Leaderboard

Popular Content

Showing content with the highest reputation on 01/05/17 in all areas

-

2 points

-

Hi all First HAPPY NEW YEAR! My name is Anthony. I am known as the fix it guy by my friends and family. At the risk of sounding immodest I can do a decent job on electrical, plumbing, appliance repairs and carpentry. I usually get interested in something as a matter of necessity, and it is also just in my nature to tinker. Thank God for Youtube. I have a few decent watches that no longer keep good time. So, I guess I'll try my hand at watch repair. While I know absolutely nothing and I know this is a highly-specialized profession which would take many years to be proficient, I’ll take a shot. What the hell, all I have is time. I do have a little of a head start, I use to be a do jewelry repair many years ago, I still have some tools and machinery (i.e.: Ultrasonic machine, steamer, mini lathe, case openers, etc.) I might be able to utilize. I purchased John Tope's, from Tick Tock Productions, watch course (still waiting for it to arrive). In the meantime, I had some Baltic birch hanging around so I put together a rudimentary table top bench. When I get deeper into watch repair, maybe I’ll build a better one. I already purchase a few tools but I am refraining from purchasing anything else until I get the watch course. I am sure between Mr. Tope’s course and the anticipated help for this forum I may learn a little something. I enclosed a few pictures of my setup. It measures 33 X 17.5 x 7.25 Regards Anthony1 point

-

Yes you are right, and this is not the only issue apparently. I also noticed that the dial looks "strange"... Hope I can find pictures of an original, untouched Sturmanskie to compare.1 point

-

Hi all And thanks for the replies. I am waiting for a new battery before I go any further with the Seiko. In the meantime I received my watch repair course a day early. A donor watch also was delivered, a side wind lever set Elgin. The watch is running and seems to be keeping good time. To be honest with you I really like it and hate to take it apart, it even has my first initial carved into it, but I guess some have to be sacrificed for the better good. Wish me luck. Here are a few shots of the victim.1 point

-

I do have one coming. I hope this will be all it takes. Once I get the new one I will disassemble the non working one and post pictures of it. I'm curious as to what it all holds inside. Sent from my iPhone using Tapatalk1 point

-

I agree with Roger above. Measure the distance between each lug to find the error before heading to your Omega shop. I have a feeling it is probably a manufacturing fault.1 point

-

That is strange. In that direction also? If it had a knock it would be bent inwards? Have you measured it? Could it be the endlinks that are different size or bent? Have no idea how to bent that back? You have to send it to Omega to replace the case or for them to bend it back into shape i think? Nice looking watch nevertheless? If you not like it send it to me1 point

-

Theory says that the higher the frequency, the better the accuracy. But wear and manufacturing difficulty increase also.1 point

-

In my opinion most Quartz movements are not worth tinkering with. I would take measurements of the movement and see if there is an equivalent replacement. This table could be useful SEIKOmovementtable.pdf1 point

-

On the bottles a Loctite we have it work I've seen a expiring date although ours have gone past that. Then if you go to Loctite website you find out that thread locker which is what were using is a anaerobic adhesive which means it hardens up in the absence of air. I'm giving you a link to the website they talk about this notice the reference to metal ions? I was under the impression Loctite basically needed metal as a catalyst with the absence of air to harden up. found what I was looking for so works on active metals their definition is brass and copper. As well as passive metals stainless steel and plated surfaces. I notice it doesn't mention steel such as the stem itself. Normally crowns are made out of brass as yours is large I was wondering if it's made out of aluminum? http://na.henkel-adhesives.com/industrial/anaerobic-adhesive-14883.htm1 point

-

Swatch Vs Cousins 1/3 by Micky Aldridge, on Flickr Swatch Vs Cousins 2/3 by Micky Aldridge, on Flickr Swatch Vs Cousins 3/3 by Micky Aldridge, on Flickr1 point

-

@jdrichard I think I know where you missed it. You say 270degrees in one direction and 270 in the other (again, I am referring to the OP video), hence the 270deg amplitude. But the amplitude is only half of that as you calculate it from the rest position (impulse jewel in-between the pallet fork) to one direction or the other. Like the sine wave - it oscilates between A and -A. About he lift angle, it is not as you defined it, but: I attach the full document from witschi Witschi Timegraph - Training Course.pdf1 point

-

I've attached an image out of one of the tech manuals. It doesn't look like lift angle exactly corresponds to the location of the banking pins. So sometimes it helps to have more references so PDF attached. This is another timing machine that more than likely none of us have. Pages 9 through 11 cover what were interested in. So page 11 has a feature unique to this timing machine. But for us it does show what happens if the waveform isn't right numerically you can end up with the wrong results. The most common time of seem this is Chinese machines with super a low amplitude. It thinks it's twice as high because it's reading off the wrong part of the waveform. http://www.greinervibrograf.com/appl/file.php?id=2311 point

-

Wow , nice lume . I put my watches under a light bulb for a few minutes after opening them . I leave the caseback on , but very loose while doing this , and tighten after I remove them from under the bulb . I was watching a Breitling Youtube video where they put the watches in a warming oven for a few minutes before tightening the caseback to remove moisture .1 point

