Search the Community

Showing results for tags 'impulse pin'.

-

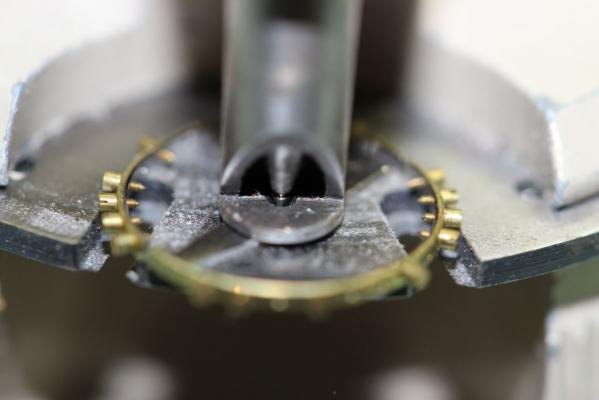

I have an old Waltham pocket watch movement which is missing the impulse pin (roller jewel). I have a limited number of actual jewels and since this is just a practice movement I thought I'd try to make one out of brass. I've seen this several times in old pieces--usually a very sloppy job. So I got some brass stock of the same diameter as the "D" in the roller table, filed it and burnished it to a high gloss. Then I took a small, very fine diamond file and filed it half flat to form the "D" I then polished the face using progressively finer sandpaper on a steel block. This works fine--so far! Problem is separation of the piece from the stock. Again I used a small cutting file to do this but it doesn't leave the end very pretty. So what I've done so far is to fit the good end into the roller table. I then plan to shellac it in place and see if I can very carefully adjust the length and clean up the end. Has anyone done this before? Any suggestions as to how best to do it?

- 5 replies

-

- roller jewel

- impulse jewel

-

(and 2 more)

Tagged with:

-

Just uploaded a new video. This one is one of my favourites, an Omega Military watch from the mid to late 40s. It had a broken balance staff, impulse jewel and the pivot on the centre wheel had a groove worn into it. I didn't film the lathe work but managed to get quite a bit under the camera. I hope it's useful to someone. Some pics: