Leaderboard

Popular Content

Showing content with the highest reputation on 09/24/16 in all areas

-

So I have done it. I have used my staking for the first time. Here is the video.2 points

-

I had exactly the same happening to me, while researching I learned two important things. The billing/shipping address of the Cousins order need to match the card billing address. According to Cousins it has to be only for the first order, but I've found differently. The customer service representative of the bank doesn't see the charging attempt, but the security specialist does and advised me of the reason.above.2 points

-

Here is the process I used to put back the roller table. Made the video Sent from my iPhone using Tapatalk2 points

-

Ask a lubrication related question and you will get as many different answers as you do responses. However, here is my take on it. Consider the amount of movement and the forces involved at the pallet fork pivot compared to elsewhere in the watch, and weigh up the pro's and con's for leaving it dry. The torque at the pallet fork pivot is probably less than anywhere else in the movement, and the angle of rotation of the pivot in the jewel is something like 5 to 10 degrees. As a result the rate of wear through friction at this point is minimal and so any advantage (from a friction wear perspective) of oiling the pivot is also minimal. On the other hand, because the torque is so small at this point, the effect of drag on the pivot caused by the viscosity of the oil becomes significant, sapping the energy that should be being transferred from the escape wheel to the balance wheel and robbing you of balance amplitude, with a corresponding drop in consistency of rate. So put simply, if you oil it it may last a little longer but the watch won't keep very good time, if you leave it dry it may not last as long but the watch will perform better. I have heard of watchmakers who compromise by merely wiping the pivot with oil so as to leave the thinnest of films on it before installing it. I don't know of any research into the benefits / pitfalls of this approach. Other opinions may differ2 points

-

Well I went for one of these Sundials instead ! Your votes invited Sent from my SM-G920F using Tapatalk1 point

-

One of my favorite chronographs to work on is the Lemania, here is one I overhauled at home two weeks ago for a friend, the hammer had been 'over adjusted' by a watchmaker in the past resulting in not resetting the heart cams correctly, I enjoy micro mechanics and made a replacement with oversized hammers and contact surfaces to allow proper adjustment to be made. The pic on the rodico is it close to completion, spent a little more time on the finish to allow it to 'blend in' as it was a display back, other pic is the completed movement. Time consuming but was a nice rewarding job to work on.1 point

