Leaderboard

Popular Content

Showing content with the highest reputation on 01/02/20 in all areas

-

Hi Vin, I was aware that Timex were not the first and that Hamilton hold that 'honour' with their 'Electric 500' model, in 1957, which wasn't ready for production despite 11 years of development since conception in 1946. It did however spur Timex to get on the band wagon and as they hadn't got an electric watch in development themselves, decided to purchase a company that did. They bought 'Lanco', who apparently had an electric movement in development, but that also turned out to be not ready for production and first appeared in a Timex watch, as the model 67, in 1962, the MUCH simpler, (and surprisingly long lived), model 40, not appearing till about 1967. Sadly my funds do not run to an early Hamilton electric, but I do have this Talis Swissonic... A couple of Citizen Cosmotrons..... A Seiko EL330........ And this rather nice 'Sheffield' with a Junghans movement, from 1969....3 points

-

Hi Guys this is a PDF supplied by Witchi explainging the mechanical watch, hope its of use Witschi Training Course.pdf2 points

-

In my Christmas stocking this year was yet another book to add to my library. Having skimmed through this book it seems great for those wishing to take up clock repair as a hobby. It covers all of the basics from bushing to cleaning and assembly. However it also covers cuckoo clocks, their repair including repairing the bellows which is new for me. Another interesting section me is lubrication because the author recommends “Mobile 1 Synthetic 0W-40” (Viscosity 215)for the pivots and “Mobile 1 Synthetic 10W-60” (Viscosity 325)for the mainsprings. If this really works then it is certainly going to save me money so I am tempted to give it a try.2 points

-

Hi Guys for those of you who delve into the workings of quartz watches there is some interesting information to be had here Knowledge Quartz Watch.pdf2 points

-

2 points

-

Hello, everybody. I wanted to share my restoration stories that I have done for a long time and thrown into my archive. First I discussed the Atomic Mars 71 Brand using Valjoux 7734. As it was seen, scratch and dial is broken. To begin with, I tried to brush the Case as Brushed and make it the first day. If it is decorated, I polished and re-painted the indexes (with acrylic paint). I usually do this in three layers so that the paint is not deleted in a short time. I replaced the case buttons and tubes with aftermarket buttons. Since the condition of the dial was in very poor condition, I had it re-painted. The quality is not so good. In Turkey, unfortunately, not doing the job well. Caliber 7734 (Valjoux) is a special and robust mechanism for me. With good maintenance and lubrication, you can reduce deflection values up to 3-4 seconds per day. I added a short timelapse video about it :) As a result, such a result came before us. Thank you Taskin https://www.youtube.com/watch?v=XKH6yTKUfpM1 point

