Leaderboard

Popular Content

Showing content with the highest reputation on 04/03/24 in all areas

-

6 points

-

5 points

-

4 points

-

The link I posted above is to Steffen Pahlow's video on creating "snailing" patterns on wheels. All of his videos are worth watching.3 points

-

I find laser welded collets will come off the staff given enough patience and flexing of the scalpels. The trick is once the hairspring work has been completed to slightly close the collet hole up by about 0.15 mm with domed stakes top and bottom in an 'inverto' staking set before refitting, as there is no longer a weld and it was never friction fitted, so the friction has to be created. I use a smoothing broach to gauge how much I've closed up the hole with the staking set. I posted on my Instagram (https://www.instagram.com/jonthewatch/) the second year students performing all these processes and they all nailed it. They started practicing with clock hairsprings which I showed in my earlier post, then scaled down in size to an ST36 spring (clone of ETA 6497) which is still a fairly large spring! Once you know what you're doing, I find it really relaxing work, as you a totally in the present moment. No thoughts of past or future, just there and then. Almost meditative.3 points

-

3 points

-

This type taps out. You need a small stump with a hole so it fits over the center of the center wheel on the train side and with a small watchmakers hammer a few light taps on the protruding bit that fits the minute hand and the center spindle will drop out.3 points

-

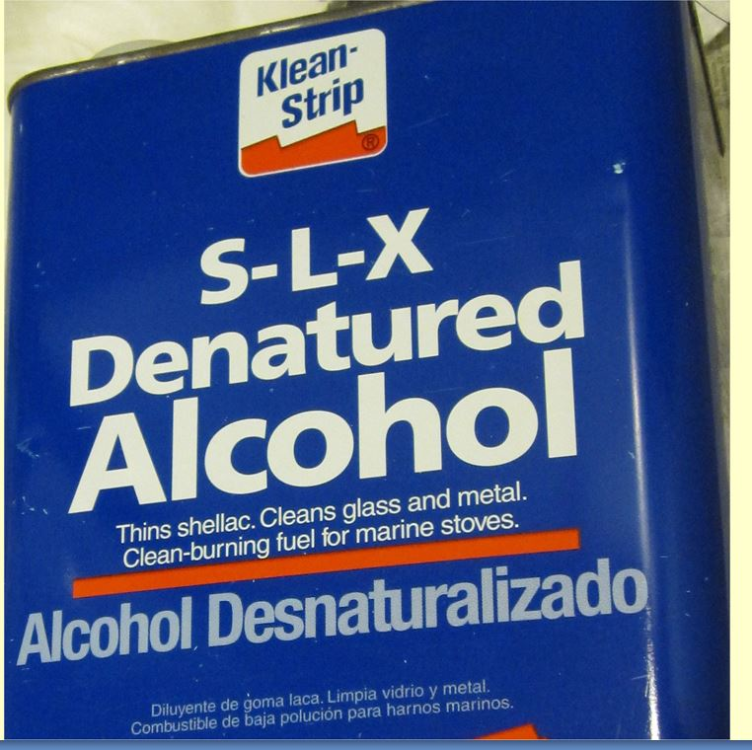

I just conducted a test a few days ago on the solvents that I regularly use as a final rinse. I put a drop of 9010 on a large cap jewel and dropped it into my test solvents and swirled it around for 15 seconds. Benzine did not do a very job. Small droplets were still visible on the jewel. Trichloroethylene faired better. It removed most of the 9010, leaving only a glistening, rainbow colored film. Denatured alcohol was the overall winner, leaving not a trace of 9010. But denatured alcohol dissolves shellac and from my tests, small blobs of shellac, like on pallet stones, can soften in as little as 30 seconds. So, now I use denatured alcohol as my final rinse for everything except the pallet fork and balance. It is especially good when I mess up lubricating a cap jewel.3 points

