Leaderboard

Popular Content

Showing content with the highest reputation on 04/02/24 in all areas

-

6 points

-

5 points

-

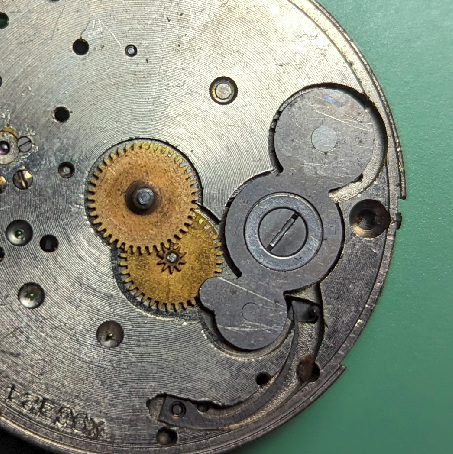

DD modules... I have 'adopted' some watchmakers who i have to save from time to time. For example, now I have an AP movement on my bench that needs to make new winding pinion and one of winding gears for it, this is for a young watchmaker that I am trying to teach and will not want to dissappoint him... I have newer worked on a DD module, but I have repivoted two times for different watchmakers the small pivot on the back side of center seconds (4th) wheel of 2892 that has break while pressing the gear on top of the wheel. I know from them that the modules are real pain and they need a special holder that holds all the buttons pressed, othervice almost not possible to assemble them.5 points

