Leaderboard

Popular Content

Showing content with the highest reputation on 03/31/24 in all areas

-

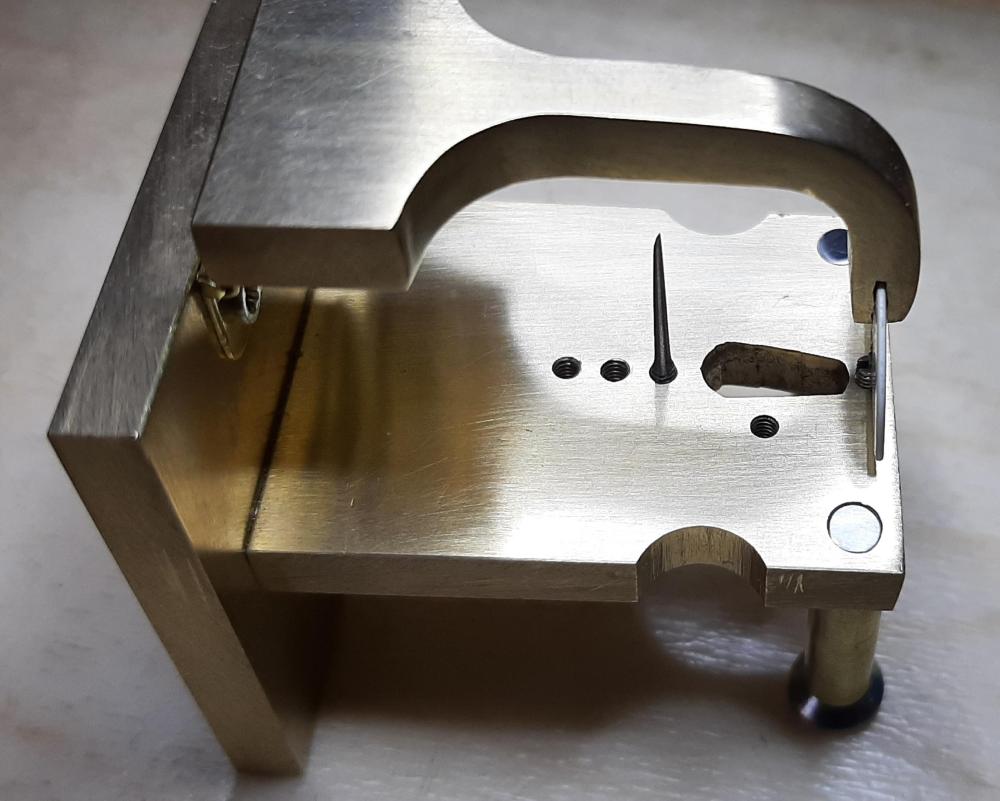

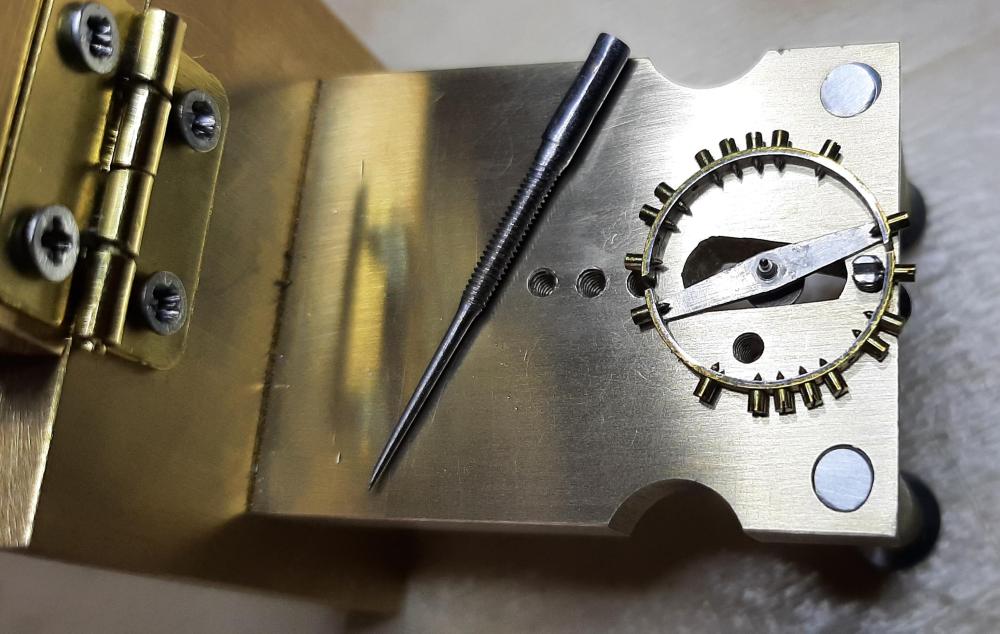

I've come to the same conclusion. After breaking ANOTHER pivot whilst trying to hold a balance+cock to adjust a timing screw, I decided all watch fettling was on hold until I made one of these thingies. I've wanted one since this post started years ago, but wasn't sure I had the tools to make one. I still don't have a workshop or any workshop power tools, but the good news is I managed to lash this one together with just the following : Vice, hacksaw, files, cordless drill (), M2 tap and die, M4 tap. Oh, and a blowtorch for bending the brass. So I bought some 5mm brass bar and started hacking. Without workshop power tools I had to improvise the hinge (I just bought a small brass hinge) and the front legs (just M4 screws). I couldn't have done it without @nickelsilver's plan and pictures. Thanks It's not perfect, but I just tried it on a balance to change a timing screw, and it works. It's great. I recommend everyone should have one. So buy some brass and start hacking. I can provide guidance if anyone needs it (but my metal working skills are pretty limited).7 points

-

An interesting question. I refuse to wear designer clothes for two reasons, firstly I don't care less about clothes but more importantly I refuse to pay a premium to advertise someone's clothing. Want me to wear a t shirt with someone's name on it, pay me.4 points

-

Yes, it's a sad, sad story and your argument is further emphasized by the fact that they now incorporate parts in plastic (cheap junk) and call it high-tech. As I mentioned previously, the issue of safety can be handled through an independent inspection authority. That's how it's done where I live, and for the past 15 years, I have employed an independent car mechanic to repair and service my car. His work has made my car pass the yearly inspection every time. Works like a charm!3 points

-

3 points

-

I thought I am the inventor of thinning torsion springs... My advice is to use this kind of tool to strain the spring in order to avoid the risk of curling it. Then, just piece of grit 1000 sanding paper needed, folded in two with the sanding surface inside. Squeeze it between fingers and slide it on the spring 2-3 times fully from one end to the other. Then try the period of the pendulum. !!! it is easy to overdo thinning and make pendulum too slow !!!2 points

-

2 points

-

You're very right about that. Some 15 or 20 years ago, Volvo, the most common car in Sweden, tried to restrict parts by making warranty void if original parts were not used and installed by authorized mechanics. Fortunately, they went on a real nose burn and sanity was restored. It is beyond all reason that Swatch is allowed to continue with its anti-customer policy.2 points

