Leaderboard

Popular Content

Showing content with the highest reputation on 06/18/17 in all areas

-

As an amateur hobbyist I find your answers very helpful regardless if the OP responds. So please continue Sent from my SM-T585 using Tapatalk2 points

-

I try and answer as many as I can with the knowledge I have. However some questions I don't because I did not have the knowledge and do not always have time to do the necessary research. Some questions are repeated such as "what lubricants should I use" "what is the best starter kit" etc but the answers to these can be found by simply using the search bar. It is annoying sometimes when answering a question but no feedback is given whether the answer helped.2 points

-

Quite common on "techie forums". I think the answer is more important to the regulars who enjoy solving the problem than the OP. I find it very frustrating when I think I can help. Cheers Neil Sent from my iPhone using Tapatalk2 points

-

2 points

-

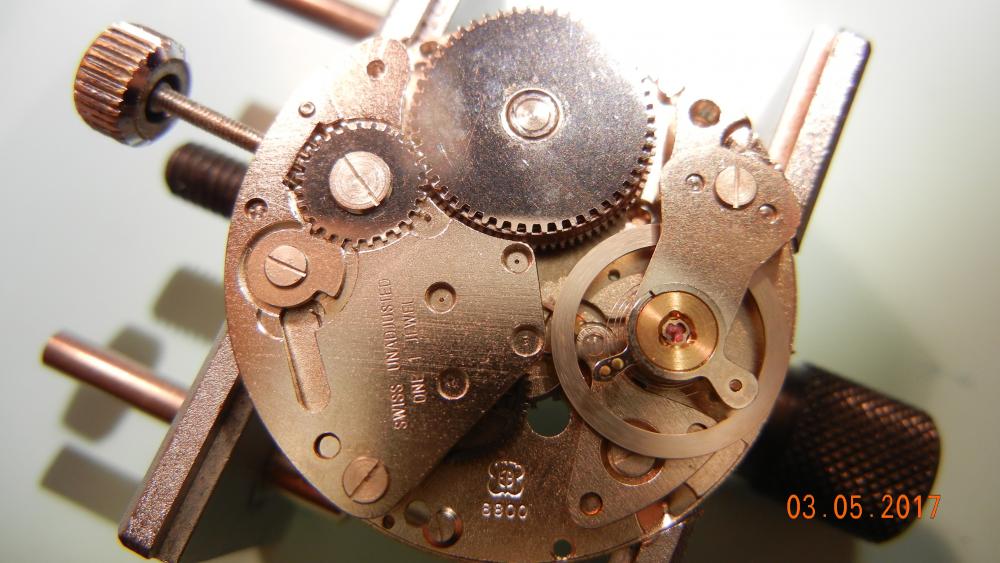

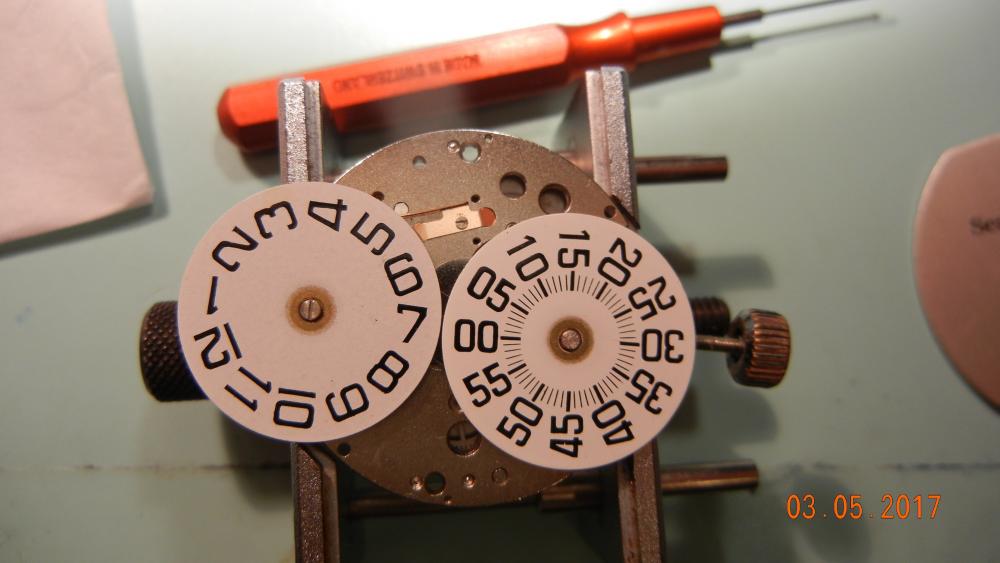

How's everyone doing? Great I hope. Have some time to post a watch that I've been working on. I've learned from experience that the cheaper the watch, the more difficult it is to work on. Here is something from the 70's that represents well that kooky period. The watch measure 40mm x 38mm. The power comes from a one-jewel Bettlach 8800 with a jump hour mechanism on the dial side. An example of what makes this watch a nightmare to work on? For starters, you have to press down hard--and I mean with your body weight--on the stem release button to get it to release. The movement has what I think is a dust cover(why?), which when placed incorrectly causes the balance wheel to rub and stop--but only intermittently so that you go crazy trying to figure out what's happening... Its not me, its the WATCH!! J1 point

