Leaderboard

Popular Content

Showing content with the highest reputation on 02/26/21 in all areas

-

I think Michael1962 is on the money and as Old Hippy says you wont be there anyway, What could she do, Bury you , burn you put you out for compost. You are safe from an ear bashing, on the other hand she might be rubbing her hands over your shrewd investment and thinking what she can invest the cash in, like a nice holiday a new wardrobe of clothes, Hmm make sure she goes first. ?3 points

-

Years ago when I was married my wife asked me did I want to be buried or cremated. I told her I wanted to be stuffed and sat on my favourite bar stool in the corner of my favourite pub at the bar. That was in the days when I could drink a hell of a lot. These days I'd sooner have a cup of tea.2 points

-

I'm afraid one day I will die and my wife will sell my watches and tools for what I told her I paid for them.2 points

-

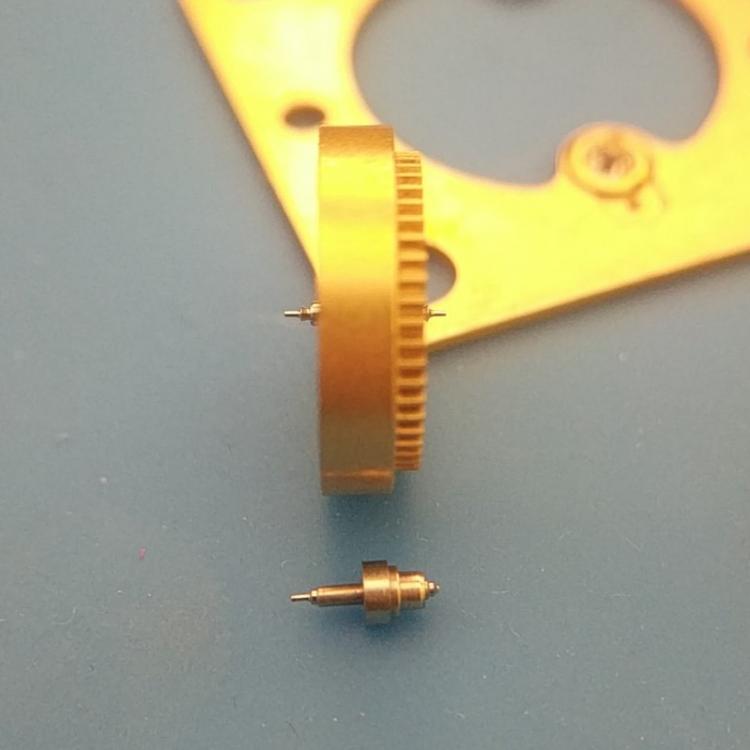

Hi all, I signed up because I wanted to answer a question, but it looks like I'm not allowed to do that until I introduce myself, so ... hello! I'm Chris, I'm a watchmaker. I'm not sure what else to say so I'll share cool photos. My most interesting project this week was a staff for the flywheel/inertial damper in a Seiko "crystal chronometer" QC951-II which is a very early quartz ship's chronometer from 1967. It had been dropped, breaking a pivot on the flywheel and it had a few other problems. This was just like making a custom balance staff. Sometimes it's easier when I know there's no hope of finding a part, and I need to go ahead and make it. That can save time! Cheers, Chris1 point

-

1 point

-

1 point

-

The one time I got lucky was twofold- I found and bought banana box in a flea market with a whole bunch of accessories for my cleaning machine (which is a very odd machine and very hard to find stuff for). Then, when I got home and started going through it there was a brand new, with protective stickers and not a scratch, JLC Reverso in there! Serviced it and swapped it to a friend for more tools hahaha.1 point

-

Mistake No 1 the wife will find you wherever you hide on the plus side you dont need a torch.?1 point

-

1 point

-

Or you could say, "Look Dear! The prices of watches have really gone up since Covid. My watches are now worth a whole lot more now. What a clever boy I am. " ?1 point

-

If you still have the original seconds hand you can easily see if the pipe is still attached to it or not. If it is still on the hand then it's clearly not still attached to the pinion so it's not that that is preventing the installation of the new hand. If it is still attached to the hand try looking through the pipe. If it is blocked then it may well be that the top of the pinion has broken off and is still in the pipe, which would then require a new seconds hand pinion before you can fit a new hand. As @watchweasol says though it would be helpful to have the dial off to get a clearer view.1 point

-

Hi I have attached the tech sheet for your interest should you need to dismantle the watch. It is not really possible to discern whether the pivot top is broken or not. Marc could well be right, the only way to tell will be to remove the dial and hands and have a side on view of the watch. If the top of the pinion is not visible the either of the above suggestions could be the possible cause. You might have pushed the pinion through the wheel. Have a look at the back of the watch the jewel if there is one might be out. Pics of the front .rear ans side on view would be helpful. thanks. 3128_Seiko 7548A (2).pdf1 point

-

This is a very good question. Cousins may state where it is from. Personally, I would not use it if it isn’t European or USA-made. I have made bushings from scrap antique clock movement pillars in the past. Partly to get the colour correct for antique movements, but also to ensure good quality brass. I also have a set of Bergeon pre-made bushes which can obviously be adjusted to fit.1 point

-

1 point

-

1 point

-

1 point

-

I've serviced others where you don't need to touch them but with this one I had to replace the barrel bridge and train bridge and replace the eccentrics so I was starting from scratch essentially.1 point

-

I had no idea anyone had produced "friction jewel converters" ! Haha. I have made them many times though. It's a quick lathe job, and when done neatly you have to take the bridge off and look underneath to see that there isn't an original rub in jewel in a rub in setting. Having nickel bar is handy at it blends very well in german silver movements, for a high end gold plated movement with a visible setting the converter gets plated.1 point

-

1 point

-

Where did you get that BDP (big damn pulley)? Looks like a fun thing to build. Got some more lathe stuff coming from Ebay...thinking about doing something similar.1 point

-

And as you can guess, none on Ebay in Australia. Ahhh, to live in the colonies........1 point

-

For full plate watches you really need an escapement matching tool. This is sort of a movement holder and depthing tool in one; there are 3 (sometimes only 2 but 3 is best) arms that carry runners that can be accurately aligned with the balance, escape wheel and pallet fork pivot locations. The plate is put in place (well, upper plate), then the components with one end supported by a runner. You can then check the escapement functions in full view.1 point

.gif.7c9570fcd326178cb503b97df0467439.gif)