Leaderboard

Popular Content

Showing content with the highest reputation on 12/06/22 in all areas

-

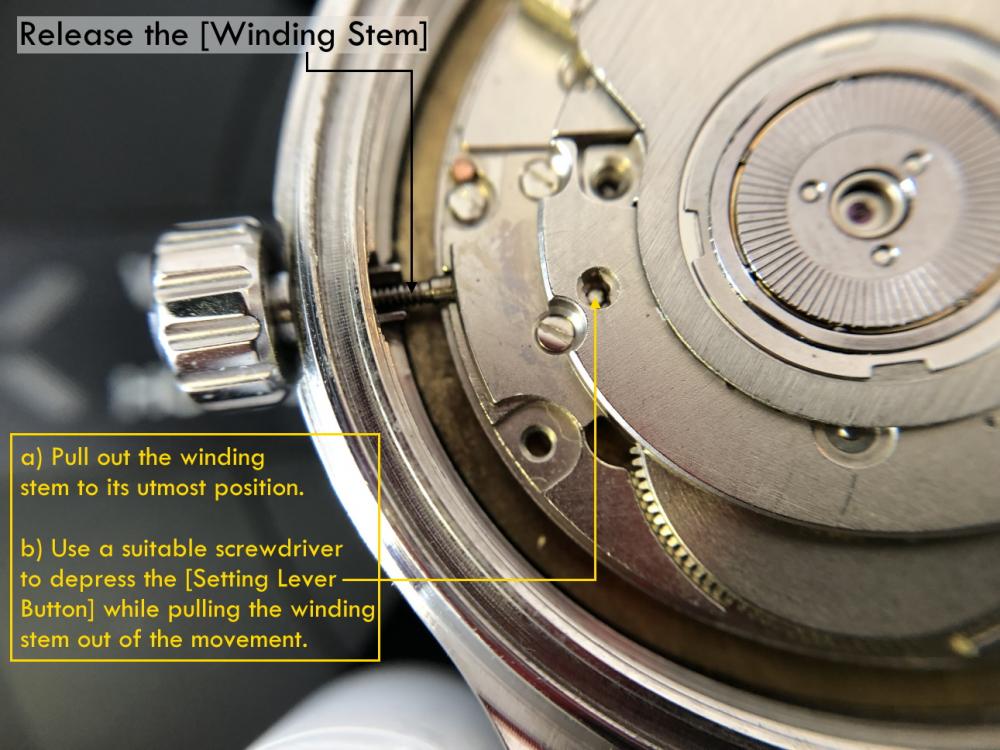

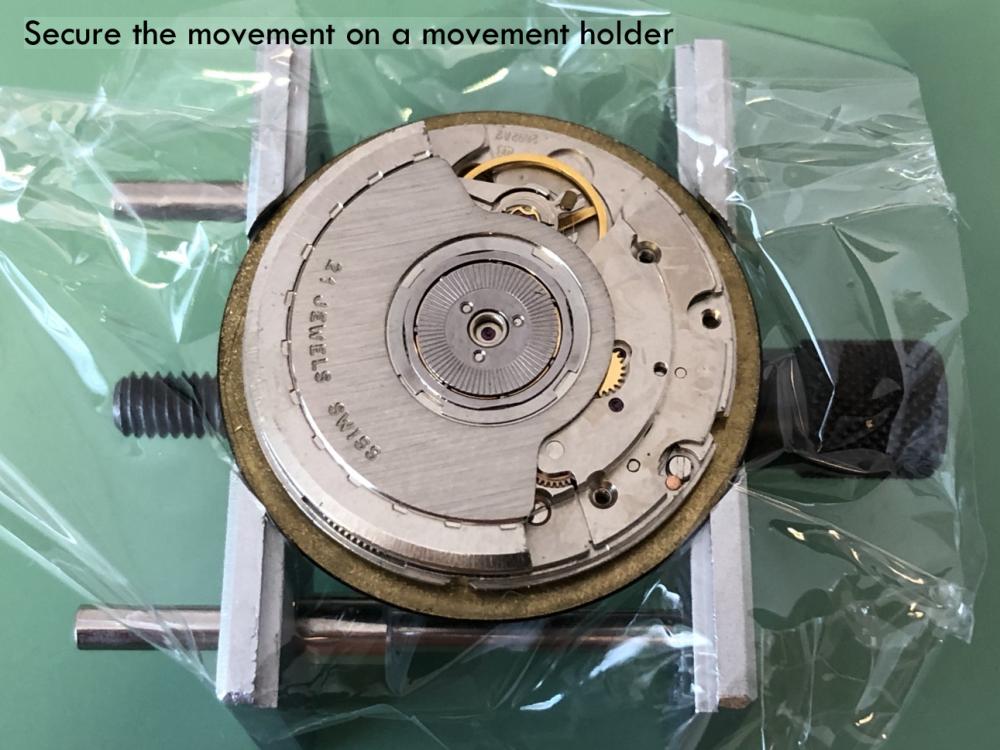

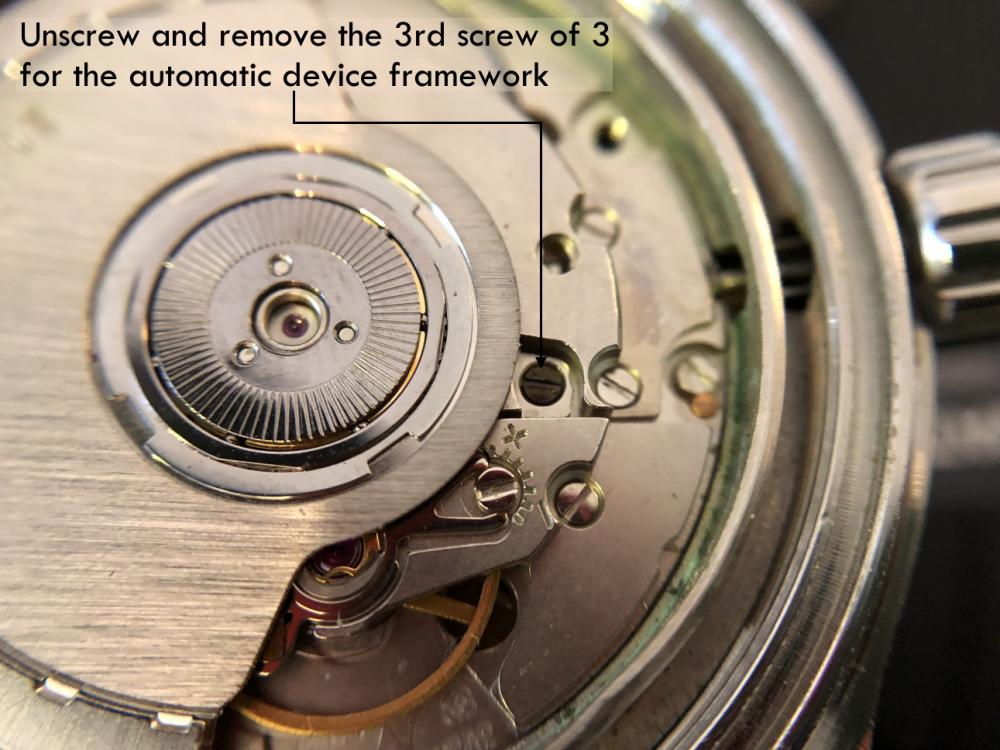