-

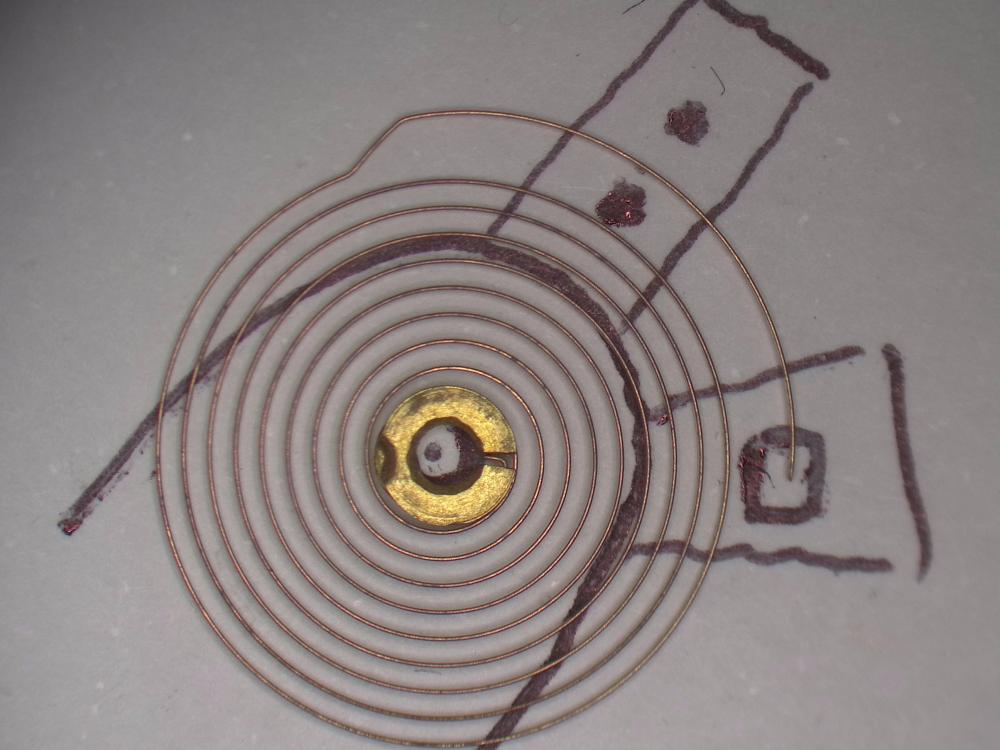

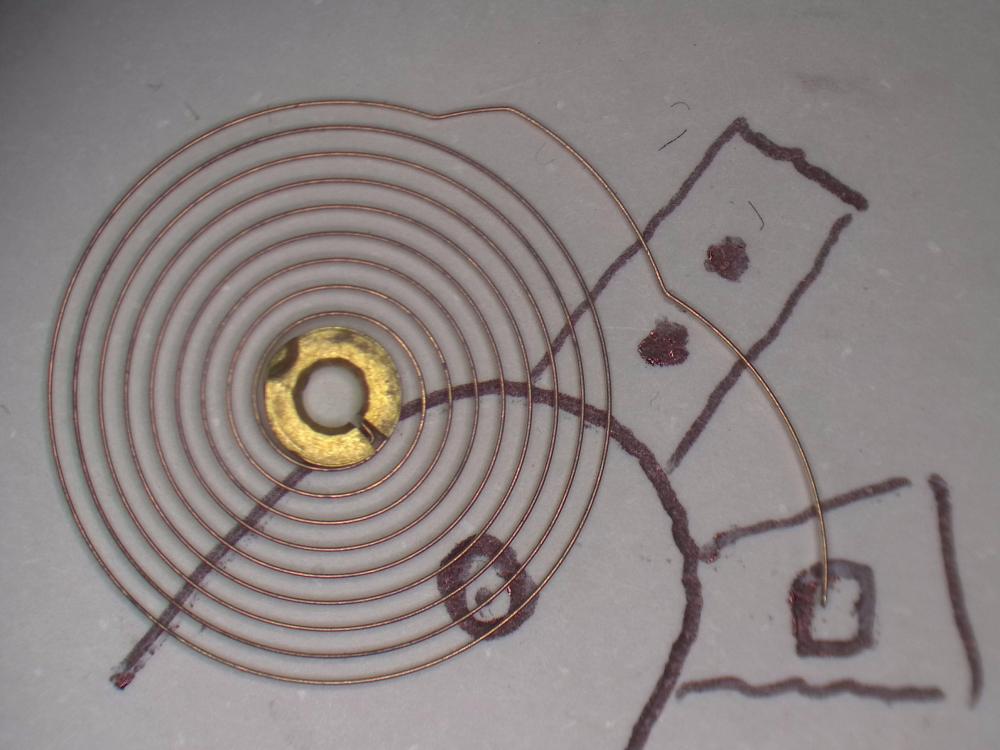

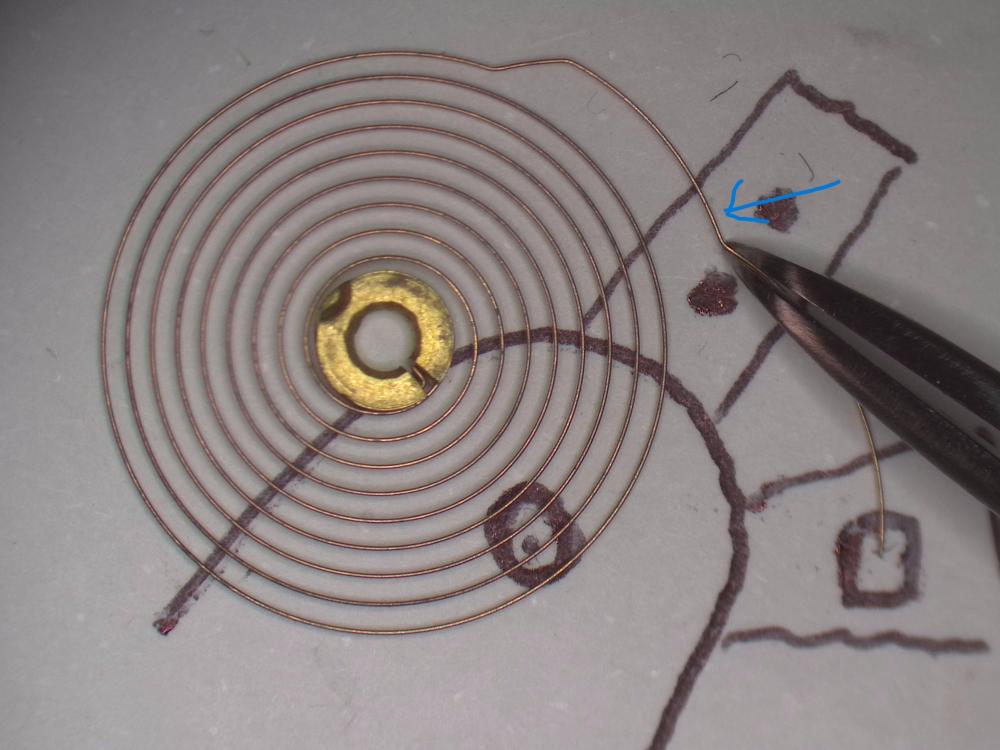

How did you clean the balance assembly, by hand? If you clean the balance and mainplate together, so the balance is mounted on the mainplate, this wouldn't happen, unless you're prodding with a brush if it is hand cleaned. Funnily enough, my students have just spent the last three weeks learning how to manipulate hairsprings and shaping end-curves, first by working on clock hairsprings, then scaling it down to ETA 6497 hairsprings. It isn't a bad bend, but I would remove the hairspring from the balance and then lay the hairspring on the underside of the cock then bring the end-curve back to where it should be. It's very important to place the stud in the stud support and tighten with the screw to get it to position properly to give you an idea where the collet will end up once assembled. There is a small groove in the stud that the screw will locate with. I've taken some photos of a clock mainspring and drawn the underside of the balance for it to position on. The first pic is the underside of the balance cock (I know the curb pin and boot is quite a gap, but I wanted the pic to be understood well). The second pic is how the hairspring and end-curve should ideally be with the collet bang on the jewel hole. When the index is moved the hairspring shouldn't be pushed or pulled by the curb pin and boot, or in modern watches the regulator pins. If that happens you'll see a difference in beat error when you move the index arm from fast to slow. You have to make sure there is a gap between the curb pin and boot before you move the index, otherwise it will bend the hairspring, which might have happened in this instance. The last pic is the hairspring being manipulated to form the end-curve again. This is done away from the cock and then try for shape on the cock remembering to ensure you tighten the stud screw to get the proper position of the spring. I have gripped the spring with No. 7 tweezers and where the arrow is, push the spring until the kink is out and the collet is on the jewel. If you've never done this type of work before, it's best to try with a scrapper first. It is a lot safer to remove the hairspring from the balance first. I use scalpels to lever the hairspring off, or very fine hand removing tools, but I still prefer scalpels4 points