-

That is how we operate in the UK with vehicle owners applying for a ministry of transport yearly inspection. Without that insurances can void in cases of accidents. Resistriction of parts in the instance of vehical repairs would have a major impact on the average consumer. In today's world it would make life very difficult for a lot of people.2 points

-

2 points

-

2 points

-

Being concerned about their reputation i suspect is just a convenient excuse. Without parts a repairer is now less enabled to carry out a proper repair and will be forced into using second hand parts and bodging. A luxury watch put to bed and swapped out for a 10 quid digital watch still gives the owner the means to tell the time and almost everyone has a phone as a backup anyway. We cant do this with a car, taking it to an AD is not an option that everyone can afford with charges double that of an independent garage. Restricting car parts would cause a lot of inconvenience to a lot of people, and bodging up work on a car would be very dangerous. Tbh it's professional watch repairers that i feel sorry for, the ones that used to repair relatively recent made luxury watches. The vast majority of hobbyists repair vintage watches that are found on ebay, these parts were ceased to be made long ago. The parts that are being used now are remaining stocks and salvaged parts, thats something that most of us have been getting used to for a long time. As an aside question, do Ronda, DCN and such companies still exist make and supply watch parts to anyone.2 points

-

Hearing about this court case raises feelings of outrage in me. Even though I primarily work on antique watches and must resign myself to finding mostly used parts or to making parts, I am outraged by the lack of consideration and empathy which the Swiss show toward the independent members of our honorable profession. It is as though they are implying that, because they suspect some of us may be ham-handed hacks and they don't know who is, then NOBODY gets parts unless you're willing to be put under their thumb. A poor repair says more about the repair technician than it does about the watch. If the Swiss were truly worried about reputation they would understand that. Ownership should mean something. So should a right to have something repaired. With cars, it is a slightly different issue; a poor repair can place the lives of the owner and even other motorists at risk. Not so with a watch. The Swiss can argue how they like, but I suspect this has more to do with their right to take more of our money, and exclude those who do not have enough of it. It feels like they have legislated their snobbery.2 points