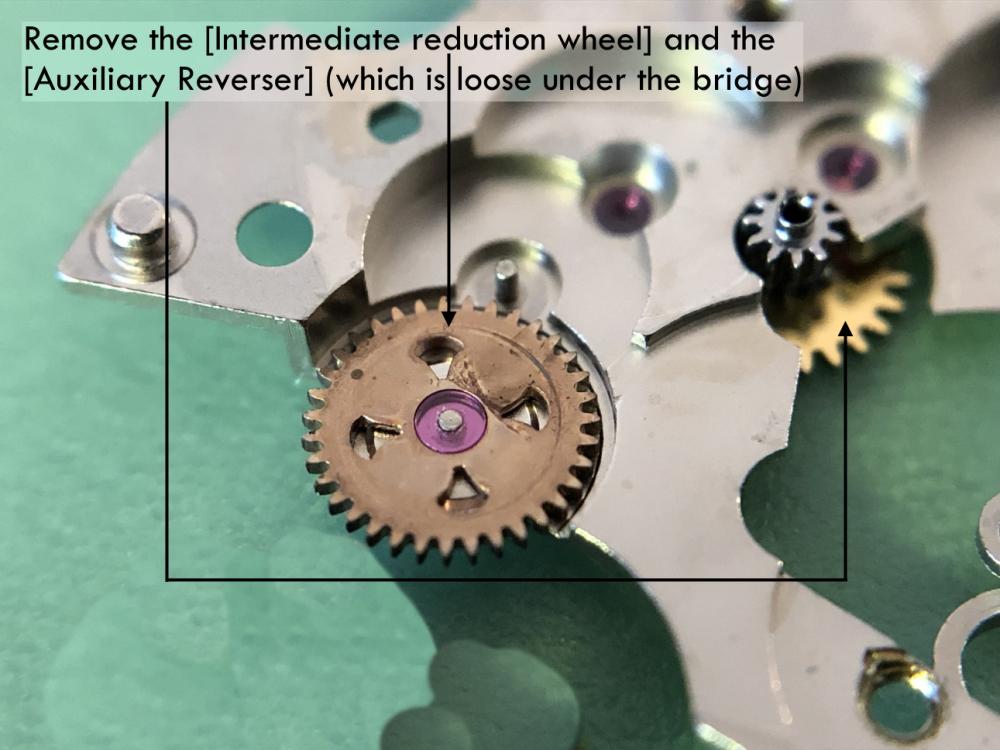

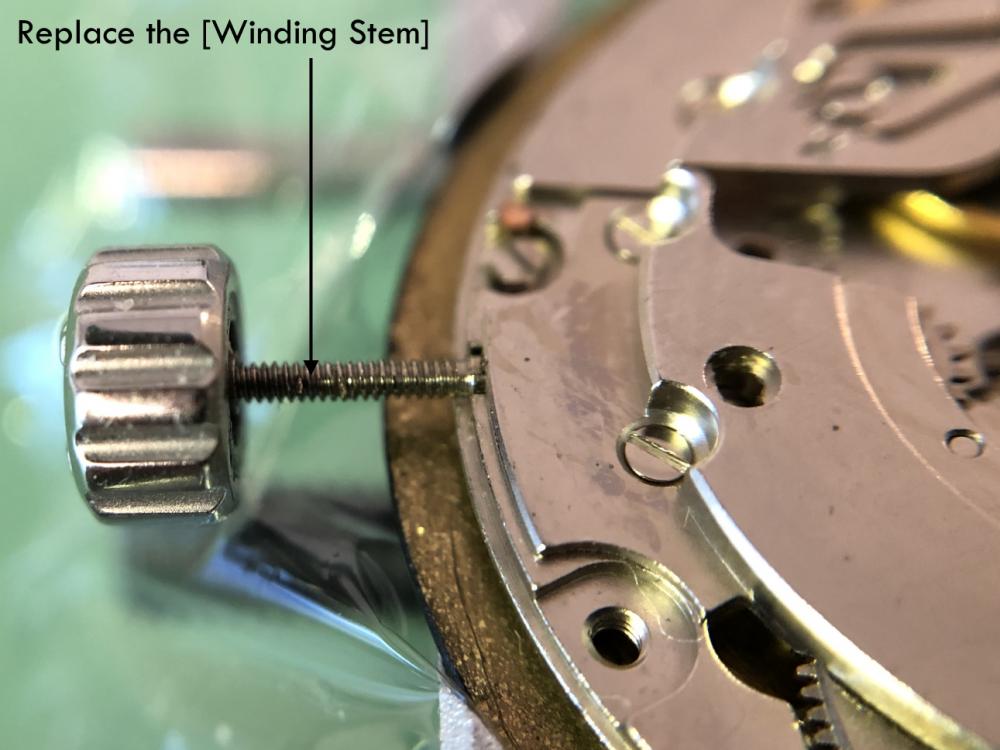

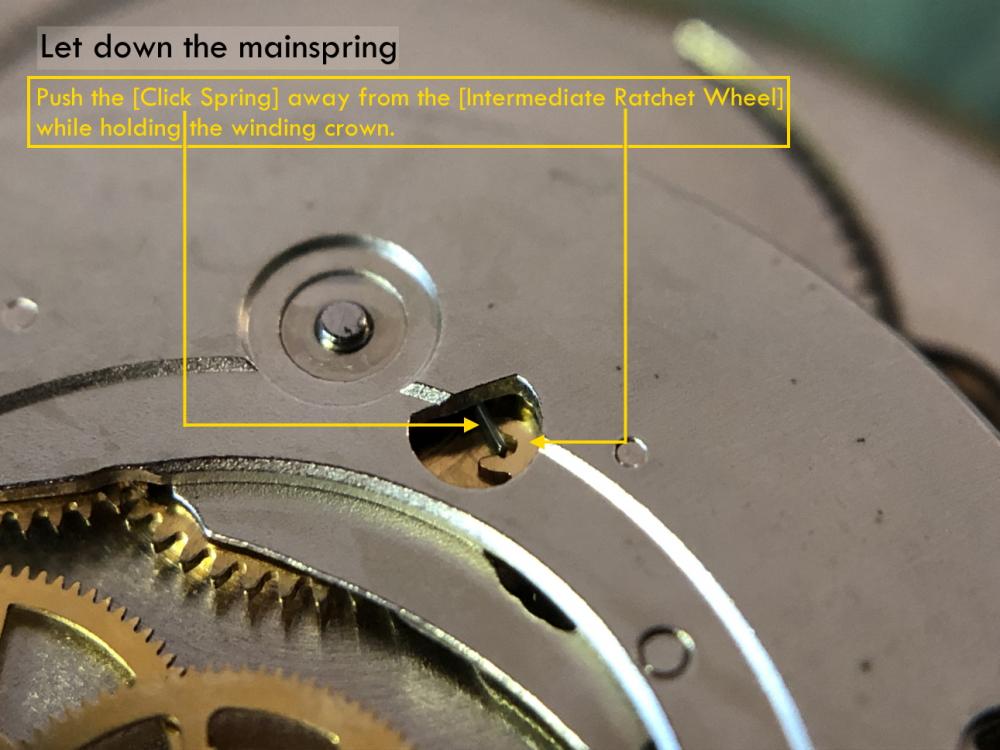