-

Working on a ladies Seiko that is testing my patience, full service and had it running sweetly - and put it on my winder rig for a 24 hour test, but found it stopped after an hour. I took it apart and found the ubiquitous red fibre wrapped around the pivot of the escape wheel, removed and the watch is up and running again, victory! ......Then it stops again after about an hour, complete strip and notice some movement on the arbor of the barrel... hammer time.... and the watch is up and running again, victory! ......Then it stops again after about an hour. Another complete strip and clean after checking all the jewels on my new LED light box i notice a slight chip (but probably just an inclusion?), re-jewel anyway .... and the watch is up and running again, victory! ......Then it stops again after about an hour.... Top up swear jar, have an argument with Mrs W. and then watch crap TV for the rest of the day. But I got to wondering, where do those red fibres come from??? I do not wear red or have any red rags or cleaning cloths etc... conclusion is that watch gremlins wear red sewaters ->4 points

-

I have a different view to the DD module world. I began watchmaking for one main reason: To understand and enjoy complicated mechanisms. So when I already had some years of experience with several ETAs, PUWs, Rolex I entered the chronograph business step by step. Landeron 248, Valjoux 7734, Valjoux 72, Buren 12. And while working on the last one I came across a picture of the DD2020 without cover plate and had only one thought: Wow! Freaky! How the hell does this thing work? So I bought a Omega Speedmaster Reduced just for the sake of disassembling, reassembling and understand that thing. I wrote a little article on the r-l-x-forum about this (not a service-walkthrough as this is not a watchmaker-forum, but just a description how it works): https://www.r-l-x.de/forum/showthread.php/197912-Konstrukteure-auf-Speed-–-das-Omega-1140-mit-Dubois-Depraz-Chrono-Modul There is a lot of information on the internet which guided me, especially Marks videos about his Breitling for Bentley service and the Omega 1140 tech sheet availiable on watchguy UK: https://watchguy.co.uk/cgi-bin/files?showfile=Omega/Omega 1140.pdf&filename=Omega 1140.pdf&dir=Technical Manuals&action=documents I am not familiar with the DD4500 but after a look at this article https://www.thenakedwatchmaker.com/decon-dubois-depraz-chrono-big-date I am quite sure that in the area of the chronograph there are a lot of levers and wheels which are identical to the DD2020. Of course this doesn't change anything on the situation that parts are not availiable (when I worked on the DD2020 I was lucky that no module parts where worn). I like the DDs as they are freaky mechanical stuff, interesting challenge for advanced amateurs with lots of time. If I was a pro and had to do a service in a short time at reasonable costs maybe I would get to a less positive judgement.4 points

-

I avoid these at all cost! They really aren't pleasant to work on, and the absolute unavailability of parts or tech info just makes it a gut wrenching nightmare. You can have friends in the biz with parts accounts all over the map, there are no parts available from DD. A friend of mine even lives about a block from their main building, and is their local fireman, and a trained watchmaker, and I'm 1000% sure he could show up with brownies and croissants for the whole workshop and no parts.3 points

-

2 points

-

You have to face the uncomfortable truth " the watch is cheating on you ". Sorry to have to point it out.2 points

