Leaderboard

Popular Content

Showing content with the highest reputation on 11/10/21 in all areas

-

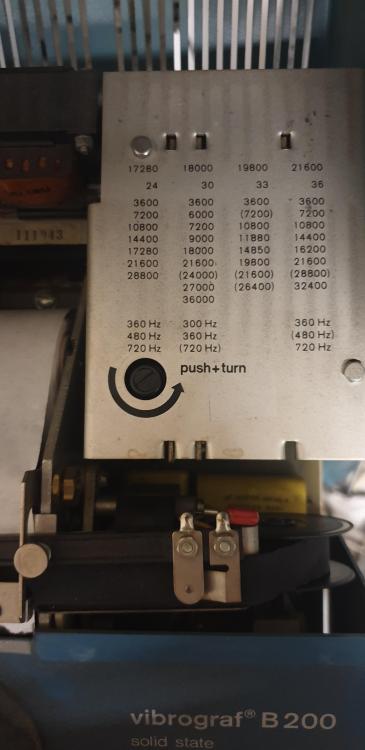

Actually the picture looks like 21,600? Then what happens if you change the setting for the Weishi to 19800 Then as far as calibration goes for the B200 some of it depends upon which oscillator board it has? Over the years they had different versions some running at insanely low frequencies with really huge crystals and others that much much higher frequencies divided down. So is probably quite a bit of variation of how well the different boards are going to work with time as far as needing calibration goes. Then that may be a problem? The B200 is a real interesting timing machine made over a span of years and basically was the sole timing machine of anyone in watch repair the factories everyone use this machine. Then it came in variations they all visually more or less look the same on the outside. The US version does not have a ribbon like the machine in your picture because that's a European version. The Europeans could use cheaper paper with a ribbon we get stuck with expensive pressure sensitive paper. Then the various ways of changing the print density like I've attached an image. The basically a machine that's blue in color has a number B200 made over considerable quantity of years that has a whole bunch of variations. That other than the electrolytic capacitors drying up or leaking the machine will probably last forever.2 points

-

Hello team! I have scoured various forums for any hacks on how to open a Baume, or Rolex case back that just won't yield to a ball. I did not have a Horotec dye of matching size to open my new acquisition, but the drive to get inside was simply overwhelming and orders of magnitude more urgent than the 32.5 dye's delivery option. Before I start getting criticism (constructive feedback) for not using expensive tools to open such watches, I want to go on record that I have ordered a proper dye to close the case, but I do not think that even with the dye I would have been able to open it. It was just way too tight on. So I glued it:) Superglued a larger matching socket to the case back, put the case in a vice and used my trusty car wrench to open the case. The case back and gunk did not stand a chance:) Removal is easy, just a bit of acetone does not hurt the stainless steel and dissolves the clue. I am going to put the case back on hand-tight with the proper dye, but this glueing technique might help someone in the future to crack open a case without ruining tools or the case2 points