-

Certainly all the big high end makers haven't supplied parts in many years. Swatch will provide parts if you meet certain requirements, and for a professional those actually aren't that hard to meet (certain equipment, training etc.). Richemont forget it. For a long time Rolex would supply parts to professionals who met their requirements for training and equipment. Then those requirements became harder and harder to meet, and finally they just stopped supplying to any other than Rolex dealers (who still had to meet the requirements). But they actually put in place a service network of their own during this time that works (pretty) well. Other makers tried to cut off abrubtly and suddenly "factory" service took 2-3x or more than before. I do kind of get that they want to control the quality of service. But ultimately even they often mess up- I have seen and repaired the results (from upset customers who absolutely didn't want to send it back again, even under warranty). Geez 25 years ago Patek would sell you parts! Not long ago I made a ratchet wheel for a fairly recent JLC perpetual calendar; customer had dealt with JLC before and waited like a year or more just for the watch to go back again, wait again. They were happy to find someone who would/could do it. But it's nerve racking work: if any part is lost or damaged, which can happen any time to anyone, woo-boy. Mechanical parts I can make, haha, but a scratch on the dial or something is another story. It actually makes more sense for car makers to restrict at least some of the parts- I was a mechanic as a very young man before watchmaking, and I've seen stuff on brakes, suspension, etc. that were definitely from a shade-tree mechanic and a definite safety issue. But you can get whatever you want and do the work however you want on your _____ car.2 points

-

Made one of my own. My remaining pieces of 1/4 inch brass were narrow so I had to adjust the measurements a tad. But it functions very nicely. I like that it supports the wheel at a predetermined distance and does not allow the hairspring to hyper-extend. A nice tool in theory, and I plan to put it into practice and judge how often I use it and how it performs. Thanks for all these replies to my query, folks. You have given me the more thorough discussions I was seeking.2 points

-

1 point

-

You're going to enjoy using it. I've been using mine for just over 3 years now, and it makes working on balance screws so much easier. Between this platform tool and a balance screw holder, the work is barely a hardship.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Your problem lies on the dial side, must be something wrong with the cannon pinion or how the pinion interact with the fourth wheel pinion's tube. So disassemble the movement side would not solve the problem at all. About removing the C snap I saw people on youtube pry it up using a screw driver, I prefer to use a pair of small and thin hand levers, be careful as you don't want to scratch the day wheel or damage the hour wheel's post in the process, if this's your first time it probably a good idea to put a small rodico blob on top of the hour wheel's post to prevent the C clip from entering the 4th dimension. Still if what you got is a loose cannon pinion, best option would be to find a replacement part/donor movement.1 point

-

The circlip on Seiko day disks lift off the hour wheel quite easily. Use a pair of sharp hand lifters with a piece of plastic as a dial protector and use a wedging action to slip the lifters under the circlip. The circlip does not grip like normal circlips and lift up vertically quite easily.1 point

-

@VWatchie I am not happy that your spending your time here and not working on your ETA 2763!? Did you ever take it out from your saw dust box?1 point

-

Lol join the white t-shirt and jeans brigade brother. I can buy five plain for the price of one that has a name on it.1 point

-

Hi yes moebius as well hence the crazy prices, got you by the goolies again, it’s a wonder the batteries are not the same as it’s a consumer market where once used throw it away , but the competition for batteries has a wider market there is no shortage of suppliers. Watch oil is different in as much they created their own market by reccomending which type of moebius oil to use where and this is slavishly followed by enthusiasts and professionals so once again a gotcha. The one thing they are clever at is marketing and no matter those not in the know don’t care and will continue to fill their coffers for no other reason for show or elitism you only have to look at the wrist of footballers and show biz stars. All sport high end SWATCH PRODUCTS and Joe Public likes to imitate them. Again hence the trade in replicas / fakes call them wha5 you may. I just had one through my hands a fake Rolex and lt looked good felt right but the movement was Chinese, and on it goes as long as we have those sheep they will buy anything the media makes a fuss off and in that I include the modern music song industry. My car radio is now obsolete never turned on.1 point