-

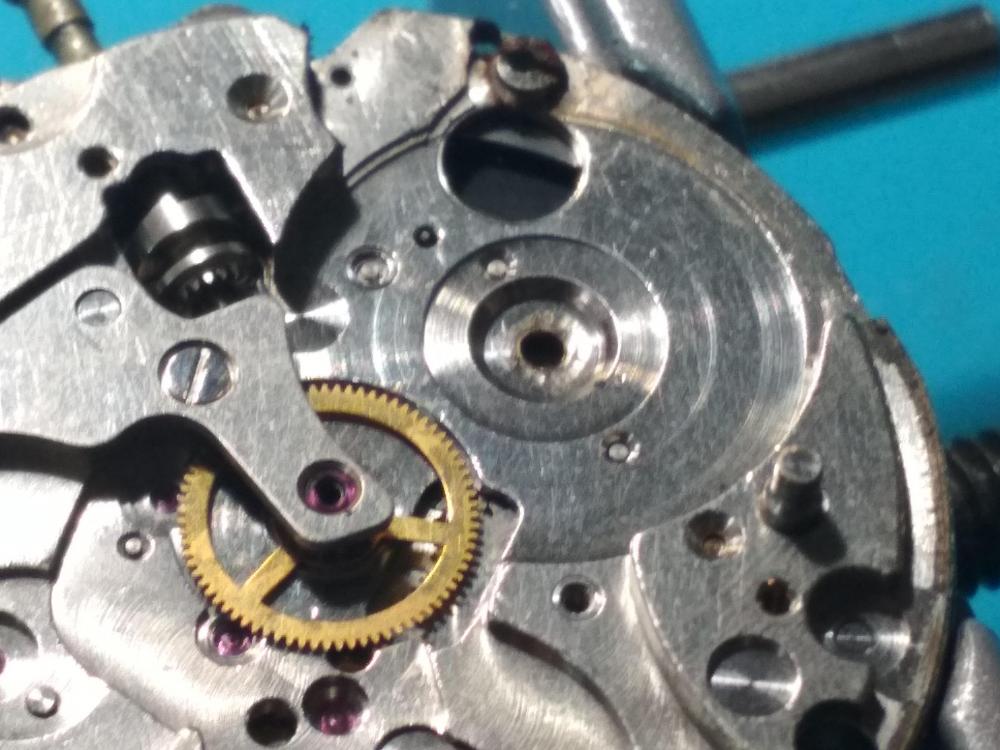

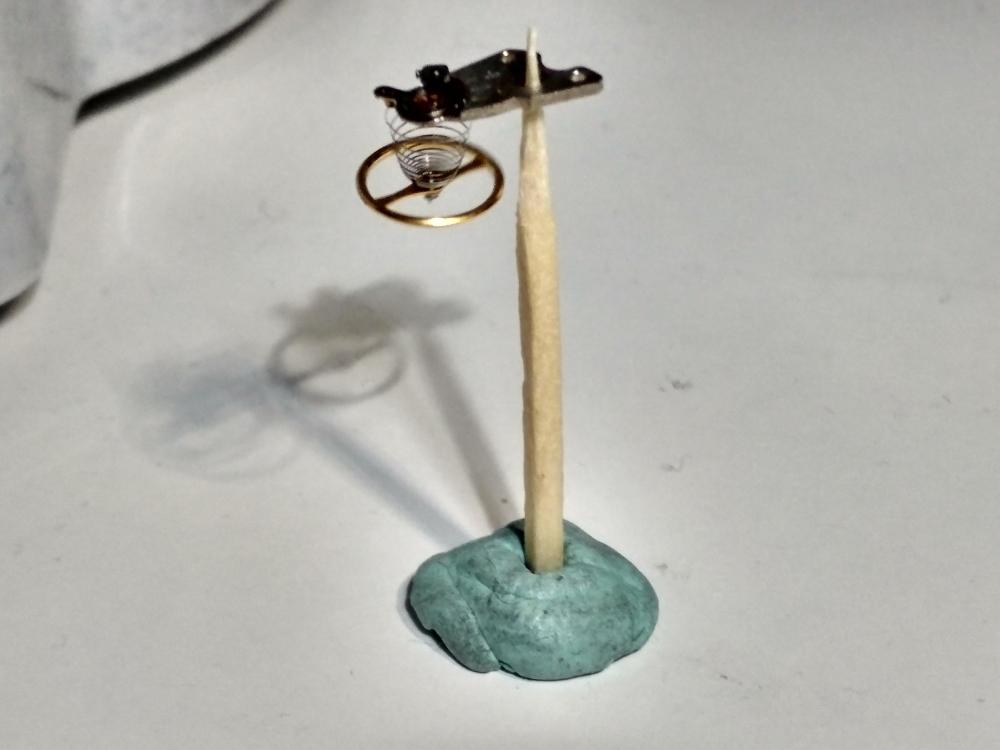

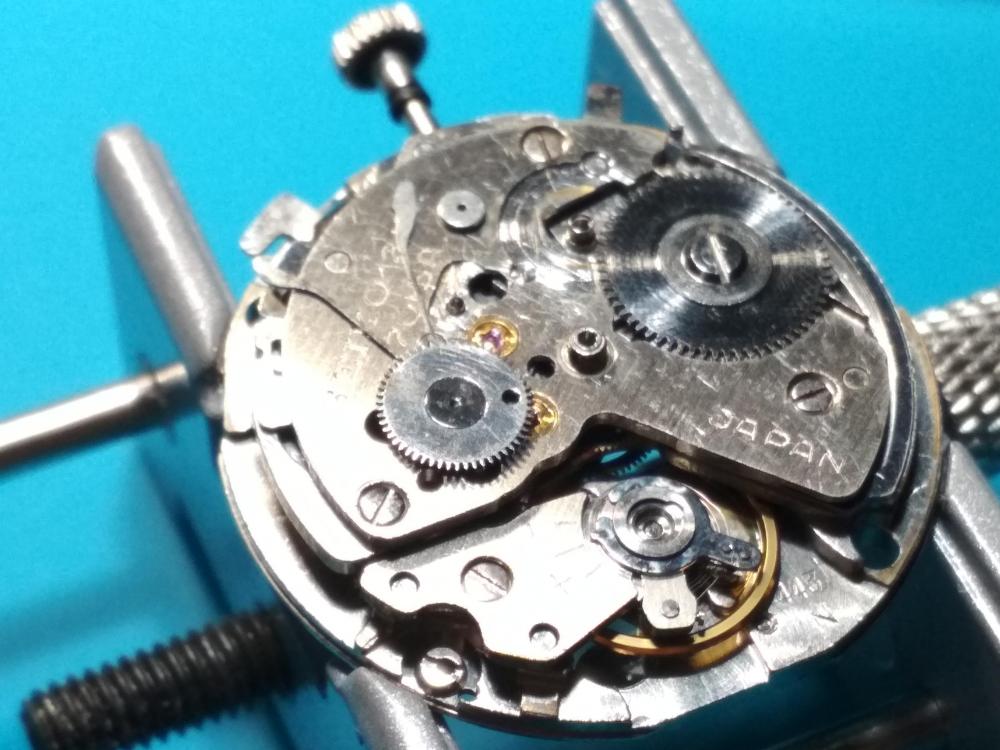

Hello guys, I want to show you my lately restoration project. This time it was a Seiko 7015-8000 with blue dial. Watch came to me in very poor condition. As you can see on photos the case was scratchty, crystal was totaly tarnished with deep scratches. Everywhere was dirt, gunk and mud...yuck. Movement was running and stopping with very low amplitude. After opened the caseback I wasn't suprised - it looked like as case - dirt and signs of wear. Rotor was loose and fall out the case. When I take off the crystall I saw dial which had faded Seiko logo, some scratches and hands which lost their lume. Next step was strip down the movement - everywhere dirt and dry old oil. Time to cleaning bath Look at this - it's my temporary balance wheel stand - I suspect that from temporary it will be permanent. It does job well. After cleaning it's time to assembly movement. Now it looks better - maybe not pristine but clean and shiny. New oil here and there and movement starts to run. Now it's time for bench testing before install it to the case. Meanwhile I took care of the case, dial and hands. Case got some polishing work - not to much cause I didn't want to loose the sharpness of edges. That is effect: Dial and hands got new lume - I am not perfect in this work but I still learn to do this. Additional the seconds hand was repainted to orange color. I didn't change the crystall but i just polished it with waterpaper and on the end polish paste. Effect suprissed me. Time for the pleasant work - putting this all pieces together into the watch. VID_20190927_195610.mp41 point

-

Never heard of him. What qualifications does he have in horology? He has books about all sorts of stuff.1 point

-

Which "naptha"? If you use "refined benzine", or "petroleoum ether", or Hexane, that leaves no residue. These products can found online, or a chemist store, or even at the pharmacy. That being said, I do rinse in demilitarized water and IPA myself. And I took the habit of looking at liquid against light, if I can spot more than one floating particle I re-clean the (appropriately named) benzine jar and replace the fluid. Correct. But as in any lubrication / cleaning discussion, pre-made opinions are mostly impossible to change. Fortunately for Ronsonol1 point

-

1 point

-

No Vin, but they all run on modern Silver Oxide 1.55v cells, you just have to match the physical size to a battery that will fit in the watch, being careful not to get one that is fractionally too thick..... I forgot to mention the model 84 Timex (Timex update on the Lanco movement, also with back crown), that I have. The current electro mechanical collection, I'm going to have to get a BIGGER box!.....1 point

-

There are many phone apps which you can use to help you get it running right. I have Wildspectra on my mobile. It takes some time to set up and a phone is not really the right tool as the magnets in the mic may affect the watch but its better than nothing. Another app I use is watchcheck. Basically you set the watch as close to the phone time and after a few hours you tap the button when the seconds hand hits the 12 marker. I check the watch in the morning and evening.. you will see the variation as well as the average deviation per day. Anilv1 point

-

1 point

-

Just 'discovered' the early Timex electrics, I've got five up and running now (Model 40 and derivatives), currently waiting for this rather novel example to arrive... seems a bit scarce, cant find anything about it on the internet, just pictures of two other examples, one chrome and the other gold..1 point