-

Many thanks for that - very useful. From what I am reading it seems that the Super2035 is in Miyota's "Power Engine" range - meaning that it is already a high torque movement. Interesting... Yes, it's going to be my nod to a Ressence! I have some vintage military watches in my collection. One of the things that really appeals to me in the fact that the combination of a (black) dial set high in the case and a domed acrylic crystal gives the effect of the dial almost being painted inside the crystal - and a very good viewing angle. I have a 1980 CWC G10 'Fatboy' which exhibits that effect, and recently discovered some cheap Chinese copies of the CWC that will make excellent victims for my oil-filled modding experiment2 points

-

I don't think I've ever used a metalwork lathe - (as you) I have experience of using a woodworking one though! I took 'A' Level (remember them) Woodwork at school. I reasoned that I could always be a chippy if all else failed. Turns out that the grammar school I went to (rural Yorkshire) has a very good reputation, and I wasn't as daft as I thought I was. Ended up with an Aero Engineering degree and worked all my life in the aerospace industry. But not much hands on - I was mostly driving a computer.2 points

-

I would have to go and find the can but for the final rinse when I was cleaning watches at home this is what I used. I was using it as the final final rinse I think I usually spent about 30 seconds and they are just can a swirled around and pull it out and put it immediately in the dryer. You'll notice that says for cleaning glass and metal and is a reference to shellac. In other words it dissolves shellac. Unlike isopropyl alcohol which may or may not dissolves shellac this definitely does but it still made a nice final rinse as I'm not leaving the watch parts in there all day and I wasn't using the ultrasonic at that stage just dipped it in swirled around so washed off the rinse in the cleaning process and it works great then when I search for Klean-Strip Gallon SLX Denatured Alcohol I keep coming up with the other product which clearly says fuel. The reason I bring this up is we had a small can of it at work and normally use isopropyl alcohol spray on things cleaned and water speed up the drying process and somebody swapped for the fuel alcohol. So the fuel alcohol is definitely a different product as it left the slimy feeling on my fingers and was actually floating on top of the water. So their new fuel alcohol is definitely different than whatever this is and I don't remember where but I heard this was being discontinued for I don't remember why which is sad I rather liked it. As sometimes there's a need to dissolves shellac.2 points

-

Difficult question, from what I have read, ethanol is hydrophilic and doesn't leave a residue but I couldn't find anything clear cut. If it's your only choice, try it on some scrap parts and test for residue.2 points

-

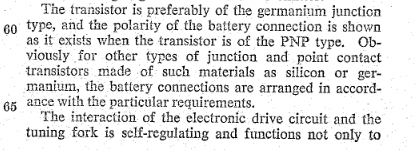

No, You don't need 'digital' transistor. What You need is small comon use transistor, where small usually means Ic max about 100 mA. The other thing important is to know the material of the transistor - well, looking on the schematic we see it is NPN, which usually means it is silicium transistor. But You have to check to confirm, as it is possible that they may have used germanium one. So, use digital multimeter and check the Uf of the PN junctions, directly on the PCB (remove the baterry). If it is about 650 mV it is silicium and if about 200 then germanium. If it is, as I suppose, silicium, then use BC548C or similar. If the H21 is much bigger than needed, then the index wheel will move twice faster, and to avoid this, You will have to increase the '*R' on the schematiic.2 points

-

As a relative newbie myself I’d recommend this: Decent tweezers - as soon as I upgraded my £10 set of 7 tweezers for a single pair of Dumont’s my parts stopped pinging, and I was suddenly able to do everything much more effectively. Screwdrivers - my first set were a midrange set from Amazon - 0.8 - 2.5mm. They were fine, about £50. You can keep spending and spending on more tools. But don’t skimp on the basics.1 point

-

Ethanol will start to remove the zinc(?) plating from brass parts, then attack the brass if you leave them to soak for a day or two. I'll not be doing that again in a hurry. At a guess, methanol will do the same but faster, and IPA is more idiot proof, which makes it the best choice as a final rinse.1 point

