Leaderboard

Popular Content

Showing content with the highest reputation on 08/23/16 in Posts

-

6 points

-

Not that anyone would have or should have noticed, but I completely stopped coming to this site since the beginning of July. I've had lots of projects going on throughout the summer and I feel bad but since I started selling vintage watches and offering services, my journey here on a daily basis has ended....to the point that I forgot about it for a good minute:( I am aware that no information can be listed here from other sites so all my time has gone into sales and service versus posting tutorials here. I miss coming here to chat and will hopefully have time soon to reflect back and possibly do a few tutorial/service walkthroughs for everyone. They do help you guys, correct? lol Favorite project this summer was a customer's watch -> 1960's Fortis sporting an ETA2622. He reported that it didn't work; go figure. The winding plate was pretty much GONE; the stem chewed through it! Was very exciting stuff but the re-lume and case restoration were the most exciting!2 points

-

Handy chart for checking different Seiko movement coils? https://www.seikoserviceusa.com/img/pdf/battery-no-cross-reference-chart.pdf1 point

-

I have over the years refinished a few Speedmaster MkII cases for friends. They are fun to work on as they are,usually quite beat up och the surfaces have been polished a few times to many. Last week a friend of mine told me that there was a 1970 MkII for sale on a Swedish auction site. I was born 1970 so this watch I just had to have! On Sunday when the auction was about to close the website where the auction was held started to act up and I could not log on......... About thirty seconds before it closed the webpage loaded and I was able to submit my offer....then it was down again......did I win or not!!??, I waited for the usual confirmation mail when you have won an object and five minutes later I had mail, -Yesssssss..... The watch arrived On Tuesday and looked like this: Not to bad, but the sunburst was gone and the top surface had......"straight graining" .....I guess the previous owner used a abrasive rotating mop or something! The case was practically free of deeper scratches and dings so a good prospect for a lapping session! The case was stripped and I started with the sides: I do this part in my small Boley lathe with 90mm discs that I have made and a small tiltable table to set the angle. Depending on the geometry of the case you can either slide the case directly on the table or use a adaptor to get the right angle - in this case no adaptor was used. First run on one side done: First disc is 400P so you have to be careful, especially with the start/edge where the case can grip the disc - and you do NOT want this as you will have a case with scratches in places they where not intended to be! After 400P I move up to 1000P and finally a last run with 2000P. This usually gets the surface almost up to mirror finish but,a quick final touch with a mop gives it,that final shine. When the surfaces are flat and when needed polished, it is time to grain the sides and lapp the sunburstpattern on the top. This is done in a small mill I have with a tiltable spindle using a 305mm rotating disc and another home made tiltable table. For this case I use a 120P paper so you really have to take it slow and be sure all the angles are set up correct or the disc will chew material in places you do nor want it to! The result I was not 100% pleased! There where some spots there the graining did not go al the way up to the grained edge around the glass. This was obvious in the pictures and reflections in some angles on the wrist - I relapped to top surface.... Some grease from my fingers on the chamfer in the pictures but the graining is better now! I am waiting for a NOS dial and crown - when they get here I will strip and clean the movement as well.1 point

