Leaderboard

Popular Content

Showing content with the highest reputation on 07/19/20 in Posts

-

Hi everyone, I put together this document after my experience with watch tools and oils as a hobbyist. This is my humble opinion based on my reading and experience. I understand some things (like the lubrication) may not be up to standards, but I tried to make this with the beginner/hobbyist on a budget in mind. All suggestions are welcome and please post your experience as well. I have attached it as a PDF for simplicity. I would also like to thank everyone in this forum and especially Mark Lovick for all your teachings and suggestions. best, Guido Tools for the Hobbyist.pdf4 points

-

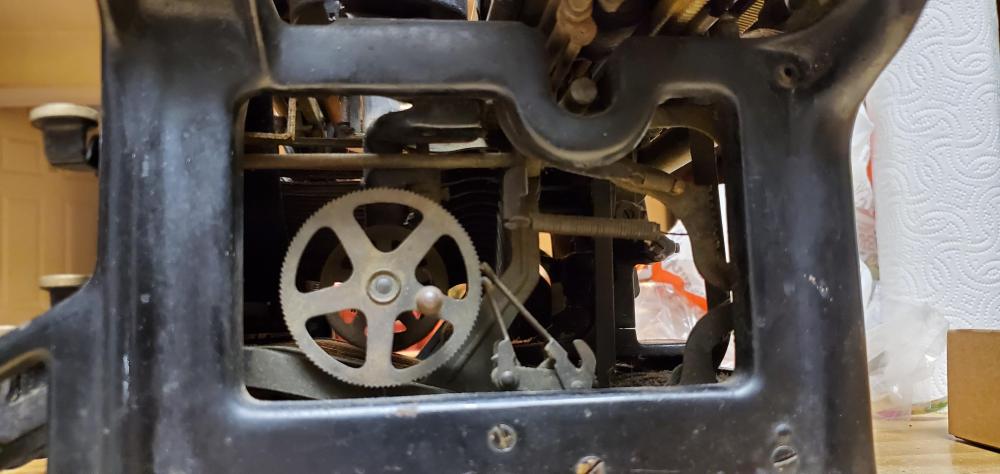

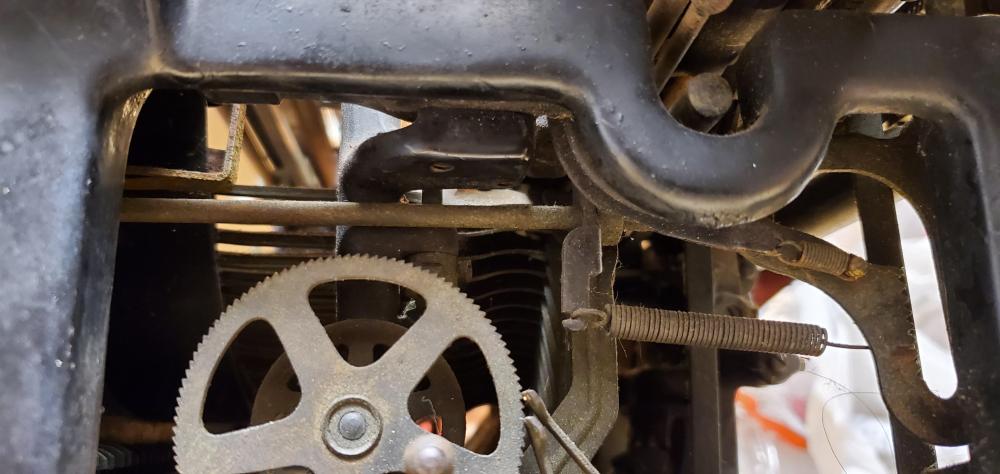

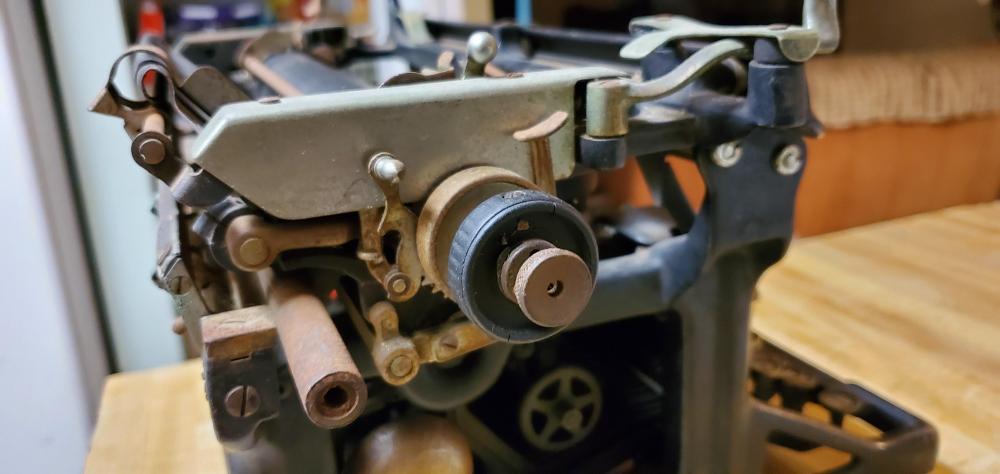

As the title States, I have found another early mechanical device in order to occupy my free time between watches or while waiting for replacement parts from overseas. I picked up this 1915 Underwood Model 5 Typewriter. I plan to do a full restoration on it. Mechanically it's in shockingly sound condition. A bit rusty, but nothing a good soak in some Evaporust won't take care of. The only part missing is the drawband, the part that provides tension to the carriage and allows it to advance with each keystroke and return at the end of each sentence. I've already got a plan to address that. The platen (roller) is stiff, but there is a company that offers a restoration service, if the pricing is reasonable. Somewhere over the last 105 years, the machine was repainted and all the original decals were painted over. Thankfully there is a seller on Etsy who has recreated all the decals for nearly every vintage and antique typewriter. This weekend I will be giving it a 24 hour soak in evaporust and then rinsing it and making sure it's dried and oiled to prevent any further rusting. I will then begin masking it off to sand, prime and paint a high gloss black lacquer like when it was new. Then decals and order a new black and red ribbon. I'm excited for it. The best part, the typewriter only cost me $30. Will share updates One interesting sidenote, someone has compiled a database for typewriters nearly identical to the pocket watch database. An invaluable resource!2 points