-

Do You have lathe? You need lathe and some attachments to make such effects. There are Stephen Pahlov's videos showing and explaining how it is done1 point

-

Try giving this guy a look to see how this type of finish can be achieved. You may want to have a look at his other videos as well, they're well worth watching.1 point

-

I see no reason why you couldn't follow the matt technique and then use polishing compound to get a polished finish.1 point

-

1 point

-

Hi and welcome to the fo4um. One way it to use a pin vice and pull vertically or putchace a presto canon pinion puller, there are several makes on the market Attached the basics document. TZIllustratedGlossary.pdf1 point

-

Hi As mentioned by Richard your options are somewhat limited by how much you are prepared to pay the value of the watch etc. but the cheapest method I’d to try to march the paint, not impossible but time consuming not to mention the colours required to achieve a match as a one off. It may take a few tubes of paint which will never be used again… professional restoration is not cheap.1 point

-

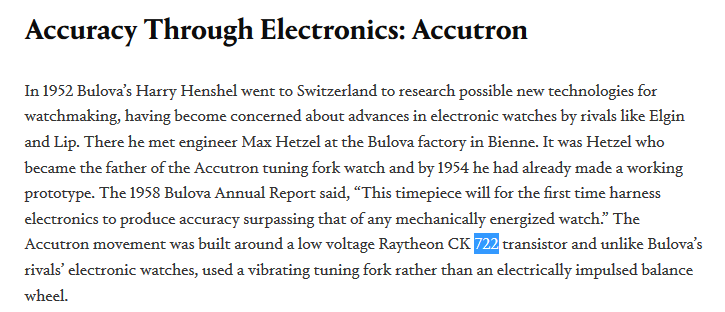

what? We live in the digital world everything is digital today except I believe this is a linear circuit seems like it should need something that's not digital. then I suspect pure digital transistors designed for high-speed switching might not actually be happy to biased it into to a linear mode. I wondered about this because for instance the 214 came out in the early 60s and I don't know how plentiful silicon transistors were? Then yes the 218 is later but the circuitry is basically very similar. out of curiosity as doing a quick patent search the see if it tell us what the transistors they used our and right this instant know they have not been to have schematics though. Then unlike general concept patents Bulova was very nice and made exact patents for a variety of their watches because it wanted the mechanical + aspect patented .then I did remember something about the transistor so I searched for a transistor number and Bulova this came up first all snipped out an image. Now you have at least one transistor that was used in tuning fork watches. So this will give you an idea of specifications. Then yes I really like where the meaning of Accutron comes from you can see it in the title down below. Which works out nice for them now that they have all kinds of electric watches including one powered by static electricity and it does not go against the name which everyone thinks means tuning fork watch. Yes you really should check out the nifty static electricity watch it's really quite amusing. https://www.hodinkee.com/articles/five-star-general-omar-bradley-special-bulova-accutron hadn't quite closed out my patent search basically the patents for the 214 we have this. then before I closed out my Google patent search added in NPN and it only came up three entries of attaching one of them as it says silicon. US3421309 Bulova NPN silicon.pdf1 point

-

Hello guy’s it’s already a while a go since I’ve been on the forum. The problem was the glass it looked like it was a original glass but by measuring it wasn’t so bought a original glass and now the bezel rotates but thanks for the tips. Finally I can close the chapter collecting seiko’s arctura kinetic Jorg Hysek 1998 models. I was lucky enough to find all 5m42-0e60/69 different dial colors and all the 5m42-0e30/39 different dial colors.1 point

-

1 point

-

Locking tweezers is inspiring to alter regular tweezers for the purpose Canthus explained. https://www.amazon.com/Diamond-Tweezers-Stainless-Serrated-Straight/dp/B098QTSP82 The design can be simplified to just a screw limiting the arms.1 point