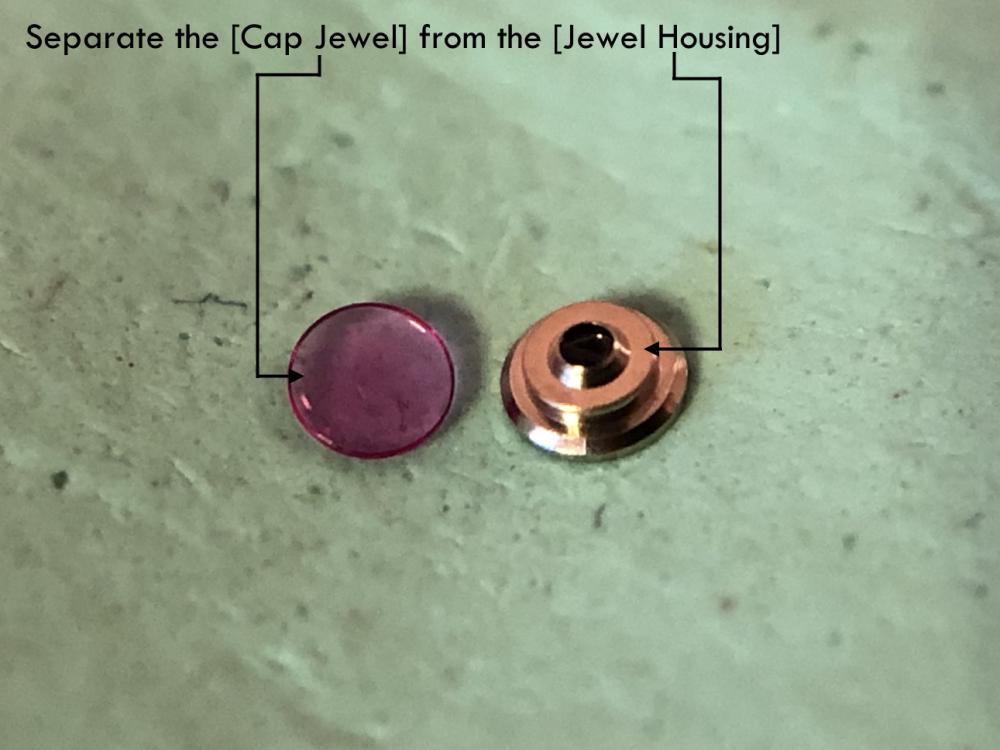

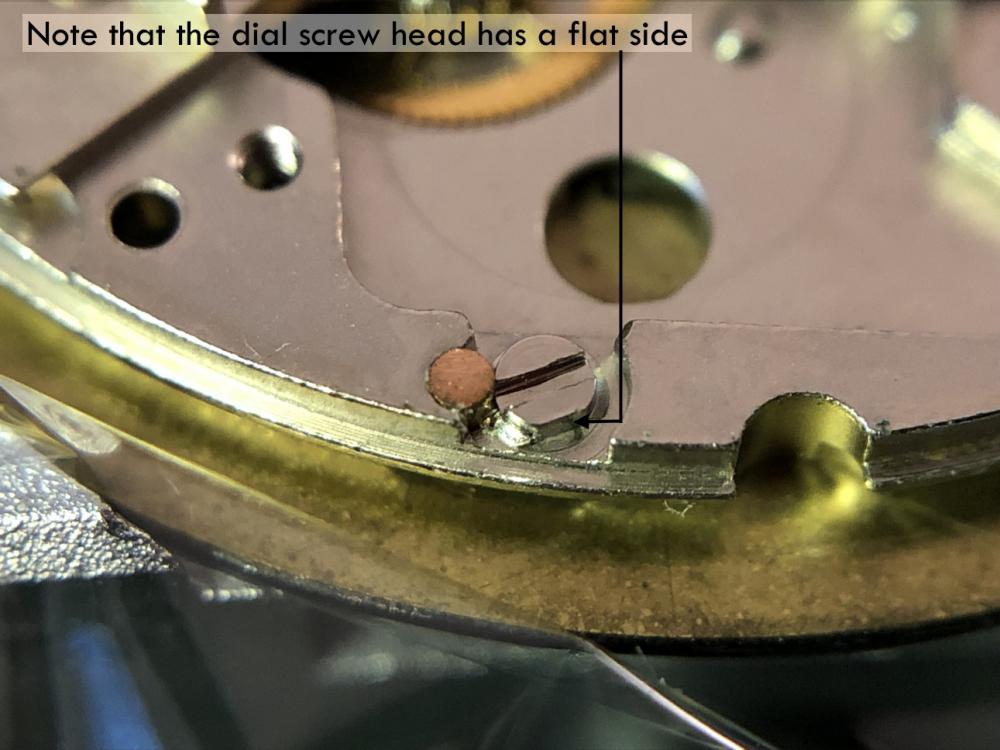

