecture with her lecturing on lubrication and you corner of the instructor Dell refer you to the tech sheet but once again does the tech sheet cover everything? It's only relatively recent times were the tech sheets start to cover surface treatment. It's why companies like Eta to get away with insanely thin lubrication's for the setting parts where personally I would prefer grease they are using oil but their surface treating. Omega's been surface treating since the 50s and yet it almost never appears in anything. Even companies like Eta now talk about it did they mention that they surface treat their balance staffs? That's in the manufacturing information sheets not the technical guide. Out of curiosity where did you see in this discussion? May be? Minor disclaimer before we go down the rabbit hole? Typically for people new to watch repair there is going to be a problem. Biggest problem is it's the basic things that will trip you up. It's all the things that you don't know and you don't even grasp that you don't know them. It's of things that you can't see it's also where getting a microscope doesn't help. Making something bag if you can't grasp what it is you need to look at what you're trying to see doesn't help at all. So simplistically it's probably something pretty darn simple but if you don't have the expertise to grasp this simple task which you don't because you don't have the experience yet then we can go looking for the obscure things maybe learn something along the way,? The above quote assumes something it assumes that it fits the narrative maybe it doesn't fit the narrative in which case this will not work. We need something we need something from the old days when the manufacturer grasped that the watchmaker had no idea what a timing machine is So they did a decent manual. It's interesting from the manual as this is a transistorized machine and it's the same manual for the vacuum tube machine that they did years later so it's a good manual. http://www.historictimekeepers.com/documents/Micromat.pdf PDF page 15 what is it talking about? Page 16 shows you the wheels gives you time frame your watch won't be exactly the same but it will be close. if you really needed no yes to do the math to figure out what the timeframe is for things. Then continuing on the page 17 the vantage of paper tape you might build a C trends? Now notice I use the word might be able to I've have some experience with this and sometimes it's really hard to see stuff especially when it's back much closer to the mainspring barrel this is where we need something different. I've attached a PDF Page 9 titled 2.2.2 Display Mode Trace. Their demonstration pictures aren't the best but you get us started and I'll see if I can find a better image to make a point.You notice there showing initially a really short time span a lot of variation all watches will have variations like this. Gear train's gears have power fluctuations all gears do the watch will never typically show them including typically on a timing machine as they get averaged out. On the next page you can see the amplitude of the time fluctuation this is what gets averaged out you'll ever see. Notice this is a reasonably high grade watch because the fluctuations are really small if you run one of these on a Rolex watch still be really small or Hamilton 992B has a really tight timing like this other watches they can start to look much worse and yet it's not exactly an issue because it's just the quality of the watch Other things useful in a really expensive timing machine is the oscilloscope mode they show it on page 11 although? The next page where it shows it like the 400 ms setting the timing machine that I use at work as this Senate 400 ms it's better because you can see the spacing between the escapement sounds. This is where if you had a hairspring rubbing issue providing it would actually make a noise of its gently pushing on the balance wheel it doesn't always show up. But just because you see a noise on the oscilloscope doesn't mean it's easy to figure out where that noise is coming from. Then another example of what the time trace future looks like image attached. The amplitude probably isn't right because the lift angle wasn't 52°. But here you can see the effect of the center wheel meshing with the mainspring barrel that's what the longer issue is. The faster one is one of the other wheels. This is a situation where this would average out on a timing machine you would never normally see it. Yes it looks like a USB port what exactly does it do? So I would suggest running on buying the witschi timing machine how much could that possibly cost you? Then some of the software machines they can either make I can the discussion group for others will do similar things. But doesn't get us any closer to finding the problem? In the absence of all of these newfangled fancy things if you look at the that's the original posting person if he looks at your timing machine and the graphical display is too hard to look Look at the numbers are they going up and down? If they are looking to watch and see how fast the going up and down and see if they correspond to an actual repeating pattern. If they're not repeating then what is the problem? I would go back and visually check everything make sure all the pivots are nice and clean and shiny make sure all the holes look like they're nice and clean make sure all the jewels are nice and flat. I don't think I've seen it yet but if you put enough pressure on things you probably not the jewel out of alignment that would give a binding issue. Go back to the mainspring barrel how much side shake you have? I don't remember on this Seiko but did they jewel the main plate for the barrel if not check that the bushings or whatever are still around and you don't have too much side shake. One of the problems that pops up on seven jewel watches is the train will spin nice without the pallet fork again but as soon as the pallet forks in and there's pressure the holes are out around and things will bind up. Everything is jewels in this watch except at the barrel and it's possible you of where they are. On the other hand it could be as simple as a proper cleaning and something resembling reasonably close lubrication. But at least the watches running. Versus buying a broken watch on eBay thinking you're going to fix up the first time and usually people give up and move on because not every watch can be fixed but the Seiko t least it's running and it should do better than what it's doing now. Test and measuring technology mechanical watches.pdf2 points

