Leaderboard

Popular Content

Showing content with the highest reputation on 03/05/17 in all areas

-

2 points

-

Scouseget, When you harden metal (steel) it will be more resistant to wear, more difficult to machine, but also will become brittle and more prone to breakage. When you anneal metal (steel) it is in a softer state and easier to machine, but the yield strength (the ability to resist permanent deformation) is lowered to a point where it can become unusable for some applications. Normalizing metal is a process to relieve stresses in the metal in order to reduce warpage when it is machined. This is necessary when machining prestressed metal such as cold rolled steel. Yield strength is a critical factor to consider when machining pivots. This is the major reason the steel must be tempered. Tempering will back the steel down from a hard brittle state to a state between soft and hard. The goal is to maximize the yield strength and still have sufficient wear characteristics.This state can also be called spring hardness. This will be the metal's optimum ability to resist deformation. When pressure (cutter pressure) is applied to the pivot, it will be less likely to break. Spring tempered steel will also provide a certain amount of protection from pivot breakage in the finished product. If you have tried to machine a pivot from steel in a soft state you should notice that it cuts fairly easily but once you turn the diameter down to about .015 inches (.38mm), the pivot will bend and break under the cutter pressure. Even though the pivot is more difficult to cut when tempered to a spring hardness than with the metal in a soft state, the resistance to deformation and breakage provides a way to get the pivot from .015 inches (.38mm) down to the required .004 inches (.1mm). There are alternative ways to reduce the pivot down to the required size such as grinding it down with a stone in a Jacot lathe, but machining it this way can run the risk of getting the pivot out of round and destroying its concentricity. david2 points

-

1 point

-

If it has the same watch case too, you better get your hammer and chisel out. Next time I don't even bother trying to "pop-off" the lid, but make a gap with a scalpel knife and a small hammer first. Chances are that you ruin the flat rubber ring, but I think that's better than scratching the lid or deform the edge. Also, today I put the dial and hands on the movement, but wait for another watch-case to arrive. That case has a back-lid with a screw ring. I'll put the movement in that case for a while until I know for sure that the movement runs fine. Then I'll transfer the movement to its original case, which has then to be pressed-closed........ and stays hopefully closed until the next service is due. Once closed ........... is closed. At least that the story with my watch case, perhaps yours is better??1 point

-

1 point

-

Here it is back in place. The Russian design isn't ringed on the end like the one on the incabloc web site. Instead the closes end of the lyre slips into a retaining slot. My rakita now runs without immediately stopping. Thank you so much for helping. Sent from my iPhone using Tapatalk1 point

-

Wow, very nice. I'm sure that will come in useful. I'm no good on valuations unfortunately. I do know that when it comes to swiss tools you can usually turn around and sell them for whatever you paid though.1 point

-

Okay, well now you've done it. I pulled the trigger on one last night after honoring the late Bill Paxton with a viewing of Aliens. Had a bit of disposable income available and since the Poljots are still in the affordable end of the mechanical chronograph spectrum, it just seemed like the right time. Thanks for the link to the Polmax3133 site too. I'm sure @GeorgeClarkson had referenced that before but I must have missed it! That was a great read for someone like me (someone who can't seem to read enough about horological engineering & history). I've set my bookmark for future reference. I think if it's still ticking after 54 hours then your good to go.1 point

-

LOL, very witty noirrac. My movement is the Ronda 715 LI, which is the same but has a plastic full diameter adaptor to take a larger, 10 year battery. I had another look for the spring today, swept the floor clean, but no sign any where. How does one go about making a replacement? Is the special wire available on a reel or do I just reshape from another similar spring?1 point

-

1 point

-

Oh come on! The chances of two such two similar events occuring under the same circumstances is a bit hard to swallow....1 point

-

Have you seen this video? Might give you some ideas. Watch Hand Restoration1 point

-

1 point

-

1 point

-

Thank You David! Completely forgot this video. Just prepared a steel piece yesterday. Hardened to glass hardness but did not anneal it. Will do it today before start turning. I will turn it in a collet and grind between centers. I am curious how things will turn out1 point