-

When I first started manipulating hairsprings I wrecked plenty simply because I let my tweezers open too quickly. My fix for this was to put a small elastic band (or similar ring that won't slip) around the tweezer and slide it towards the points to reduce the 'normally open' gap. Then if you let go too soon the tweezers will not open to a large gap and possibly wreck some coils. I also keep a couple of tweezers just for hairsprings, having dressed them to be true and square. Don't tackle if you are tired or time pressured. Take a rest if you are getting annoyed with yourself !! Sometimes on the bay you can get a cheap mixed pack of balance springs. Whilst these may be in good shape, you can practice by creating your own damage and then repair it without any risk. Your current problem could easily be replicated this way so you can the try to repair as practice before working on your movement. PS I still manage to wreck some.1 point

-

1 point

-

Hurry up Levin lyre hairspring truing caliper i want to know what the embarrassment is .1 point

-

1 point

-

I know this is a late reply, but I just repaired a 1969 Hamilton GG-W-113 and went through the crystal debacle. I bought 4 crystals from ofrei.com. The crystals I purchased are as follows: Stella 27 1/4 - "LD" low dome wedge ledge Stella WEC 27 1/4 - High dome wedge ledge Stella 27 - "LD" low dome wedge ledge Stella WEC 27 - High dome wedge ledge I installed the size 27 WEC crystal first but it spun in the case and was just a little to small. I then installed the size 27 1/4 WEC and it worked as intended. No spinning and the height of the dome was good as well. This is for the Hamilton watches with the ONE PIECE CASE design. Hope this helps,1 point