-

Well guys, I finally solved the issue. Thanks especially to the suggestions of @Nucejoe and @rogart63 with the HS installed in the movement I pressed slightly in the stud area and I managed to straighten it. Time keeping is now even better than it was before.1 point

-

Hi T de Carles book chapter 6 there are several pages explaining the pin pallet operation and adjustment. Mine is the second edition and quite old. But as Joe explains its just a job of observing the lockings and making any adjustment as required. In beat is when the arm of the fork is centered between the index/banking pins at rest no powerand the pallet pins are just about to release and lock to achieve this its the same as theJewel lever done by adjusting the balance spring on the staff to achieve the center.1 point

-

Another bargain basement low cost filthy animal waiting for me on my return from holiday. A Grovana 23 Jewel with very mild green dial pox. Grovana seem to be still around, and their current products remind me a little of some of the Fortis watches, both in terms of quality and style. Click the link to see what I mean -> https://www.grovana.ch/Herren-Shop.htm <- Other than the crystal and the filth, and assuming the balance is in good order, I suspect there is little wrong with it. Interestingly it claims to be "Tropicalised", so it should be well suited to any future trips to this part of the world. I think I'll probably ditch the date cyclops when I swap the crystal, as it seems a little unnecessary and clucky, and spoils the look in my opinion.1 point

-

The click spring is under the ratchet wheel. Clockwise rotation of the crown results in CCW rotation of the crown wheel relative to the screw, so a LH thread ensures that the torque tends to tighten the screw. CCW rotation of the crown wheel causes CW rotation of the ratchet wheel. However the ratchet wheel is attached to the arbor which has an opposing (CCW) torque from the main spring. The LH thread on the arbor ensures that the CCW torque on the arbor tends to tighten the arbor screw.1 point

-

1 point

-

Hi Yes the position has an influence on timing, Face up the balance bearing is on the end cap , face down on the other end cap, left and right on the sides of the jewel so the area in contact varies with the position, watches are timed in six positions. If you are interested I have some training data some where.1 point