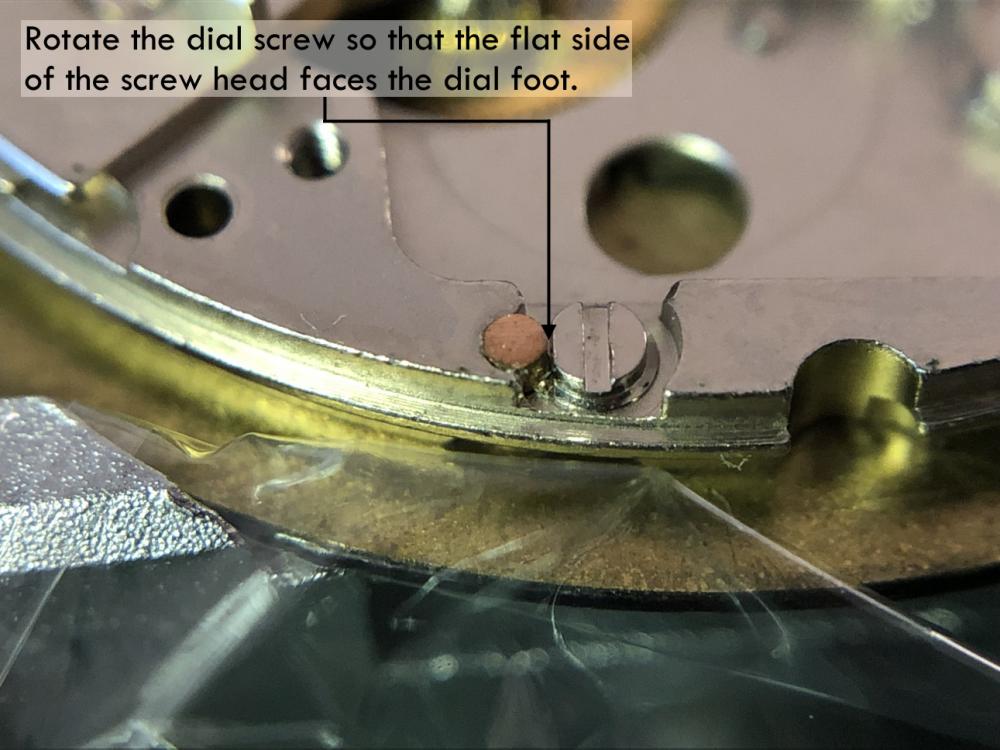

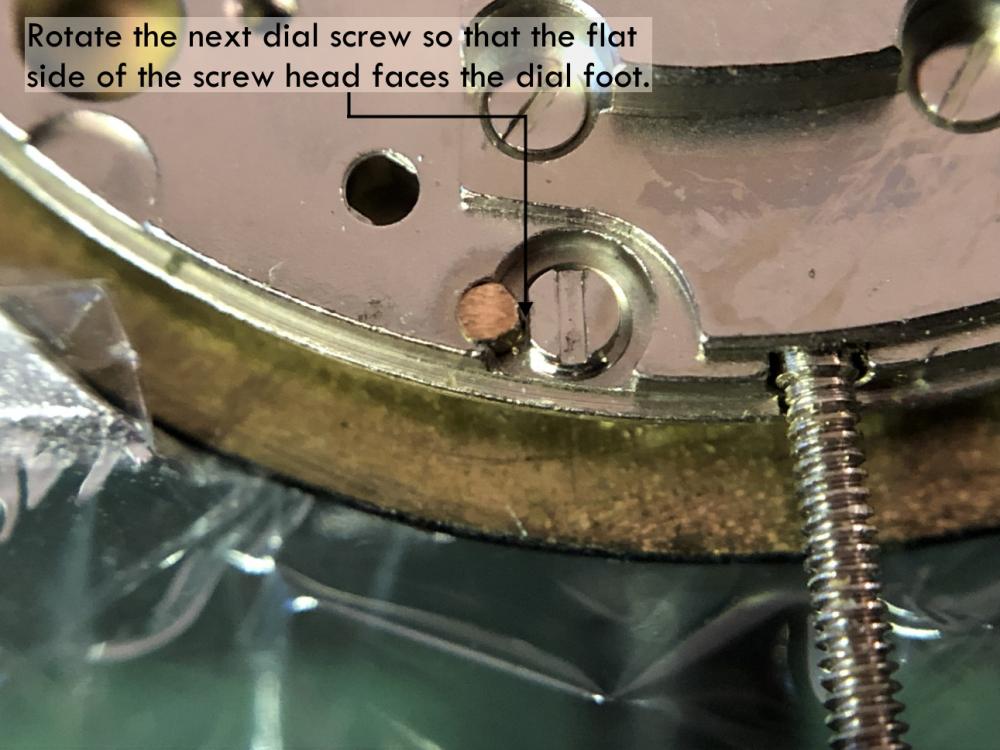

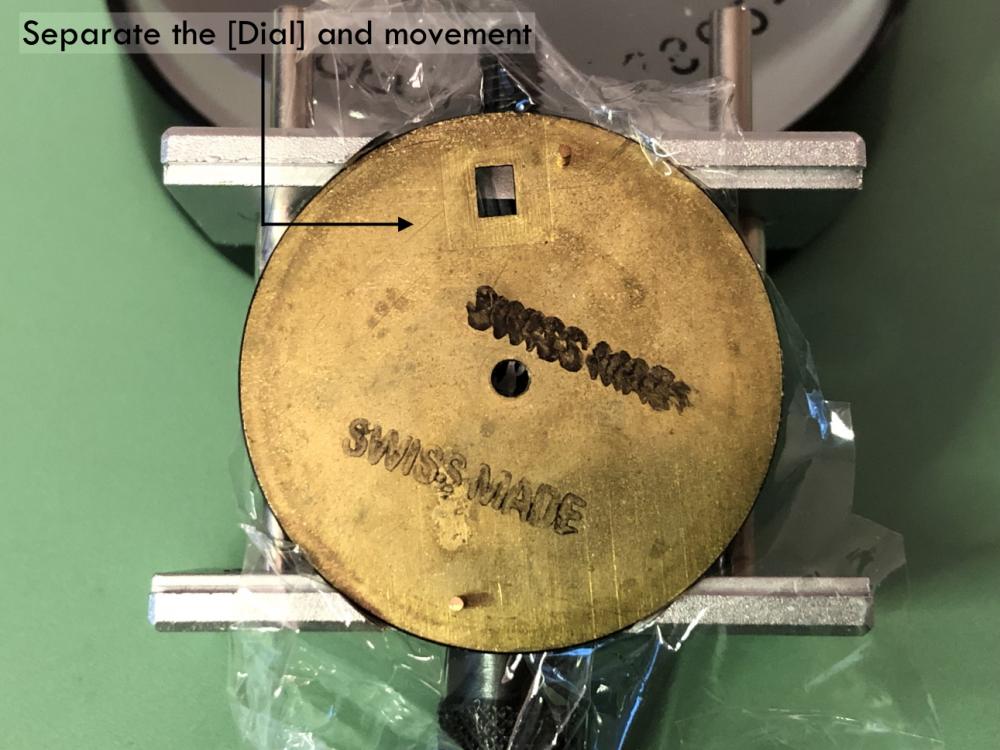