-

A while back after servicing a 6138 or 6139 , I don't remember which , my chrono second had would stop at the 58 second mark . I did some reading and found out that this was not an uncommon problem and I was able to do the adjustments that are in the troubleshooting section of the 6139A tech sheet . I think the adjustment is for both calibers . As I said , it was a while back . Also I remember replacing part # 893612, the intermediate recording wheel holder . It's a bushing that's attached on one of the plates by a screw . I have attached some tech sheets in case you haven't seen them . Checking and adjusting the chronograph mechanism starts about Page 8 on the second attachment and troubleshooting is a little further back . This may be a moot point since you bought a new part , but there's some good info in there anyway . 6139B.pdf Great One- 6139A.pdf.zip1 point

-

Its been raining a bit over the last few days so that's why I've been brushing the dust off all my water-proof watches. I ride a bike to work, the only time I drive if its raining in the morning. Rain on the way home doesn't bother me much but the watch needs to be reasonably water-proof. The Tissot I posted yesterday was fine and survived the slight rain on the way back without fogging up but I wouldn't take it diving as the crown is still an original T crown with the 40 year old o-ring!. For today I'm wearing something a little more modern.. A Seiko 7S36-01E0, also known as the Atlas. From what I know these were available around 2005 (my watch is Oct '05). There is also a black-dialled version which is actually much nicer than the one I have. Problem with this is that chrome/lume hands on a white dial does not make for easy telling of the time. The hand now installed are after-market from a different model and has a black base.. original were all chrome. The crown at 9 turns the internal compass bezel.. handy if I'm lost in the woods but doesn't work around the equator. Also the compass crown turns way too easily so if you're using this to get out of the woods you need to make sure you don't accidentally move the compass bezel. The fact it turns easily makes me doubt that it will survive a 200m dunking but I have used this at the beach and it was fine. Lume is still good. I understand that the problem with Seiko Lume is that it starts to go 'off' once the case is opened and the dial / hands are exposed to air. When swapping out the hand I re-cased it and left it in an air-tight container with a bag of desiccant for about 24 hours with the crown unscrewed. Hopefully it would have removed some moisture. I was in two minds about this as I was concerned that the dessiccant may also dry up the oils. Ah well, I can always re-service the watch but good dials will be hard to come by! Anyway, here are some pics. Original lume on the dial, after-maket hands. Pic after charging the lume with the handphone LED for about 5secs. Anilv1 point

-

I wish to offer an apology for the irregularities of the previous entry. I could not edit the content. But I leave here the link to see my idea on how to improve the sound of a microphone for the application Wach-O-Scope http://reparacionderelojes.weebly.com/watch-o-scope-mic.html Guido.1 point

-

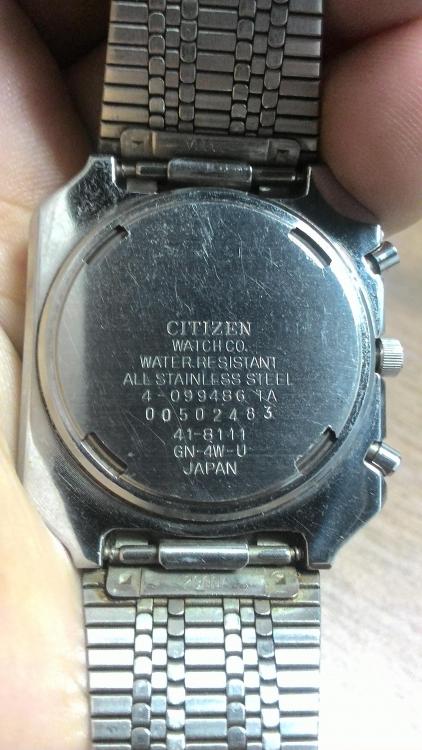

Wearing a Citizen Ana-digi with 8920 movement which I got a few weeks back. All functions work well but the water-resistance is kaput. I'm enjoying while I can but this watch will not last forever as the plastics and electronics will degrade even if kept in an air-tight/light-proof container and buried in a coal mine. Dial is one of those which appear blue from some angles and black from another. The pushers still have its original colour coding .. Happy New Year all! Anilv1 point

-

Hi. I'm currently servicing a Waltham model 1908 pocket watch, and so far, so good. I have cleaned all the parts in an ultrasonic cleaner, using Naptha (actually Coleman camp fuel), with the exception of the pallet fork. I have a few of questions about this process, if you would indulge my ignorance. Will cleaning with Naptha be sufficient in general to clean watch parts? It's so difficult to get alternative cleaners here that I default to Naptha. Will Naptha dissolve the shellac that attached the jewels to the pallet fork, and if so, how shall I clean the pallet fork? In general, does this type of untrasonic cleaning, using Naptha, get into every nook and cranny such that there's no need for additional manual cleaning? How about critical spindles and jewel holes? I see a lot of recommendations about additionally cleaning out the jewel holes with pegwood, but there's just no way I can see of whittling a piece of it down to a size where it will fit into such a tiny orifice so what should I do? Is it absolutely essential to remove the cap jewels or will the ultrasonic cleaning have done an acceptable job of cleaning it up? How about the subsequent oiling of the cap jewels? I use Tri-Flow lubricant, which contains P.T.F.E (teflon) for the mainspring lubrication - any opinions on this such as, "it's awful Roger, buy some Moebius grease instead"? In general, do the same principles and oiling choices apply to a pocket watch as applies for a wrist watch? You'll be happy to hear that, even though we had snow in Edmonton last weekend, it's sunny and warm today, and the leaves are out now - I think winter has run its course for a few months at least. Now if I could only find my shorts and sandals.1 point

-

1 point