-

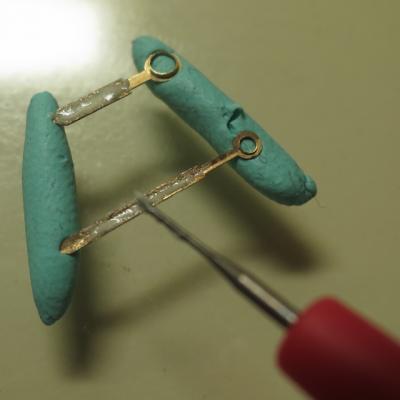

In one of my Uncle Mario's bags of modest pieces I found two Chinese "standard movement", aka Tongji. For those that don't know its history, it has been developed as a copy of the Enicar AR 1010, a 17 jewels mov't form the '50s that has been also made in COSC grade. The Chinese began producing it at multiple factories in 1972, and I believe is still made today. I will service both of them, as I'm curious to learn about any difference, if parts interchange, and such small things. Let me proudly introduce Darts Target, and (Farting ?) Lady. Target runs happily, but Lady only does for a bit when shaken. I will start with Target, and then move to Lady for comparison, with the hope of having them both run nicely. To be consistent with how the piece was made and repaired back then I will only do manual cleaning with basic chemicals, and use just two lubricant types. I also wanted to use my Chinese driver set, but the screw slots are of the narrow type so I will resort to my A&F set. If you have Chinese or Indian drivers that don't fit narrow slow when new, dress the tips to a thin wedge and, then buy another set for Seiko and all the rest. Target is actually a front loader, just pop the crystal out pushing up on its base. There are dial screws, but no dial feet, conveniently replace by glue. To minimize heath exposition I took the unorthodox approach of removing all parts on this side parts before warming the glue. Two dial screws that I can save for spares. Balance is shock protected with movable stud arm. Counting all parts that make it, these should be 17 Let power down by doing as to wind but holding the crown, keep the click opened with sturdy tweezers, and slowly let the crown turn in your fingers. Crown wheel screw is left handed, with its wheel and core, plus ratchet wheel and screw, click and screw that makes 7 parts. The latter two screws are the same, and all three have the same head size, WOW! Pallet bridge screw, bridge (which has a nice snug fitting), and pallet fork, 3 parts. Remove the barrel bridge first. Barrel complete is 4 parts, for a total of 7. Also remove the stem, sliding and winding pinions for 3 parts. Here's my method to open the barrel. Keep it upside down on the mov't holder and push the arbor down with the handle of the tweezers. The mainspring will not fully come out, but for safety sake keep a (gloved) finger on the lid and do this away from face and other parts. Of course I take no responsibility whatsoever. Slowly and patiently remove the mainspring and make the due observations. In my case it was totally dry, not flat, and the arbor does not want to leave the hook - I will not compel it to do so. Moving on to the main bridge, again a snug fit, then the usual train and escape wheels, 6 parts. It's marked Zhongguo (meaning China) Bengbu, that's the city where the factory was located. Center wheel bridge has two screws and these are the same as the other bridges! However to "precisely" set the train endshake, few notches have been punched on the underside. I could not remove the center wheel yet, but the total here is 4 parts. Few seconds of hair dryer and the superbly applied dial can be separated, dial washer and hour wheel set apart. The cannon pinion does not require any special tool to be pulled out and the center wheel simply dropped on the mat. The keyless / motion works is very simple, from left to right we removed the screw plate, plate, minute wheel, and intermediate wheel. Then the jumper screw, jumper, yoke spring, setting lever and its pin. 9 parts. Only the yoke was a bit more difficult to remove, requiring a bit of prying near its post, here's pictured separately. A notch was made near the plate screw to adjust its height The stripped main plate, E could be a variation or inspection identifier? I have counted 70 parts including jewels (plus or minus) for this simple movement. This concludes the first part, thank you for patiently waiting for the next.1 point

-

Hello, As a 'Newbie' I'm browsing the net to discover technics , guidelines etc. on my new hobbie. I found that document from US war department dating 1945 about : 'Ordnance maintenance for Wrist watches' ...as you'll notice it's also an introduction manual for vintage watches, and some american watch models Looking at it, I thought to myself how lucky we're to have internet and online courses ... P.S : name of the attachment, is the official document name in US army archives TM 9-1575.pdf1 point

-

the link below has the meaning of export codes in your case it is BXP Bayer, Pretzfelder & Mills, Glycine, Imperial, Norwich, Ulysse Nardin, Vauchay, then usually chronometer grade watches have serial numbers which is what the big number is probably then identifying the watches going to be a challenge. We might be able to a figure out what the movement is from the setting parts on the dial side. But otherwise any kind of research into a watch like this typically comes up with nothing. Also you can't get a hairspring for it you'll need to get a balance completes unless you can find somebody to why write a new hairspring for you. probably the best place to find parts would be eBay where the movements show up at a variety of amusing prices.1 point

-

Your timing is perfect! Turns out I picked the same amazon screwdrivers as you did, great minds think alike Appreciate you putting the information together.1 point

-

Hi DrG A useful document full of useful information for those starting out.1 point

-

I always sign my initials on the inside of the watch back cover, just recently someone on facebook ask me to repair a Casio AMW-320 for him, he mailed it to me and when I opened up the case back I was surprised to find my initials on the inside of the watch back cover!! I was very surprised that after all these years, what are the chances that a watch I worked on years ago comes back to me sent by a new client that found me on Facebook. I was shocked.1 point

-

Wonderful. Watches, clocks, typewriters, calculators, pin balls, jukeboxes, sewing machines, I love them all and I love to watch people restoring and taking care of these. Fortunately I managed to control myself until now, but what will happen when I'll have lotsa of new more space? BTW that lawn looks to be in stellar shape!1 point

