Leaderboard

Popular Content

Showing content with the highest reputation on 01/31/21 in Posts

-

For small hole drilling you'll see massive rpm recommendations, this for the theoretical sfm or surface feet per minute. The upside is the tool manufacturers who researched this are right. The downside is to get the cut you want in~0.4mm of material at say 10krpm you have to feed at 50mm per minute, or 0.8mm per second to get that, which is undoable without a cnc machine. You have to get through your piece in 0.5 seconds, otherwise the drill will be rubbing rather than cutting which will dull it and work harden the steel part and you press harder and something breaks. The up-upside is, if your drill is capable of cutting the metal, you can hold the drill in a pinvice and do it at 5rpm and get your hole (Scottish members hold your tongue). Levin wrote a terrific pamphlet on small hole drilling, where they destruct the recommended sfm and focus more on the feed per minute, and of course they had a drilling attachment for their lathe that allowed a very fine feed. I'm pretty sure a normal HSS drill will cut your part, and a drill in a pinvice carefully used will get through4 points

-

I imagine your zinc isn't the issue. What grit is the diamond powder? What type of oil are you using? The mixture should be thick, like twice as thick as peanut butter. Natural plant oil is better than mineral oil. The plate should have a textured surface, like from a very coarse file. It does have to be clean of course, and it's good to keep a file that is only used to dress the plate. When polishing you want the paste to dry out. If it's wet the grains can ball up and give you scratches. It will get to a sort of "magic" state where it's just dry enough but not too dry. Some guys will use one part of the plate with wetter paste and have a dry patch for the final bit. Generally you'll flatten the part on self adhesive precision graded abrasive paper stuck to glass, 12 microns is a good general grit, and you can go straight to polishing. Clean the part extremely well to not transfer grit to the plate. Something like your set bridge you'd want to glue or shellac to a subplate and hold that in your tripod. I use round plates about 80-10mm diameter. When I dress them I make a line down the middle of the plate and keep the feet of the tripod on one side, part on the other. If the polishing is going well but it get just a bit too dry and you don't want to mess things up reapplying paste, just breathing on the plate can help. Most folks I know use tin rather than zinc, but both work. I prefer tin. Swedish and Finnish watchmakers like to add about 0.5% of silver; but when I asked several how they add the silver they said they just add a little piece to the melted tin- which is nowhere near the melting point of silver and just proves how much superstition surrounds polishing. As for abrasives, as Hector said diamond isn't necessary. I used to use aluminum oxide from Linde, 0.3micron, which was great. Around here everyone uses Biodiamant, which is a prepared diamond paste in like a giant chapstick tube, so I use that now. Both work fine.3 points

-

2 points

-

2 points

-

I own a Ollie Baker mainspring winder and also a home made one made out of wood and a converted mainspring winder. Both work great the issue to be aware of wood changes in shape as it ages and changes as it takes up or looses moisture so it looses its original smoothness in operation. The issue with the Ollie Baker is you are required to hold the barrel with one hand while winding with your other hand. I got around this by making a various sized wood clamps to hold the barrels see pic below for both my hand made winder + the Ollie. I know my hand made winder looks crude but be assured it works and is better and safer than trying to wind springs by hand.2 points

-

Hi there, my name is Brandon (as you may have guessed) from the San Diego area of California. I’m admittedly not a watchmaker, nor have any sort of engineering mind. I’m hoping the members here can answer a question from me from time to time regarding watchmaking. My primary focus these days in collections is the Independent Watchmakers and enjoy some of my older pieces in my collection from the Big Brands. Cheers, Brandon1 point