-

1 point

-

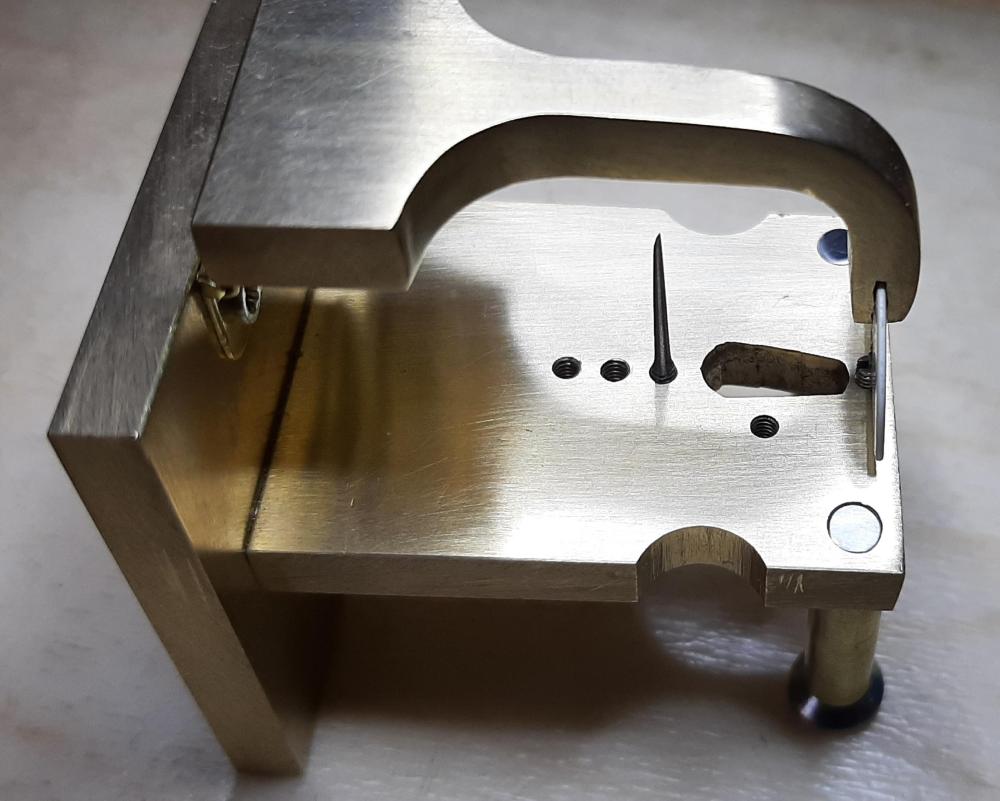

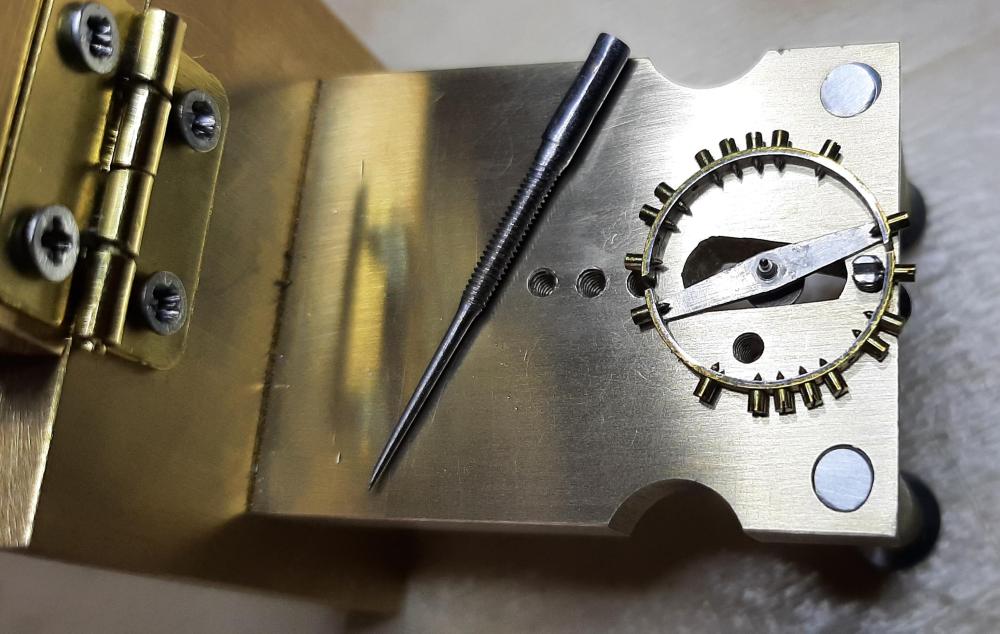

I've come to the same conclusion. After breaking ANOTHER pivot whilst trying to hold a balance+cock to adjust a timing screw, I decided all watch fettling was on hold until I made one of these thingies. I've wanted one since this post started years ago, but wasn't sure I had the tools to make one. I still don't have a workshop or any workshop power tools, but the good news is I managed to lash this one together with just the following : Vice, hacksaw, files, cordless drill (), M2 tap and die, M4 tap. Oh, and a blowtorch for bending the brass. So I bought some 5mm brass bar and started hacking. Without workshop power tools I had to improvise the hinge (I just bought a small brass hinge) and the front legs (just M4 screws). I couldn't have done it without @nickelsilver's plan and pictures. Thanks It's not perfect, but I just tried it on a balance to change a timing screw, and it works. It's great. I recommend everyone should have one. So buy some brass and start hacking. I can provide guidance if anyone needs it (but my metal working skills are pretty limited).1 point