-

1 point

-

1 point

-

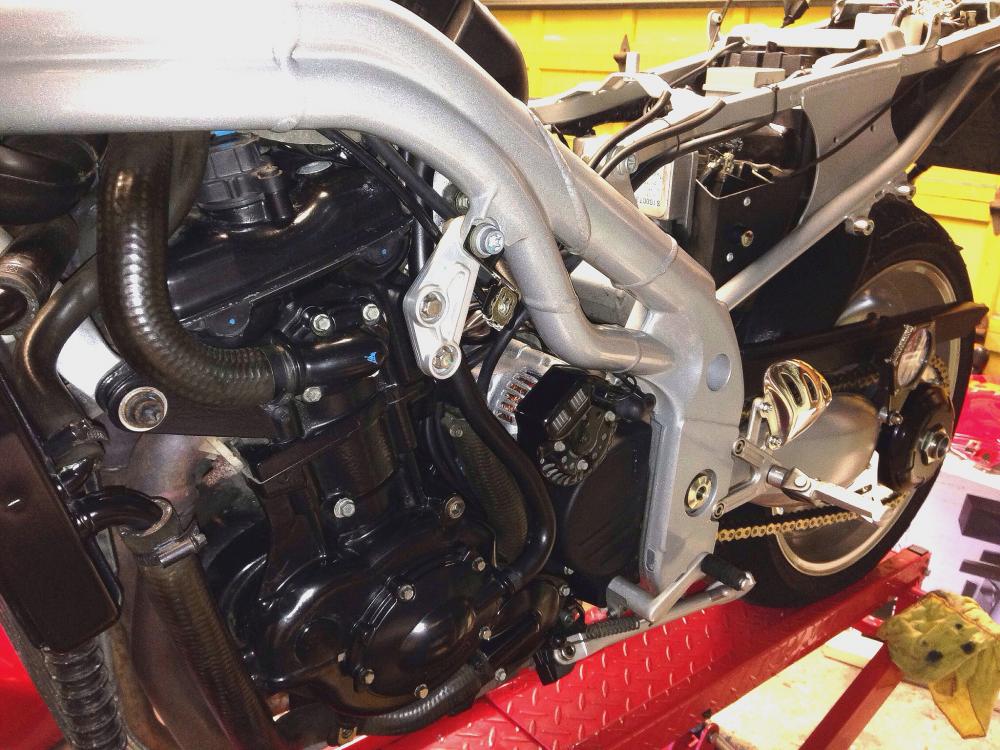

Looks great! (I forgot to mention I was also a bit of a petrol head in my intro! I guess my profile picture gives it away!1 point

-

Class work GEO [emoji3] My attempts are a pale imitation of your standards of workmanship in both watch and bike restorations. NAD1 point

-

1 point

-

1 point

-

This Longines should arrive this coming week. Cal 12.68Z movement Comments very welcome.1 point

-

1 point

-

1 point

-

Never enough hours in a day. Nice to know you have been hard at it, and to see you have popped back to let us all know you are in fine health.1 point

-

The case is presented to disc at 270deg as close to the edge as possible and at the horizontal center using a tiltable table shown above. The case is rotated in this location using a specialy made holder/chuck and "viola" you have a sunburst pattern! As the length of the case in contact with the disc is so short the brushing will be almost straight, but it will NOT be perfectly straight - that is the reason I want as big a disc as possible! For now I have settled for 305mm as this is the largest dimension I can get pappers for - easy! I'm using standard paper right now but have a set of old cast iron discs that have been used by my grandfather to lapp using glue and a special absrasive mixture he had when lapping diamonds. To use them I firs have to renovate the matching headstock of the lathe he used - but I think it will be woth while as that lathe will be a good base for a more advanced lappingmachine! Here is a video of the principle for getting the pattern: Sunburst lapping a Omega I like to use a much lower rpm setting and use a fixture for the watch case - but thats just me! Here is another machine1 point

-

Learned much from this case however. First, noticed that the drilling bit batch ordered last time is completely is a waste. The cochleate shape of them is deformed and not regular. Second, the method how i wanted to mke this was totally wrong. Now i have found the copy of a hungarian watchmaker book where the procedure is written precisely. One has to drill three time as deep as the diameter of the hole. The pinion with a small taper has to fit in the hole all the way down and has to come off. And then cut it a bit shorter, so if one put it back it will tight fit and not over-stress the hole walls. It is easier to make another pinion until it fits like above than start again from scratch. Now i have shaved the staff and started drilling again... with proper drills1 point

-

Welcome back Jeff. Post some pics of any of your interesting encounters so we can all drool. PS love the Fortis a real stunner.1 point

-

welcome Pip; one should learn about watchmaking [disassembly AND reassembly];there are several ways to do this; trial and error, read a book, watch a video AND take a course right here. good luck and God's Speed. vinn1 point

-

Hello pip welcome to a great forum. Yes clockboy has done the right thing by pointing you towards marks new watch repair course I'm sure you'll learn alot. But everyone on here is always pleased to answer any question you may have.1 point

-

I ultrasonic cleaned them a few at a time to get rid of crud and dirt then put each one in a hand held drill and cleaned them with very fine grit wet and dry paper then each one with wire wool. The punch ends which had a flat polished surface I left I only polished the shafts . Took me about a week to do the whole lot.1 point

-

Very, very nice. The small bezel/all dial with the sub seconds hand is right up my alley. I like the numerals, markers, hands, logo, in fact, everything!1 point

