Leaderboard

Popular Content

Showing content with the highest reputation on 01/11/22 in Posts

-

Back in 90s when quartz movements were popular , there were jobbers in Iran who rewound watch coils all day in a funny looking home made rig that consist of an electric motor attached to some hand made adaptors on which they mounted these to rewind. I never watched how it was done, they did solder terminals as well, you could get a rewound coil for a dollar plus exchange. @AliMoloodian a WRT member used to rewind them for his own use. He doesn't understand much English so I'll ask him to show pix of the gear.3 points

-

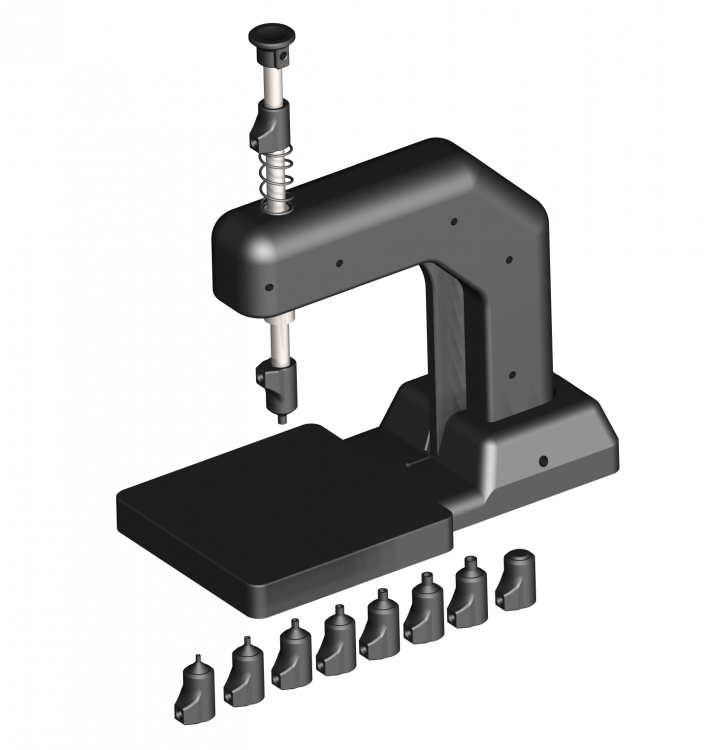

That is called a front loader case and your is the most frequently asked question by beginners that proceed to take apart things the wrong and potentially damaging way before researching about how to do what they don't kno how is done. The metal ring around the crystal is called bezel and is removed by prying gently around. In some case a special tool in needed to do that without damage - for a conscious professional even a small mark is damage. And when there is no bezel the crystal is maade pop out with a small air pump, see? No smashing needed. Then in either case you need a caseback or crystal press to put things back together, Of course ordering quartz modules online is easy, but for proper repair one need knowledge and tools also,2 points