-

1 point

-

1 point

-

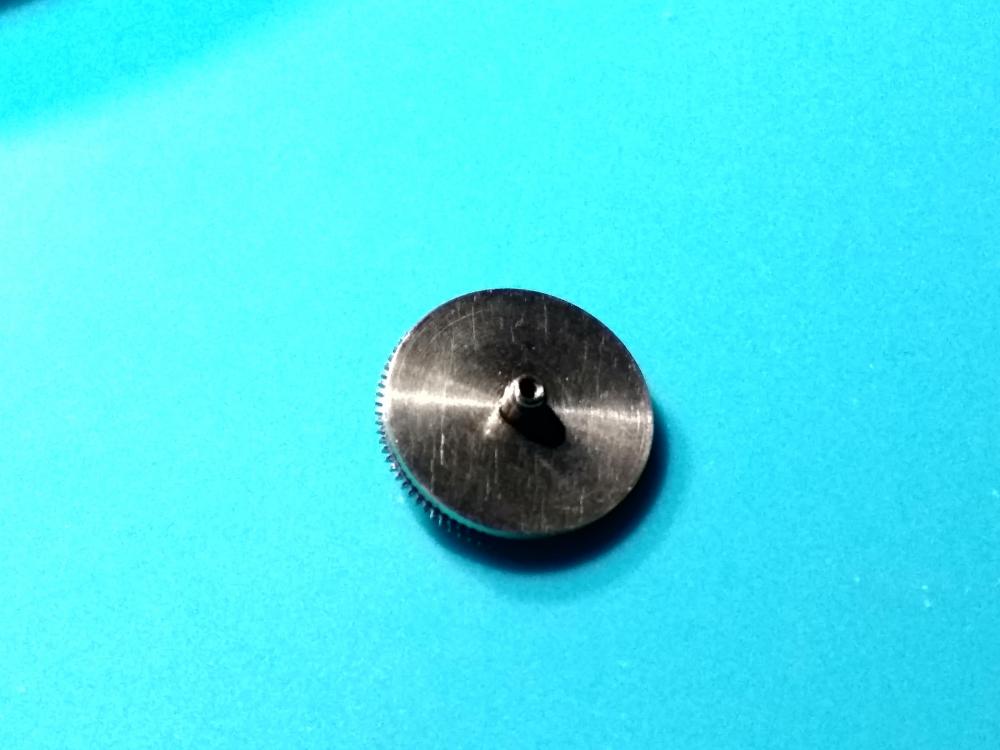

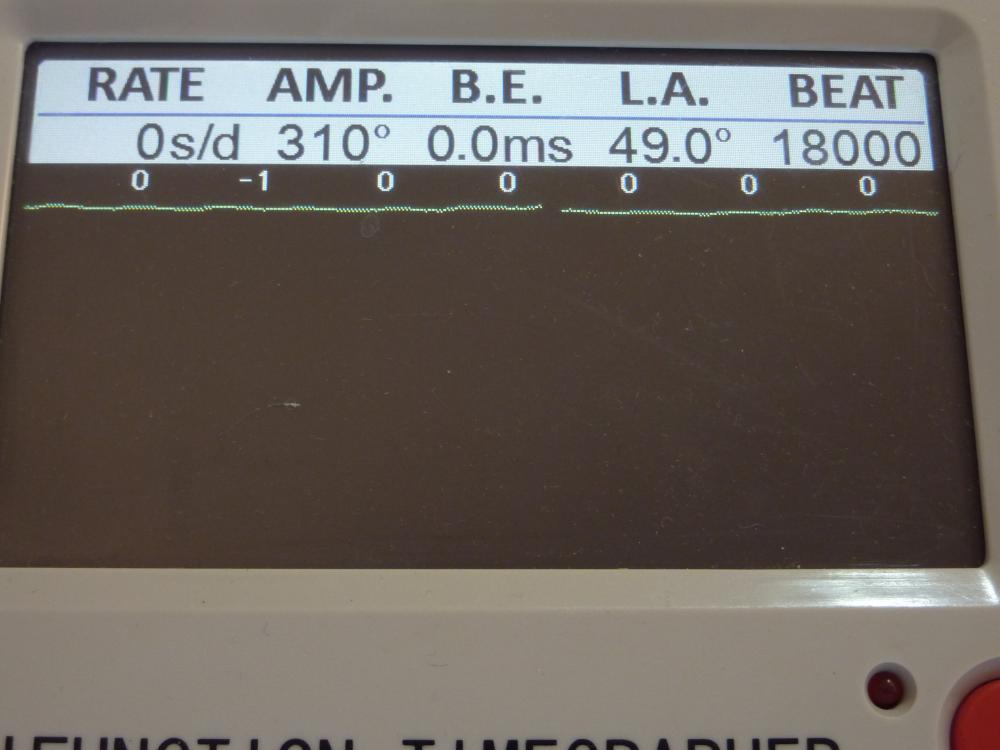

I haven't done one of these for a while and as this is my 1000th post I thought I would do something a little less ordinary. As the title says it's one of those crazy Russians, a USSR Sekonda from the 70's sporting a Slava 2428 in all its quirky glory. This one came to me as a non-runner and a preliminary investigation turned up a broken balance pivot so it went into the "to do" box until I could source a replacement, which it turned out I had all along from another watch previously scavenged for parts a while ago, as I discovered during a recent tidy up. So here goes...... Looking a bit sad, a grubby face and a bit of corrosion on the hands, and as already mentioned, not running. Also the date corrector pusher which is above the crown is jammed in. It's obviously seen a bit of wear in its time as the plating to the rear of the case has started to go through. Inside doesn't look too bad. Dirty and dry for sure but I've seen worse. The stem however suggests that things may not be so good further in. Uncased and the dial doesn't look so bad. The hands may need a bit of a spruce up. Oh dear... with the dial off the hint that the stem was giving earlier becomes a grim reality and the reason behind the frozen date corrector is clear. Heavy rust around parts of the date quick set mechanics has seized everything solid. With the day and date wheels out of the way and safely bagged the full extent of the problem can be seen, and maybe it's not quite so bad after all so long as none of the screws shear off as I try to undo them. Success.... all the screws out and nothing stripped. The rusty parts have been carefully rubbed down and are now enjoying a strong cup of tea.....to stabilise the remaining rust deposits. And here is the first quirky bit, all of the date quick set mechanics are mounted on the movement ring, not the movement itself. Strange but true! The movement now flipped, balance cock and barrel bridged removed, and the second and third deviations from the everyday run of the mill design philosophy become apparent; that curiously asymmetric pallet fork, and those tandem main spring barrels. The first of the going train bridges removed .... ... and with the second train bridge and wheels removed, the replacement balance is installed without jewels ready for a spin in the Elma. And here we have all the bits nice and shiny out of the cleaner, with as much of the rust issue dealt with as possible. Is it me or are there a hell of a lot of wheels in this little baby? Both main springs are in good shape so they are greased and rewound into their respective barrels. I don't know if it was strictly necessary but I did take the precaution of keeping the barrels, lids, and arbors together as sets during the cleaning process so that the same bits went back together as came apart. Balance jewels inspected, lubricated, and reinstalled. The hair spring is pleasingly flat, parallel to the balance, and concentric, and once set in motion the balance doesn't seem to want to stop. A good sign... In goes the first set of train wheels along with the idler that couples the twin barrels together. With the first train bridge in place the escape wheel and centre seconds wheel are installed. Second train bridge goes back on followed by the tandem barrels Barrel bridge with all of those amazing coupling wheels to keep everything turning the right way all the way back to the crown wheel and its clearly marked lefty screw. At this point all of the pivots have been oiled and a quick test of the free running of the train is done. A couple of clicks on the ratchet wheel and the escape wheel spins nicely down and then back with just a little recoil. After that the pallet fork goes back in and the pallet stones are lubricated. Typical of many Russian watch movements, the balance