-

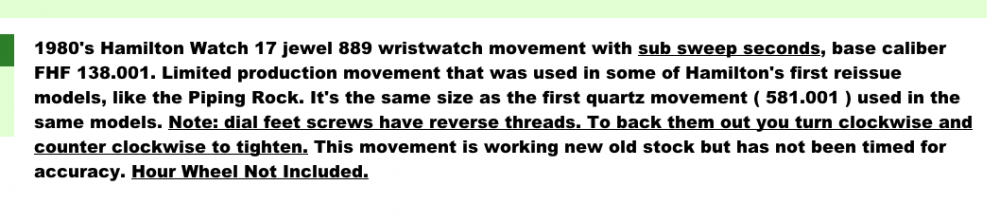

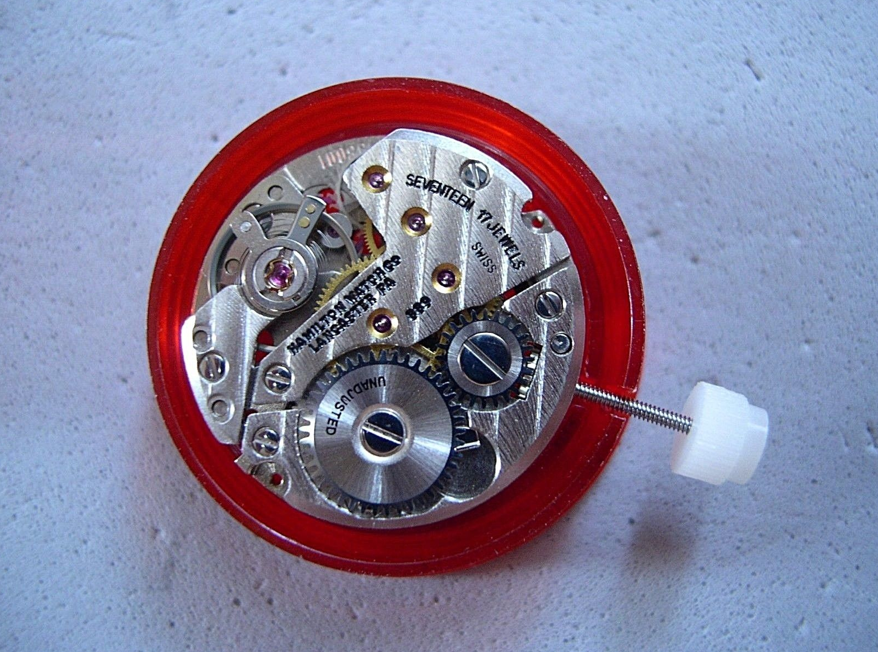

A converted Hamilton for me today.... This is the "Registered Edition" Piping Rock that had a Hamilton Quartz Movement in it until yesterday when I exchanged it for a Hamilton automatic movement . The new movement did not come with an hour wheel so after not being able to find the proper hour wheel for this movement , [yet] , I went rummaging through some old movement watch lots I have had for about 4 years . These junk movements were sitting in the back of a drawer , and there were bits and pieces from different watches with names I had never heard of . There were several hour wheels so I figured I had nothing to lose by trying to fit them to the Piping Rock movement . Would you believe one of them fit the cannon pinion and mated with the minute wheel . I was looking at it and I couldn't believe it . The hour wheel was .06 mm too tall , and the O.D. was a skosch larger than the hole in my hour hand . I carefully filed the hour wheel down .06 mm and finished out the rough edge with a sanding stick . Then I very carefully broached out the hole on my hour hand and fitted it . By another stroke of luck the winding stem with the crown from my quartz movement fit the automatic movement to wind it and set the hands , but the stem from the auto movement is a tiny bit too big to slide into the quartz movement ,....I'll use the quartz stem with the crown attached as the length is correct . The watch has been running for about 8 hours so far with no problem , but I'll wear it for the next couple of days and see if it makes it through the trials . I've attached some links at the end in case anyone is interested in a little history of the Piping Rock . http://www.hamiltonchronicles.com/2012/09/1928-piping-rock.html http://www.hamilton-museum.com/museum http://www.vintage-hamilton-wristwatches.com/2015/03/hamilton-piping-rock-registered-edition.html1 point

-

I recently conducted an experiment to compare the solubility of shellac in isopropyl alcohol and acetone. I put equal size flakes of shellac in small glass beakers containing equal volumes (about 20 ml) of solvent. The shellac did not at all dissolve in the isopropyl alcohol. It did slowly dissolve, albeit incompletely, in the acetone. The acetone was discolored by the shellac. I let the acetone evaporate over a few days. By then, the original flake, somewhat blander in color, was still present. However, the bottom of the glass beaker was coated with hard shellac. I needed to use acetone and vigorous scrubbing to clean the beaker. If I were a REAL scientist, I would carefully measure the weight of the shellac flake before and after its immersion in the acetone. Then, knowing the volume of the acetone containing the decrement of shellac mass, I could calculate the concentration of shellac in a saturated solution of acetone. From that I could calculate the volume of the saturated solution I would need to fill a hole of known volume with shellac, probably by multiple applications. Fortunately, a microdrop of acetone has a very high surface area to volume ratio, and will evaporate quite quickly. I suspect that heated acetone would contain more dissolved shellac, but heating acetone sounds like a hazardous activity. I hope that one of you guys will try this approach and report back to us. —Eric Ohio. USA Sent from my iPad using Tapatalk1 point

-

Very nice, How did the shiny side down work out?1 point

-

Great job JD! Thanks, it is even better with your excellent video! Most enjoyable and educational! Cheers, Bob1 point

-

You can make one out of many things a popular one is piano wire and a bird quill, don't ask me the thickness of the wire I don't know.1 point