-

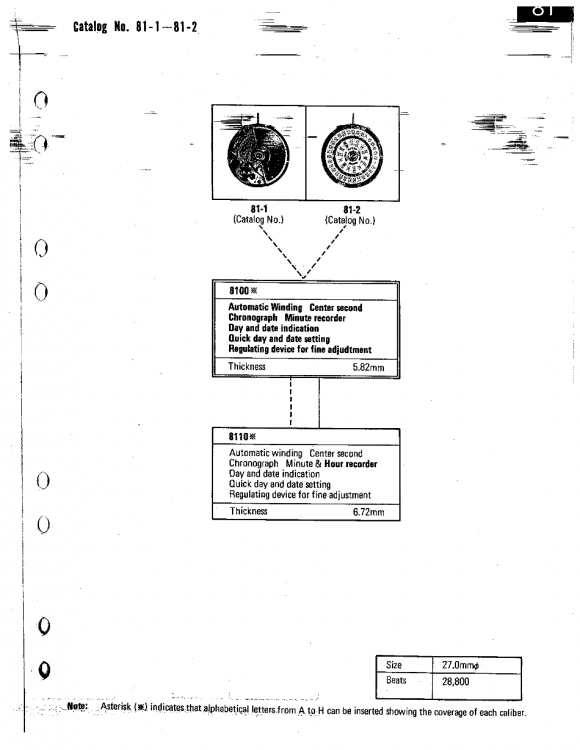

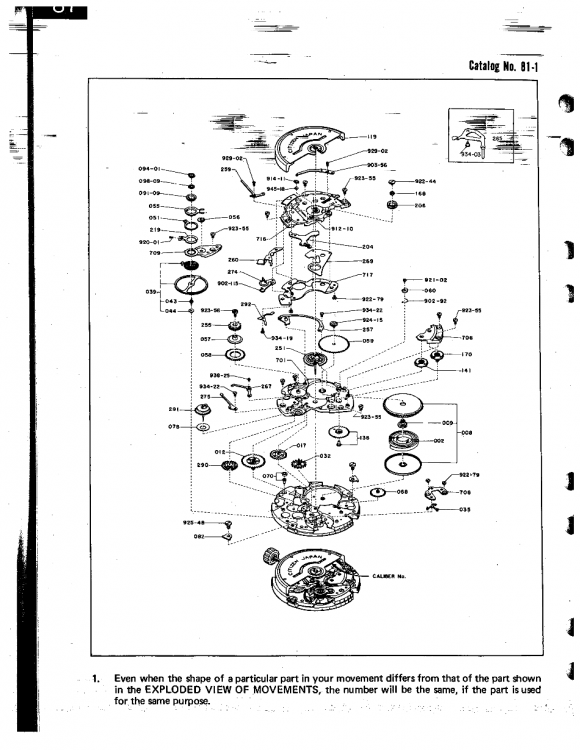

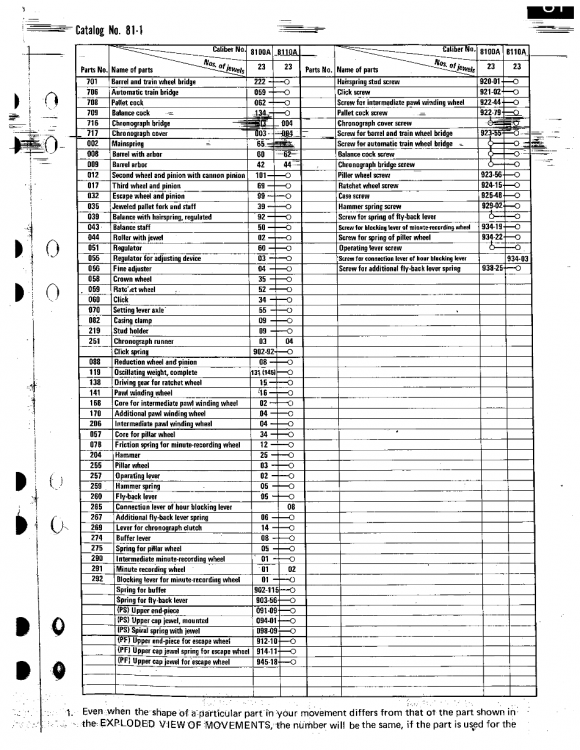

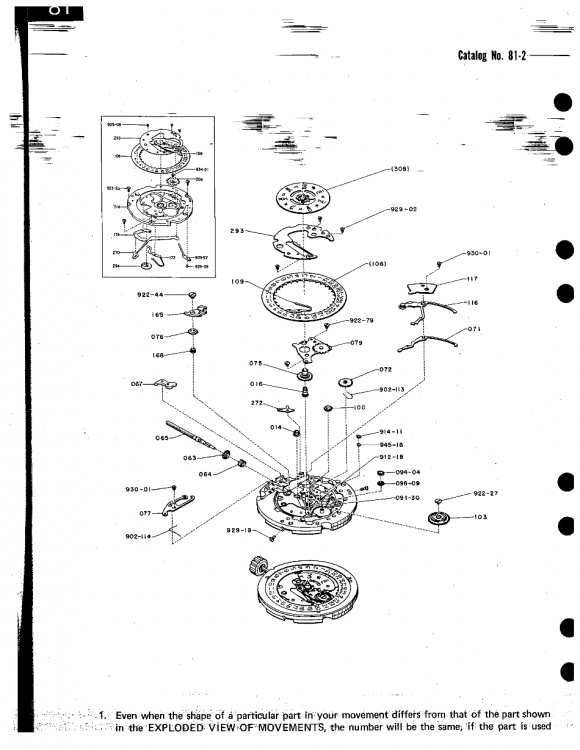

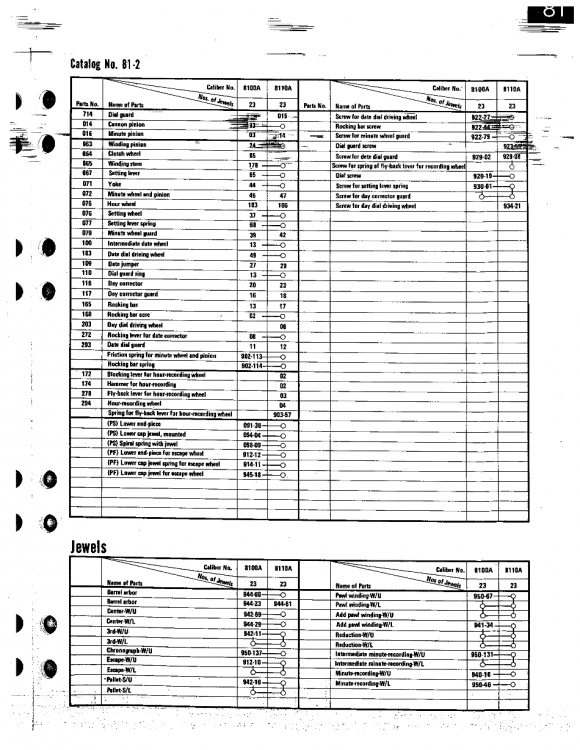

Sometimes I think what we have ignored and are well capable of doing on this forum is COLLECTIVE WALKTHROUGS. A type of help& advise in which members can choose a project like this 8810, anounce joining, and pledge to work together until completioton. The difference with what we alreday do, would be in collective walkthrough group , each memeber who joins pledges to works as if the project was his own. I think toptime is capable of overhauling a chrono complication or he wouldn't have attempted it, but have run to an issue which he hasn't so far figured out. HOW ABOUT THAT WRT?2 points

-

2 points

-

2 points

-

1 point

-

Thanks @watchweasol, I may opt for the latter method as I find the train bridge rarely goes on cleanly and I would end up moving about the oiled pivots while trying to get the bridge on properly and then that oil would be everywhere except in the jewel!1 point

-

Hi all, Thank you very much for the tips and feedback. As promised, I’m reporting back on my findings. For (1), I added a very small amount of 9010 to the pallet pivots and saw amplitude increase from 230 to 250 almost immediately. When running with no lubrication (2) and then adding 9010 to the pivots (3), I saw minimal change. I moved on to 4, stripped and cleaned the movement (including cleaning the mainspring - it is a new, alloy mainspring that I had previously oiled, and am now running with no oil), then oiled as I noted before, this time oiling the pallet pivots and the pallet jewels with 9010. After the movement sat overnight, I saw amplitude around 285 in dial-up in the morning. I’m happy with the results, and at simply trying out a few different oiling methods. The watch is now timed, cased, and sitting in a makeshift stand on my work desk where I can enjoy it. The last remaining item is to replace the crystal. I polished it, to remove the major scuffs, but as you can see, it is yellowed with age and needs replacing. Dave1 point

