Search the Community

Showing results for tags 'omega'.

-

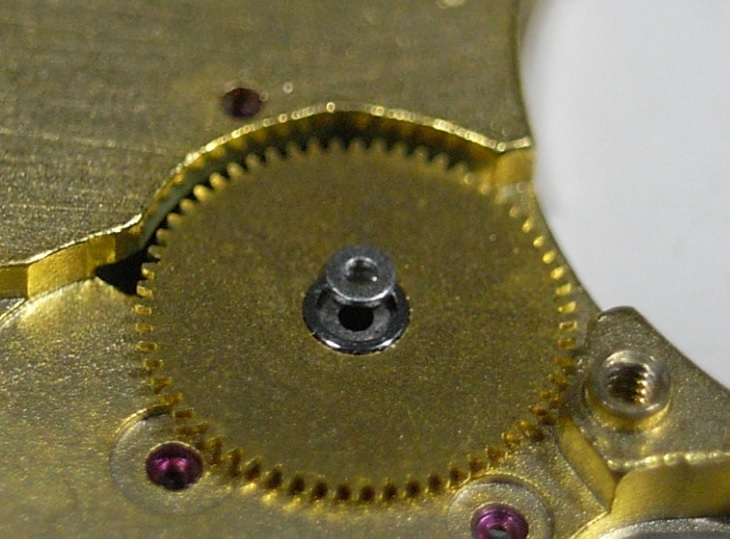

Omega 620 Complete Service I'm servicing a nice vintage Omega DeVille for a friend at work, and I promised her I'd post a walkthough of the service online so she could see the progress. It's an old 2 hand mechanical, which is rare to find in the DeVille range these days, and it has nice patina on the Dial. Along with the service to the movement, it will need a new leather strap, as the original one has succumb to age. I'm glad that the glass is in good condition, as replicating it would be an endeavour to say the least; and fitting a standard flat glass would take away from the elegance of this timepiece. It's only fitted with a dust-proof snap back, so I was expecting to see the normal amounts of corrosion on the stem, and keyless work. But I was pleasantly surprised to find virtually no corrosion on the stem or movement. So this watch has definitely been well looked after, and from the markings inside the Caseback it has also seen it's share of trips to the watchmaker for servicing in it's lifetime. From my initial inspection the first issue I noted was a suspected broken Mainspring, as the Crown spun freely whilst in the winding position with no resistance felt against the Click. Now the watch is open, and can see there is damage to the Crown Wheel and Ratchet Wheel, I am even more confident my first thoughts were correct; but I'll know for sure when I open the Barrel. There are also a couple of fibres inside the case. You can see one here resting on the incabloc setting of the Balance. So a good clean and service, along with a new Mainspring, should see this little 620 movement running nicely for my work colleague. I don't have time to strip the movement and remove the Barrel until the weekend. But in the meantime I will get pre-approval for the purchase of a new Mainspring from the owner, so once I've removed the Barrel and confirmed it's broken I can place the order. Is the Mainspring truly broken? Will the owner agree to spring for a new Mainspring? Does Mark enjoy wearing 70's disco outfits at that Retro Nights more than he lets on? All these questions and more will be answered in the next episode!! So stay tuned .... same Watch Time, same Watch Channel!!

-

Hello all, I am restoring an old Omega Geneve with Cal 601 and while I was disassembling the movement I neglected to note the position of the 'pressure spring for sweep seconds pinion' against the leaves of the actual pinion itself. Should the spring provide pressure to the pinion against the pinion cock (underneath the leaves) or shall it be positioned providing pressure against the top of the leaves (between the cock and the leaves) so to push the pinion towards the watch dial? Any clarification would be appreciated. Thank You