-

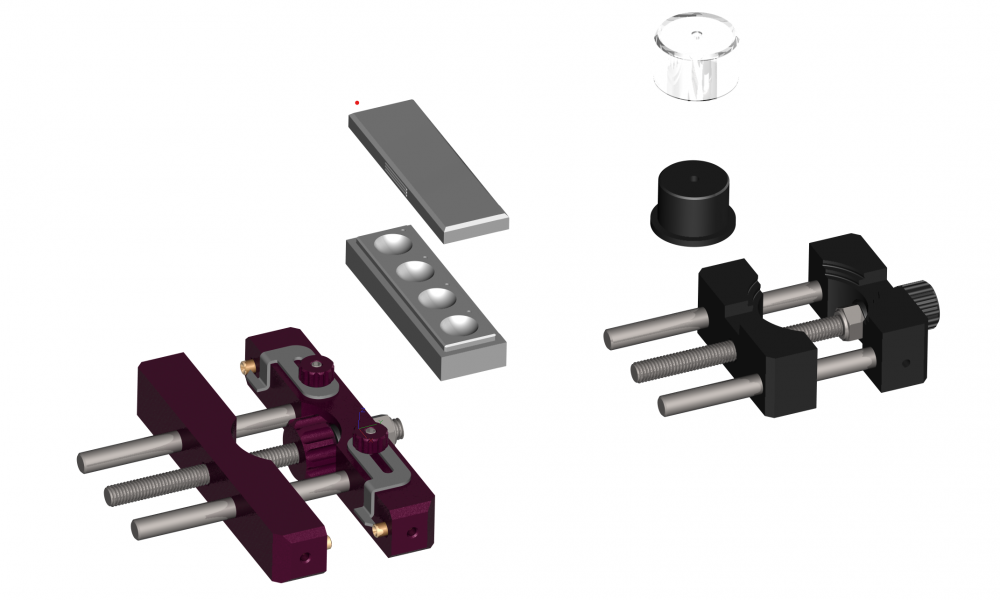

Many thanks! Yes, your are right, my "Mühle" is a 29er, too . Because I'm not at home, I can only post the rendered views at this time. You can see the hand placer an some tiny tools such as the wheel centerer, the movement holder but also an oil bowl and - I don't know the correct name is - a barrel assebler. Some of them are made out of CFK-PLA such as the lower part of the barrel assebler, the movement holder and the hand placer. To get a fine surface I presst some hot ball-bearing balls in the pits of the oil bowl. All axes are made from 6mm-steel and the threaded rods are M6x1 best regards Tobi2 points

-

Jolly good. A little tip about hands, never rotate the hands from the tips always move the hand as close as you can get at the center, that way you will prevent bending the hand or even breaking the thing off.2 points

-

Hello, I'm just a beginner, too, and I'm verry interested in mechanical watches at all. I'm a physicist and engineer and work in a university of applied sciences in germany. Because I get a new watch from "Mühle Glashütte", there is a high motivation for me to do the service by my self. So obviously there will be 5 years time (following the manual) to learn how to do that until the first service will be necessary (please excuse my poor englisch - it's not my highest qualification ). I will did my first practice on a Seiko watch with a 7S26C movement. And I dissassembled it following the youtube videos, clean it and put it together again two times, and it's still alive . But it has some problems I'm not able to solve - I will post in a an other threat. I do al lot of 3D-printing, so I developed a couple of tools such as a movement holder, a wheel centerer and a hand placer by my self and produce it by my 3D-printer - and all works fine Thats all from me for this time and I'm verry glad to be here. Many thanks and best regards from good old Germany Tobi1 point

-

I would say that the impact of reducing coil resistance in these ranges is insignificant. That is my SWAG anyway. The model for the coil includes inductance, resistance, and capacitance. All of them change as a result of shorting some turns. Since the coil is functioning as an electromagnet (versus a resonator), I cannot imagine it making much difference. It will likely increase current but that means changing the battery a month or two earlier perhaps. The actual answer requires carefully modeling the driver circuit, the load (the stepper rotor and train wheels), and the coil, and then simulating. Short a few turns and move on!1 point

-

The rotor gear could be pushing on gears of the auto device whereas they should mesh. Loosen the screw so the balance starts tor run, then turn the rotor so to get the gear teeth to mesh and tighten back. Another possibility is a longer screw will protrude furthure out the otherside and exerts stress on the auto device.1 point

-

I think jdm said it all. there are tools to do the job but knowlwdge of how to use them are of paramount importance. Whats wrong with the old module. Ask first then proceed with the answers. Its always best to accompany questions with pictures of the movement you are enquiring about.1 point

-

Does the rotor move freely when tightned up ?. Was the movement working prior to being dismantled and cleaned ? If so then somthing has happened during thre cleaning reassembly process , The above answers regarding the screw are the first check loosen off the screw a turn at a time and see when/if the balabce srarts, if so the screw is distorting the bridge stopping the movement.1 point

-

@gary17 just beat me to it, are you sure that it's the right screw? It looks to me that if you're using a screw that's too long it will protrude below the bottom of the auto bridge and possibly foul the balance wheel or maybe another wheel in the train.1 point

-

1 point

-

Just got through calling him, he promised to post some pix or a video in couple of days.1 point