-

You can adjust the strike force on the B200, I think you are seeing ghost lines. The heavy line looks like the two beats, and that the watch is in beat to me. If you look inside the cover you'll see that it can detect some duplicate beats over different frequency buttons, this is down to how it chops the time signal and speed of the bar under the paper (with the spiral on it). In the pic you can see that on 19,800 it will also pick up 21,600. It's been a while since I tried but I seem to remember that the frequencies in parenthesis end up with some duplicate lines on the paper- which come to think of it could be what you're seeing. If you want to know the true beat just count every other beat over 30 seconds and multiply by 4, then 60. The little knob at bottom left adjust the force.1 point

-

The problem with how much oil or even the type of oil is whose instructions you want to follow? The older rules which are super minimalistic or the newer rules which? For instance some of this is been covered before. Go to the link below the bottom of the page nice image. So when you look at the image of what's acceptable today you'll see it totally conflicts with the rules of yesterday. https://www.watchrepairtalk.com/topic/20630-pallet-fork-lubrication-pallets-and-pivots/page/8/1 point

-

Having read all these posts I think its fair to say that most people including the Chinese workers do not lack the talent to do a first class job but lack the motivation due to the upper eschelons attitude to wards its workers and the product it produces. It it is produced to a standard that works well enough, so why the extra spit and polish. Others like Sellitia will go the extra mile for the quality. I am old enough to remember when the Japanese watch industry was in its infancy and had a reputation like the Lada car but unlike Lada they pulled them selves up to the standard they are at to day which holds its own within the industry today and in some cases it is a market leader in innovation and design. Many people will disagree with that statement but its all a matter of preference. The Japanese industry Is free in supplying the parts to the independents and also the technical documentation required, Not something one could say about the Swiss closed shop practice as now Swatch controls the industry wholesale. The communist ideal is brilliant in theory where all peoples are the same but in practice falls apart because there are always those who are in charge who think they are better than there fellow man and as such treat the "lower"classes (workers) . with complete distain They are there to do a job and that's it period.1 point

-

1 point

-

Nice job! Normally we would glue a large nut and use a wrench, but a socket would work too.1 point

-

Both Randa 1223-21 & 1242-21 have alarm complication. One is pin lever the other has Swiss lever, set levers should interchange.1 point

-

Interesting... Millionendorf. Leave it to ze chermanz to come up with a word like that. Wittgenstein and all that; language and vocabulary opening new avenues of thought. I used to live in Dallas (pop ca. 9MM), and moved to Denver (pop ca. 1.5MM) a decade or so ago. The destination aspect may have something to do with it (people just want to be here rather than resigning to living here due to a job or something), but I haven't found anything in terms of amenities, commercial opportunities, etc. lacking. Meanwhile, in Dallas it took a good hour to get from pretty much any point A to any point B due to traffic, whereas here we live up in the mountains to the west without any distractions from the city (aside from tourists driving/biking through), but can be anywhere in only 45 minutes with a good 20-25 of that just being getting from the mountains down to the flats. I'm sure there are other manifestations of this, but I haven't finished my coffee yet.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Agree with OH I watch all of his vids really high end top quality workmanship. How I would I would love to own some of his machinery or have even have a workshop.1 point

-

Tommy Jobson I watched this the other day. It's a good video. It shows you how much preparation and skill that is needed.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Bulova Seaking Automatic from 1975 I believe. Just restored and serviced this for my next door neighbour. It's 'on test' for the next day. He told me he got it for his tenth wedding anniversary and has been in a drawer for 25 years or so. Going to give it back to him tomorrow evening. I hope he will be pleased to wear it again.1 point

-

Hi Jthing You might find this tech sheet handy in the future. Cheers 8391_Ronda 1223.pdf1 point