-

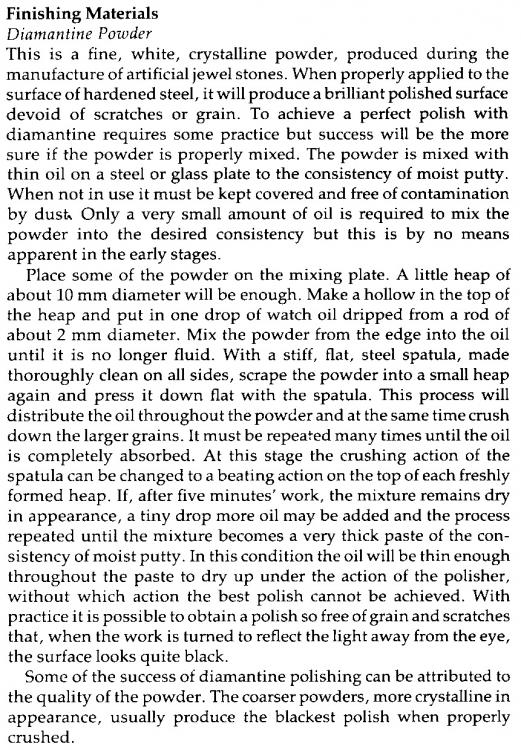

It's interesting is if you go to the bergeon and search for polishing powder you get something and I snipped out the image. But if you do a search for diamantine the classic watchmaking polishing compound which is not diamond but aluminum oxide it also comes up as a separate product. I snipped out both images. Then a really good book to have is watchmaking by George Daniels. It covers all kinds of interesting things related to making a watch. Although action the book does cover how to make a watch but it covers all the components used to make a watch. Then aspects like polishing so I'm quoting a section but it's too big to quote so I just scanned it.1 point

-

Don't try and go through in one go, peck at it, take your time....those tiny carbide drill sets are pretty good for it1 point

-

Thanks yes it works but it is not the best engineering for sure. The clamping system I use is really good when dealing with either small or large mainspring barrels. The key to working with mainsprings is having control.1 point

-

The real question is is it really diamond powder? It will be nice to have the catalog numbers so we can look up what it is. This is because traditionally watchmaking there is a another polishing powder that has a name kinda like diamond. This other Powder is white and it's basically aluminum oxide. Than one of the things that would've been nice to see is what they both look like before you tried the final polishing? The reason I ask is Polish out scratches. If both parts had been finished previously differently then you results are going to be different. Usually you have to go through several steps of finer and finer grit whatever you're using to slowly reduce all the scratches down to almost if not nothing then you can polish. Otherwise you're wasting your time. The link below might be helpful. https://watchesbysjx.com/2015/01/explained-the-fine-art-of-black-polishing-aka-speculaire.html1 point

-

Hi I like the way that you have modded the spring winder, I also used the let down tools as fit the spring arbour properly. As for looking crude the fact is it works and it overcomes the problem of holding springs by hand. The wood if and when it becomes less effective can be replaced cheaply and effectivly. I used mahogany for the clamp its good and hard. A Great idea, engineers answer to a problem based on what you have available. I for one think its brill. It May inspire others to do something similar.1 point

-

What is nice about the above link is we find out that the 1791 is very similar to the 1691 other than frequency.In other words one is running at 18,000 and the other 21,600. So everything else should be the same except the balance wheel and maybe some minor changes the gear train. As I have the 1691 series parts list I'm attaching that. This is why for first time disassembly or practicing the 6497/98 or its clones from China because are cheap are usually the preferred watch the start with. The parts are little bit bigger technical documentation Is available versus starting with older watch where all your money get is a parts list if you're really really lucky. On the other hand not having a lead helpful information you grasp the importance of pictures. Often overlooked by all of us from time to time. 656_AS 1691, 1693.pdf1 point

-

1 point

-

First thing to learn Johnts59 is you cannot over wind a clock or a watch. The springs will only ever wind up to their fullest. If it still doesn't go them there is something more wrong with it. Normally its dirty or wear or in most cases both. As others have said photos will give us a lot of help in helping and advising you.1 point

-

A princess that one is. I love the watchmaking period between the wars. Just notice the click spring. It deliberately bends at it's thickest point to prevent breaking. True swiss artistry. Cheers Alex.1 point

-

Great article. That dude is impressive. I also read his description of the Spitfire Watch.1 point

-

Hello and welcome to the forum, It would be helpful if you could remove the back and post a picture of the movement, That way members could see and perhaps diagnose/help. The symptoms you describe sound like a service is in order. There are many things to stop a watch usually congealed oil and dirt thanks.1 point

-

Hi Brandon ,Welcome to the forum this article might peak your interest.https://www.great-british-watch.co.uk/designing-and-making-a-british-watch/ This article a watchmaker takes an ETA 6498 and adds a complication with 2 more hands to it . It takes a lot of skills and knowledge.I think you will get the drift .1 point

-

nicely done - the crown \ stem is one piece. what is the dial code on the base of the dial?1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

That's terrific! Look up Joe Collins. He's one of those guys with the gifts of natural mechanical ability to repair or build anything and with people skills to share with all.1 point

-

I think these yellow things are great. https://www.cousinsuk.com/product/compartment-tray-revolving They stack on top of each other and you only need to uncover the compartment you're working with.1 point