-

1 point

-

1 point

-

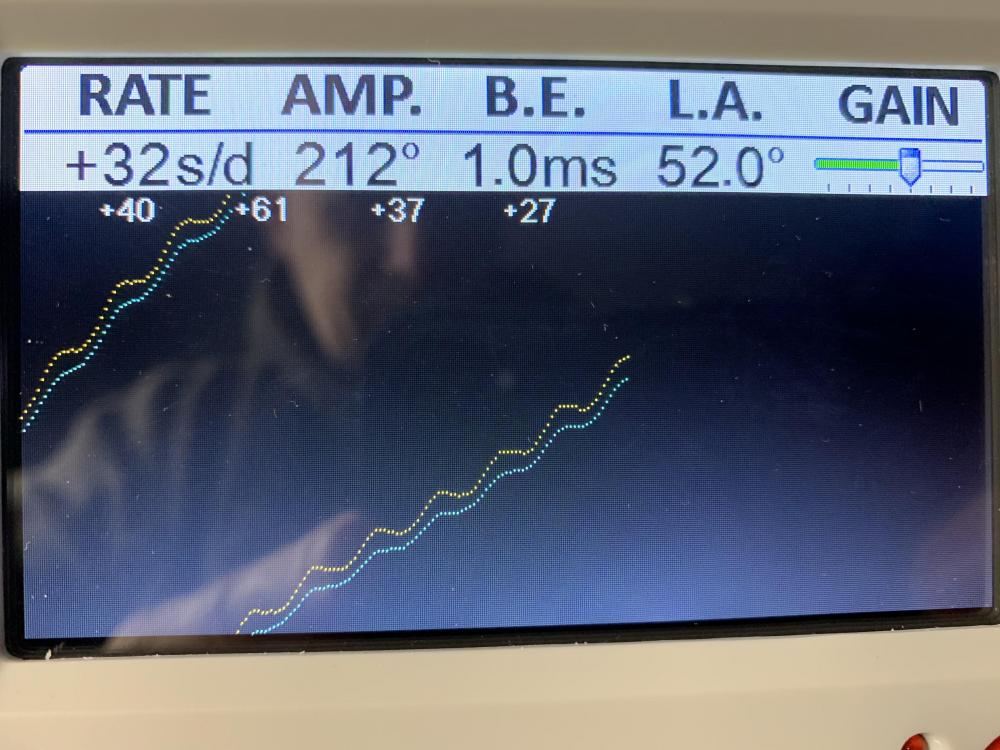

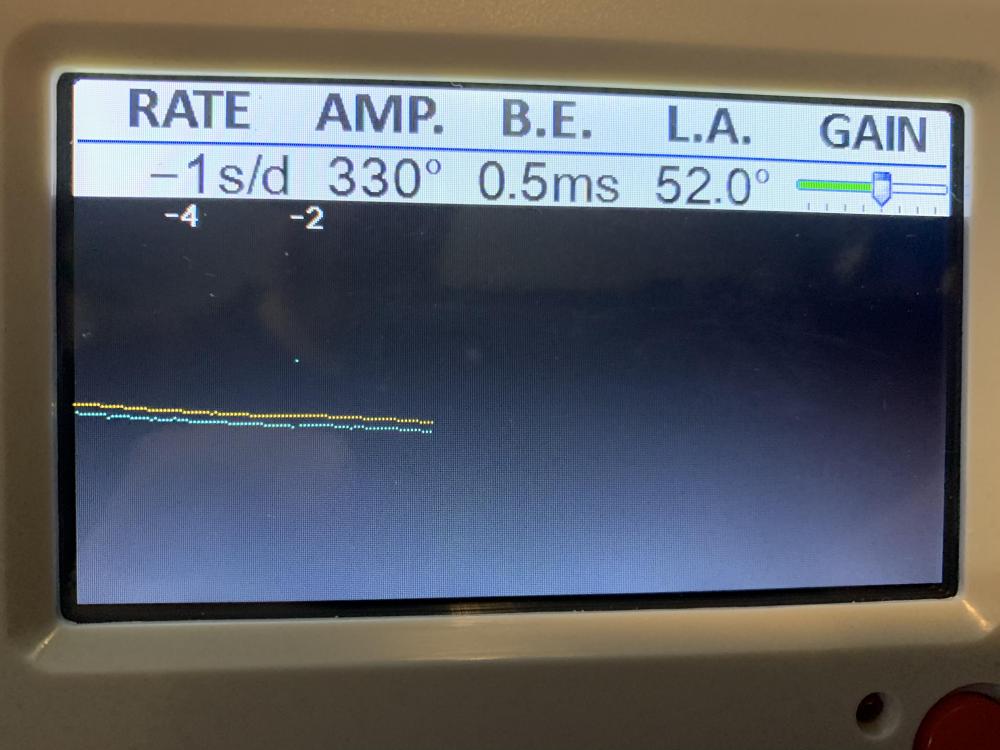

If you find a patern in fluctuations, you have spotted where the fault is likely to be.1 point

-

Herzlich willkommen, herr Tobi. I have lived in the US all my life, but my family can here from München and surrounding cities. Ich spreche eine kleine Deutsch, aber es ist lange her, dass ich diese Sprache viel gesprochen habe. I need to practice more. Enjoy our forum. It has many valuable resources. And there are experts here who can help with a wide range of difficulties. Have fun!1 point

-

Don't worry, i've been using Birthdays and christmas's to subsidise the tool collection. Just need to get myself some decent hand removal levers and hand setting tool.1 point

-

Thanks jdm very interesting. Without having the genuine watch it is very hard to spot the difference and you certainly need to handle it. A photo is utterly useless.1 point

-

I really like my Voila brass tweezers. They have served me well. I’m going to buy a couple more styles.1 point

-

1 point

-

They are incredibly easy to lose. One trick is to put the movement in a baggie and poke a hole in the bag to release or insert the spring. If it takes flight...it stays in the bag.1 point

-

It's been about 2 years since I last touched a Timex Electric. I vaguely remember having a problem like this. I think mine was due to a demagnetized indexing magnet. There is a small magnet on the main plate that pulls that thing that looks like a pallet fork so that it has some snap action like a conventional pallet fork. I think someone ran your movement through a demagnetizer. I tried to remagngetize it by rubbing the strongest neodymium magnet I had on it. It helped a little but the watch still stops unexpectedly. Moral of the story... don't demagnetize a Timex Electric.1 point

-