-

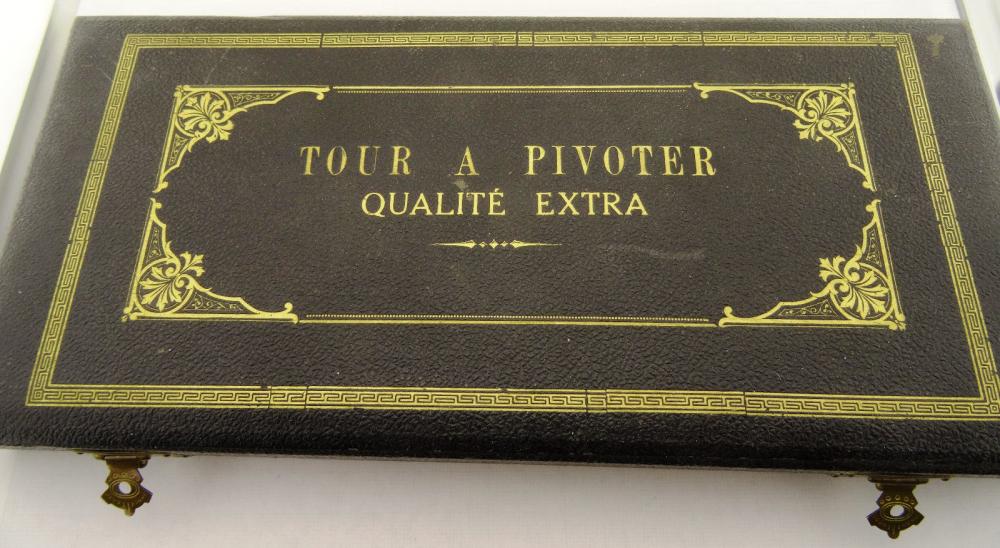

Nice jacot tool with no damage very nice indeed. I presume you found it on the bay.1 point

-

Very nice, its not very often you find a second hand jacot tool complete with the bow. Do you intend to use it or just have it for decoration? Many people just collect tools.1 point

-

Alum is the last resort if all else fails. You don't have to submerge the whole plate.. just make a paste and apply on the screw head. If the opposite end has a 'well' fill that up. Alum usually works best with hot water but that just accelerates the process. Room temp water just takes longer. Anilv Ps.I've come across people recommending mixing alum with Vaseline to make a paste ..never tried it but makes sense.1 point

-

1 point

-

This is a video showing the pivot turned to .01mm over the finished diameter and "burnished" down to the final .1mm diameter. This is not the only process that is used to get the pivot to the final diameter, but removing almost all of the material in the turning operation will help maintain the concentricity of the staff. Tempering steel to a spring hardness will help ensure that the cutter pressure has less chance of pushing the pivot out of concentricity due to pressure from the cutting tool. This is because the pivot has the ability to spring back after the cutter pressure is removed. A higher yield strength gives the pivot a higher resistance to strain. An extremely sharp tool and a light touch will reduce cutting pressure on the pivot but the steel will have less ability to spring back to its original concentric position. There is also the element of microscopic warping due to heat treatment after the part is turned. If the heat treatment and normalization is done before turning, the warpage of the metal will be negabile in the final product. In the end everyone has a different perspective on this subject but this is my perspective based on my background and the many failures I had when I was learning how to do this. david Here is the video: https://www.youtube.com/watch?v=mkGygB7BMsQ1 point

-

@RyMoeller Thank you and I'm glad you liked it The prices of the Plojot / MakTime 3133's are rising, and fast ! The last official 3133 was produced by MakTime in 2011. There was some old stock, but that sold off quickly. There is also the older 3017, but those prices are through the roof. Be aware that there are many Frankens out there. Read this guide first before you dive into them; http://www.polmax3133.com/guide.html Actually, the whole website is an interesting (must to) read: http://www.polmax3133.com/ The demand for the popular types such as Strela, Shturmanskie, OKEAH etc is very high, so the ?!"supply"!? is accordingly. The "Poljot 3133" is still "made" by a big German seller, but it's very unclear where those parts come from (China??), who owns the Poljot license (if anybody?), what happened to the old worn machinery and more of those interesting questions........... very opaque and surrounded by big misty-clouds It seems to me that the current game is "grab-the-authentic-stuff-while you-still-can" ........ Oh, yes, I did an endurance test on the movement. It's still running after 44 hrs on a full wound1 point

-

I just finished working on this Seiko Bellmatic project watch . I received a beat up Bellmatic that had a filthy knicked up case and bracelet , broken pallet fork , broken hairspring , a paperclip holding the band to the case , about a quart of oil in the movement , BUT , nice blue dial and rotating chapter ring . I bought a working Bellmatic on the bay with no bracelet , and Poof !! , it morphed into this very nice , properly working project watch . I have worked on Swiss , Japanese , and other mechanical watches including chronographs . Accutrons , Hamilton electrics ., and AS 1475 alarm watches that are used by a few different Swiss manufactures , But these Seiko Bellmatics are a bit of a challenge to work on . I have the Seiko manual in a binder that has the tech sheets for this watch , and the info goes on for page after page .1 point

-

I am not sure how to make a jewel hole bigger. There was a post on this forum a while ago doing this job using diamond paste & a Dremel. However getting the size hole correct is going to be difficult. If it was me I would just purchase the correct size jewel and replace.1 point

-

1 point