-

It was not my intention to imply that you were wasting peoples time. I was trying to participate in the diagnosis, nothing more. Mainspring lubrication appears to be one of the complicated and potentially contentious subjects in watchmaking. I have seen recommendations to not open the barrel at all. To put the spring in dry but dab a few dots of oil on top before closing it up. To grease it between fingers. To grease it in the crook of a small fold of watch paper. Pretty sure I've seen Mark grease a spring between fingers and remove the excess from the edges with rodico after winding and after installing in the barrel. I'm sure I've also seen mark install a white alloy mainspring for an automatically wound watch totally dry, but with four or five dabs of grease on the inside walls of the barrel. And this reminds me of the long thread on pallet fork pivots, which we never lubricate, except when we used to and sometimes still do. I recall seeing that two certified watchmakers who both studied at Neuchâtel swore that they received distinctly differing instructions. As for my assignment: It is apparent that the 7S26C is experiencing periodically higher resistance to delivery of power. If we knew some details about the frequency and duration of the period of higher resistance, we could combine this with knowledge of the movement's design to guess where it might be, because we know how many times per hour each wheel turns. This is a shortcoming of the otherwise quite darling LCD timegrapher. Sometimes it is better to have a log over a long duration. Otto Frei offers a printer attachment for their branded version of the Weishi. I wonder if some clever hackers could implement logging through the USB port which is marked "Calibration". I wonder if i can determine how to connect the Weishi microphone to one of the XLR inputs on my audio workstation for this purpose. I wonder if the MEMS type lavalier mic i picked up at a surplus sale is sensitive enough to use with open-source timegrapher software -- really interesting piece of tech, looks like a flat piece of ABS plastic on the end of a wire to me. Under high magnification i have discovered things like partially corroded wheel teeth with little flakes of metal oxides hanging off them at odd angles. This would certainly increase resistance while those teeth are engaged. I've discovered that the bottom pivot of an escape wheel had a subtle Z shape to it. I've found cogs that had some kind of hardened emulsified grease or something embedded in a few of the grooves. Please understand that i am decades into a career in quality assurance. It's not ego, it's habit.2 points

-

One of the issues with the common modern presses is that they do only that - press the crystal. What you often need for acrylic crystals without tension ring is a set which allows you to deform the crystal by using a cup and a corresponding dome to compress the crystal over.2 points

-

I apologise, but an error has slipped into the assembly sequence of pictures. For detailed info, please read this post: OneDrive Disassembly pictures here (please sort by name in ascending order) OneDrive Assembly pictures here (please sort by name in ascending order) When I first started out trying to service and repair watches, I took a picture of every step, and I needed those pictures as I didn’t have the knowledge to deduce where the parts should go, how they worked, and how they interacted. Now that I’ve gained some experience, I no longer need all those pictures, but I still need some pictures. For example, it’s very convenient to have pictures of the train of wheels or certain parts of a date complication, and so on. Anyway, I enjoy taking these pictures as I go, and I organise them and keep them on my OneDrive for future use. For this project, servicing my brother’s Atira Plana housing an ETA 2472, I felt it would be fun, interesting, and perhaps even useful not only to take the pictures but to edit the pictures, adding visual and textual instructions. These pictures are made for my personal use and are not intended as a tutorial or to tell other people how to service an ETA 2472. The pictures simply document how I went about it. Nevertheless, I guess others may find my work useful, so I’m happy to share it. There are many ways to service a watch, and I’m still learning. That said, I do follow the practices taught on watchfix.com, and they work very well for me! Here's a post with links to some of my other service walkthroughs on WRT:1 point