Learning is an interesting process we all learn differently. Most of us will try to discourage newbies from working on things they shouldn't but there's a limit of how far we can push that. It's really hard to tell people sometimes that they should Not work on things they just don't want to accept. This is where the painful expensive lessons come in where hopefully they will learn.1 point

-

I made a comment on here at the outset of this debate, some 7 years ago and the same thing is being discussed, now, as was then. My particular take on the whole aspect of US, is that if it works for you, then great. If, in the other hand, you are the wary sort, then use a full blown cleaning machine at some vast cost. I have made my own cleaning implement, giving me total control via a digital timer, it works perfectly, and has never let me down over the last 5 years. I must admit I have the Elma US, which does give 37 & 80 mhz, also Drying machine. The quality is superb. All the component parts are in an Elma Basket and trays, attached to motor in Elma RM90 jars, then 15 mins @ 37mhz, 3secs agitation at 1600rpm, every 30 secs, remember the agitation is dampened by L&R cleaner. Then span off for 30secs at 1600rpm, then into 2 separate rinses at 80mhz................ then into dryer for 30 mins. Never had anything disappear or loose shape. I have just done 2 separate services on the thinnest movement 1.6mm, an AP 2003 & VC 1003, all as above. The hairspring is minute, not a problem............ If it works for you, great.....................1 point

-

Most all of my Vintage items are made with coin silver. The Native Americans had little choice where it came from and used it right from the beginning of trading with the 'newcomers'. The Jewelry is beautiful, craftsmanship outstanding and Alltribes is owned and operated by the original inhabitants of our great Country...my way of saying 'we should have dome better'.1 point