-

This is why I no longer discouraged people starting on Rolex watches or family heirloom watches or any of the other things people like the start on. Because it seems to be really hard to convince people that may be watch repair isn't as easy as they think. So disasters are definitely good things in watch repair the more expensive the better. Having your family forever Never forgiving you for destroying great-grandfathers watch or breaking your Rolex seems to be a good lesson. Although the last person with a Rolex did succeed. That's the purpose of these lessons don't discourage people from doing this. Without painful lessons and killing off a few people how would the world ever learn?1 point

-

I bought a slightly modded Seiko SKX007 off of eBay, about which in general a more experienced man than I here aptly quoted Obi Wan Kenobi: "you will never find a more wretched hive of scum and villainy." LOL. To be fair, the watch was accurately described cosmetically, more or less, but I didn't take the time to read the description. One thing that wasn't entirely accurate was the representation that the watch "works well." Well, it did run, but not to expectations. The amplitude was low, the beat error high and the rotor felt sluggish. So what's a newby to do? Well, a full service of the 7S26 is still a bit beyond my skill set. So I replaced the movement with an NH36, which meant removing the hands and dial from the 7S26 and mounting them on the new movement. I also discovered (last to know) that the crown and stem were not a clean "switch over" between the two movements so I measured, cut, and filed the new stem that came with the NH36 movement and epoxied the crown on to it. Now I know that this hardly qualifies as watchmaking, but I have to admit feeling a bit proud that the watch is now better regulated, that I managed not to bend or lose the hands, that the epoxy is only on the intended part and that the thing is back together with no extra bits sitting in the tray. Or, more precisely, you have to celebrate your small triumphs along the way to some level of actual competence. Remember that feeling when you first got parts to play well together to resemble a functioning timepiece? Well it's been a pretty good morning so far. My family appears to be tolerating this with an air of bemusement, as in, "I wonder what crazy scheme Dad's up to now?" But you all will get it. Happy Wednesday . . .1 point

-

Hi yuo will find some data on your watch on this link http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&AS_1791.1 point

-

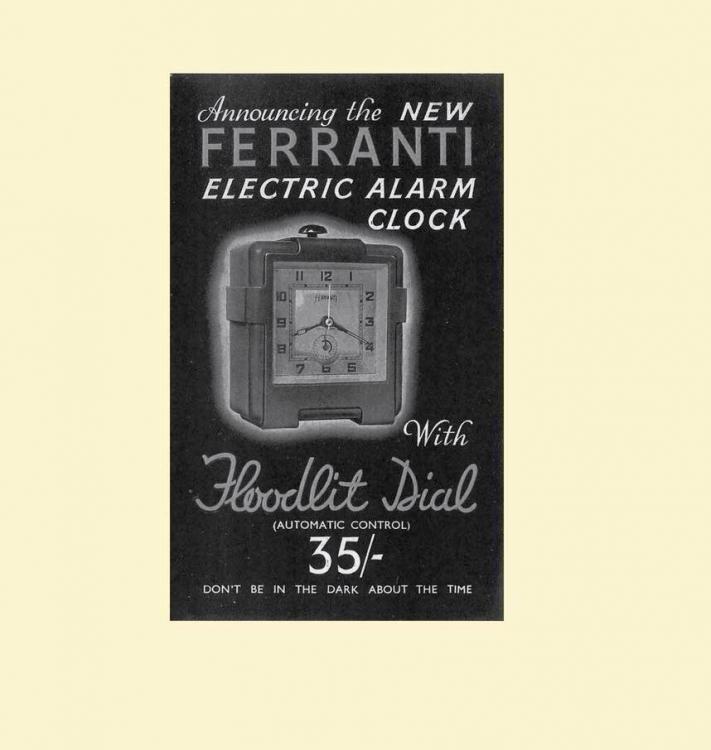

Well Andy, all of my early ones are made by 'Ferranti'. This is their 'Model No2', and was made between 1932 and 1936, (shown prior to restoration) This is the 'Model No4', again 1932 to 1936, Both of the above have the 'broad spade' hands so date to 1932/33.. This is the 'Model No8' alarm, which dates from 1936.... This 'was' originally a 'Model No6' 'Floodlit' alarm, made between 1936 & 1938, but about 60? years ago someone broke the Bakelite case and then rehoused the works in a home-made wooden case (which I have attempted to 'sympathetically restore') Would have originally looked like this....... And the pièce de résistance, this 'Model No12' with a solid pewter case, only made between 1934 and 1936........ All the above clocks do, and are currently running..? Typical movement for the non alarm varieties (in the No4 Model)......1 point