-

Hi find attached the Moebius oil information including descriptions and uses. horotec Moebius oils book.pdf Moebius Oil and Grease Application Chart - Leosics.co.uk.html1 point

-

1 point

-

Definitely. Measure it, you may find a high dome glass crystals on AliX to make the watch more solid and contemporary.1 point

-

1 point

-

1 point

-

1 point

-

I don't think so. It would be good if you at least try to identify the problem instead of going by rote. Listen to the actual sound Closely examine balance and escapement Check pallet fork springiness from one side to the other Check train sprinning freedom These are just some checks, more would be descrine in so many of the postings here and in watchmaking books.1 point

-

Gruens would have a 2 arm balance (with some exceptions maybe). From dead zero the balance arms will switch places at 90 degrees when the are above the pallet fork. 180 degrees is when the look like they are hitting their rest position. Wind the watch until they are there, it's easy to see, then set your machine so it reads 180 degrees. Now wind up fully and you know where you are. With 3 arm balances it's worth making magic marker marks at 90 degrees each side of the pallet center. Remove them after with pegwood and alcohol (works for permanent marker too).1 point

-

I just received a Gruen VeriThin Pentagon pocket watch in the mail. I'm in love: The dial is gorgeous and in beautiful condition, and the movement is stunning. I didn't expect the mirror polish in some of the movement components. This is probably the most beautiful movement I've ever seen in person. This may just be a white gold filled case, but it's my first non-SS cased watch. Next steps: Figure out if this is a good candidate for me to overhaul. My current thinking is that this is far too "fine" a movement to practice with, and I don't know about parts availability. It's running okay right now, with a healthy amplitude but losing 3m/day.1 point

-

If you were to send this watch to a pro it’ll probably cost you more than what the watch is worth to fix. Go on eBay and search Waltham 1898. 0s. There are plenty of them up there right now. I want to practice taking it apart and putting it back together. You will understand what I meant by everything being under the barrel. It could be quite tricky to get it together but it’s not impossible. Pocket watches are the easiest thing for a beginner or novice to start with. I don’t think you need a couple of years experience to do this. If you are a quick learner And you think you can handle tedious work you should be able to get this going on your own. You can always get a movement that is already running and just replace the dial and hands. I don’t know if this is something you wanna delve into but if so I think you should give it a shot. Sent from my iPhone using Tapatalk1 point

-

Cheers for the replies guys I ended up finding one on ebay for £38 including postage, so although it was a hard swallow, it could have been much worse.1 point

-

JDM and the others stated things very well. If, as you say, you have no experience with this sort of thing, then I feel you probably already know by now, thanks to the above advice, that this is far too handsome a watch upon which to gain said experience. As others have also stated, there are cheap "for-repair-or-parts" movements to be had on auction sites, which will give you opportunity to practice. This very site offers courses which can help, if you still wish to learn to service it yourself one day. I got lucky with the Swiss 5-bar movement I am working on right now. It had a similar issue (in addition to having been abused by the prior technician's apprentice). When I took the dial off, I saw right away that the yoke had somehow slipped out of its groove on the clutch pinion (sliding pinion). Whether that was due to inept crown removal or whether the chunks of porcelain in the works (from the damaged dial) got between the parts and forced them asunder I do not know. Luckily the watch was not running even after that "service" they gave, so I did not see grit sprinkled throughout the works. She still got the world's most thorough cleaning though. I mention all this, not to say "There's yer problem", but to illustrate that someone with a bit of experience will know how to locate the issue, identify it, safely get to the parts in involved, and rectify it along with all associated perimeter duties to the movement. If you are content to place this beautiful watch on the back burner for a time, you could learn to become that person. There are loads of resources here, and plenty of willing and knowledgeable and patient people. Basically, you've found the right place. If you want to do this, grab yourself an old, beat up movement or two, similar to the that one, and let's get crackin'!1 point

