Leaderboard

Popular Content

Showing content with the highest reputation on 01/28/17 in all areas

-

What I thought was a bargain Omega Seamaster Cal 1010, has turned in to the watch from hell (see below*)! At least it's been a good learning experience. I thought I'd finally got it all sorted, but on final checking found that the plastic date change finger (part 1562) is worn, and doesn't quite flip the date over. Cousins want £70+VAT for what seems to be a relatively simple part (now changed to metal, the plastic wearing was obviously a problem). The cheapest on ebay about £35. Is it just rarity keeping the price high ? Anyone know a source of anything cheaper. Thanks Mike * On stripping the watch I was dismayed to find the dial stuck on, the dial feet had been removed. It seems that there had been water damage - the dial feet screws were corroded in, as was the screw for the wig-wag pinion spring. The keyless work was discoloured, but useable once cleaned. Fortunately I found a good new mainplate on ebay for a cheap price. I bought some dial feet, and superglued then on, - I'm very happy with the result. Then I found severe wear in two of the automatic unit bushes and pivots - again a replacement of the whole unit from ebay, I hadn't spotted a damaged tooth on the minute wheel until final assembly. A new one from ebay ! Then today I find the date change finger worn. Arghhh1 point

-

1 point

-

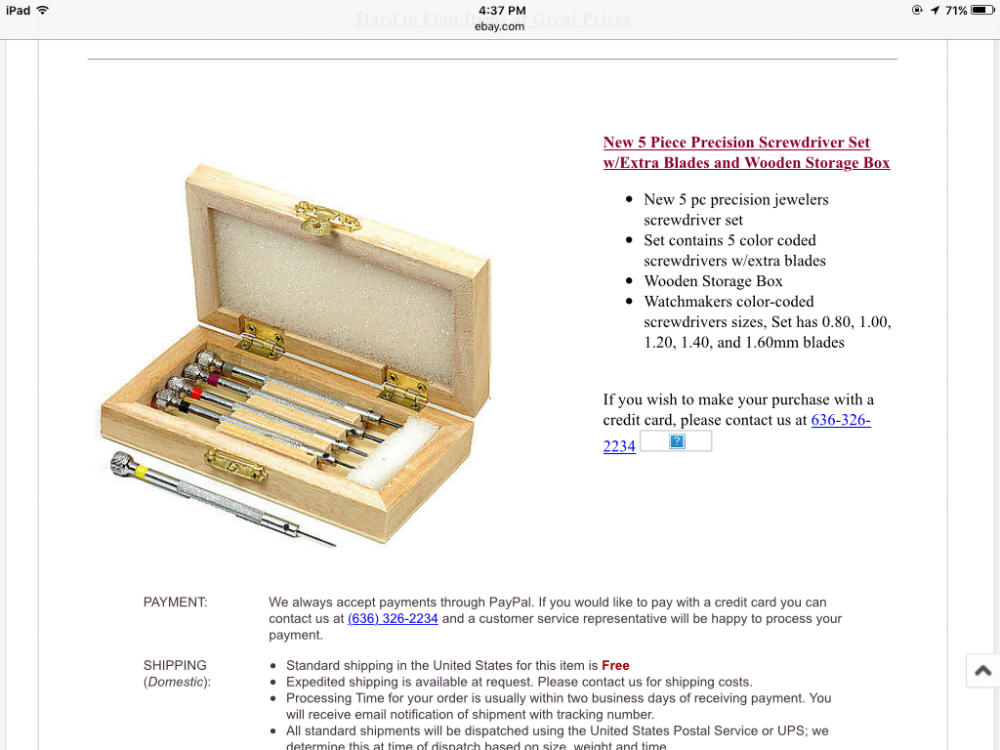

The tool set is handy to get started, but speaking from experience when I bought a very similar kit in November on Amazon, those tools are pretty low quality. The screw drivers especially, there are no bearings on the ends which makes them had to function the way they should. The tips are also very soft which resulted in bent/burred tips which was frustrating to say the least. The case knife is also super soft, which I am sure is partially to help protect cases, but the very first case I attempted to open I ended up rolling the edge of the case knife. The case wrench has a ton of play in the screws which makes it difficult to tighten it and keep it in one place so that it doesn't slip out and scratch the case. Those are just a few personal experiences I have had. I am currently in the process of replacing with middle of the road stuff from amazon, as well as looking for certain pieces as "vintage" on the bay.1 point

-

Many cheap tools are just fine, if all it takes to get them working better is a little refinishing, that's not a big deal really. A good source (if not in a hurry for delivery) is aliexpress.1 point