-

If oiling is undertaken correctly as I have all ready said the amplitude will increase.1 point

-

There are a number of reasons why were not supposed to oil the pallet fork pivots. First it's considered unnecessary because it's a non-rotating part. The second the pallet fork has to move very fast when it does move. Lubrication has an interesting property of reducing friction but it also has a dampening effect. Depending upon the watch if you have a timing machine that can measure amplitude you can see a decrease if you oil the pivots. Of course it depends on the viscosity of the lubrication and then of course with time should the viscosity increase the loss of amplitude will be dramatic. Then images of Seiko lubrication charts. Notice one has the pivots lubricated and the other one does not. Seiko is interesting in that sometimes they oil the pallet fork pivots?1 point

-

Ask a lubrication related question and you will get as many different answers as you do responses. However, here is my take on it. Consider the amount of movement and the forces involved at the pallet fork pivot compared to elsewhere in the watch, and weigh up the pro's and con's for leaving it dry. The torque at the pallet fork pivot is probably less than anywhere else in the movement, and the angle of rotation of the pivot in the jewel is something like 5 to 10 degrees. As a result the rate of wear through friction at this point is minimal and so any advantage (from a friction wear perspective) of oiling the pivot is also minimal. On the other hand, because the torque is so small at this point, the effect of drag on the pivot caused by the viscosity of the oil becomes significant, sapping the energy that should be being transferred from the escape wheel to the balance wheel and robbing you of balance amplitude, with a corresponding drop in consistency of rate. So put simply, if you oil it it may last a little longer but the watch won't keep very good time, if you leave it dry it may not last as long but the watch will perform better. I have heard of watchmakers who compromise by merely wiping the pivot with oil so as to leave the thinnest of films on it before installing it. I don't know of any research into the benefits / pitfalls of this approach. Other opinions may differ1 point

-

if its a high beat (28800vph) then 9415 is the correct oil, its an oil that turns to grease on impact, however on low beat (21,600 vph) 9410 is the correct oil which does not have these impact characteristics Pallet jewels should only be lubricated on the impulse faces, not on the top at all. it is good practice to have no visible bead of oil on your oiler when you apply to the pallets, just "wipe" the oil across the face of the jewel, the actual contact area of the pallet with the escape wheel is very small, so little oil is needed, too much just causes drag. there is another method of oiling the pallets, which is to apply the oil to one tooth of the escape wheel, the theory being it will eventually spread this oil over all contact points. The noise you see on your timegrapher can be the oil, if you have not applied too much this noise should settle down after a minute or two, The reason being that the oils spreads over the escape wheel contact points over this period, however another symptom of the noise is the pallets themselves, incorrectly set pallets will generate noise.1 point

-

Bought six Vostok movement to work on . Needed a better balance than the one i got . Hopefully there is one in the movements a bought . like to work on this movement as they are easy to find parts .And the parts are very cheap . This is the service work done by someone at WUS . The movement is a 2414 but that is similar to the 2409 .http://forums.watchuseek.com/f54/vostok-caliber-2414-service-notes-very-long-many-pics-226237.html1 point

-

This is a great question. It would be nice to see a list of lubricants with an acceptable substitute/multi-use suggested. I have a small fortune invested in many oils/greases and the shelf life is only so many years and I'll never use them up. Mark, although you're a pro and would have on hand all needed oils and greases, is there anything you can put together that would help us novices/hobbists? Many thanks in advance and I'll follow this closely. :)1 point

-

Since we're on the subject of lubricants, what basic lubricants (oil and grease) should the hobbyist have on hand?1 point

-

Assembe movement and let it run 5 minst. Afterwards I do it using 9415 on every second teth tip of the escape wheel. Only on the tip of it not on the top or bottom of the wheel I check it under the microscope after 24hours of work if its not enough i do it once more Enough is when the escape wheel tip and the pallet jewel meet you shoul see a droplet of oil between them which is aprox. 30% of the pallet jewel tip length(its dificult to explain) And of course i use epilame as it makes this job a lot easier and the grease stays in place afterwards and does not travel along the surface which will leave the pallet jewels dry, at the begining i said let it run 5 mins, this will wear of the epilame coating and will leave the oil on that places. I hope i made it a bit clearer for you now br emso p.s: sent from my s****y phone so sorry for typing mistakes1 point

.thumb.jpg.cb6ddfb7bdaa48c5569b12b1edb563c6.jpg)