-

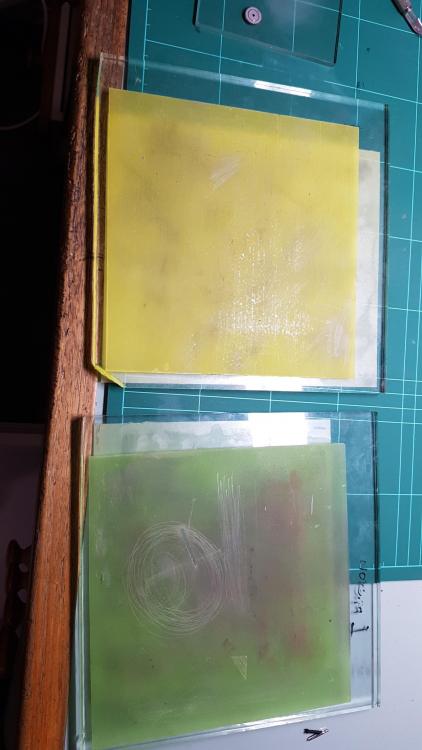

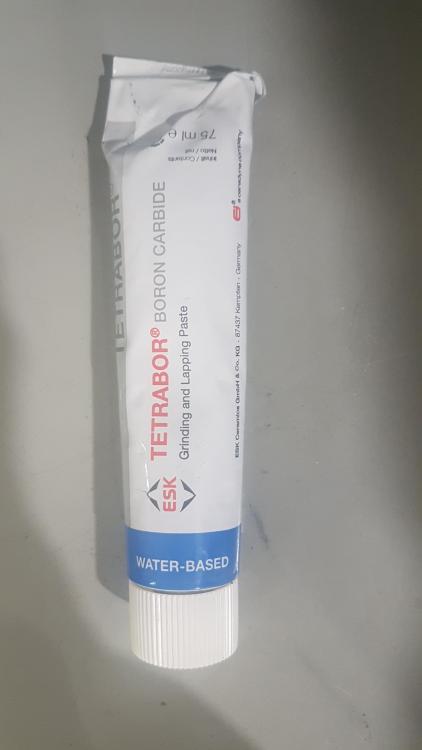

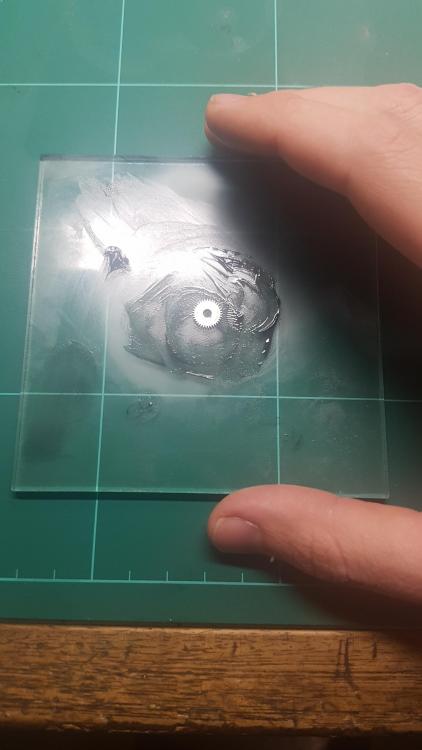

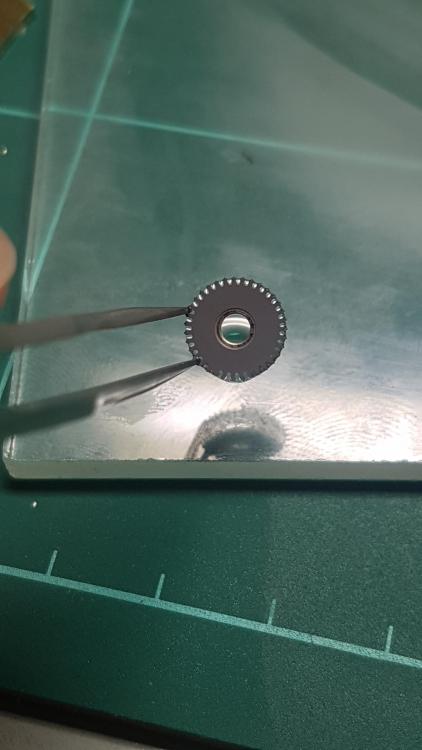

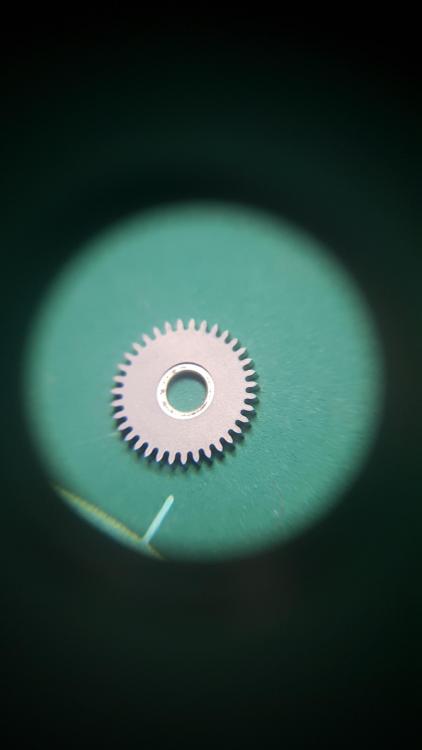

Hello All, This is my first post so I thought I would show a little finishing technique I learnt a while back. It basically turns the ratchet or crown wheel into a matte/ frosted finish. It was popular back in the day with some high end companies and still looks good in my opinion. I'll run through how it's done and try answer your questions as best as possible. What you need: 1. glass plate 2. Micron paper in various grits. 20 and 12 will do. 3. Tetrabor 800 grit/ mesh 4. Ultrasonic or cleaning machine 5. rodico First thing first, you have to flatten your ratchet wheel. To do this I use some lapping paper on glass. I start on a 20 micron and rub the ratchet wheel with my finger in a figure 8 pattern or circular or however I feel. (we arent trying to achieve black polishing flatness) If you are worried you can set up a jig to hold the ratchet wheel. but I often find using your finger will suffice. Once happy, move onto a 12 or 9 micron and do the same. At this point it is imperative to clean the wheel so that you remove all the grit from the paper that may be stuck between the teeth. So chuck it in an ultrasonic or your cleaning machine. Next place some tetrabor onto your plate, no need to add oil or water. place wheel onto plate and start rubbing it in. Generally it doesn't take to long no longer than a min or so. Doesn't hurt to check the piece to see how the finish is developing. if you want to check you can dab it with rodico, very carefully to remove the tetrabor. Do NOT wipe with a tissue or anything, this finish scratches so easy its crazy!! you can always chuck it through the ultrasonic (carefully) to see how the pattern is going. Its the checking and chasing that one last scratch which takes up the most time. The slightest bit of dust or dirt on the glass plate will scratch the