-

The condition and how complete the set is that is the thing to look out for. No point having a set where the stakes are broken, or the holder for the stakes has taken a hammering and it’s out of line. A nice box also plays its part. Some stakes get blocked and you cannot remove what has blocked them. So before you buy ask the seller about what he or she is selling.1 point

-

1 point

-

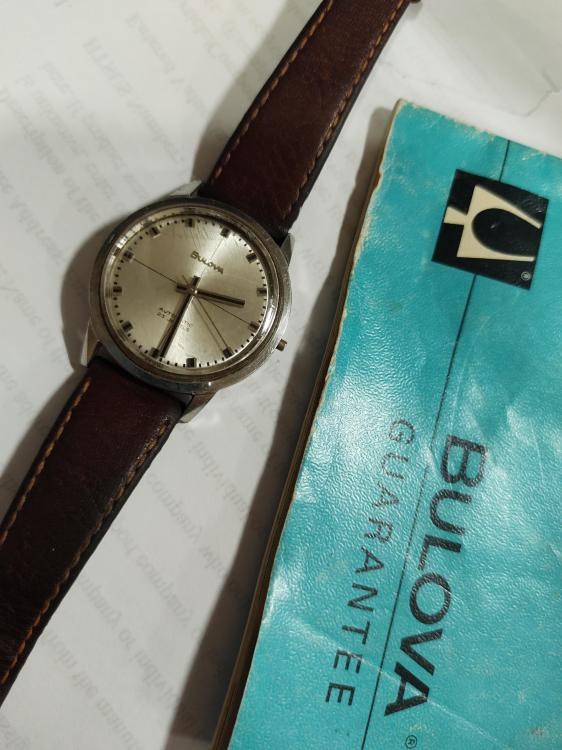

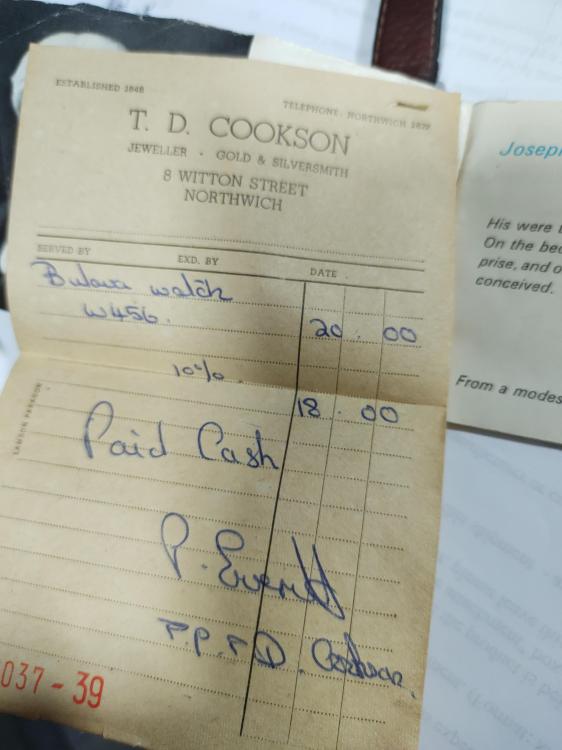

Guys firstly I must say that I am impressed on all the fantastic vintage watches you all collect Recently I purchased these 2 from ebay First is a Precisa automatic of unknown year but looks maybe 1960 ish Second is a Tissot manual wind of unknown years as well Maybe some of you may know brand and how old? Both these are very nice shape Precisa is gold and Tissot is rose gold1 point

-

1 point

-

I'm not sure about the U pin, maybe you could try a minor correction from below without removing the hairspring. I advise you not to let dangle the balance, and not to use a tack, especially with minuscule and delicate hairsprings like this, as that will distort them and espose to risk of accident.1 point

-

Holiday present to myself. I ordered an ETA 2824-2 elabore movement, PVD coated stainless case with sapphire crystals, dial and hands from a watch materials supplier in Switzerland. None of this stuff was cheap, but the seller guarantees that all the parts are Swiss made and I don't have any reason to believe the items are not genuine. The strap is made in China, but I don't believe in spending big money on 'designer' leather straps. So what do you folks think?1 point

-

1 point

-

1 point