-

I have a large, unsorted, quantity of potentially useful watch screws of all sizes and types. Unsorted... I also encounter many missing screws. How to reconcile this problem? Is there any kind of mandrel (similar to the Bergeon hand hole sizing tool) which can be used to identify the size of screw holes? - case screws are the most common culprits it seems. I realise this begs the question of thread pitch but it would be nice to have somewhere to start. Then I might one day attempt the sysyphus-ian task of sizing some of the screw pile. How do others deal with this? Roy1 point

-

With the risk of opening a can of worms? Why are there so many new questions that the OP doesn't answer. We try to help out as good we can but no feedback from the starter of the thread. Makes me mad and sad and don't want to answer any more questions. Whats the good for the forum i the OP doesn't answer our questions or get back if he finds out himself or if he gets the answer on an other forum? This is not specific to any member. It's just in something i have seen lately.1 point

-

Nice watch. A lot of Favre Leubas show up with repainted dials for some reason. I think they were popular in India and haven't aged well in the climate. I like the movement but I wouldn't want to pay for two mainsprings in one service- funny but that's the first thing that came to my mind when I saw the double barrels!1 point

-

Sorry to say but i think that dial is repainted. Movement is a genuine Favre-Leuba though . A so called Twinpower. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Favre-Leuba_259 A really nice movement . It would probably need a service. It has double mainsprings so probably not the easiest movement to start with?1 point

-

Often see the plates on Tradera that has lots of different holes in them. But you can measure them with a caliper. Sizes are usually 0,65 0,70 0,75 0,80 0,85 0,90 So they are often pretty easy to recognize.1 point

-

eBay can be a great source but the bidding can get ridiculous where if not carful the price is higher than buying new. If I really want a tool item I first look at these three suppliers. If worried about wear then if possible I purchase new. https://pennyfarthingtools.co.uk http://www.daveswatchparts.com http://www.execulink.com/~lfoord/tools.html1 point

-

This is exactly i wanted to ask You if this device would do the job? Just was browsing around on the bay and found a digital dial indicator down to 0.001mm accuracy for ~30 USD. It could be turned to a IKA Feintaster. It seems that the measuring poind is detachaeble so i could make a similar measuring point like on the IKA. The IKA deial showing 0.01mm accuracy, so i think the 0.001 should do even if it is not as accurate as stated. What do You think? Or someone has experience with this particular indicator? http://www.ebay.com/itm/Dial-Indicator-Gauge-Digital-Micrometro-Metric-Inch-Range-0-12-7mm-25-4mm-/262993144297?var=&hash=item3d3b9ce9e9:m:m5KZd8qX64Ejlv4_pdZqTfQ1 point

-

1 point

-

£30?... wow. I just bought a really nice set of 18 winders, lovely condition. For £300 on eBay. There really are no alternatives -I'm never going to spend whatever Cousins/HSWalsh want for a new set.. probably nearly £1k... I am no stranger to disappointment losing auctions- Top tip is to be braver and put in a BIG bid with 10 seconds to go on a set you know looks right. the actual amount you pay will of course be just £1 more than the other guys bid..1 point

-

I have just looked at the video and that is bad. If you decide to fit a jewel or a brass bush be careful when you to pushing the cannon pinion back on, you could push the jewel or bush out. The hole in the plate has some nasty scoring which looks as if at some point a hard piece of dirt has been stuck in the hole and has been rotating. The steel that the wheel has been made of is much harder then the bottom plate.1 point

-

1 point

-

Yeah, there are people who have a thought or question, hop on their phone and ask in a forum or two, and then lose interest. I knew someone who would start his post with "Dear Lazyweb - " when he thought he was doing that. Usually these folks are clueless and don't realize how aggravating their behavior can be to the folks in the communities who try to help.1 point

-

It gets me mad too Roger, some folk are just plain ignorant. I'll better keep my preferred solution to myself!1 point

-

Guys, I would appreciate if you could translate your post into English before posting. It allows others to appreciate what is being discussed. Thanks Geo!1 point

-

I have not posted in a while. I'm still loving this new hobby! Just acquired a timegrapher...I just love the ticking noise. Just picked up a watch and threw it in to see it work...now to learn.1 point

-

1 point

-

At about 5 minutes and 50 seconds into the video below they show finishing the plates then how the girl puts decoration on and even one of the templates they used. https://www.youtube.com/watch?v=ys4ChOWYNy8 In the next links they show a variety of techniques and you learn some new terminology like GENEVA WAVES (COTES DE GENEVE) and CIRCULAR GRAINING (PERLAGE) http://www.thehourlounge.com/en/vacheron-constantin-articles/movement-finish-true-mark-haute-horlogerie-557275 http://www.watchwow.com/2013/09/110008/basics-of-movement-finishing?page=2#.V9hSrIJ0-70 Then a different technique which unfortunately uses a really expensive machine but does produce interesting results. Plus from time to time she runs classes with the machines she has. https://mechanicalcurios.com/2016/02/15/photos-from-engine-turning-ii-class/1 point