Leaderboard

Popular Content

Showing content with the highest reputation on 09/21/19 in all areas

-

Thanks, and yes, that could very well be the problem! The design definitely seems to leave no room for imperfections! However, I'm happy to say that I just came up with a solution. I'm not a technical guy so I really, truly surprised myself (än är inte undrens tid förbi ). I realized that the case was big enough to insert the movement into the case with the stem attached to the movement, crown unscrewed of course, and then hold the stem with pliers inside the case while screwing back the crown from the outside of the case.2 points

-

1 point

-

Hi Watchie As above I usually start with the keyless work and work my way back to the balance. I think it all depends on the construction of the timepiece and your own preference.1 point

-

Thats a point. to be more exact I should have said based on my experience with larger fasteners, why hollow ground is better, and how you'd measure that, is how much torque it can apply without damaging a head. There could well be other factors in watchmaking sized work. Pet peeve of mine - taking apart some 100 year work of art and some hack before you has messed up all the fasteners1 point

-

Correct. Just measure and order by size. Cousins UK has by far the largest selection, I would use the occasion to get few tools and other useful stuff at the same time.1 point

-

I suggest doing the keyless works firsr. I have done some after, but one rather annoying watch, was a complete !! Had to re-dissaemble and do the keyless works first. We learn by our mistakes.1 point

-

Hi, All my life I've been interested in watches of all kinds. I started watching videos about watch repairing on YouTube and ended up taking Mark's online course. Before I new it I had bought some tweezers and two China versions of the UNITAS 6497 to tinker with. Great Fun ! Hope I'll see you around /P1 point

-

Hi Watchie Looking at the setting lever I should say the threaded hole is worn out and not giving the right drive when unscrewing there for best bet is to replace the pair as suggested.1 point

-

To quote measuretwice from a previous posti g: In the common vernacular, hollow ground is used to describe the resulting parallel No matter how many years one has done something is always good to try to understand what others mean. Searching the Internet alsio helps https://toolguyd.com/lee-valleys-parallel-tip-screwdrivers/1 point

-

Here is my quick video for making a leather belt for a Watchmakers Lathe. Enjoy. Sent from my iPhone using Tapatalk Pro1 point

-

If you've used properly fitting hollow ground blades for larger fasteners you know they can handle a lot more torque than a regular screw driver without damage fasteners. The difference is so pronounced you just should not work on antique machinery/equipment with slotted fasteners without using hollow ground blades or you will botch up the fasteners. However, relative to the current debate, two things occur to me 1) To get the performance noted above, the bit has be a very good fit in the slot. My set has I think 85 or 90 pieces. Without that selection and ability to find a perfect fit, their advantage pretty much disappears. Is a watchmaker going to have a similar selection to ensure that perfect fit and futz about constantly checking microscopic differences in fit? 2) Performance is superior, but the metric is torque handling ability. Does this even matter in watching making? My limited experience suggest no. otoh, if you are regularly damaging heads of screws with taper blades than yeah, figure out how to get an assortment of hollow ground bits that work for you....but otherwise, why worry about it? imo there is no debate to be had on what is superior, the debate is simply whether it matters given the torques involved. A young guy I know worked for Roger Smith for few years (talk about a learning opportunity!).....I'm curious on he was taught1 point

-

1 point

-

Nobody needs a 600m diver's watch or for that matter not even a 200m one or a diver watch at all. Diving, even recreational, is done with wrist computers not watches, since some 25 years now. That being said I like to wear a diver's watch often, especially in water. A single piece case construction is simply a sophistication and perceived robustness aspect, which is appealing to some buyers, like a tourbillon is to others, for a different style.1 point

-

1 point

-

Please be patient - there's a lot of work to do. I will announce when ready for sure!1 point

-

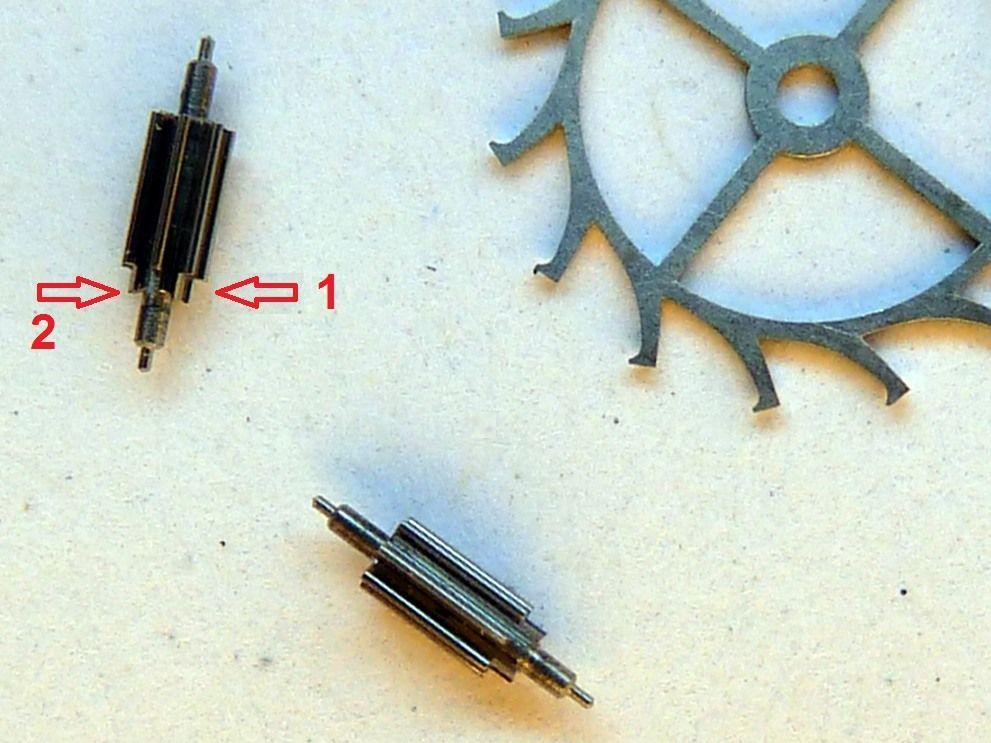

I understand that the following doesn't apply to (all ?) Swiss making, but on contemporary Seiko pinions may not be riveted to wheels. First, no wheel / pinion/ arbor / staff combo is considered to be separable. On the left is the magic lever reduction wheel, on the right the escape wheel and here things get interesting (for the maniacal), the vi pinion teeth are really really small, but it seems to me they are not riveted? Their diameter is (probably) the same as the central section of the pinion, which has been reduced to reduce mass possibly. Of course the wheels seats against a larger section. Please disregard the dirtiness of the parts pictured, these are just from the scrap bin.1 point

-

There is no other way. Note well, it is a 600m waterproof watch, these are normally built with as single piece cases, quartz or mechanical.1 point

-

Think i have some 2472 parts . Can have a look . Maybe the threads ar worn in the setting lever. They look a little short?1 point

-

1 point

-

1 point

-

There's gotta be another way. This is a battery powered watch. Why would citizen make it such a PITA to do such a routine chore as battery replacement? I just can't envision having to remove a bezel and crystal to replace a battery.1 point

-

1 point

-

Indeed, perhaps I should have been clearer, the watches I referred to were not Seikos, but the fact remains that you should not assume things are as they appear.1 point

-

Which tools are you using? For really tight caseback you need either a 5700Z bench opener, or a wooden case holder in a vice and a two handles Jaxa opener. Get either one and you will be fine.1 point

-

1 point

-

1 point

-

0 points