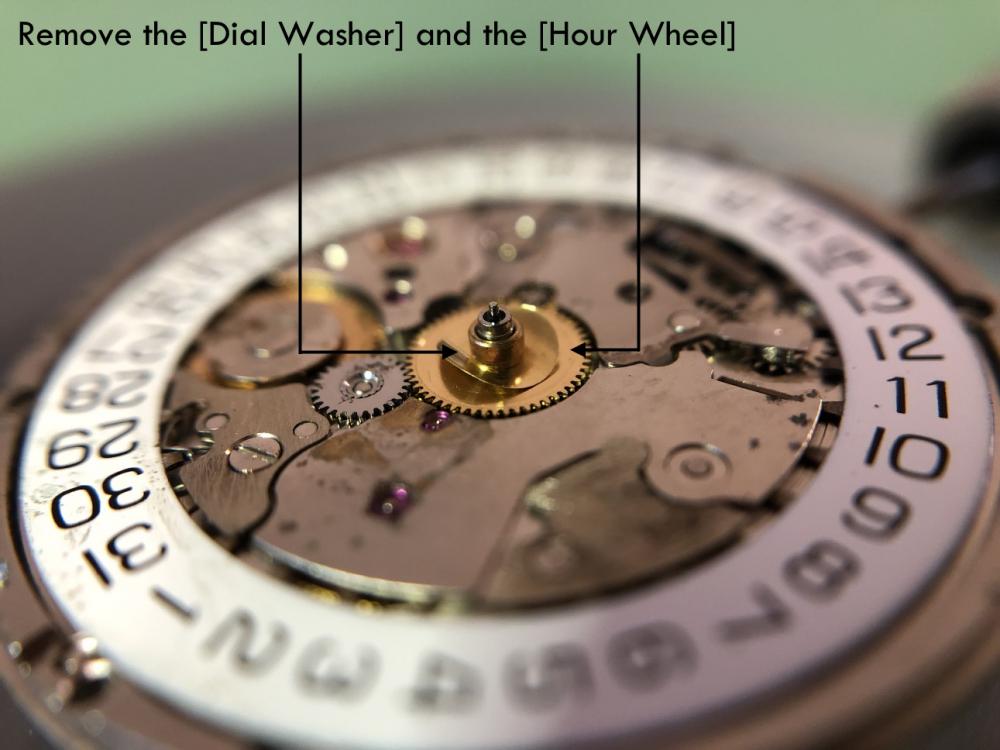

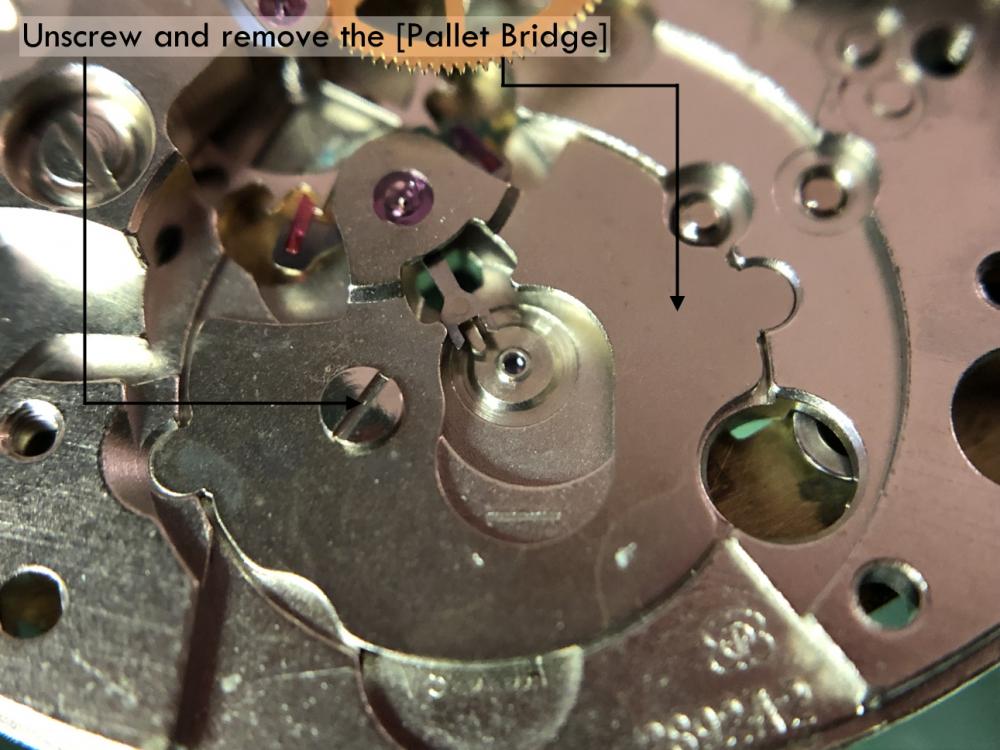

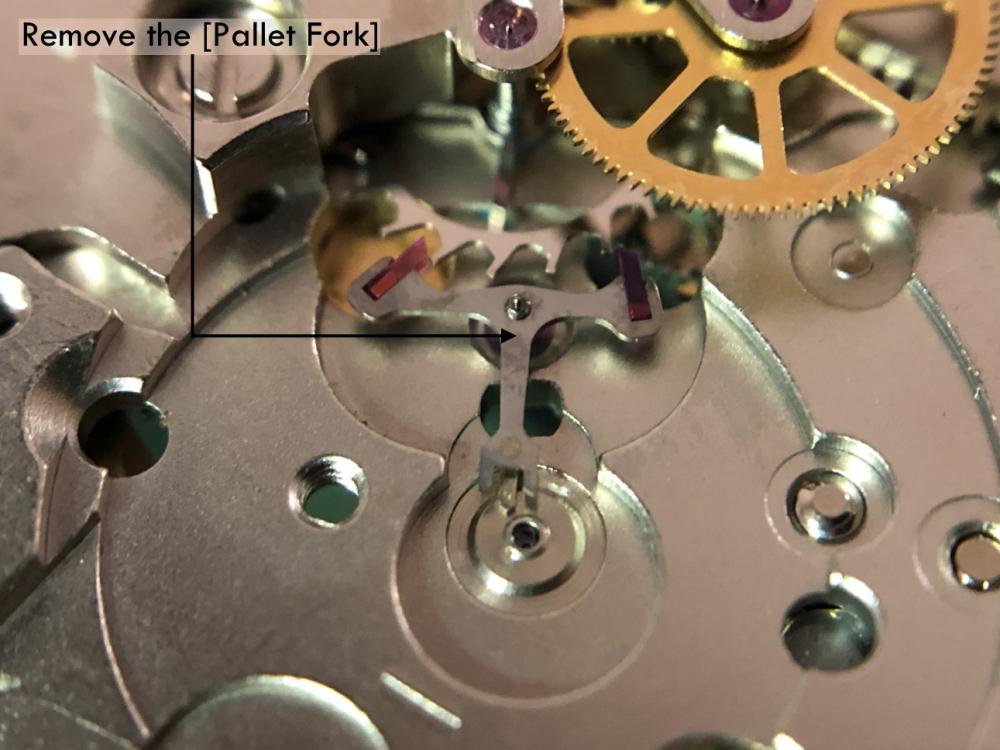