-

pound of curiosity is this a radio control watch? According to Amazon it came into existence around 2012 and that would make it vintage four a quartz watch. The problem with that really complicated citizen watches would be no service information and no parts availability typically. in other words usually there really complicated watches they suggest sending it to the factory. otherwise for the normal rechargeable watches if you in find the service manual. Often times they would have a test point to check the battery voltage. Then you place it under bright light to charge it up more and see if the voltage gone up.1 point

-

https://timeandtidewatches.com/landeron-history-in-depth/ I think you are correct, read the link.1 point

-

I wouldn't have known it either, but I remembered seeing one while disassembling a President "P" and lost it.1 point

-

A spring! Holy carp! That explains why a Bulova President which I worked on a little while ago always felt loose in its case. I wondered why the stem hole looked larger than it needed. Thanks for showing that. I honestly hadn't seen that before.1 point

-

1 point

-

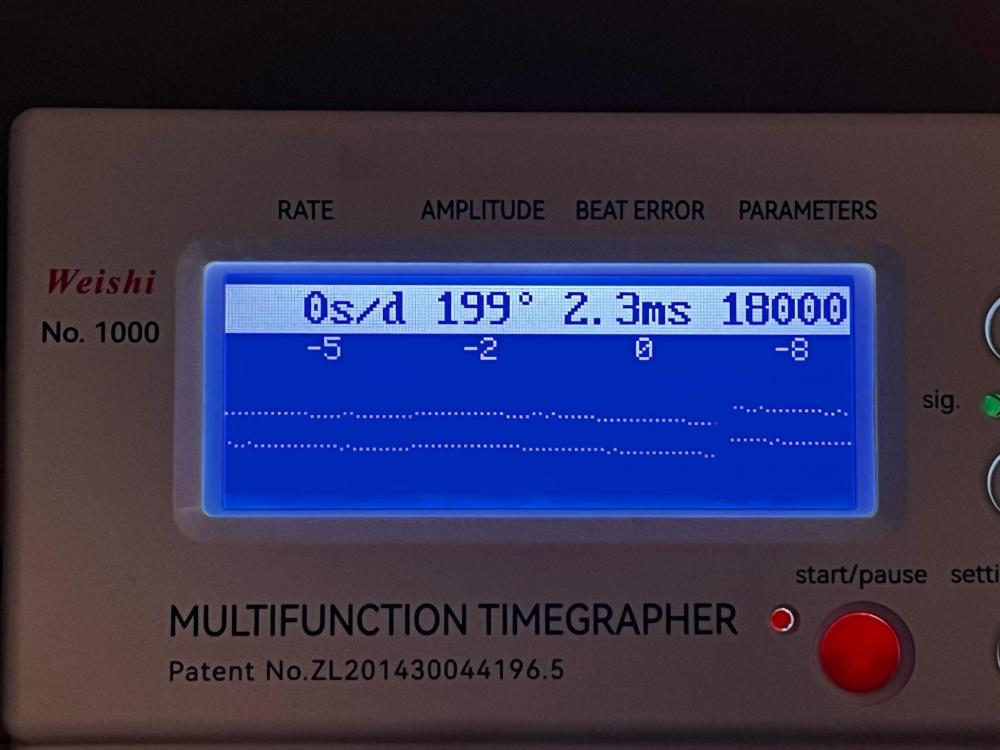

Well I added two small size (smallest I had) screws of equal weight opposite and removed two timing washers which were on opposite sides and on equal screws. I also cranked the timing screws all the way in. I was able to achieve this result. I'm quite please for a junker movement, it's a Waltham 1894 7 jewel with a grade 220 train bridge so it's a 9 jewel (basically rail grade in my house)1 point

-

We all know aliens roll up the windows and lock the doors when they pass by this planet. Even Klatu rolls his eyes every time he recalls his last visit.1 point

-

Its a last resort idea but still an idea if you cant find one or make one, its also not permanent and could possibly work.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