-

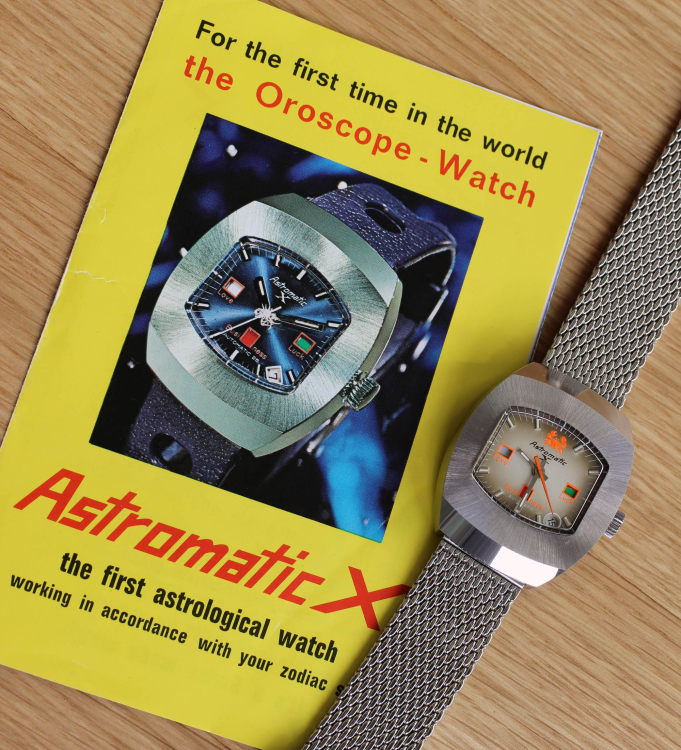

ological-watch-astromatic-x/ Interesting find Andy, the seller in the link Miklos, i contacted a couple of years ago, he specialises in buying huge joblots of nos from around the world mostly retro style but some other obscure stuff as well for repair, moisture damaged due to long storage. When i came across him on ebay at the time he had a massive inventory of spaceman watches, leds and funky Tressa that caught my eye. Some really nice retro gear and not overpriced for what would be old unused watches of good quality. I wasn't shy in coming forward like the chap that did the write up, i dared to ask Miklos how come he had so much nos , if you dont ask questions then you dont find out . No thats pretty cool as well, although i could sell it and buy all 12 of the Astromatic zodiac signs2 points

-

I'm not sure I have any question left here, but want to relate my Captain Ahab story getting this junk Elgin grade 206 7j watch to run. It came to me in a bag of broken watches a relative's acquaintance handed over. The "before" picture hides the fact that all 3 brass wheels were seized together with green corrosion. The case was black, but this I learned right away was just a badly tarnished coin silver. It cleaned up really nicely. It's a type of case I have not encountered before, extending a 6 size movement to more like the a 16 size case with a broad spacer ring. When disassembling the case, I broke the stem sleeve. It was rusted and brittle. I figured this was unimportant and I would eventually replace it. Though I was surprised to find how much those parts sell for. I expected them to be available by the sackful, but instead sellers want $15-$20 for a single one. I kicked this down the road so I could get the movement to run. The movement cleaned up okay, and I was able to remove corrosion enough to reuse all but the 4th wheel. It had 5 or 6 teeth that were eaten away not enough to stop the watch, but to send its timekeeping haywire every 45 seconds. I worked on this over several months, replaced some wheels with spares, tuned the escapement to my current skillset. The movement ran, eventually acceptably well. The balance is out of poise I think, based on a 40sec positional delta. I can deal with that when I have a poising tool. But with the dial and hands installed, it would never keep accurate time. Sometimes it would be good for a day then suddenly lose ten minutes or lose 6 hours. It felt like a cannon pinion problem. I got the tools to tighten the cannon pinion. This didn't help at all. I replaced the center wheel because its arbor was kind of worn. That did not help either. I replaced the cannon pinion entirely with a donor's. It had a positive snap on install and good feel to handsetting but still no change in behavior. I thought maybe the hour wheel was riding up out of mesh with the minute wheel so I tried manipulating and eventually stacking dial washers, no change. I learned how to close the holes in the hands for a firmer fit on the hour wheel & cannon pinion. I was going to give up on this one when I found someone selling a bag full of stem sleeves for a reasonable amount. I bought them and installed one that fit, planning to sell this watch on and note its fault for someone else to figure out. But after installing that stem sleeve and recasing it, the watch is now keeping time all week without any issues in the motion works. Why? Because the keyless works on this type of watch are inverted. The stem must be pushed in and secured by its detent with a stem sleeve to engage the winding mode. Otherwise, its default position under spring tension is to engage the hand setting wheels (in the photo above, that spring is not engaged but that's not the problem). All the while I was trying to get the hands to keep time, it was running uncased and the cannon pinion was therefore driving all the handsetting wheels. It can't do that without slipping occasionally and that was its issue all along. It still isn't perfect, I need to troubleshoot a problem with the spring tension in the keyless works while it actually is engaged in winding mode. But now it's all together, and will make a nice little desk clock or something once I clean up the dial a bit to hide those cracks. And the next time I work on an American stem wind/stem set watch I will make sure it is cased when I test it out with dial & hands.2 points

-

I found a very good article about these, so if you don't want to peek behind the curtain to see how the magic works, don't click the link. Those gravity sensors are pretty slick. https://www.fratellowatches.com/tbt-first-astrological-watch-astromatic-x/2 points

-

Unlike Swatch, who will sell you something if you pass their requirements, or Rolex (who used to be the same, but-) if a pro there's always a friend or friend of a friend who can get it, or at least Ebay, DD has simply never sold parts. If you have the right security clearance with the brand using their module, you might get the entire module, but that's that. I've never had to resort to it so no idea even what the whole module costs, but c'mon, they really are the worst of the whole bunch. A. Lange & Sohne, 50K watch, yeah I get they don't want to sell a winding stem to Joe Schmo. But DD is commodity level mass produced stuff. Which I think is actually the issue- they would have to employ probably several people full time to deal with the logistics of taking orders and filling them for parts. Hmm. Imagine if someone at DD realized they could charge 15 bucks for a spring that they cost out at 0.30CHF in a module... Nah, while the Swiss do like money, they like being stubborn more. They are difficult to work on because of how they are constructed. Which is to the lowest possible price point. Lots of spindly long springs that have to be situated just so, no real logic to it if unfamiliar, and of course the stress of knowing if you can't get it back together you're hosed. I have worked on lots and lots of chronographs, and still see stuff that is new to me, and I would bet that even if presented with a complete unknown chrono completely disassembled, I would get it together in a reasonable amount of time. All bets are off with DD. I know some folks are actually familiar with them so probably not a big deal, but DD makes Seiko and Citizen chronos look like world class Swiss stuff from 1940 in comparison. (And I don't really like those either, haha.)2 points

-

Judging by this, you could get them with whichever sign of the Zodiac seemed appropriate. History does not relate whether the "water signs" were waterproof, but I suspect not. I'm intrigued to see how the "love, luck and business" mechanism works. We have to assume it uses some very advanced gravity sensors to detect the positions of all of the planets and a very intricate arrangement of cams and levers to align those coloured flags (or alternatively it is driven by the hour wheel).2 points

