Leaderboard

Popular Content

Showing content with the highest reputation on 11/05/20 in all areas

-

All I’m suggesting is that we control what we can, with the greatest accuracy possible, to better understand the things we cannot control.3 points

-

2 points

-

Hi On a watch of that vintage they were mostly snap on case backs. Get a stanley knife and a pair of protective gloves and insert the blade into the join and apply twisting pressure. There is always the case that it might be screwed on in which case get a sticky ball or alternativly glue a large nut on the back with superglue and try that to un screw. The nut can be removed with acetone (nail polish remover) and it will not mark the case. Can you post some pics of the case side view from alternate sides What ever you do do not use the dremel. Men made it men can remove it. Another possibility is that it is a front loader and with the bezel removed the movement lifts out through the front It may require a little help as some are a snug fit. Looking at the back and the front this is a distinct possibility, CHECK THIS OUT BEFORE DOING ANYTHING ELSE.2 points

-

More than that it would be silly, unnecessary violence. Your first step in learning is how to open and close back watches without damage. In this case, I think, you just need to lift the lid inserting a thin tip under its edge. The right spot to begin may be anywhere, just try going slowly around.2 points

-

Yes, Wakmann use the Valjoux 92 in a bunch of their 3-register chronographs. Certainly a well respected movement. And that blue Seiko looks great!2 points

-

2 points

-

Hi, just introducing my newest addition. I am not usually interested in battery watches but this one caught my eye as it is rechargeable and came complete with the charger and spare bracelet links. It's keeping perfect time and appears to be virtually unworn. I don't know anything about this watch, age etc and if anyone can enlighten me I would be grateful. Bought at car boot sale for £12.50 so it didn't break the bank and seems very well made.1 point