wheel. You can always blue the wheel after, it comes out with an interesting tone when blued with this finish. This technique is fairly hard and does take some time to get good at, because it's just so easy to scratch and because of this scratches stand out against the matte surface. I'll try answer questions as best as possible. I try and post interesting stuff on Instagram regularly at least 3 to 4 times a week. obr_horology is my account on insta. its just time consuming to post (slow at typing) I plan on doing a youtube video in the coming weeks to better explain it. I learnt this from Henrick Korpela. Check him out if you haven't heard of him. He also writes in the AWCI and gives away a lot of info. Thanks O1 point

-

So it be nice to have a picture it's always nice to know what I'm looking for. So I found it on the cousins websites and you can buy the movement it is rather pricey. Strangely enough no batteries are listed as a replacement parts. So perhaps you can only get the battery if you buy the movement. But they had other parts and those have a different movement number. This actually has two separate numbers it's listed as this Frédéric Piguet - Cal. 820 But it also is a 8.20. Then I don't know what the differences in the numbers. So first link we get a picture and a lot of times batteries are listed it's not listed this time. Second link also makes a reference to the number difference in other words one number at the top another number in the description and the comment about the cross referencing to the 81. So carrying on the theme of the most common replaced parts and zero reference to the battery number. So third link is a nice PDF and of course it does not tell us which battery to use sort of. At the very bottom it gives us the size there are two different thicknesses same diameter so it's either a 341 or 315. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Cartier_81 http://www.ofrei.com/page1113.html http://www.phfactor.net/wtf/Frederic%20Piguet%20Tech%20Sheets/330_fp820.pdf1 point