-

Thanks to you all, I decided to use a barrel from another movement, this time cleaning thoroughly by hand and have managed to wind the mainspring back in by hand... I now have the barrel reassembled complete.1 point

-

There looks to be many missing stakes and plugs. New stakes/plugs can be bought from good suppliers. Have a good look at what you might buy, Do the stakes line up with the holes in the bass, make sure there not blocked, the same goes for the stakes. Looks like it all needs a good clean, this can be done and it should then look fine. You can also find second hand stakes on ebay. The price is fair. Just make sure it all works and moves free.1 point

-

Hi Found another data sheet 2113_Roamer 351,352,364SC,400,401 (2).pdf1 point

-

Hi Mst, Medana, Roamer same movement, tech sheet attached. Roamer 400, 401.pdf1 point

-

You may have noticed a few changes - I have removed the Gallery section and the CMS pages app from the site as it costs too much to 'rent' those modules with comparatively very little use by members - it just did not make sense to keep them going. I apologise if this inconveniences or annoys anybody but I think it is better to keep the core of this website to be a discussion forum. The WRT website is costing me a lot of money per month to run and I am making a few changes to help with that - there is a little income from eBay affiliate ads but not enough to cover the cost of hosting and some help from Patrons and for this we are very grateful. The site has over 30GB in uploaded media now!!! And the notification emails generated is quite high too - I have to use a separate company to handle this so that the site doesn't get email black-listed. One of these services suddenly and without notice stopped our service a few months ago and it was a few days before anybody even noticed (password reset emails were no longer working). I did manage to find a new email provider and things have been running smoothly ever since. Getting back to the uploaded media, as mentioned it's over 30GB and this covers images in topics going back several years. I do back this up every night and I backup the site database every hour in order to protect the content should we ever have a disaster I have a Synology NAS here in the office which has a full backup on and I also keep a backup offsite on a cloud service. I have also decided to use Amazon Cloudfront to host all the uploaded media. I am in the process of migrating this content over and you may notice broken images for a very short period during the migration. But ultimately this will maintain and even improve performance of the site. Anyway, all being said, this is a fantastic community and I am fully committed to continuing with it's administration, keeping our little corner of the net alive - Just a little update to let you know what's happening -1 point

-

Not to brag or anything... but my question about the arbors being too thick for some Mainsprings was featured in one of Marks videos. Bogdan1 point

-

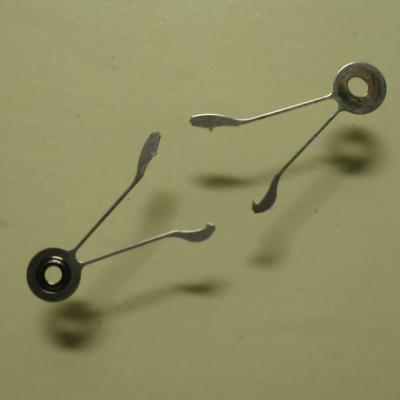

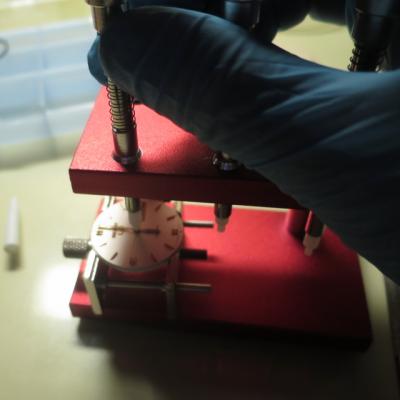

Don't worry, this is the last part. As I was wrapping up the movement service, I noticed that the automatic winding will not work. I found out that the pawl lever and the second reduction wheel are worn out. Compare the worn out parts in the left and the replacement parts in the right. After replacing the said parts, I went on to work on replacing the crystal, cleaning the case and bracelets and re-luming the hands. Yeah, I could have done better on the hands. The lume was too thick. I then installed the hands, placed the movement inside and demagnetized the watch. And here's the before and after shot. All done for a friend for free. :D I hope you enjoyed it. Please let me know any suggestion on how I can improve on my hobby.1 point