-

Hi, My father who spent many years collecting pocket watches and repairing them has recently moved into a Care Home suffering from Alzheimer's Dementia and I have got the unenviable task of clearing out his workroom. My husband and I both have engineering backgrounds, having worked at Rolls-Royce Aerospace, and are familiar with or can work out what some tools do but are less familiar with some of the more specialised watchmaking/repairing tools that my father has. We have already used watchrepair talk.com/forum to gain knowledge on some tools, thank you, and would very much appreciate using the knowledge of the members to identify some of the more obscure tools and their manufacturers, if possible. Hopefully, this is within the remit of the website. Julie1 point

-

Well, I fashioned a replacement click spring from a ball point pen spring but then got the hardware store to buy a big magnet. Lo and behold, the magnet found the spring!! I am back in business with original parts. Thanks for the advice.1 point

-

1 point

-

I would put a pair of timing washers on, opposing screws, this is exactly what they are made for.1 point

-

I'm back in India visiting my wife's family for the first time in a very long time. While here I needed a screwdriver to sort out my spectacles, and there was nothing really suitable locally, so I headed off to Amazon. I wondered if there might be some watchmakers screwdrivers for a reasonable price, and sure enough you can get a set for a whopping ₹ 789.00 INR (about £7.76 GBP or $10.61 USD). Imagining they were most likely terrible, but compelled by the need to know exactly how terrible, I bought them. They arrived a few days later from a seller in Mumbai, and are actually not nearly as terrible as I assumed. Not great, I'll grant you, but not actually terrible. They didn't come in any fancy packaging. No nice storage case, or indeed any case at all, and I didn't spring for the optional plastic stand for them (shown above), which would have added about ₹ 100.00 INR or so more. In fact they arrived in a small Amazon plastic shipping bag. Inside that there was a small zip lock bag and in that, taped in a slightly grubby polythene wrapping and covered in machine oil were nine screwdrivers, and a complete set of replacement bits. The handles are pretty sturdy, and surprisingly, as well as being colour coded, are actually individually stamped with their relevant individual bit size ( 0.5mm - 2.5mm ), so you can replace the bits with the correct replacement. The set appears to be based on the infinitely better engineered Bergeon 30081-A10 set sizes, (but without the rather attractive case and the $180.00 price tag). (Picture of the Bergeon set courtesy of Esslinger.com) It will be interesting to check, when I get back to the UK and have access to some calipers to measure them, how accurate the bit sizes are. Also I doubt if the Indian bits will remain sharp for very long (although they do appear to be hardened steel of some sort), but as a novelty item, for fixing my spectacles (now fixed, thank you for asking), I'm actually relatively pleasantly surprised by what turned up. I may even try to service a couple of 404 club watches with them to see if they are up to the task. Another worry with these cheap bits would be rust, since unlike the Bergeon ones, they are certainly not stainless. I guess that is why everything arrived with a liberal coating of heavy machine oil. The packaging suggested that the MRP for them is ₹ 1800.00 INR which, at roughly a tenth of the price of the Bergeon set (and more than twice what I paid), is probably about the most I would be willing to spend for a similar set. I would of course far rather have the Bergeon 30081-A10 offering, perhaps I'll sneak that in to next years Dear Santa list. In the off chance that you want to try to find a similar set, here are the relevant Amazon key words. (DIY Crafts Micro Precision Screwdriver Set 0.5mm - 2.5mm with Stand Replacement Tips Jewellery Watch Repair Electronics Hardened Tips 35-40 HRC (Pack Of 1 Set, Watch Repair Screwdriver Set) EDIT: Just to be clear, you get nine screwdrivers in the set I bought, it does not include the 300 Brown (3.0mm), however the first picture in the listing does show ten screwdrivers. Not that this actually matters overly much. EDIT2: Most (all?) of the Chinese sets I found online go from 0.6mm upwards, the set I got goes from 0.5mm which may prove useful when you are trying to remove those tiny screws on older balance cocks, or masochistically servicing one of those really tiny ladies movements. The fact that it differs from the Chinese sets in appearance, and in the inclusion of a 0.5mm driver suggests this may be an Indian made set rather than a Chinese import to India, but since it is completely anonymous, I guess we will never know.1 point