cock has a shim. Whether or not these were available in different thicknesses so that end shake could be adjusted I have no idea. I've never had a problem swapping them between watches though which suggests that they are all the same thickness. Balance back in and that lovely moment when it starts to beat again. And then back into its big metal spacer ring come date quick set extension. Time to rebuild the dial side. It's a bit cleaner now. Keyless works back in place. Motion works reinstalled. Incidentally, as can be seen here 5 of the 26 jewels are vertical rollers for the date wheel and 4 are set into the main plate for the date wheel to ride over. Cynical marketing ploy anyone?? The date corrector mechanics are reinstated into the movement ring, all now free running. Most of the rust damage cleaned up reasonably well but there is significant pitting at one end of the spring. If I ever find a donor I will replace the worst affected parts but for now they work and the rust has been stopped. Calender wheels back in place. Date wheel back in place and the day wheel jumper and spring installed. Day wheel drops into place. Dial and hand back on following a clean up and a little fresh black paint in the hands where it was beginning to crack. This is the date corrector pusher and is I suspect the origin for the water ingress that caused the rust damage. It has a little neoprene seal on its back face so that the spring tension should seal it against the inside of the case. It was bone dry and all it would have taken is a little dirt stopping the pusher from closing properly and its an open invite for any contamination that comes along. Now cleaned and re-lubricated with silicon grease it will hopefully keep the water out. Re-cased and ticking away nicely. With the exception of the date corrector pusher issue these are well designed cases. Although they make no claim to water resistance they do use a design similar to that used in the Vostok Amphibia cases, with a thick gasket, a steel back that drops into place, and a threaded clamping ring to hold it all together. Looking a lot happier than when this all started. You can now see the date corrector pusher protruding from the side of the case above the crown so it is definitely sealing against the inside of the case. A new crystal allows the cleaned up dial and hands to look their best. And there is something about the dial layout and hands that just seems so Russian to me. I really like it. And of course the proof of the pudding.... This is dial down. DU was almost the same, only difference was amplitude which fell to 298. The vertical positions showed a tiny bit of beat error, up to 0.4ms, amplitude down to around 275, and slight rate errors, coming in at -5 s/d at one extreme and +3 s/d at the other, quite a respectable result. Maybe those crazy Russians aren't quite so crazy as they first appear. The little design quirks here all add up to a nice piece of engineering. The train wheel layout, and the asymmetrical pallet fork allow for a comparatively large balance wheel for this size movement (thinking about it without the date quick set and the extension ring). The use of 2 main springs running in tandem allows for a more even torque delivery as the springs wind down which should help to reduce isochronism errors, while also making good use of the available space. It all actually makes quite good sense in a kind of lateral thinking sort of a way. If you should be tempted to go for one of these then I would suggest that the earlier USSR ones are the better ones to go for. The later "Made In Russia" versions at some point were updated to a 21600 train, but weren't so well finished, and that date corrector/spacer ring became plastic with the mechanics riveted on, presumably to reduce costs. Bit of a shame if you ask me. If you made it this far then I guess I haven't bored you to sleep. Thanks for reading.1 point