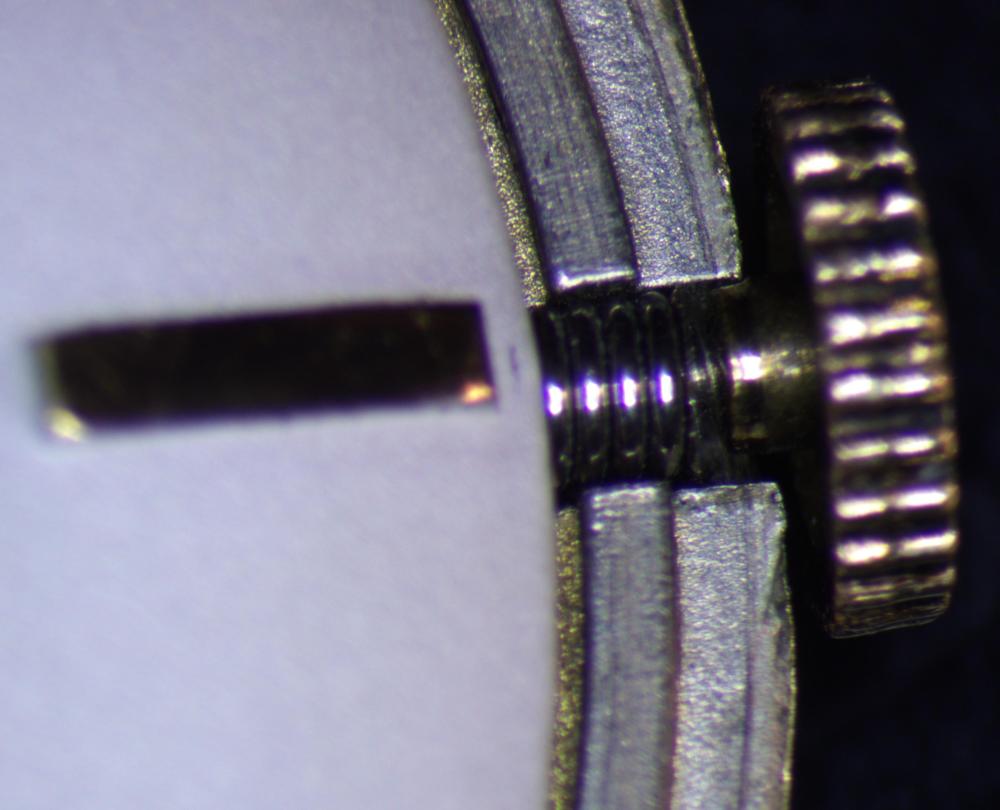

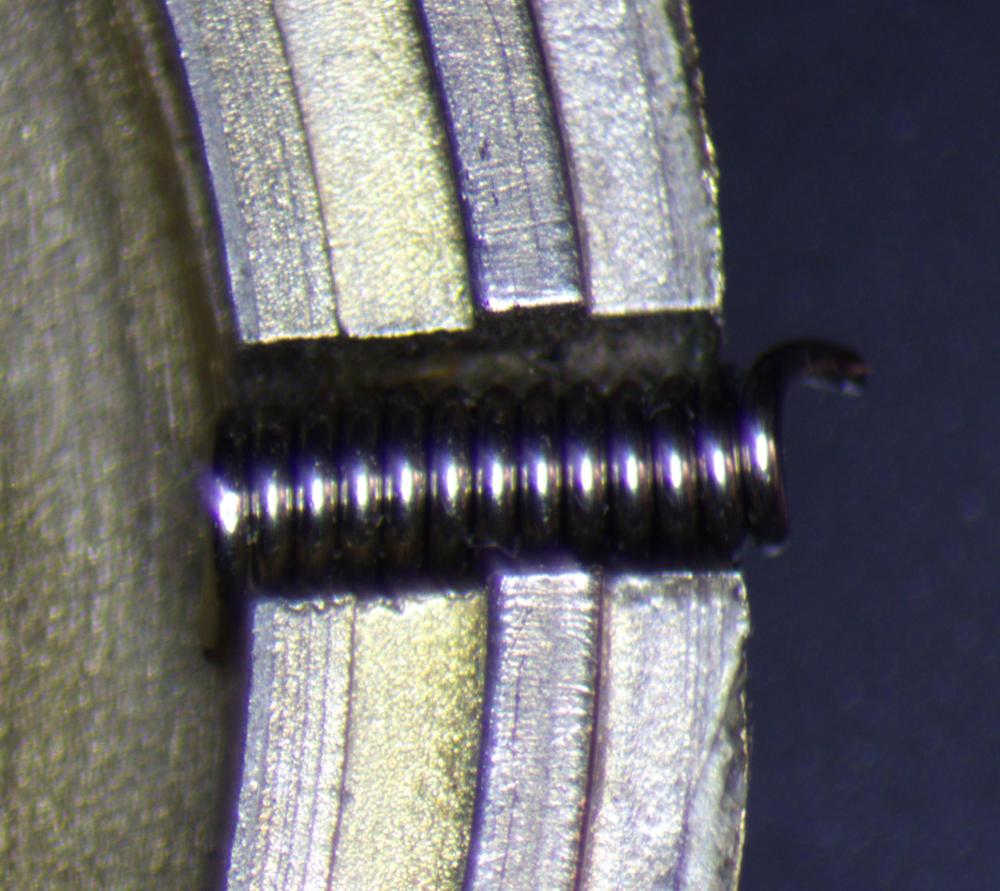

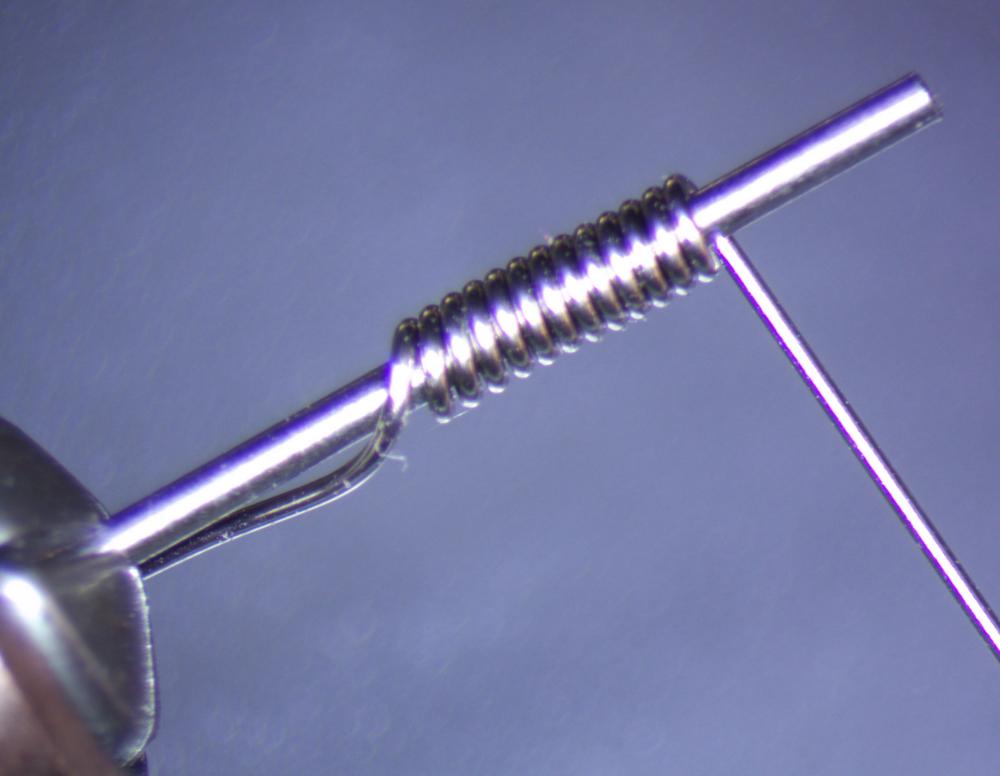

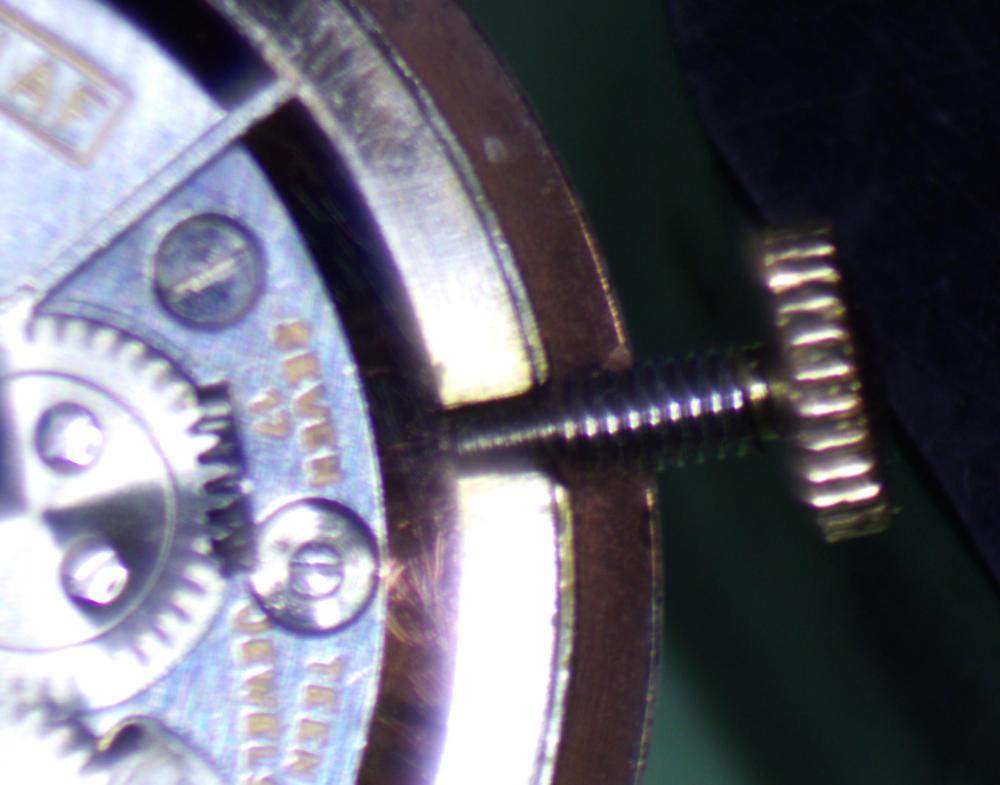

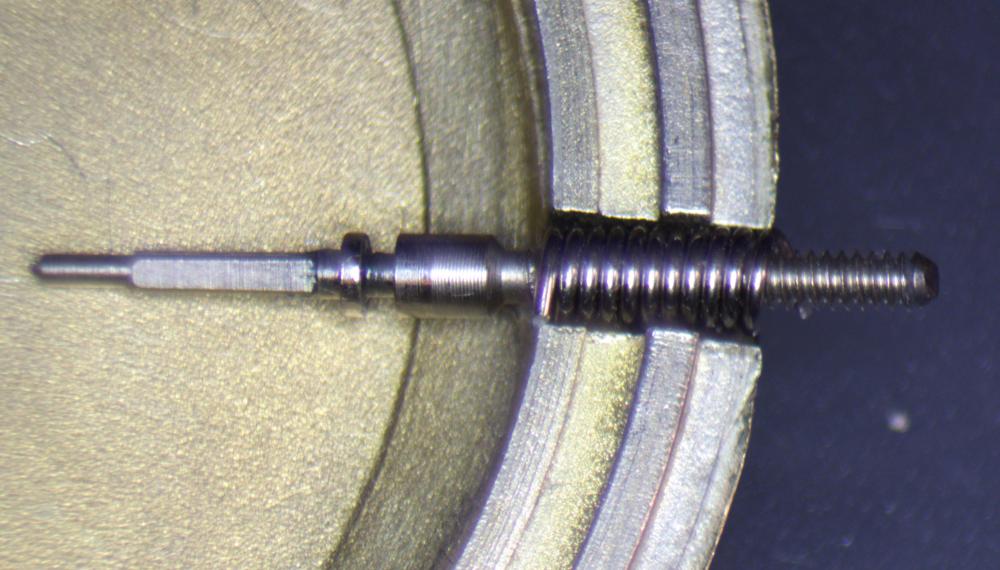

I had to uncase this guy recently because it stopped running. Looks like I'd pressed the hour hand on too far and it was touching the dial. While I was in there, I took the opportunity to take @Jon's advice and make a little spring for the stem to keep it from rattling around in the case when it's in the setting position. I had some thin stainless wire I got from Amazon for a different project. I found 0.3mm wrapped around a #64 drill bit seems to be the best fit. A little cleanup on a diamond wheel in my shop, and I think it's pretty nice. First try was too small. Second try with 0.4mm wire was too thick. Third try with 0.3mm and a larger mandrel was just right. After cleanup.1 point

-

This is where our right to repair has been removed. If you can't access the parts then you can't repair.1 point

-

@VWatchieis correct, once bought the product is yours, whatever the product is and therefore you should be able to do as you feel fit.1 point

-

In my opinion, manufacturers should be obliged to sell parts for a "reasonable price" to anyone. If I own a product I should be eligible to handle it in any way I see fit. As the owner of a product, you should have complete control over it. When it comes to safety issues, like with cars, there must be an independent inspection authority. Simple as that!1 point

-

I don't think these are any good for watch repair as there's not a lot of room to get your tweezers and work comfortably1 point