-

I my early days of watch repair I did purchase two of these cheap Chinese tools. The Crystal lift tool & the hand press tool. The crystal lift tool would not grip the crystal & I had to dress the claws but it was never that good. The hand press tool the plunger would stick when pressed & I had to burnish the shaft for it to work. Since then I have purchased a Bergeon crystal lift tool & a Horotec hand press tool and they worked perfectly from the start. Conclusion cheap tools are expensive in the long run.1 point

-

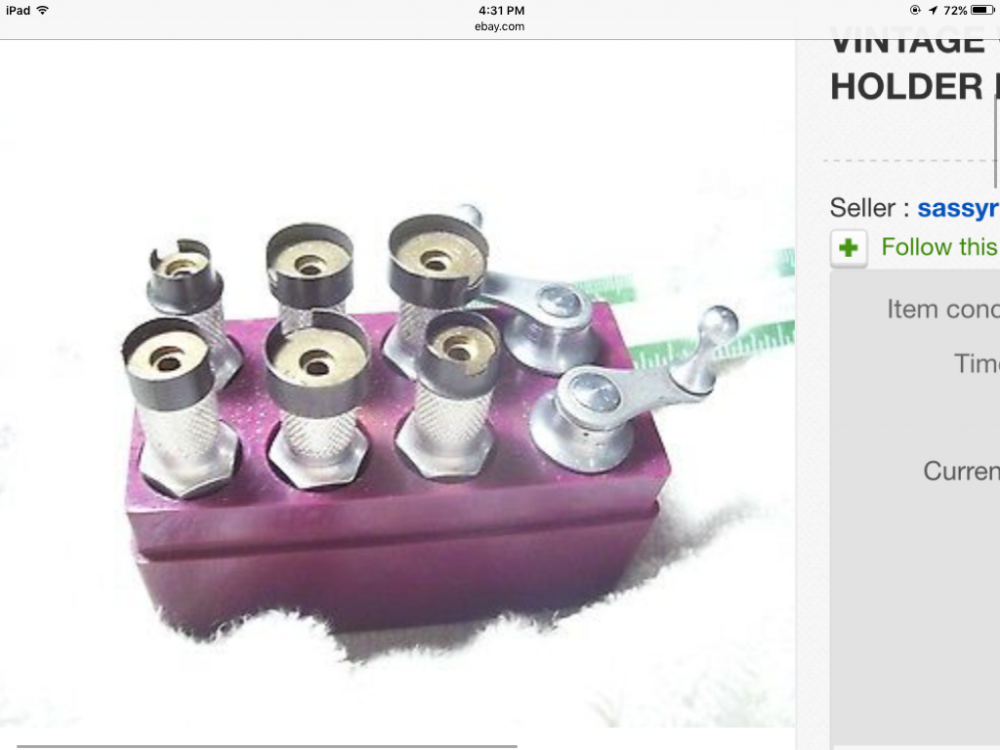

Douglas, To get started you will need a few basic items. These do not need to be ultra high end expensive items and some of this stuff can be purchased from Harbor Freight and Red Rooster UK for not a whole lot of money. 1) You will need something to open the watch. If it is a pry off back you will need a prying knife. If it is a screw off back you will typically need a spanner wrench. These items can be found on Ebay. 2) Once the movement is out you need a movement holder. These can be very inexpensive and can be found on Ebay. 3) You will need a set of watchmaker screwdrivers whose cost can range from inexpensive to very expensive. You can also find these on Ebay. 4) You will need some decent tweezers. Red Rooster UK sells a nice working set called STELLA TWEEZERS for about $30.00. You should also get one pair of Dumont #5 tweezers that will probably cost what you paid for the set of the other sizes. 5) You will need some form of magnification. Bausch & Lomb eye loupes are very good and not horribly expensive. Harbor Freight sells a set for less than $10.00. They are not as nice as the Bausch & Lomb but they do work. 6) You will need a way to remove the hands. The plastic bag/prybar method works well and is an affordable solution. 7) You will need a way to remove the cannon pinion. I use larger tweezers or fine tip needle nose pliers for this and have had mixed results with my cannon pinion remover This is a basic starter set and as your skills improve your can replace and add tools as your budget and interest progresses. Some of the items you posted in your pictures are sold in the Harbor Freight stores at dirt cheap prices. In general watch Mark's repair videos and look at the tools he uses. Most of the work is done with a pair of tweezers, an eye loupe and a couple of watchmaker screwdrivers. david1 point

-

The hand setting press is not really needed in most cases. But you need a presto tool to remove hands.1 point