-

2 points

-

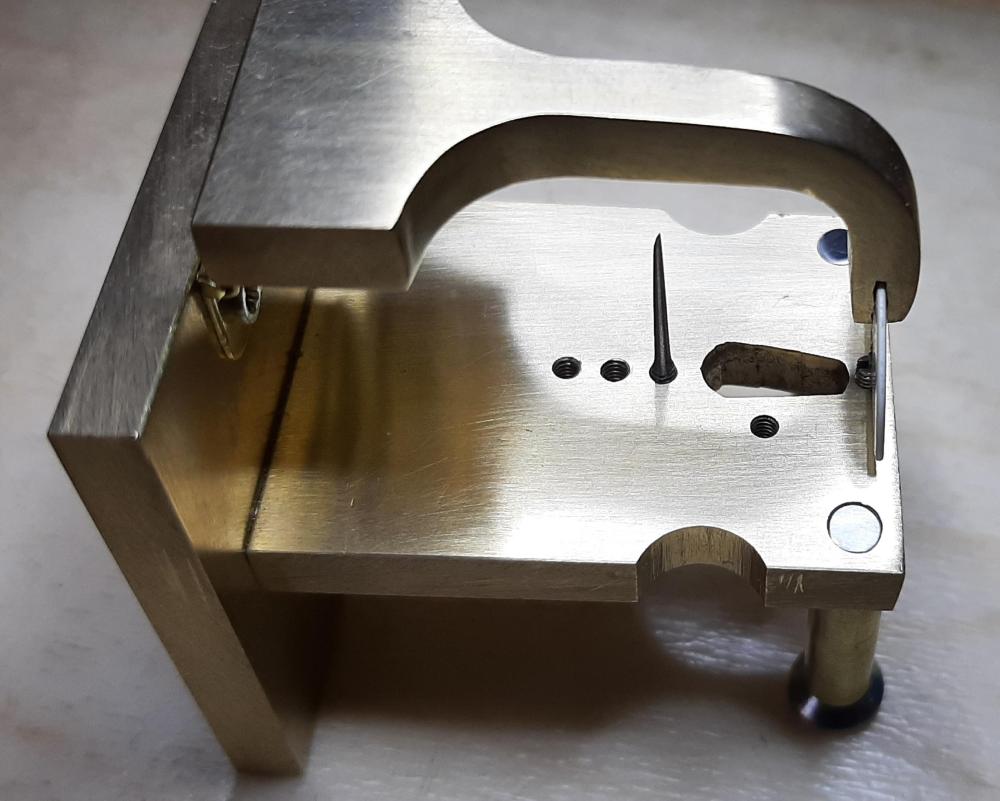

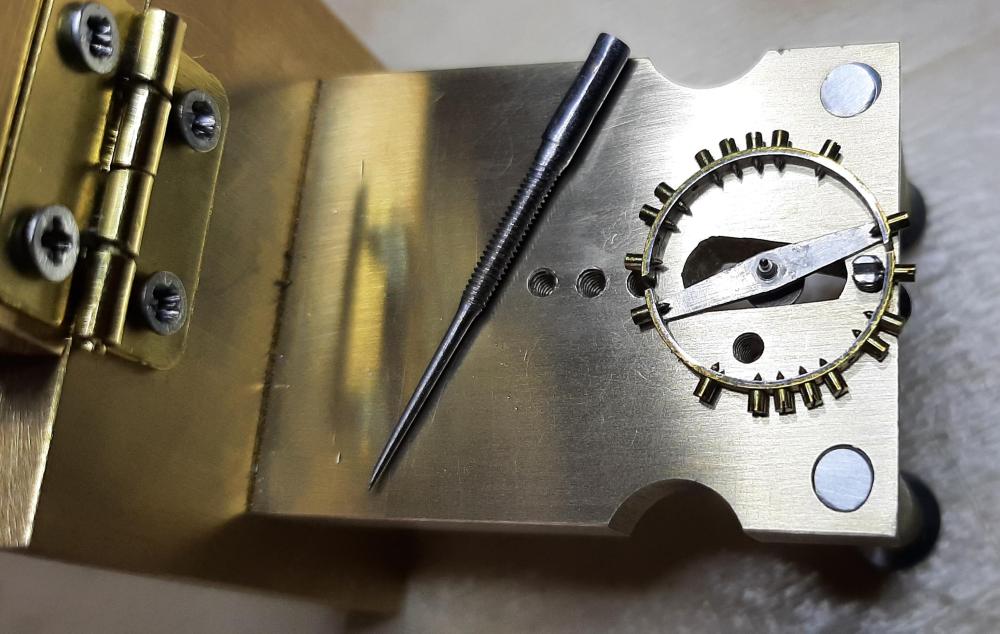

I've come to the same conclusion. After breaking ANOTHER pivot whilst trying to hold a balance+cock to adjust a timing screw, I decided all watch fettling was on hold until I made one of these thingies. I've wanted one since this post started years ago, but wasn't sure I had the tools to make one. I still don't have a workshop or any workshop power tools, but the good news is I managed to lash this one together with just the following : Vice, hacksaw, files, cordless drill (), M2 tap and die, M4 tap. Oh, and a blowtorch for bending the brass. So I bought some 5mm brass bar and started hacking. Without workshop power tools I had to improvise the hinge (I just bought a small brass hinge) and the front legs (just M4 screws). I couldn't have done it without @nickelsilver's plan and pictures. Thanks It's not perfect, but I just tried it on a balance to change a timing screw, and it works. It's great. I recommend everyone should have one. So buy some brass and start hacking. I can provide guidance if anyone needs it (but my metal working skills are pretty limited).2 points

-

Hi all, 1st post here, happy to be on board! I am currently assessing a newly acquired watch with a Dubois Depraz 4500 chronograph module and it looks like I will need at the very least a replacement hour recorder. I understand new DD parts are unobtanium so I am looking in the used market. I am curious if anybody knows what interchangeability (if any) there is between DP modules? According to WatchWiki the existing DD chrono modules for the ETA 2892 are: DD 2020 - Chronograph DD 2021 - Chronograph DD 2027 - Chronograph with yacht timer (used by Audemars Piguet, Bulgari, Omega) DD 2030 - Chronograph with small seconds at 3 00 and 30 minute counter at 9 00 DD 2071 - Chronograph with sweep minute counter, hours at 6 00, and seconds at 3 00 (used in Mido Multifort Center Chronograph) DD 4500 - Chronograph with big date DD 4900 - Chronograph, big date, four-year calendar, month window at 4 301 point

-

Hi and welcome, i feel there are reasons for this, 1 we have excellent moderators to keep some order and 2. There are a good few regular lads here that all get on well together and all with great positive attitudes. We all look out for each other, are considerate, encouraging and banter with good humour and any newcomers are heartily welcomed and treated with the same respect. I have not experienced this kind of attitude anywhere else on the internet you will be well looked after so ask, look, read and learn from this wealth of knowledge, enjoy the time you spend here1 point

-

1 point

-

Thanks everyone, really helpful replies on my first post here. The balance needs a bit more tweaking but atleast it runs now!1 point

-

Welcome to WRT, Sam. Is that quote from Aristotle? Or was it something you heard in a Bob Dylan song?1 point

-

Welcome to WRT. I think at some point we all fantasize about scoring an antique Breguet original at a yard sale, fixing it up and selling it on the Antiques Road Show for half a bazillion. But, the alarm will eventually go off and we get up and fix watches. The latter is more fun, anyway. BTW, if the alarm doesn't go off, I know some people who fix them.1 point