-

1 point

-

For the past few months, I’ve been working on a custom dial project. I’m still not ready to show my first production examples, but the project has gotten to the point where I’m comfortable sharing my progress. I’ve been documenting this process, and am committed to sharing my process notes. I believe in open source information, and I’ve benefited immensely in watches (and in life generally) from the wisdom and experience of other people who have been willing to share what they know with me. My hope is that by sharing my process notes, I might be able to encourage other folks to take a risk and try to make something cool. I’ve never attempted anything like this, and even if this project is ultimately unsuccessful it has been a ton of fun. I'm sharing my progress and process notes on this forum because folks here have been incredibly friendly and patient with me. If you have any questions about my notes, please feel free to let me know and I'll try to explain things better. I'm happy to answer any questions, and I'll be sharing more photos as I can. I've received a number of comments from people I've been corresponding with that essentially conclude that "this is too hard to pull off". Bur for the serendipity of finding a source of half-height Seiko dials and having free access to an incredibly expensive precision saw, I would have agreed. If anyone has suggestions or concerns that I'm missing something key, please let me know. Background: Seiko & ETA 6498 Custom Watches My project started with customizing my own Seiko watches, and with assembling several custom ETA 6498 watches using available parts from Chinese sellers on eBay. I greatly enjoyed manufacturing my own ETA 6498-1 based “marine watch” using high quality components, and produced a watch that is nearly equal to the Stowa Marine Original I wanted but couldn’t afford. I could have saved more money using lower-quality components, but instead assembled a watch using high quality components (heat-blued hands, an especially nice 41mm case with a sapphire crystal, an elabore-grade ETA 6498-1, etc.) to build a final product that was high quality but still significantly less expensive than the Stowa. Here's my 6498-based "Marine Watch" On the Seiko side of the house, I’ve built a couple of custom Seiko watches using some of the really amazing dial and hand combinations available from lots of internet sellers. (My favorite seller is called Lucius Atelier.) In browsing the offerings of several different Seiko part dealers, I saw that some suppliers sold higher-end dials made out of meteorite, damascus steel, carbon fiber, and other neat things. Knowing how much I enjoyed building my ETA 6498 watch, knowing how many people enjoy modifying their Seiko watches, and being generally fascinated by exotic dial materials, I realized that it might be possible to design my own watch dials. I enjoyed reading many articles on restoring dials using decals, and thought a lot about using electrolytic-etching or laser-cutting to customize brass dials. It was at this point that I stumbled across fordite and fell in love ... Fordite Several months ago, I ran across a limited series of very expensive TAG Heuer watches that featured unique dials made out of “fordite”. There's no way I'll ever be able to afford once of those £5,500.00 watches, but I couldn't get the idea of working with fordite out of my head. (Here are some quick shots of my first fordite samples, to give folks an idea of what it looks like in unpolished slab form.) Fordite is also known as “Detroit Agate,” and it’s actual industrial waste. Back when car manufacturers used to spray paint cars by hand, they generated a lot of overspray. This overspray accumulated over the years, and hundreds of layers of overspray built up into large chunks of waste material. This stuff was repeatedly heat cured at the same time the painted cars were heat cured, and the resulting chunks of waste are durable and nice to work with. I don’t know the first time it was discovered that cutting open the waste chunks revealed beautiful and psychedelic patterns of paint, but for some years jewelers have been using lapidary techniques to create bizarre and fun jewelry with fordite. One of the things that I find particularly fascinating about this material is that it’s possible to source fordite from specific assembly lines. Consequently, one can obtain fordite in Jeep, Corvette, Cadillac, Peterbilt, and other colors. I’ve even obtained some fordite from the “Cadillac Ranch” in the Mojave Desert. It’s much softer and more fragile than “normal” fordite, but it also has a wider variety of colors and textures. In order to work with this specific soft fordite, I'm going to need to stabilize it using some cool lapidary techniques. Heat-Blued Steel I have been enchanted by heat-blued steel watch components for a really long time. I started researching how I might myself heat-blue steel with an eye towards designing and selling heat-blued steel watch hands compatible with Seikos and other watches. For quite a few reasons, this isn’t feasible (yet?), but I’ve enjoyed polishing and bluing steel pocket watch hands. As my dial project progressed, I realized that it wasn’t practical for me to add applied hour indices, and there are some significant obstacles to using film-free decals on the dials I'm making. I realized that some manufacturers of exotic-dialed watches got around the problem by attaching a short chapter ring directly to the watch dial. This solution really appealed to me, so I set about designing a chapter ring that could be cut out of very thin (0.01” or 0.254 mm) high carbon steel, polished, and then glued to the dial face without risk of fouling any of the watch hands. I worked with an engineer on Fiverr, who converted my really rough sketch of a chapter ring design into a DXF file. My first 20 carbon steel chapter rings are currently in production at a laser-cutting facility. I don't need to share photos of the steel I've heat blued here to prove that it's a work in progress. Temperature control is critical, and I'm going to be switching from a propane camp stove to a precision digitally-controlled laboratory grade Cole-Parmer StableTemp hot plate to get consistent, high-quality results. I know that large manufacturers, including Glashütte Original, are doing essentially the same thing: In this Glashütte Original watch assembly video, one can see them using a $50 digital soldering-station with a brass attachment to blue screws. I'd go that route myself, but my chapter rings are a lot larger and so I want a larger heating area with better temperature control. I'll specifically be using a 1" thick 4" x 4" block of aluminum mounted on the hot plate's ceramic heating element to ensure uniform heat distribution. Chapter ring, from concept sketch to technical drawing to first prototype. Obviously, I'm going to need to do a lot of polishing before I re-blue these for installation! [Continued ...]1 point