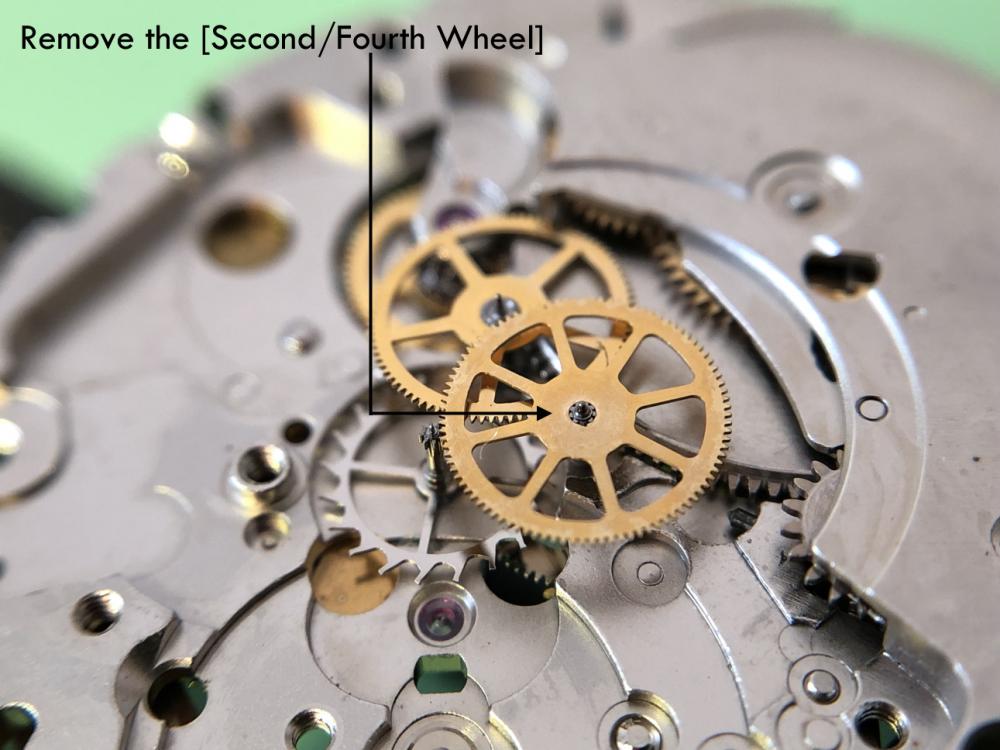

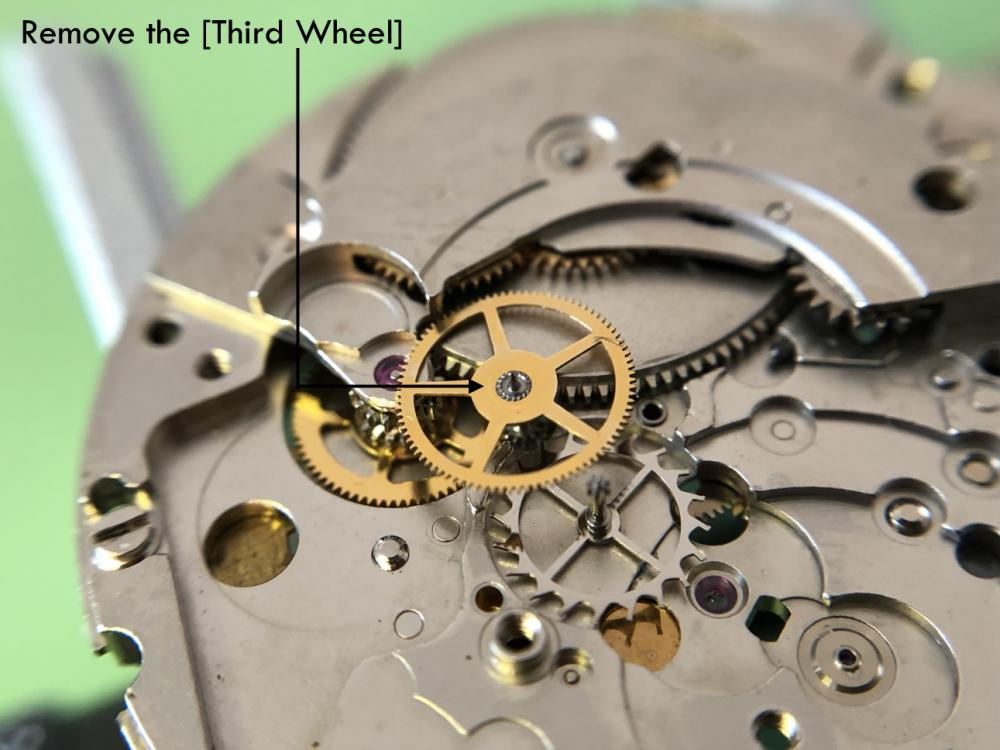

