Leaderboard

Popular Content

Showing content with the highest reputation on 04/21/20 in Posts

-

4 points

-

Photo bomb this morning. My cat chuppy decided he would make a good back drop. My 1984 Marathon GG-W-113. This watch was made to military specification with a hack movement. The most intresting point is that they were assembled by the Gallet Co and stamped so inside the caseback. They are somewhat rare as they were only made in 84' and 85' and were meant for the military.3 points

-

3 points

-

2 points

-

I've see melamine dials before.Hamilton made them back in the day. Not exactly paper, more a very early thermoset plastic that often was used to impregnate a paper or cotton fabric substrate. Formaldehyde is the chemical used in conjunction with melamine to create the resin. A Hamilton Melamine dial. Cracking is very common with melamine as it ages. On a weird side note, when I was an apprentice machinist we used to practice machining on chunks of Phenolic, which is very similar to Melamine in many ways including the use of formaldehyde in its formulation. When Phenolic is machined it gives off an incredibly strong Urine smell from the formaldehyde.2 points

-

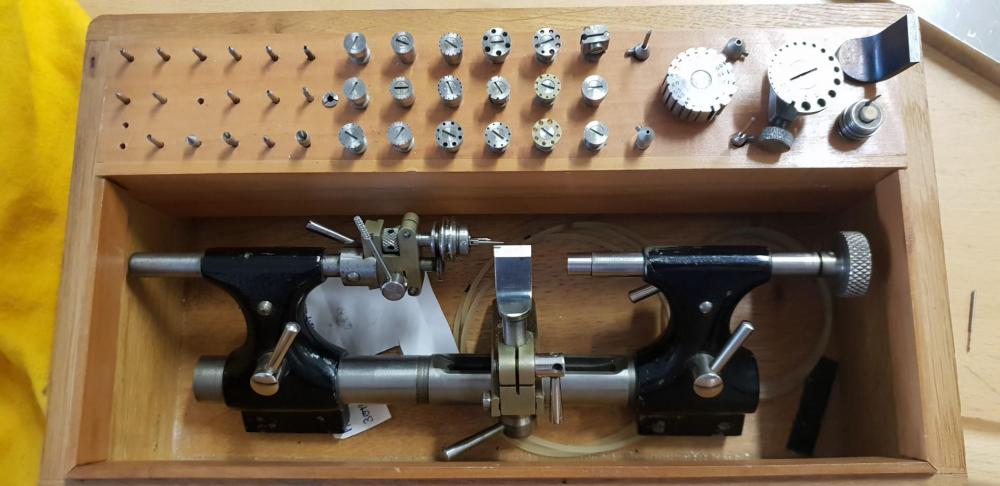

Here are some pics. It's not set up for turning at the moment, will get some more when it is. You can see the "headstock" takes simple round centers (there are a bunch to choose from), and is adjustable to line it up with the tailstock. The rows of tailstock centers are a little different from conventional in that they are basically drums with female centers cut all around the periphery. They are marked, so one marked 20 will produce a 0.20 pivot (or slightly larger) when the graver, held parallel, hits the side of the drum. Some tailstock centers are discs to allow the pivot to peek through, resting on a shoulder, to work the end of the pivot. On the right are a burnishing drum for large pivots (like a Jacot), and a setup for drilling arbors that are held by their shoulder. This is really handy for repivoting arbors that are difficult or impossible to hold in a collet. The parts will always be fitted with a driving dog, either the fish shaped spring clips (99.9% of the time), or with the clamp on dogs that look more like traditional machinist driving dogs. A finger on the headstock pulley engages the dog. The little discs above the dog box are small pulleys which clamp on the work, this was the first way of driving the work, with a bow directly driving the pulley. Traditionally, and still in many schools that teach the use of the turns, power is by a handwheel mounted below or behind the turns. They can equally be powered by a motor like any lathe. I still use a handwheel, as I just like the total control it offers. You have to be accustomed to holding your graver in one hand though.2 points

-

Speaking of smells, I used to love the smell that came from working on celluloid knife or straight razor handles. It was a camphor smell. Very unique. Sent from my iPad using Tapatalk Pro1 point

-

I'm happy with the eyepiece tube design and dimensions. The fit is snug without being too tight, so I can place the two eyepieces at fractionally different heights if I need to correct for mismatches in focus, and the internal fluting works, so there is no internal light scattering and base flange all look to be correct. I'll see if I can integrate a suitable pair of M4 nut holders into the base pieces design, and then print the remaining parts tomorrow.1 point

-

I think it’s worth pointing out that it’s easy to cause faults in some quartz movements just by applying too much pressure when fitting the hands. It’s certainly happened to me before. If the seconds hand slips then the wheel must have disengaged with the train. This can potentially happen if you press the seconds hand too hard. Is the old movement running at all?1 point

-

Indeed. The latest ETA 255 which I've replaced didn't wanted to run, fortunately I found that with insisting push and pulls it would start, after a good while running the problem went away. It is much worse to leave a quartz module stopped than a mechanical caliber,, even if you buy new you can't know for how long it has been sitting in stock.1 point