-

Overview This is my first attempt at resurrecting a broken mechanical watch. Bought this on ebay for a total cost of $20.00. The seller had acquired it from a retired watchmaker's estate and it was definitely not working. I don't know the exact age, but it's certainly nothing recent. The movement suggests 1960's. It is a man's watch, but is the same size as the ladies automatic my wife has. I'm including the "before" pictures from the ebay listing and a couple of pictures of the watch now that I've got it working. First impression When I first opened the watch, I had no idea what I was looking at. I didn't know what this movement was. I'm not familiar with older movements and especially not manual wind movements. So I began looking around online for info on swiss movements. By sheer luck I came across a page that had a picture of this movement. It's an FHF-96: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?12&ranfft&0&2uswk&FHF_96 This watch is a front-loader and so I had to get a tool to pull the acrylic crystal before I could do anything else. Once I finally got it open, I began stripping the movement down, carefully taking pictures of everything since I didn't expect to find anything remotely like a how-to on getting it back together again. Repair process All old parts got a bath in my $30 ultrasonic cleaner using distilled water and dish detergent. Rinse in distilled water Dip in alcohol (except balance and pallet) Set out to dry. Balance and pallet got one-dip Crystal got worked over with polywatch, saving it. Case got scrubbed down with toothpaste then rubbed down with nevr-dull Put it all back together, including new parts D5, 9010, 9415 and molykote where appropriate. Put it on the timegrapher and let it sit in various positions for a couple of days Regulate it Profit! Faults found The center wheel was stuck to the mainplate. Would not turn. I got it free and examined it. Corroded. The mainplate itself was okay however. No jewel where the wheel got stuck. The set spring in the keyless works was missing. I suspect that the watchmaker used this as a donor. The crown was also missing. Parts ordered Center wheel set spring mainspring barrel barrel arbor stem Set of 300 crowns from ebay Leather strap Mistakes made When working on the movement, I accidentally screwed the balance in while the staff wasn't seated properly, putting stress on the staff ? ? ? I assumed that I'd ruined the staff, but discovered that the balance still swung freely and didn't wobble. I still think there was damage from this, which I'll get to later on. I put the mainspring in upside down. I'm a newbie, and so I assumed the new mainspring should be inserted into the new barrel the same way I'd seen on all the youtube videos, with the colored side of the shim facing up. Nope. I'd put the spring in backwards, which means that the barrel arbor won't catch. Since I don't have the tools yet to rewind mainsprings, I re-used the existing mainspring Problems encountered I couldn't open up the end stones on the balance or mainplate. I don't yet have the skill to deal with these competently. My novodiac tool is too big. So I couldn't clean or oil these. I've got additional tools on the way, but they are not here yet. The balance will sometimes start beating erratically, causing the watch to gain. I know this from the timegrapher. It tends to start doing this if I tap it good, or shake it. It will, after a while, settle down and beat correctly again. I suspect that this is due to damage to the balance shaft, described above. Or maybe because I couldn't deal with the endstones. I'll have to get these open to find out for sure. Surprises Polywatch works miracles. I thought for sure the crystal was done for, but I bought some polywatch just to see what would happen. I ended up keeping the crystal. It isn't perfect, as can be seen in the photo below, but is definitely usable. Nevr-dull is great for getting brass shiny again. I got a can of this and used it to clean up the corrosion on the case where the gold plating had worn through Status after restoration The watch keeps good time....most of the time. I'm wearing it right now, and when it is not acting up its beat error is 0.1 and it runs between +20 and -35 seconds a day in various positions. The balance may be damaged a little. Not entirely sure yet. I'm not done dealing with the end-stones and I may be able to resolve this yet.1 point

-

on the surface it seems like moving the hand would solve the problem except this is a perpetual watch. If you look at calendars over the years there's variations. Otherwise we'd only need one calendar forever. The perpetual watch providing it's properly set knows what each calendar is for each year. Your perpetual watch has lost its setting or somebody did a battery change and didn't follow the proper setting procedure and just set the watch to time and didn't set the year would be quite common.1 point

-

1 point

-

1 point

-

Hello east3rn this watch has a perpetual calendar , there are instructions on youtube for programing or resetting your watch , not advisable to tinker with hands as this will throw settings out .Here is the manual that will show how to set.https://storage.seikowatches.com/production/files/2018/03/20/143340135354/pdf/SEIKO_7D56c.pdf May need battery change .hope this helps1 point

-

Hello KarlvonKoln Wakmann made some of the coolest chrono's around back in the day .Check them out1 point

-

"Cash back"... Unfortunately cash removal is the main problem with the 404 club. I'm slowly going bankrupt in £4.04 steps, although I am having a lot of fun in the process. As somebody here once said, there are worse addictions. (*) I know.. you meant case back, but I couldn't resist.1 point

-

Cool! I hadn't heard of a Wakmann before now. I have an alarm pocket watch with a Baumgartner 222 in it, and I have a Poljot alarm wristwatch, and I knew about the Vulcain Cricket, but I will have to read up on Wakmanns now. Interesting.1 point

-

I had a Simonet 450 for a while but sold it on before ever really running it. Very very nice machines. Milling and grinding attachments for Schaublin 102 should work fine. W20 collets are quite plentiful secondhand and sell for far less than the W12, which so many Schaublin 70 owners are constantly looking for. I have a Schaublin 102, which is the same center height as the Simonet 450. I find that with that and my 8mm (50mm center height) lathe I can cover everything I've needed to do, the perfect combination. I had a 70 for a short while and sold it on, just a little too big for small work and a little too small for bigger work, haha.1 point

-

If that's the case I think you need to check all the wheels on the strike and chime side to make sure they are all in line. Then you start adding the strike and chime works, making sure each part works as it should. Just ask if you are not sure. I can take a bit of practice with a chime, understanding how it all works is the ticket.1 point