-

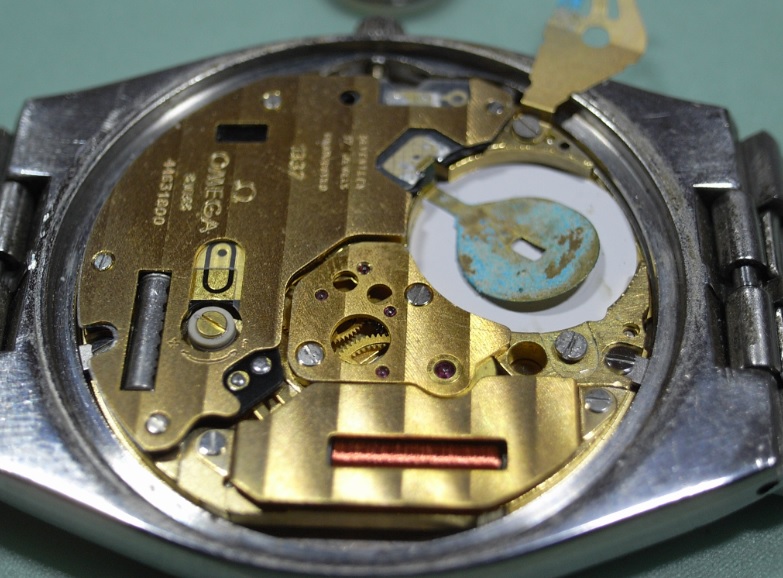

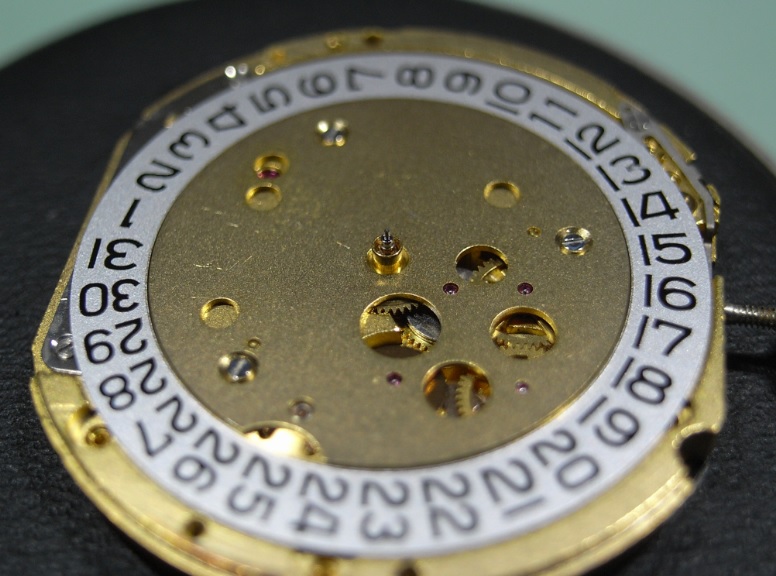

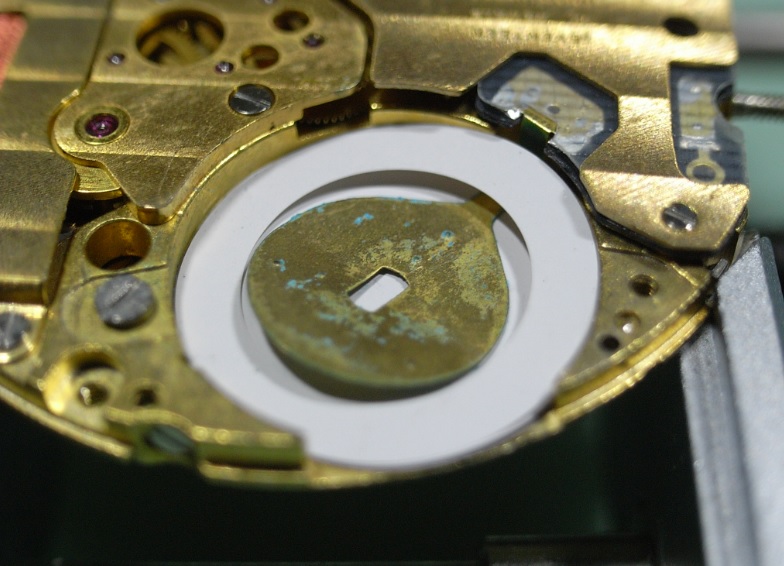

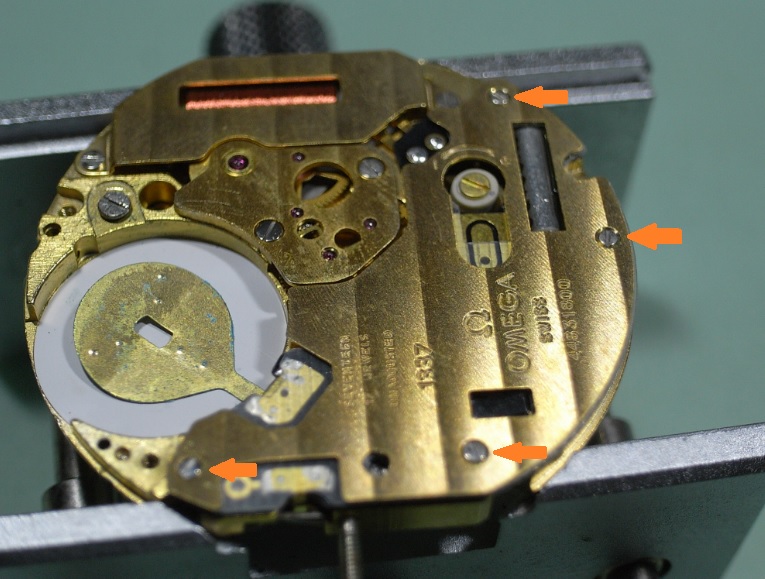

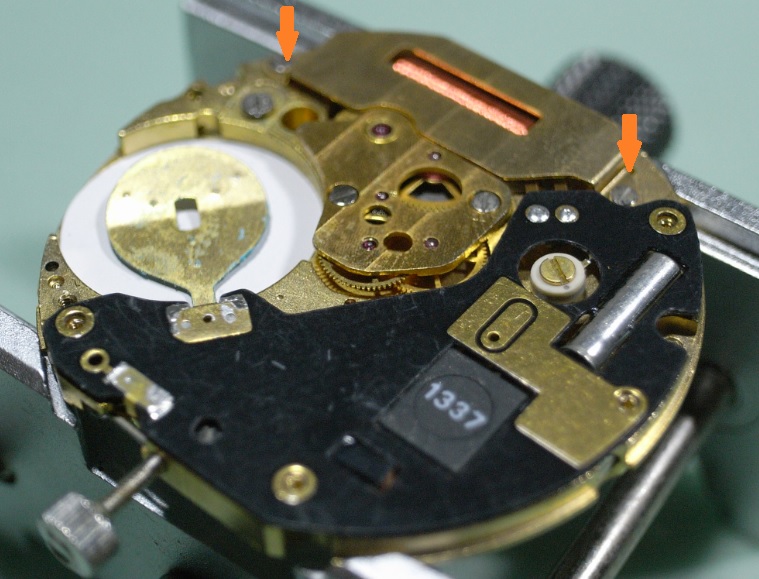

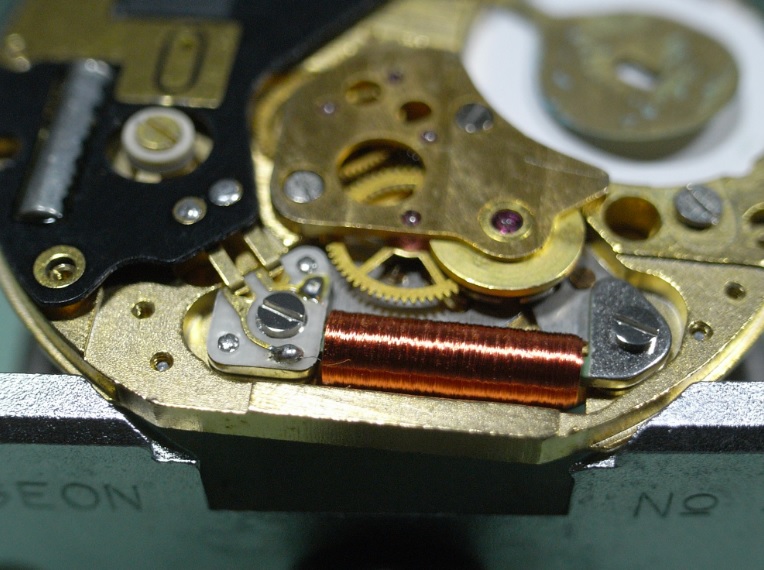

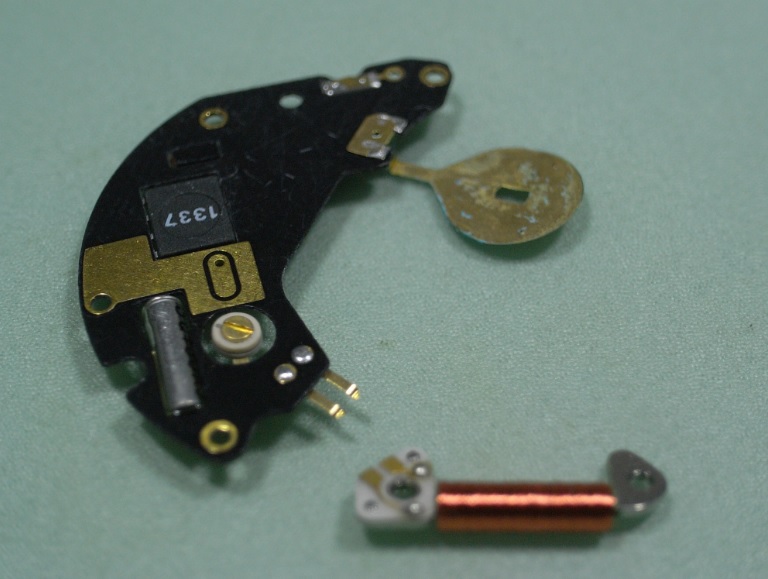

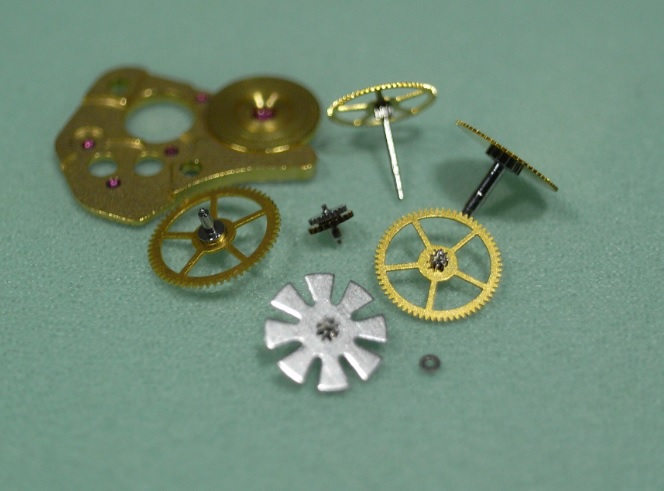

Hello fellow watch freaks. It's been a while since I've posted a service walkthrough, but I had an accident that destroyed my left shoulder and needed surgery. It's been a rough 6 months for me, with a LOT of soul searching throughout my recovery period. But I'm back on the bench ... at least at home anyway; work is a different matter, and my close friends on this forum know about that ... nuff said. This watch is owned by one of my older brother's friends. My older brother is one of the most selfless people I know, and has always been there for me. So when he asked me to do this for him it became TOP priority. It was the first item his friend purchased after he left school and began work: so there's a lot of good memories tied to this watch. As you can see it's an older quartz Seamaster with an 1337 Movement. On first inspection you can see water damage to the Dial @ 3 o'clock. So I wasn't expecting to see