-

That is fine, but please understand that input coming from a professional watchmaker (not me, but at least I have fought various times exactly what the OP reports) with thousands of services and repairs under his belt means that experience is talking not just speculation, and it's normal that are looked as having a different authority weight. Actually isn't so apparent to me. When a mov.t basically pass the "free train" test like the OP's did, we know that at least most of the power gets to escape wheel. But, amplitude is not just a function of that, what makes maximum amplitude is also: Perfect shape and setting of the escapement, as in perfect teeth, stones, and their depth of lock. Perfect lubrication of the above, e.g. using the right amount of 9415 can easily increase amplitude by 10 - 15 degs. Perfect condition of the pallets horns, in the past watchmakers polished their face to a mirror to decrease rolling friction to the impulse jewel, which of course must be also perfect and steady in the plate. Perfect shape of the mainspring, I have seen myself that even a small defect like the OP has can return 5 - 10 deg when corrected. And of course, perfect conditions and lubrications of pivots, their jewels, and correct end-shake. In other words, my approach follows Occam's razor: if you have a problem with how the balance oscillates, look at it first, then to its close companion the escapement, and only if all that is ruled out to all the rest. Of course, one could also have both problems at the same time: reduced power delivery to the escapement, and imperfect balance/escapement system. In that case the predictable outcome would be a low base amplitude, with relatively small variations. I believe that is in fact what the OP is experiencing. That could be an approach if the balance/escapement was in perfect conditions with no variation between DU and DD. But, that's not the case here. Clever hack as in reverse-engineer the hardware of the device, then rewrite firmware from scratch, so you would then be able to do anything you want with it; not a small feat really. Easier is to use a PC based timegrapher, which leads to my next note. The microphone connector looks like an XLR but it's not, it's an aero type. Check related discussion: No jewel there on the 7S26. It was added later to the better calibers having the same base.1 point

-

The platform escapement must be dismantled to clean and oil it correctly, else you risk leaving old oil and dirt in place and just adding new oil will turn it into grinding paste ruining the pivots. The platform escapement is more like servicing a pocket watch than a regular clock and does require extra care. If its the anchor that has lost a pallet stone rather than a broken balance staff that is better as you can pick up ABEC escapements with broken balance staffs reasonably cheaply that will have a good anchor in them that you can take out to fix yours, but you need to make sure you buy one the same as yours.1 point

-

Its one of the ways out of a hole used it a few times and never failed to get the back off.1 point

-

You can get by for threading a short object by reducing diameter on near a sized one that has the right pitch, but for a complete thread you need to single point thread a complete new one on the lathe. Below a good example, the author then proceeded to make a die from the tap, because he needed to make a new make threading. Also very interesting an insight on how tap are (were ?) made in the industry I will stop with links now because YouTube is better than me at suggesting! These are the Indian ones discussed above. What material and diameter you are trying?1 point