-

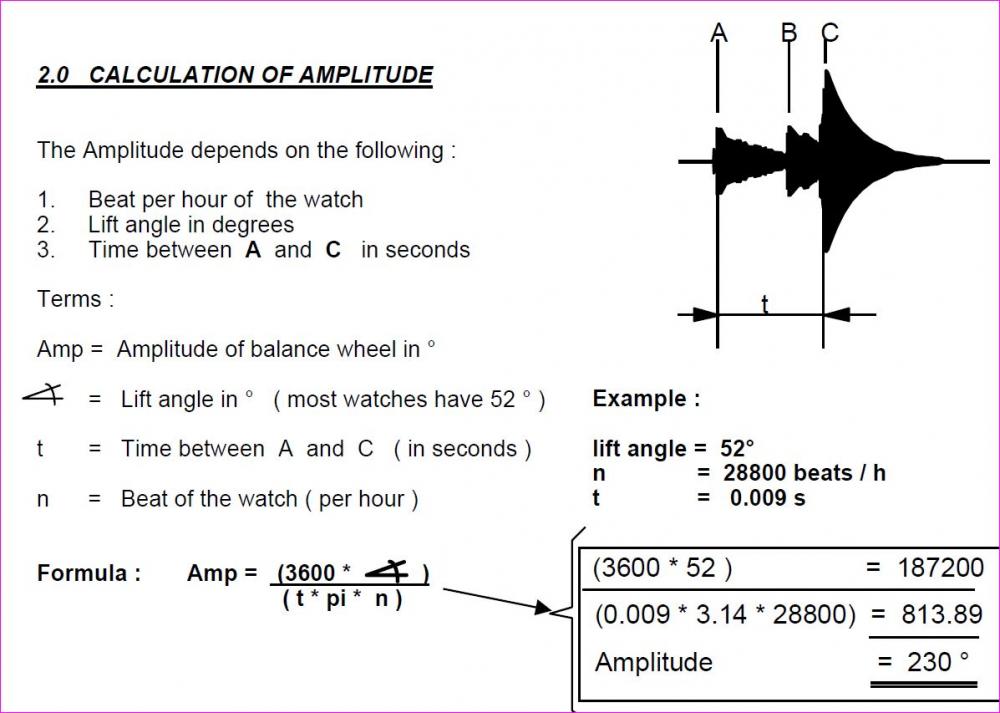

All I did, if you allow me, was to provide a factual bit of information to guide not only the the OP, but any beginner when it comes to diagnosing low amplitude. Now for the technical explanation. Below the amplitude calculation as provided by JohnR275 in the relevant topic further below. In the example if we replace the lift angle with the correct value of 50° for a 2824-2, we get 221°, to correct an error of about 9°. Which is significant perhaps for fine adjusting, but not in cases of severely degraded amplitude.1 point

-

The C&E Marshall uses a leaf spring to retain the stake so it does not drop through the holder. Simple and effective.1 point

-

Today I finished cleaning up a rather tatty Sekonda branded 2nd Moscow Watch Factory 2360 Calibre Black Dial with date. The major issue with it was that the case back was effectively welded shut with gunk, so I eventually resorted to supergluing the case back to a small steel block that I use as a mini anvil on my work bench. Grabbing that with my vice, and pulling the watch upwards to remove the back. All other methods had resulted in dismal failure, and I have to admit I came pretty close to me stabbing myself with the case back knife in several occasions. The dial and crystal were filthy and spotted with mould, which all cleaned up quite nicely, however the crystal still has a small crack in it, but this wouldn't be a 404 club watch without a few minor blemishes. Here it is with the "lost Casio" and the rest of the recent club members.1 point

-

Rodico works. You can also put the watch+movement holder inside a clear plastic bag, punch your tweezers through the bag to work on any fidly flyer. Mastering this ends loosing springs.1 point

-

Can you post a timegrapher picture, that may give an hint. A common cause is the hairspring touching somewhere. Sometime that can be revealed by listening or looking at the waveform, but the primary inspection is always visual.1 point

-

Hello again. Just to let you guys know that as a collector of Helvetia watches I reached out to bjd1020 with an offer to buy this watch for restoration. I received it a couple of months ago and have been slowly getting it back to it's original condition. I received the crown I needed today and here is the result: And with it's 13 away serial number brother I found while looking for parts for this one. Thanks. Carl.1 point

.thumb.jpg.79cd54531fdb66a0e42e8f668447971b.jpg)

.thumb.jpg.3607a5d4a6b44497ae02c92d95a8cb34.jpg)

.thumb.jpg.47c82e034fa4461c1d19f09415d638cf.jpg)

.thumb.jpg.212641f1850ba24a13950998b34c9648.jpg)

.thumb.jpg.60d7d8821a5e24f1557d27976c7687c5.jpg)

.thumb.jpg.d467e5495eea4b5a9a322c918aedea9a.jpg)