a happy movement inside. But when I got the Caseback off things didn't look too bad at all. Just a bit of corrosion from a cheap nasty Chinese battery. The movement still looked nice and shiny and the Stem only had a touch of rust up near the Crown. So this watch looks like one we can save :) Disassembly OK, lets begin. Fist remove the Hands and Dial from the movement. Again, absolutely no moisture damage under the Dial ... this made me VERY happy indeed. So on to the Movement Holder it goes. Remove the Battery Clamp and Insulator Ring. Then remove the 4 screws that hold the Circuit Cover. Note that there is an insulator under the cover. It is very delicate, so great care should be taken when handling it. Once the cover is removed the circuit is exposed; but before removing it, unscrew the 2 screws holding the Coil Protector and remove it. Then unscrew the Coil, and remove the Circuit and Coil. Place both the Circuit and Coil in a safe place to avoid damage, as this parts are obsolete, and if damaged you'll have to scour the internet for a donor movement ... good luck with that!! Next remove the Train Bridge Here is a reference photo of the train. As you can see, the Rotor is a very different looking animal to the modern ETA rotors. Carefully remove all the wheels, and store the Rotor in a safe place AWAY from the rest of the parts to be cleaned ... as this has to be hand cleaned due to it being magnetic. Please Note: There is a very small washer that fits between the minute wheel and the extended pivot of the Second Wheel. Be sure to identify it, and make sure it's put in the small parts container for cleaning. Here's the complete train removed from the movement for reference. Flip the movement over in the holder and remove the 3 screws of the cover that holds the Calendar Ring. As you can see that Motion Work and Calendar Work are fairly complex on this movement. Make sure you take good reference photos and study them carefully so they are not confused with wheels of the train. Remove the Calendar Ring. Remove the Motion Work and Calendar Work. Here's the complete Motion Work and Calendar Work removed from the movement for reference. The Crown and Clutch should now be able to be removed. Flip the movement over once again to tackle the Keyless Work Unscrew and remove the Setting Lever Spring. Lastly unscrew and remove the Setting Lever, Intermediate Wheel and Yoke. The Omega 1337 Movement is now completely disassembled and ready for cleaning. I will post the assembly soon.