-

Yes it does, then on the outer case back the numbers 6657 785.1 point

-

They have the most of the tech shhets still online, but some of them which have been obselete for quite a time is taken away. https://shopb2b.eta.ch/?___store=en Up in the left corner you just choose if you want the quartz or the mechanical tech sheets. The 579.002 is one of those movements that is no longer supported and it was replaced with the ETA 902.002. https://shopb2b.eta.ch/902-002.html#technical-documents1 point

-

Look on ebay under tissot bracelet. Have a couple of bracelets for 18 mm Tissot but not sure it's the same one for 20 mm . The endlinks need to fit also.1 point

-

1 point

-

1 point

-

I expect the whole dial to be porcelain. Could be very cracked that is why a paper dial has been put on to stop it cracking even more, a form of protection.1 point

-

There's a preamp in the microphone itself. Depending on what it does once it gets to the primary board (none of the photos are high enough resolution or at the right angles to really see what's going on), it may be possible to tap directly off that right at the plug and pull the speaker out to just play what's coming from the microphone (assuming it's not doing some other critical thing). It's all conjecture without having one in hand, but that'll come soon enough.1 point

-

I think the Vibrograf B200 Microphone might have a little more space in it. Then whatever I saw somebody had used a piezo disc and they do come in a variety of sizes. Then because the originals are water-soluble I'm reasonably sure that they're made of Rochelle salt (sodium potassium tartrate tetrahydrate) It's amazing what you can find on Wikipedia. So what will happen with time is They will absorb moisture and just disintegrate.1 point

-

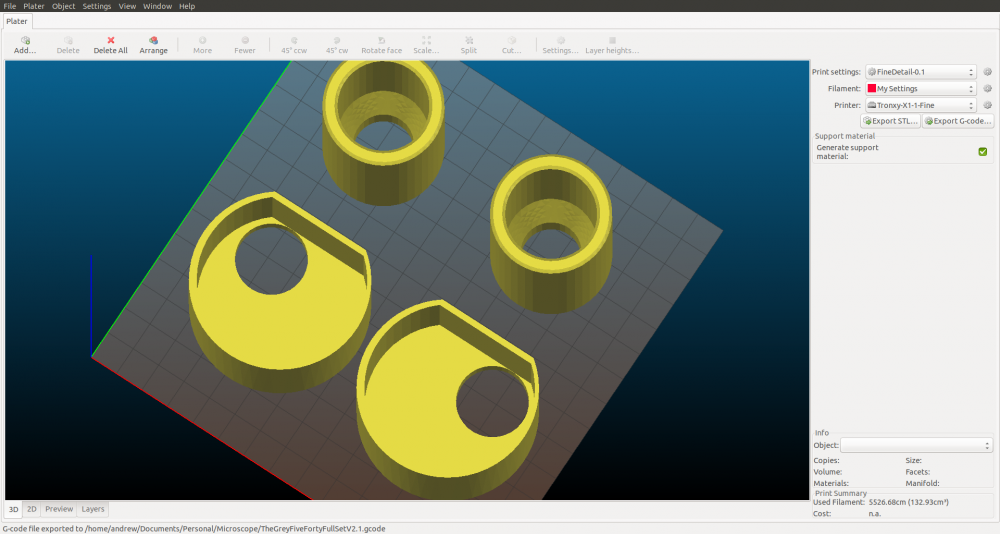

A lot of tinkering and some more FreeCad time, and I have all of the parts ready to print. I increased the length of the eyepiece tubes from 32mm to 60mm as this allows for better binocular separation. I added a flange on the eyepiece tubes so they should mate directly into the bottom sections, and I increased the diameter of the hole to accommodate this flange, and a bunch of other refinements. It is way to late in the day to start printing anything, so I'll probably start this job in the morning.1 point

-

1 point

-

Hello, I hope this information is useful to you. Saludos. Y Quédese en casa. Stay Home!1 point

-

Related but no. Turns, also called a dead center lathe, hold the part at its ends, usually in female centers at watch and clock sizes. The upside is guaranteed concentricity, and you can remove the part as often as you like to measure or test without risk of losing concentricity. The downside is it's a bit more fiddly, and trickier to use a cross slide if wanted, and measuring usually means taking the part out. Turns can be pretty sophisticated, like the Horia/Steiner sets, but in essence they are the simplest form of lathe. I'll snap some pics of one set up tomorrow.1 point

-

Daft question, but, you haven't put the fork in upside down have you?1 point

-

You are correct. I was using a ball with a rubber dish washing glove prior to getting the right rubber ball. You are right in that the simpler the tool the better it will work....most likely invented by a very practical individual.1 point

-

1 point

-

I can totally relate. I restored my father's favorite Swiss Army watch a couple years ago. I haven't seen him get so emotional in a VERY long time. Hope it's a hit!1 point

-

There are a lot of these watches around so you may be able to buy a junker watch and use the back. By the way, several versions/models of the Seiko watch back will work. Good luck1 point

-

1 point

.thumb.jpg.911e67c94d3507e643d626b18f367d9c.jpg)

.thumb.jpg.1d13f797edc16b562c95826e06160cc1.jpg)

.thumb.jpg.c64bbfc69ba34b416e81ca995de8b743.jpg)

.jpg.3389607bb76f5398d21d0ca9c6bbd96f.jpg)