-

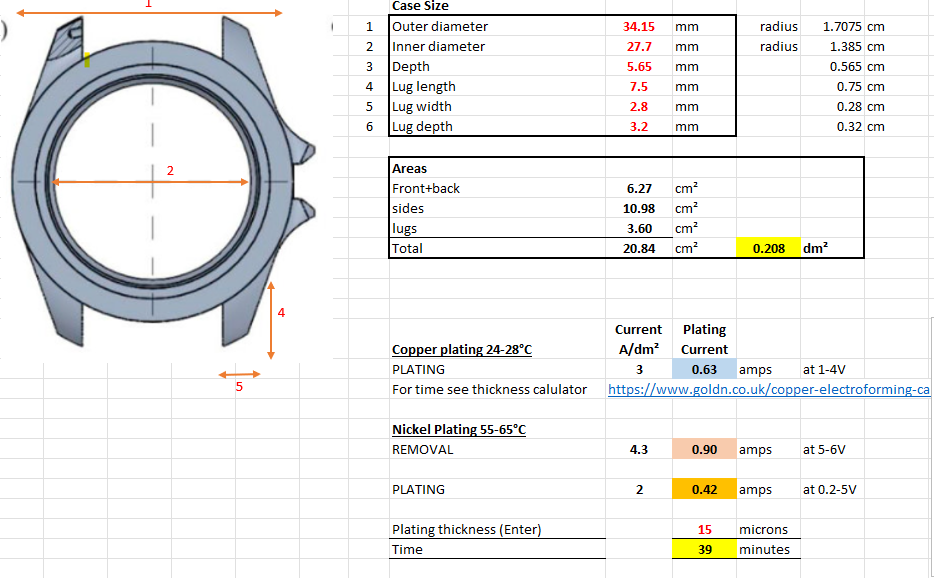

I just work out the area of a cylinder for the centre, and add on a bit for the lug. I can't attach the spreadsheet, but the calculations are, Front+back area = (outer radius-inner radius)* Pi² Sides (inner & outer) = 2 * Pi * depth * (inner radius + outer radius) Lugs = No. of Lugs * ( length * width *2 + length * depth * 2) (width and length I use average values) Add them up to give an area in cm². divide by 100 to get it in dm², as plating currents are often in these units. I use Watts Nickel plating solution. Current density are often given as 2-10 A/dm². Lower values give better finish. I use 3 A/dm². So just multiply your surface area by 3 to get the current. You can see below the values I use for nickel removal (4.3), and copper plating (2). You set the current, and the voltage takes care of itself. There's a nickel plating calculator : https://www.goldn.co.uk/nickel-tank-plating-calculator/ and copper : https://www.goldn.co.uk/copper-electroforming-calculator/1 point

-

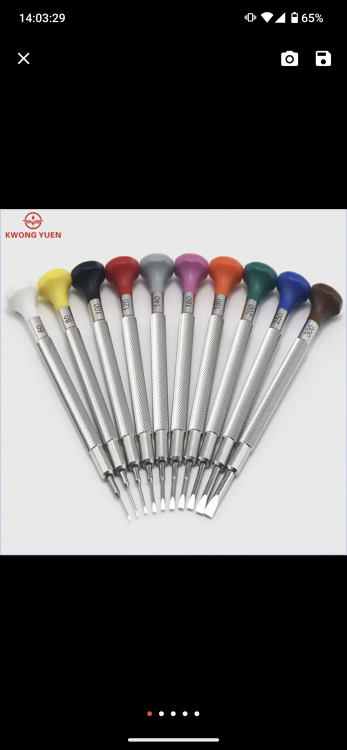

Hi all, I took delivery of some new screwdrivers a few weeks ago, and although these are a Chinese brand (Kwong Yuen) I would highly rate them, may even prefer them to my Burgeon set. Nothing in this for me, just hope that someone who is looking can take advantage of this experience. Link here. As a side note I also have some auto oilers of the same brand and they also work well.1 point

-

@Waggy I have seen comments here and elsewhere recommending this brand as being the best quality out of china. Tom1 point

-

That is one of the barrels that separates from the edge, not from the top or bottom. I like to use a sharp razor and a screwdriver as leverage, but you must be VERY careful when doing it this way not to mark up the side walls of the barrel. With a light touch and steady hand they will separate. Here's one on a 7006A (same barrel as a 7009A) I did the other day.1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)