-

The watch is an Omega cal.601 from 1969 and I bought it about a half a year ago. The watch had this weird sound in between the pallet forks ticks, sounds a bit like a metall releasing tension, witch made me thinking its either the mainspring or the hairspring. I've now disassembled the watch, cleaned all the parts, replaced the mainspring, oiled the jewels and put it back together. I noticed that the hairspring sounded quite a lot then I tried spinning it without the escapement in place, do you guys think the sound comes from the hairspring? Can I correct it or must I buy a new one? clock tick.mp3

- 3 replies

-

- Omega

- Ticking noise

-

(and 1 more)

Tagged with:

-

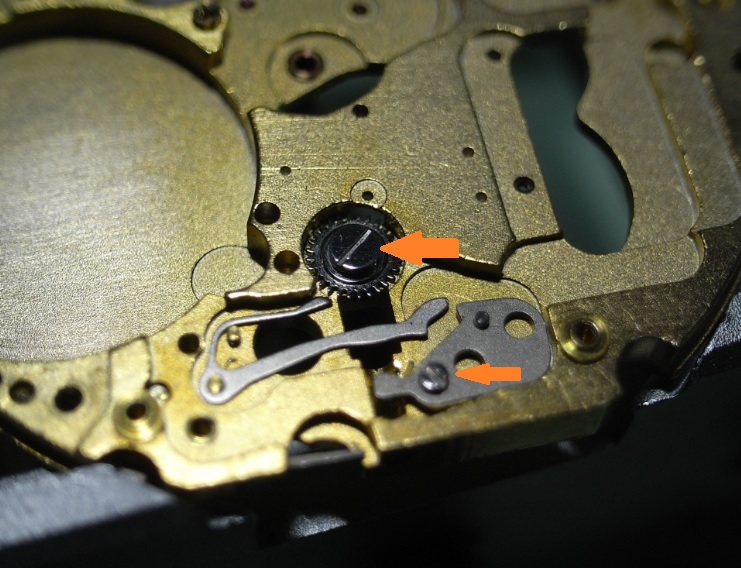

Hi People :) I have an short Question maybe someone can help me out? I am here with an Omega 1138 Despair :) Ok let me Explain the Problem... I have Service the Complete Movement... The Base Movement Runs nice and Strong now... But the Added DD Modul that are on is the little prob... All at the DD Modul is Working Fine only one thing not... When you Start the Chrono and Stop them and Press then Reset the Chrono Hand didn´t Move to the 12 I mean if you Reset them the First Time it Reset at 12 if you Reset Second Time it Reset to 12:01 if you reset again it Stops it Reset to 12:04 for exsample... When i Move the Chronohand Freely without Press Start/Stop and i Reset them they Reset always Perfect to 12 Could it be that the Chronograph Wheel is Bad? i have check them... I can´t see any Damage on it... And the Gear self Rotate. Second thinking was the Clutch Wheel i have check them too and seems also ok. Or could it maybe the Clutch Spring ?!?? I hope someone have an idea!?!? ;) Many Thanks...