-

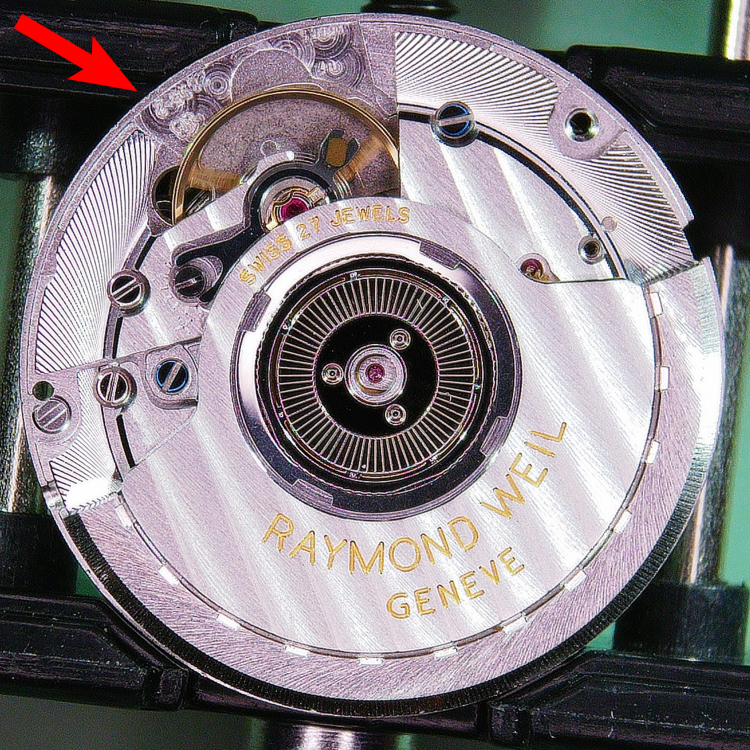

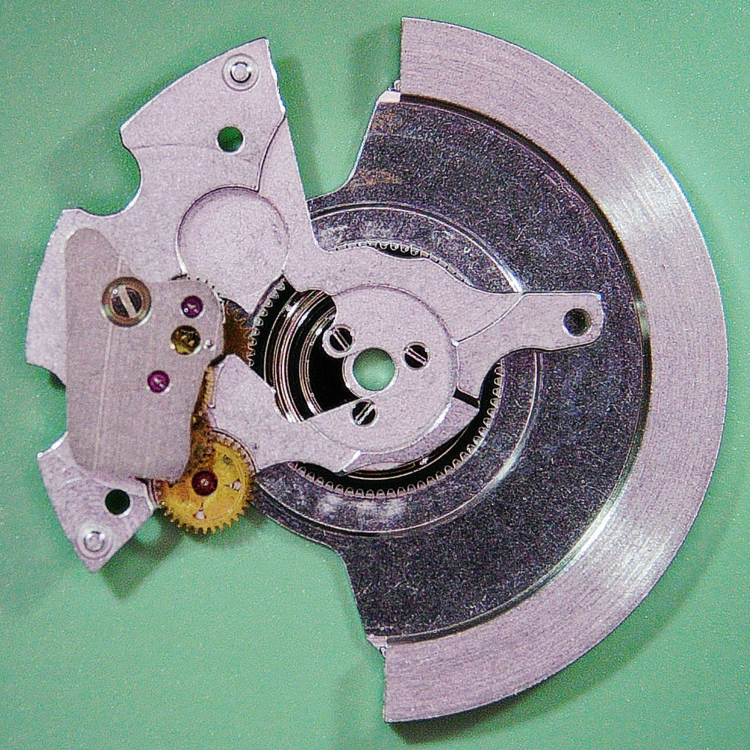

Actually it looks like a 2895. You can find the model number stamped into the plate right under the balance. And, no, on this movement there is no center screw holding the oscillating weight onto the winding works. It's held by three small screws from the underside. I can think of three scenarios where the weight on the rotor would be "sloppy". First, the three screws holding the weight to the rotor were loose. Second, the movement encountered an impact that dislodged or damaged one of the bearings in the rotor. Third The entire automatic works wasn't screwed down properly. Those would be the three blued screws you see as you spin the rotor around. Did RW indicate what was repaired during the warranty service?1 point

-

Locking tweezers is inspiring to alter regular tweezers for the purpose Canthus explained. https://www.amazon.com/Diamond-Tweezers-Stainless-Serrated-Straight/dp/B098QTSP82 The design can be simplified to just a screw limiting the arms.1 point

-

When I first started manipulating hairsprings I wrecked plenty simply because I let my tweezers open too quickly. My fix for this was to put a small elastic band (or similar ring that won't slip) around the tweezer and slide it towards the points to reduce the 'normally open' gap. Then if you let go too soon the tweezers will not open to a large gap and possibly wreck some coils. I also keep a couple of tweezers just for hairsprings, having dressed them to be true and square. Don't tackle if you are tired or time pressured. Take a rest if you are getting annoyed with yourself !! Sometimes on the bay you can get a cheap mixed pack of balance springs. Whilst these may be in good shape, you can practice by creating your own damage and then repair it without any risk. Your current problem could easily be replicated this way so you can the try to repair as practice before working on your movement. PS I still manage to wreck some.1 point