-

First of all my apologies for not having documented the disassembling, but the watch arrived in a terrible condition and I stripped it down right away to get rid of all that dirt. If you have worked on some watches yet and think about entering the chronograph world with a 7734 let me give you 3 advices: Do it! The 7734 is a solid construction and not too complicated. Take your time and watch all the 6 parts of Mark's Venus 175-service on youtube. Of course the Venus is a column wheel system, but the basic movement is very similar and also on the chrono layer you can learn a lot especially about lubrication: https://www.youtube.com/watch?v=EI3T-IR3AgM Download the 7734 service manual. A lot of information here: https://strela-watch.de/valjoux-7734-7733-7736-technical-documentation/ Here we go. Some 8200 for the barrel and the new mainspring goes in (got it from cousins - what I'm gonna do after Brexit? ). The complete barrel. Some D5 for the arbor. Putting in the wheels and the bridges. Lubrication: 9010 for the escape wheel and the second wheel, D5 for all others. The keyless works. 9501 for the stem and the gears. D5 for the wheels and the lever axis, 9501 for the contact points of levers and springs. The click spring. D5 for the click and the crown wheel, 9501 for the contact point of click and its spring. Finally the ratchet wheel goes in. The pallets go back in, no lubrication for the pivots. Lubricating the balance jewels with 9010. The balance back in. The escape wheel and the pallets got epilame so I let run the movement with dry pallets for some minutes. After that 941 for the pallets (work from the dial side through the window). Now I start with the chronograph. First the bridge and the spring for the levers go in. Fly back lever goes in with some D5. Operating lever, again D5 for the axis. A little bit tricky, you must upline the integrated spring with the upper lever first (9501 for the contact area). The second pictures shows the final layering. The sliding gear goes in, D5 for the lever axis, no lubrication for the wheel! At this point I forgot to put in the minute recorder runner (no lubrication). You should install it here, later its going to be more difficult. The blocking lever (D5) returns. Some 9501 for the contact area to the sliding gear. The blocking lever spring. Be very careful, this one isn't just a flyer, its a damned Lockheed SR-71 Blackbird. The friction spring (gets a drop of 9010). The chronograph runner and its bridge (9010 for the long pivot and the jewel in the bridge). The minute recorder jumper, no lubrication. The hammer. D5 for the axis, 9010 for the lever ends that hit the hearts, 9501 for the contact areas to the sliding gear, fly back lever, operating lever, jumper. The hammer cam jumper. Before installing the clutch give 9010 to the pivots of the coupling wheel. D5 to the lever axis. The spring. 9501 for the contact point. Finally line up the driving wheel with the coupling wheel and the chrono layer is complete again! The dial side. Some 9501 and the cannon pinion goes in. Hour wheel with D5. The dial rest with its 3 screws. The date indicator. The date indicator driving wheel with some D5. The jumper with D5 to its axis. As there was no lubrication described in the manual between disc/jumper or disc/wheel and the parts looked well polished I didn’t lubricate. It works - let’s see how long. The guard with 2 screws. Finally the spring. The dial comes back and is secured with its 2 screws from the side. While disassembling I put the little hands into seperate trays to prevent mixing them up. Now I turned the crown in the setting position exactly to the point when the date switches and put on the hour hand to 12. Positioning the chrono-hand exactly on zero was that tricky that I forgot to take a pic. New springs and gaskets for the pushers. Unfortunatly I’m not good in restoring cases. So just refreshing the brushing a bit and some cape cod work. The movement back in the case and secured with 2 screws. A new gasket for the caseback and here we are. Thank you for watching.1 point

-

Firstly, you have my utmost sympathy. My own grandmother lingered many years with Alzheimer's before passing. It is a difficult thing to bear witness to. But I and the others will help how we may. Post whatever pictures you have of any tools of which you are unsure about usage, and if we know we will tell you and explain them. And that goes for any pocket watches with which you may need help. A few of us, myself included, have more experience with those than with wristwatches and would be happy to help identify if need be,1 point

-

Just about a view secounds at 200° My demagnetiser was deliverted today. Of course I used it at once and the amplitude goes a little higher up to ca. 190° (some short time up to 204°) and it stays more stable on all orientations. A little step, but a step at all... Please stay calm. For me all the content here is highly interesting and verry helpful. To this point I 've learned a lot - eaven if there will be no final solution of my problem. For me as a beginner this may no help for my secific problem, but I learn with every thread a little more and it is verry interestimg for me to read, eaven if there are controverse statments.1 point