-

Hello All, Though I'm late, but Merry Christmas and Happy New Year. I did it. With Marc's videos and your encouragement I was able to service a tiny Omega DeVille Cal 625. The watch had issues with the stem settings and it turned out that part of the Setting Lever Spring was broken. It actually fell out when I opened the case. So I ordered a new spring and a mainspring. When the parts came I proceeded. I used up a few cartons of cigarettes (for all you anti-smokers out there, I know I should quit but...) because that thing is tiny but I was able to take it apart, clean it and more amazingly put it back together. I actually made a couple of YouTube videos about it but I had to take out the sound (too much cursing). Actually I took the sound out and replaced with No-Copyright music because I had the music on and those songs are copyrighted. Anyway, thank you all for you support and thank you Marc for all the useful videos and great advise. Onwards and Upwards (by that I mean Onwards: more watches and Upwards: normal sizes) Cheers, Maz

-

Hello all, I reside in Holland, but originate from London. Hit my mid 40's and became a watch-nut - go figure? I think the main reason is that, as hobbies go, Horology can be hidden nicely away from my wife's eye's. She currently thinks I am saving up for an Omega Seamaster - and doesn't realise it is already stashed safely away in my watch box! Happy days!!! Regards, Dutch.

-

Just uploaded my new video - didn't plan this one, just a bit of fun. It's an Omega strip down and the watch came alive ! :D

- 12 replies

-

- 2

-

-

Hi everyone :) My very first post here on WRT and im hoping some of you clever chaps out there can help with a few things. I have an Omega pocket watch ( well actually its wristwatch size but pocket watch movement ) which im currently stuck trying to repair, the issue is not whether its fixable ( luckily ) but rather which caliber it is. I need to order a stem that will fit the watch but it is proving difficult as without a clue to the exact caliber i can not reference the right stem. I can provide photos if needed but the movement is just like a scaled down version of the 40.6 Omega that is well known to most in the business. To give a better idea the movement size is below ( measured with Vernier ). 15 Jewel Lever Escapement ( Dated 1915 ) Inner Diameter - 26.00mm Outer Diameter - 26.90mm The watch it belongs to is a WWII ? officers trench style watch. I have tried various similar omega pw stems with some success ( a cal 38.5 stem was closest ), but im still perplexed as to what to do. Any help would be greatly appreciated :) Also does anyone know of a book or somewhere online with good info on Omega pocket watch calibers ? ( i love restoring them but don't always know which cal they are :( ) Thanks in advance for any answers MrBeat

- 32 replies

-

- Omega

- pocket watch

-

(and 1 more)

Tagged with:

-

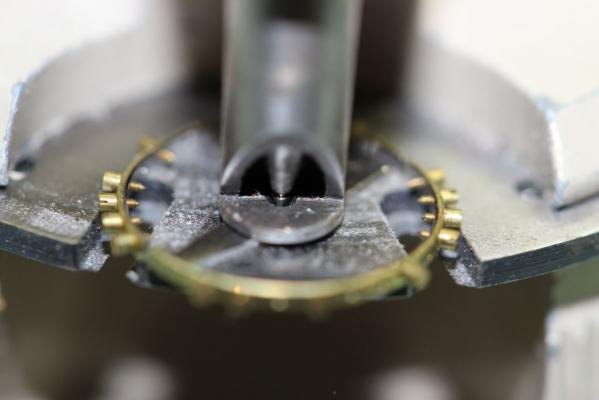

If anybody want's proof that WD40 and an Omega Seamaster Co-Axial does not mix well then take a look below. Be aware - these pictures are quite graphic... And yes, the balance spring is bent as well... I truly am not sure I will be able to revive this as the co-axial parts are restricted, but we shall see how this turns out - I am not too hopeful though.

-

Just uploaded a new video. This one is one of my favourites, an Omega Military watch from the mid to late 40s. It had a broken balance staff, impulse jewel and the pivot on the centre wheel had a groove worn into it. I didn't film the lathe work but managed to get quite a bit under the camera. I hope it's useful to someone. Some pics:

-

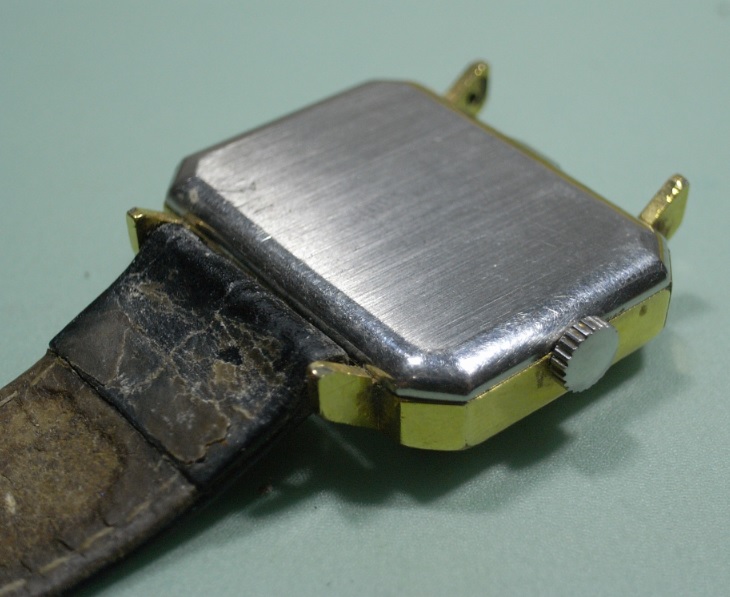

Hello all, With my success (through this forum's help) on my classic Rado, I've decided to try another battery replacement on what I believe is a more complicated watch. I've not worn this watch for decades due to outrageous price for battery replacement. However, with this forum I hope I can get some help on how to do this properly. There are four screws on each corner of the backing. I believe the screws are holding the top case with the glass or crystal thus access is through the crystal. However, if this is the case how do you remove the winder's crown to access the back of the movement? I do not believe the four screws are holding the stainless steel backing for the stainless steel backing also holds the wrist band unit. Any help is greatly appreciated. Here's a couple of pics.

-

I've just refurbished a rusty 1164 movement following marks video of the Valjoux 7750. It running like a dream. I have a new seamaster 300m dial for it but now need some genuine omega hands. Anybody know the ref numbers for silver skeleton hands to fit the 1164 please. Also while I'm on the subject does anyone know a site that references omega cases and compatible movements that fit? Thanks all !!

-

Just about to service my old Omega Seamaster Automatic in a 165.003 case (15ct rolled gold with s/st back) with Cal 552 movement but need some help before I go further. Serviced (very badly) about 15 years ago (but not used much since except for last 2 years or so) and I remember sending it back as movement was loose in the case!! Just opened it up to find gouge marks in it which appear to have been caused by screw or something jamming under rotor and only 1 dial screw fitted ( I have a new one ready)!!! However it still runs well but is obviously ready for a service. What I would like to know is;- 1. Was there a dial washer fitted to this cal/case combination (none currently present) ? 2. I do not have any Kluber P125 grease for the mainspring barrel as per Omega current spec (expensive to buy for just one watch!) but do have Moebius 8217 grease. Can I use this instead? Any help/advice appreciated.

- 16 replies

-

Hi all, If you've read my other posts you will know I'm new to watch repaires. I've just aquired an Omega Seamaster 166.003 case and seperated it into its component parts to give it an ultrasonic clean. Three parts went into the bath and four came out, the fourth being a flexible metalised ring, it looks like a metalised plastic of some sort. It isn't the case back gasket because I'd already removed it. The only place it fits is the movement clamp groove. What is it for? Photo attached I'm restoring another Seamaster which has the same casing and a 562 cal movement, and there was not a similar ring in that one.

- 2 replies

-

- omega

- omega seamaster

-

(and 1 more)

Tagged with:

-

Hi all, I'm new to the forum and am sure I'll be learning a lot. I recently purchased an old Omega Seamaster from a well known auction site. I took a bit of a gamble, it looked in a right old state with a cracked crystal, broken bracelet, covered in crud and with a slightly pitted dial. The reason I purchased it was I have never owned an Omega and always wanted an older style that could be restored. This one looked as if it had never or hardly ever been opened, and thus serviced. It has a 562 movement housed in a 166.003 case and with a crosshair dial. In taking the back off, the gasket was an off white colour and as hard as rock, it must have been the original. The movement initially looked to be clean but the rotor does need attention - to be expected I suppose as the watch is from 1966 according to the serial number. I've removed the old gasket, the easiest way was to pop out the crystal first, just used my thumbs for that, then I warmed up the case in hot water for about ten minutes, this softened the gasket enough to insert an old screwdriver to carefully remove the gasket in sections. I removed the steel bezel using a razor blade and gently pushing the blade between the bezel and case and using a rotating action, it popped off nicely. Lots of crud under that. I've given the case an ultrasonic clean and light polish ready to receive a new crystal. My question is this: I have sourced from Cousins a new crystal, PZ1543L, for the 166.003 case. Is this to be inserted with a press tool or by using the crystal lift/insert type?

- 16 replies