-

1 point

-

It does have a speed regulator on the trigger. I was wondering if it had a hammer setting to dislodge the real crud?1 point

-

Welcome Labelle I suppose I started tinkering seriously with watches with the purchase of my first Waltham pocket watch. As for tools think most of us have made the mistake of buying cheap tools ! You probably will never stop buying tools in this game but the best advice is to buy a basic set of Bergeon screwdrivers or similar. A decent set of tweezers but far more important, learn how to "Dress them" (Shape them) Tony Sent from my SM-G920F using Tapatalk1 point

-

Hello Lace, there are lots of experienced watch repairers on the forum that will help with any problems and a search through the forums on a particular topic will often provide answers. As for tools get better quality ones as you need them, for instance if you were to try to service a watch such as an ordinary mechanical that is still ticking bought from the bay choose a simple one, perhaps with a face that only has a second hand, hour and minute hand as a starter then take it apart but take pics at each stage and you will have a record on how to put it together after cleaning the parts with lighter fluid / is Naptha or the like. The tools you need will become apparent as you go and if you arrive at a problem you will have a pic to post to evince the help you need. Oils are a whole subject on their own but unless you have bottomless reserves when starting out get a cheaper "watch oil" that will suffice for your project, and take your time. If you have to force something there are three common possibilities something is wrong with it or with the way you are trying to do it or the tool you are using. I like tinkering with watches and have serviced a few now but I make plenty mistakes as well and the guys on the forum have helped me out and I am sure you will get help if needed. Cheers, Vic1 point

-

Greetings and Salutations! I got started by watching Mark's videos, and following some other online tutorials that I found. As far as tools, don't forget the optics! Can't work on what you can't see. Lots of options available, there are some good threads here on choosing something to magnify those tiny bits.1 point

-

Greetings and welcome, to answer your question: Screwdrivers, tweezers, movement holder, case knife, dust blower, as cad101 mentioned above, don't go cheap, but you don't need to spend copious amounts if your only going to be tinkering, a clean well lit area with plenty of space for parts and disassembly is crucial. There are plenty of vids here and online to help you get a better understanding of how watches work. As with any hobby or interest you have to start with the basics, I'll admit it took me a while to get the hang of manipulating tiny screws, so good hand dexterity is also a plus, and pack your patience, if at first you don't succeed keep trying, often parts will find a way to fit when you least expect it!!, finally, practice on lower grade watches until your confidence increases, don't expect to learn overnight and do take pics of your strip down in phases. We're here to help if you need it. p.s. that's one tiny violin house1 point

-

1 point

-

Hello LaBelle and a big welcome to the nicest and most knowledgeable watch repair forum there is ( well that's my opinion anyway) I would agree with clockboy full heartedly don't by cheap tools just because they look ok trust me there not if you intend to stick at this hobby it pays to spend that little bit more. And a running pocket watch movement is a great piece to work on. Just practice stripping it down take photos of every step so you can work backwards to reassemble it and see if it still works do this over and over again until you get that feeling for your drivers and tweezers and you can handle parts with confidence. Good luck and have lots of fun and don't forget everyone is here to help so don't be put off by asking what you might think is a stupid question we all had to learn and if you don't ask you don't learn. Mick P.S That's an impressive pic.1 point

-

Wow what an introduction. Welcome LaBelle to this forum. Plenty of help for you on here. I started in this line of work by serving a 5 year apprenticeship then another 2 years as an improver. During this time I decided I wanted to concentrate on the better quality antique clocks. The work shop that I worked in was very well equipped. I've been retired now for many years. When it comes to tools buy the best you can afford, lots of info on here when it comes to tools.1 point

-

Welcome LaBelle. Lots of guys here to help & advise. The first rule in my opinion is don,t purchase cheap tools because you'll have to replace them anyway. Quality tools if looked after will last a lifetime. There are courses in the USA & I am sure some of our USA members will guide you to them. If you are going to strip a mechanical watch I suggest perhaps a low grade pocket watch. The parts are bigger so easier to handle. No question to trivial with this friendly forum enjoy. PS great pic.1 point

-

The magnification is OK but how good are the optics !!. This is why I chose Bausch & Lomb & the Olympus. They are not cheap but I think the quality of the optics is important.1 point

-

1 point