-

For some reason, I started experiencing problems paying with my card, the very same card IUve been using for the last couple of years, each time I try to pay for an order, I get transaction failed notice. I contacted my bank, and they said there's nothing wrong with the card, or the cards permissions, nothing has changed etc, So what I ended up doing is applying for a new card from the bank, and this now works, very strange.1 point

-

There is no better book, school or any other information source that can provide a better learning experience than the one you just went through. david1 point

-

1 point

-

1 point

-

CB, I did a test a couple of years ago between lighter fluid and white spirit to see what residue was left after evaporation. This was done by placing an equal drop of each onto a perfectly clean piece of glass then examining the result by viewing the glass in front if a matt black background. There was only one decernable faint ring and to my great surprise it was made by the lighter fuel, not the white spirit.1 point

-

1 point

-

Whether you use water or oil to quench the piece depends on a lot of different factors, including the mass and shape (the heavier the item the more heat it can hold, long thin things warp more easily) of the piece to be quenched, and the way in which it is to be introduced into the quenching medium. In an ideal world the piece will be cooled at the same (rapid) rate simultaneously over its entire bulk, so as to avoid variations in hardness, and warping. Every now and again I indulge in the practice of knife making from stock such as old files, suspension leaf springs etc; material that needs to be annealed to work, and then hardened and tempered for use. The quenching medium of choice is always oil and this is predominantly to avoid warping. The problems with water are it's comparatively low boiling point, and the fact that steam is a relatively good insulator. I use a deep steel jug with a relatively small open surface as my quenching vessel which means that the blade has to be introduced vertically into the oil. If I were to use water then the tip of the blade would enter cold water which would instantly boil creating an insulating layer of steam around the rest of the blade, preventing it from cooling as quickly as it should. This leads to different cooling rates along the length of the blade, which in turn runs the risk of warping, and uneven crystal structure within the blade resulting in weakness. Because of its higher boiling point, with oil you don't get the insulating layer around the work piece, so in turn you get much more rapid, even and consistent cooling throughout the length of the blade. (you also get a pleasing little flame playing across the surface of the oil (pleasing that is if you a bit of a Twisted Fire Starter like me!!)) A shallower vessel with a greater open surface would allow the blade to be introduced horizontally which would probably be an improvement but wouldn't get around the issue of the insulating layer of steam slowing down the cooling process. With parts as small and with as little mass (and therefore only capable of "holding" a very small amount of heat) as watch parts, I wonder how much of a difference there would be between using oil and water. I do like the idea of quenching between two heavy steel block to prevent warping, and I think that I would be inclined to use oil if only for the prevention of rust on either the work piece or the steel blocks.1 point

-

OK, the "A" in the arrow mark is for Amida which is the movement maker. 715 is the calibre. Cousins list balance complete in stock for £15.95 + VAT. They don't list the mainspring specifically, but if you measure the height, thickness, and if you can, the length but if not the internal diameter of the barrel, and post a picture of the outer end of the spring, someone here will be able to identify the appropriate generic spring for you. Good luck1 point

-

get one with didgital camera included or attachable. you will never regret it. vinn1 point

-

Hi Ron, Don't use a screwdriver to remove the collet and hairspring off the balance, way too big and clumsy, your technique is fine but use an oiler instead, much gentler on the collet and usually you can get the assembly off in one easy gentle twist and pull maneuver, with no damage to collet itself. I'm not familiar with Waltham pocket watch staffs but reading your notes I'd say it is a friction fit as when you removed your old one there didn't appear to be evidence of you breaking off the old rivet, this would show itself as a small metal ring being left over. Hope this helps a little.1 point

-

Well done, Colin - I'm very impressed. Sorry to hear about the pallet stones, which have to be reset. Alcohol - great for the watch repairer - bad for the pallet fork! :crazysmile:1 point

-

Well done Colin for getting it back together and running, albeit with a couple of issues. The Muhle that you are about to service is a cracking looking watch with a very nice movement. May I suggest that you pick up another inexpensive movement or watch and overhaul it before staring on the Muhle. Once you have completely serviced a watch and been totaly successful, then service the Muhle.1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)