-

A word of caution the crystal glass remover/inserter is for plastic crystals, not glass crystals. It will break a glass crystal. The tool kit will give you some capability to open up a watch but there's not enough there for actual watch work. Sure, there are screwdrivers and tweezers and these will allow you to change batteries on some quartz movements (I don't want to discourage you but occasionally quartz movements can be challenging even for changing batteries so don't' be afraid to ask others if you feel there may be a problem, which is why this is a good blog to be a part of.). But there simply isn't enough to do serious work. You won't be able to do any escapement work or jeweling, for example, which are commonly encountered problems with non-functional mechanical watches. As for bracelet and band work you'll be very limited. Use caution also with the crystal/case closer. I have one like it and it's a bit wobbly. I replaced it with better ones awhile back. If you want to get serious about watchmaking you're gonna have to get a lot of tools and that's going to be very expensive and many of the most useful watchmaking tools are no longer made. To minimize cost, most of my tools are "vintage" which is to say, used tools; which I get from eBay, trade fairs, "buy outs" which I've managed to find where a watchmaker is selling his tools and we buy them all. Finding good tools takes a lot of research or expert guidance--which is why I finally decided to go to school and learn from a watchmaker with 50+ years of experience. While I've had to fork out real money from time to time, I've gotten some of my tools for pennies on the dollar; or tens of cents on the dollar. But please don't take my comments in a discouraging way. I celebrate those who want to follow the craft. I've still got a lot to learn myself (and a lot to buy). There's still a lot I can't do; for lack of skill, material, or tools. But there's a lot of satisfaction in those cases where I've succeeded. All the best to you!1 point

-

1 point

-

Very innovative! I have a watchmaker's lathe with a drilling tailstock, but I have it in one place and it's not easy to break down and set up wherever I need it. Plus your work gets across many of the essentials of repivoting. I find that to avoid breaking drills I have to be very careful to make sure the lightest touch produces sworf (curlings). If not, then the metal has to be annealed, drilled and re-hardened. Thanks!1 point

-

The crystal is round so easy to obtain, and probably hands also are. But before worrying about that, you need to get yourself some tools, and learn how to use'em. Have a read around, use the search function, watch the videos. That will help you decide if it's something you really want to undertake just to restore one single watch.1 point

-

Front and back pics please? Note, if this watch has sentimental value to you, being your grandpa's, I really, really recommend you learn on something else.1 point

-

Really I have to reiterate my thinking to make ti more clear. In this industry, there is very little relation between what you pay, and what you get. Prices are mostly is driven by passion, interest, and speculation. Spare parts are no exception. You want an better example? One 2mm x 1mm Seiko stem gasket cost 4.5 pounds, and is not like it's rare, or discontinued, or difficult to manufacture. It is because when servicing their diver's watch, most people are OK paying that in order to have "the best possible". Again to answer you question, "why ?": Because that is what they (which is not necessarily Cousins) can change for it, and still sell it. Take it or leave, really.1 point

-

I'm afraid that you are bit removed from the reality of the cost of owning and repairing quality watches. 35 pounds is what, lunch for two or something like that? Omega service prices start from 450 pounds if I'm not wrong, and they expect you to pay that every 7 years or so. And let's not even get to discuss the purchase and service cost of really expensive pieces, or even the cost of books, training, tools, consumables, or pretty much anything that relates to the subject of horology. Watchmaking as an hobby can be cheap as long you are limit yourself to swapping crystals and polishing cases. All the rest it is not, yet I found it too be still cheaper that other hobbies I have or have had. Good luck with your project!1 point

-

I'm sure I will be inspired, confused, dazzled and just generally humbled by the contents of this, but I'm looking forward to every page!1 point

-

Someone I've run across who specializes in (American) trench watch restoration is Stan Czubernat. His website is LRF Antique Watches. He's written a couple of books on Waltham and Elgin watches, and might be able to help you figure out the best direction to take with your pile of trench watches. Good Luck!1 point

-

Welcome! And you'll find lots of answers here. Browse around, tons of great threads, great videos on YouTube from Mark, and a new watch repair course that you can sign up for. Have Fun!1 point

-

Roy, There is a watch restoration virtuoso named Dewey Clark. I think his company is called HISTORIC TIMEKEEPERS and you can look him up on the internet. His email address is: [email protected] david1 point