-

Laser welded collets limit your sorting the hairspring with the balance attached, a pain. If collet is removable detach the balance & hairspring. then; Good luck1 point

-

I turned away a job last week for a ETA 2892-A2 chronograph because it has a bolt on chrono module. As others have already said, parts aren't available for the module, so if it is disassembled and a part is needed, a lot of time has gone into something that is now unserviceable and then you have to then explain to the customer why you can't do the work and why you have wasted their time. If the module needs no parts, that's great, but it isn't worth taking the risk in my experience1 point

-

is it just me, but I cant see the actual hairspring pinned to the stud, also the balance isnt sitting in the jewel so its bound to be out of shape1 point

-

1 point

-

Yes, there. It should be a smooth curve along the path of the regulator.1 point

-

If you go on you tube and and type in Chronoglide watchmakers next to where it says store you can search what video you want, type in repair balance spring, and you will see 3 videos how to do it, i think its the 3rd one which you might interest you, but i would watch all 31 point

-

1 point

-

It's bent right where it passes through the regulator. There is probably a distinct bend there. Bring it back so the regulation curve is uniform again and you will be close, do the final adjustment in the watch.1 point

-

Looks like it is best right at the stud, you could try fixing it, but it's delicate work and even the experienced amongst us don't look forward to working on hair springs.1 point

-

This (at least the ones with the movement pictures) are usual alarm clocks in cheap 'carriage clock' cases made of tin, from the beginning of 20th century. They are cheap, almost all big alarm clock manufacturers like Junghabs, GB, Haller, Kienzle... made such clocks. There are ones with latern music box, they are more interesting, but the quality is the same. Often the music box is badly damaged (broken). You can find some with cases made of chromed brass, and some with chromed iron cases. The iron ones get rusty and verry hard to restore. The movements are normal alarm clocks and restoring them is routine task, nothing unusual.1 point

-

Fork only engages with impulse pin ( not the balance staff ) during each swing of balance, any other contact between fork and roller table or balance or balance staff deters or stops oscialtion. Pivot cone might rob on the cup, in case of too much pivot side shake. Your image No 1 . Unpin the hairspring from the stud. Good luck1 point

-

The things You write here just show You have no experience at all. Of course, the balance will get in place without the pallet fork. Just some patience and stubbornness needed. You first need to do the free oscillations test, for which exactly this is needed - to put the balance without the lever. Yes, sharpening is possible without lathe. But it is easier to do with one. Actually, almost everything is possible to be done without the specialized tools which are made for the purpose. Just imagination and creativity needed. But, is this important for You? I mean, this is cheap watch with no jewels movement, which will never be more than that.1 point

-

Well it worked, but took days rather than hours. Not sure all the broken stem is out, but there’s now enough thread to screw onto a new one.1 point

-

In other news, local man ejected from Waitrose Cafe for laughing like an old goat at that last comment. Apparently my guffaws were scaring the tea cakes. OK that might be a slight exaggeration, but I did get a look that would freezer your coffee from an old lady with a particularly heavy looking handbag sitting a couple of tables away. I felt an explanation might prove long, difficult, and given the size of the handbag, potentially dangerous.1 point

-

When I was into the repair side of clocks back in the 70's & 80's Horolovar covered all the spring strengths. If previous repairs had been playing around with the mainsprings or the pendulum then you had problems, but that hardly happened with me. I did have one where someone had taken a file to a 4 ball pendulum and filed the size down by giving two flat bottoms.1 point

-

We are now in the generation where everything is within the consumer's grasp with the ease of obtaining credit. This young generation wants it all and they want it straight away. My first car in the mid 80s cost me 120 quid that i scrimped and saved for, an old banger that i patched up and learned to repair every other month, every car i bought a Haynes manual for that car followed the very next day. Kids now drive around in brand new cars and have no idea how to change a wheel over. Try telling any of them that they were brainwashed into buying that Rolex Omega Breitling whatever that they sport on their wrist. Great story grandpa1 point

-

1 point

-

Just one more greedy act by Swatch. They started a number of years ago here in the US..cutting off supplies to watchmakers that could build complications that many Swatch houses couldn't even touch. Old school masters who had gone through some of the most prestigious houses in the world. Otto Frei has some statements on their page about it. I tell all my customers to avoid new Swiss watches like the plague,..unless they just want an older one in their collection that still has some parts out on the market, or they have really deep pockets and don't mind waiting months and paying through the nose to get it back. Plenty of others to choose from..IE Seiko,..or other non-swiss brands Even a number of Chinese brands are catching up with the Swiss,..and I think that in time, their actions will be their downfall1 point

-

1 point

-

you don't because the file size would be too big for the message board. It is also not one of the supported file types. That means you can upload it to YouTube because I think anybody can have a YouTube account and just upload anything they feel like or you find some other source or location to put your video file it and give a link for people can download it.1 point