-

That's an interesting quotation above? Even though you're not versed in the subject of mainsprings or lubrication you're telling me that I wasted everyone's time? Strangely enough I agree with you but not for the same reason. Well I'll still disagree I don't actually know if that lubrication is sticky or not. I do know one modern mainsprings you're not supposed to lubricate at all and it could be a contributing factor to the problems were studying as to whether or not it's the only problem I doubt it. Tell you what I'll give you an assignment to do? As you're showing better insight into the problems of the watch than the original posting person or even maybe everybody else answering questions? Go back to page 1 read the entire discussion and where would you begin? The problem where having is and I might've already said this somewhere above so I'm apologizing for wasting people's time is? Where's the problem seems like a simple question but this is watch repair there is not necessarily simple answers. It's hard to tell in the discussion what's the original problem of a watch? Have there been any problems introduced by the original posting person who has no idea what they're doing. This is why pointed out bad lubrication on the mainspring could be an issue. So we basically have lost our way and as another new person wider to reread the entire discussion and point out where you would luck because I agree the discussion appears to now be a waste of time for one thing were wasting time discussing my lubrication concerns which may or might not be helping the original posting person.1 point

-

Hi attached tech sheet for the PUW 255 hope you find it useful cheers 3610_PUW 255 - 2570NEW.pdf1 point

-

If you enter these words inside double quotes on the search box top right you will have all the relevant discussions to learn at least the basics.1 point

-

There is no hairspring left for repinning longer, maybe it had broken at the stud and someone "fixed" it that way. I don't know Bulova and I can't tell from pics, are there timing screws?1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Hello Dan and welcome to the forum. If you are able post picture along with the questions as it helps.1 point

-

How tight is that part (cannon pinion) that goes on the center wheel shaft. It should be friction tight. When you have added the washers and collect nuts it should be tight enough for you to move the hands around and tight for the movement when working to carry the minute hand round.1 point

-

Hi whats the prob;em, is it slipping on the arbour. They are normaly a friction fit and normaly left alone unless the hole is worn and needs bushing in the plate. Closing the hole in the cam never had to do it but it would probably better to replace the cam.1 point

-

an aHA! moment. there's the missing piece of the puzzle! on one reference I had seen, I saw the 96-4 number but the chart didn't say what it was. also, the ONE place I didn't look-ranfft. figures. this is the very reason why this forum is the best IMHO. grazie, Graziano. I appreciate it.1 point

-

The point is that it is not true to say that Timex watches "were never made to be serviced". They were, and Timex published information on precisely how they were made to be serviced, and supplied service parts for that purpose. That is not to say that the Timex service procedures were the only ones that could be applied, and I'll wager that many watchmakers felt, as you do, that the Timex method was in some way inadequate, and therefor a poor substitute for "proper" methods. This would almost certainly lead to a belief that they were not really meant to be serviced at all. However, the "proper" way to service a watch is also the expensive way to service a watch, and that is precisely what Timex was not about. They developed calibres, and processes for servicing those calibres, that were, in their view (as the manufacturer) adequate, and that would keep the cost of servicing down. You can't even argue that Timex were trying to increase the failure rate of their movements and so drum up more sales as people replaced watches that had failed due to inadequate servicing, as cheaper servicing would mean that people would be more inclined to get it done, and faults detected and corrected before they became failures. Also, increased failure in a brand, even when the the manufacturers service procedures had been rigidly adhered to, would lead to poor brand reputation and a reduction in sales. No, the processes recommended by Timex for their calibres were (and still are) adequate for the way that those movements were designed. This is kind of what I was getting at when I referred to watchmakers being reluctant to adopt different processes. The full strip down, clean, inspect, and lubricate service is the only appropriate approach for movements designed with that kind of attention and budget, which covers the vast majority of mechanical watches, and in those instances I wouldn't advocate anything less. However, it's horses for courses, and Timex movements were designed differently with different requirements. Perhaps an analogy would help illustrate here. After just about every race, practice session, set up session, qualifying session, etc, a F1 car engine and transmission is stripped, cleaned inspected, and then put back together again with fresh oil (Swiss approach). My Ford Mondeo gets its oil and filters changed every 10k miles (Timex method). I would be mad to adopt F1 procedures for my Mondi, and an F1 team would last less than 5 seconds if they left the same oil in for 10k miles. Don't get me wrong here, I don't champion Timex watches because they are the best that you can get. But I do think that they do what they were designed to do (cheap time keeping that was also cheap to maintain) extra-ordinarily well. Each to their own though :thumbsu:1 point