-

Just a matter of coincidence in the months BHI mag there is an article by a watchmaker who is researching alternatives for parts supply. This guy used to live and repair watches in Canada but now he lives and has a watch repair business in France. His gives an example when he needed a Omega "Speedmaster" staff. His nearest material house supplier (in France) quoted €94. When he was in Canada he used to use the "Bestfit' catalogue system to order his parts. In the "Bestfit' catalogue it has a "Bestfit' staff system which list staffs by size & so if you know the size required to can order either as a perfect fit or some just needing a slight re-work.: "Bestfit" only supply to material houses & not individuals & sadly do not supply to any european material houses. However they still do supply to over 50 material suppliers in the USA. So he made enquiries with "Bestfit' and he was quoted €27 for a genuine Omega part or €6 for a generic part. The postal shipping from the USA to France using International Priority First Class is $7.95. Three suppliers he recommends is as follows: www.perrinwatchparts.com www.julesborel.com https://mccawcompany.com/watchparts.html1 point

-

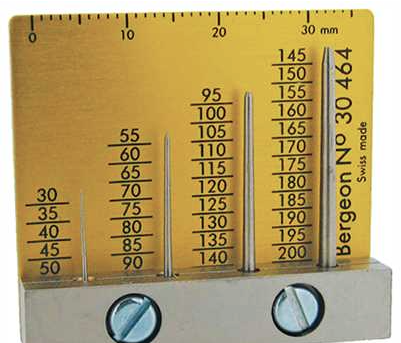

I doubt that a douzieme gauge is going to have the accuracy of a half decent vernier caliper. the ideal tool for the job though would be a JKA Feintaster dial gauge which has measuring jaws/surfaces designed specifically with the watchmaker in mind, however they come with a hefty price tag. Most of the time I find that either calipers (vernier or digital, I use both) or my micrometers are perfectly adequate.1 point

-

1 point

-

If you can identify the movements then there is always the possibility of sourcing replacement staffs new. There are a number of resources that are worth a look including; http://obsoletewatchandclockparts.com/ https://www.balancestaffs.com/balancestaffs.php etc. as well as eBay sellers and so on. I actually have a stock of getting on for a thousand NOS staffs that I have picked up as part of clearance job lots over the years. The only problem that I have is identifying them all as most of them are in glass numbered phials and the relevant index went missing long before I got them. Sorting them and identifying them is going to be a job for a very rainy day indeed.1 point

-

Making balance staffs is a long process and I personally find it very difficult. I have only successfully made one balance staff from start to finish. However I have altered balance staffs from my stock to fit but for me it in still a long trial & error process. Only a hobbyist will bother if a new one is not available as economically it does not make sense.1 point

-

Best book ever -- you'll love it. I used to read it in the library before it was finally reprinted.. I recently bought volume 1 and 2 of "Antique watch restoration" by Archie Perkins, which turned out to be the next best thing to Daniels. Very well written, excellent illustrations, etc.1 point

-

Roy, If you go to a website called THE GREAT BRITISH WATCH COMPANY you can find an article by Colin Andrews about the trials and tribulations involved in making a balance staff. The short answer to your question is no. This is because the manufacturing process to make one balance staff will be the the same for each staff in a quantity of six. It the quantity was 60,000 staffs the equipment and manufacturing process would be more elaborate and expensive put the price per part would be dramatically reduced. YouTube has several old videos of the Illinois, Hamilton and Elgin watch factories. At least one of the videos shows their staff and pivot production operation. CNC machines did not exist in those days but using cam controlled screw machines they could turn a watch pivot in less than a minute. Making a quantity of one or six staffs on a watchmaker lathe takes several hours per staff. david1 point

-

Yes please, I would like to see that... can't promise anything though, since I have been on a "Russian Chronograph Buying Rampage" lately....1 point

-

1 point

-

1 point

-

Maybe I am not properly using my demagnetizer. It's just a cheap Chinese version. I begin with the object at a distance, turn the magnet on, slowly being the item into the magnetic field until it starts to buzz then slowly remove the item until it's an arms length away from the mag. Either way I ran a few tests and maybe you can help me interpret. So first off here is just a spring bar tool that I had laying around that came with a strap recently: I then magnetized it using my mag and got: Then followed the procedure that I spoke of at the beginning to demagnetize. My reading afterwards was slightly lower magnitude than before but still noticeable: And then comes a watch that I just demagnetized following the exact same procedures that appeared to work for the spring bar tool, but repeated 2 times in 2 different directions. I am afraid maybe you are right and that my demagnetizer is too weak to demagnetize the whole watch all at once. And that I will haves to demag each part individually. Appreciate any feedback you can lend. Sent from my iPhone using Tapatalk1 point

-

There have been several Timex forums over the years, the current incarnation is here - The New Timex Forum This is a general forum, not specific to repair. The owner (Mel) is battling ill health at the moment. Since the forum is set for moderator approval of new posts, it can take some time for them to appear. I am sharing some Timex documents, including repair manuals, here - Timex Documents As far as sharing repair/restoration info,tips,and tricks, right here might be the best place that I know of, just ask!1 point

-

Hello Louis, The files (and links) have been updated since this post was originally made. You can find the latest version of them at Images Only: https://www.dropbox.com/s/7gh0lsjpkjhs8ut/StakingToolsAndHowToUseThem1910_1200dpi_ImagesOnly.pdf?dl=0 Images with OCR text: https://www.dropbox.com/s/ktjb8j2hy2rlgym/StakingToolsAndHowToUseThem1910FullTextSearchable.pdf?dl=0 Please let me know if you have any more difficulties accessing the files. Best, Tom1 point

-

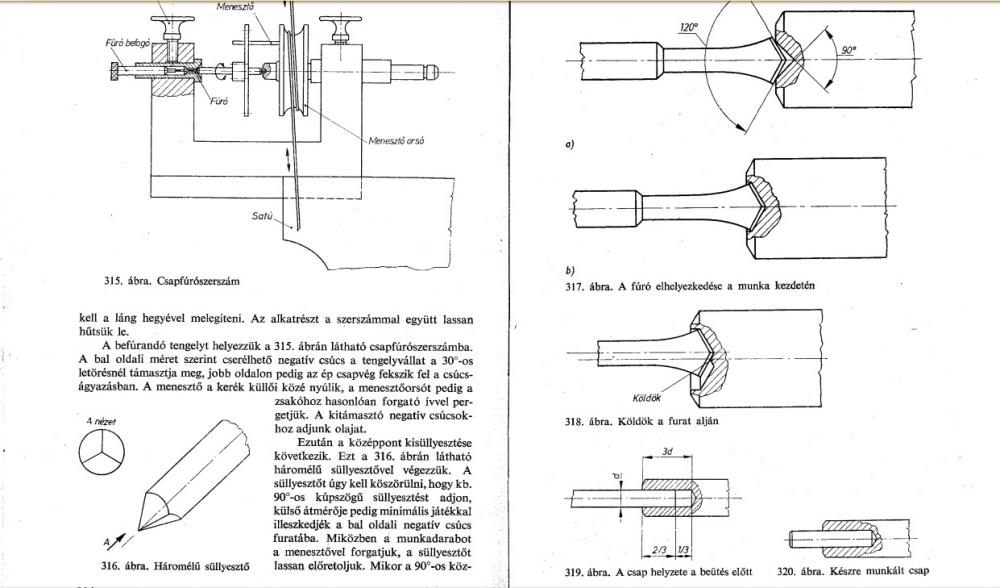

Getting the center with a pivot drill indicating that the tool is OK, leading the drill to center. This is done by the female cone which is also slef-made. Need one for all drill size. Currently i have two. First i file down the broken tip to get a half-cone ended staff. Like on the pictures. That end will made the staff turning centrical in the female cone. Then i use the drill with the corresponding cone which does not allow the drill to wobble and get the initial hole perfectly centered. From this point you can use smaller drills, since the small initial hole will lead the drill not the female cone. See the cross-section of this on the picture posted previously! The book suggests to find the center previously by hand. This goes to drilling tools without drill-leading female cone. On lathes "finding the center" with hand is not easy (at least for me ). Picture 318 showing "Köldök" which will mislead the drill.1 point

-

Learned much from this case however. First, noticed that the drilling bit batch ordered last time is completely is a waste. The cochleate shape of them is deformed and not regular. Second, the method how i wanted to mke this was totally wrong. Now i have found the copy of a hungarian watchmaker book where the procedure is written precisely. One has to drill three time as deep as the diameter of the hole. The pinion with a small taper has to fit in the hole all the way down and has to come off. And then cut it a bit shorter, so if one put it back it will tight fit and not over-stress the hole walls. It is easier to make another pinion until it fits like above than start again from scratch. Now i have shaved the staff and started drilling again... with proper drills1 point

-

Well, this went wrong. The pinion was to thick and/or the hole is to big compared to the staff diameter and/or i tapped it to hard. Not to mention that the drill was first broken in the hole and i had to turn it out first. 1 of 3 staffs repivoted succesfully until now. Need more experience or better tools1 point

-

1 point

-

It is a truly excellent lamp - I was going to keep it packed away until next week, but I could not resist giving it a test :)1 point