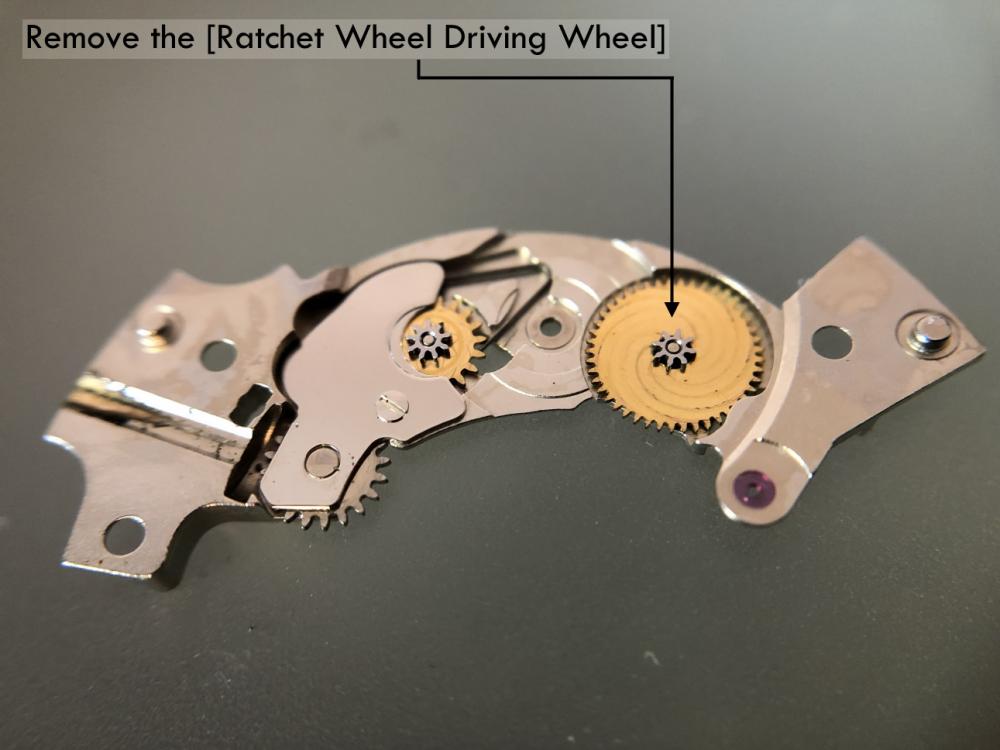

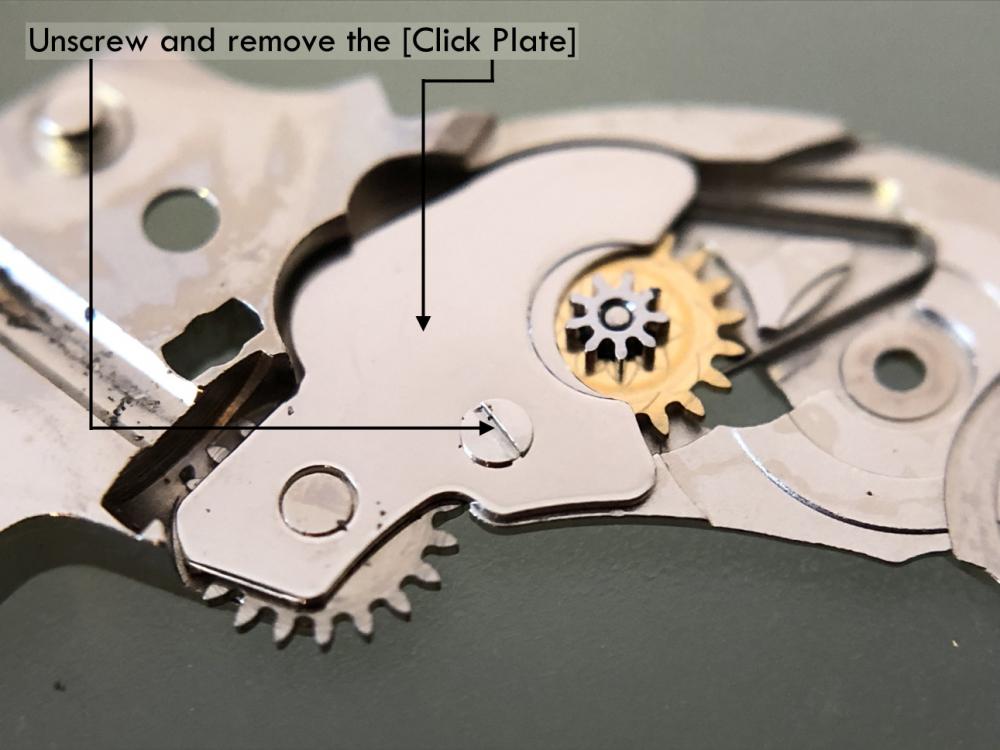

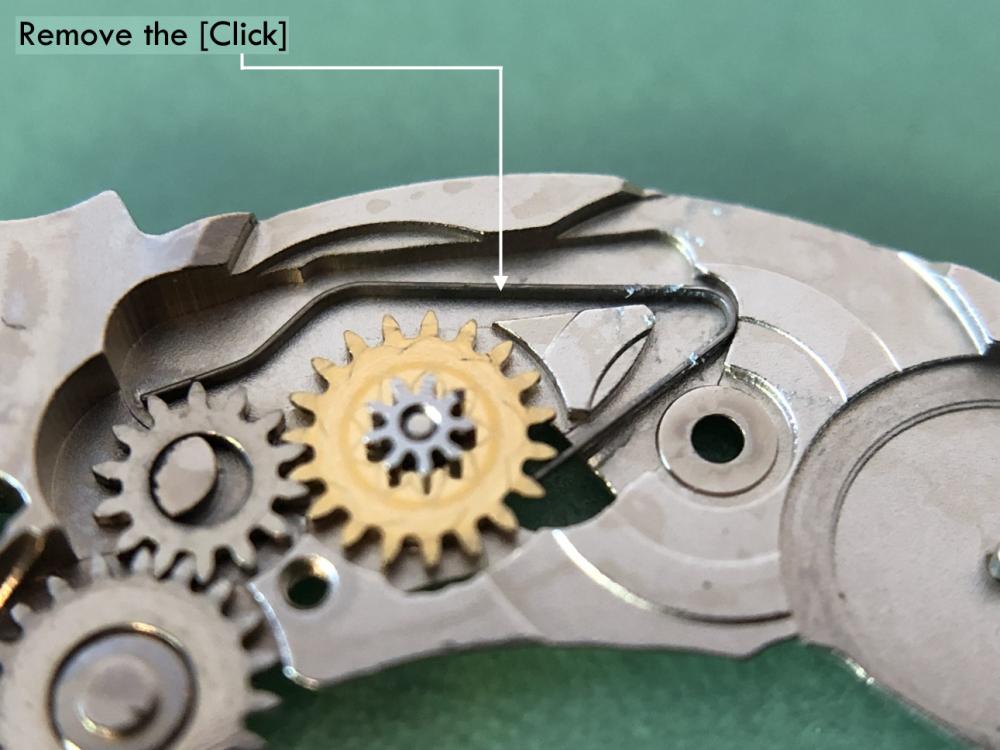

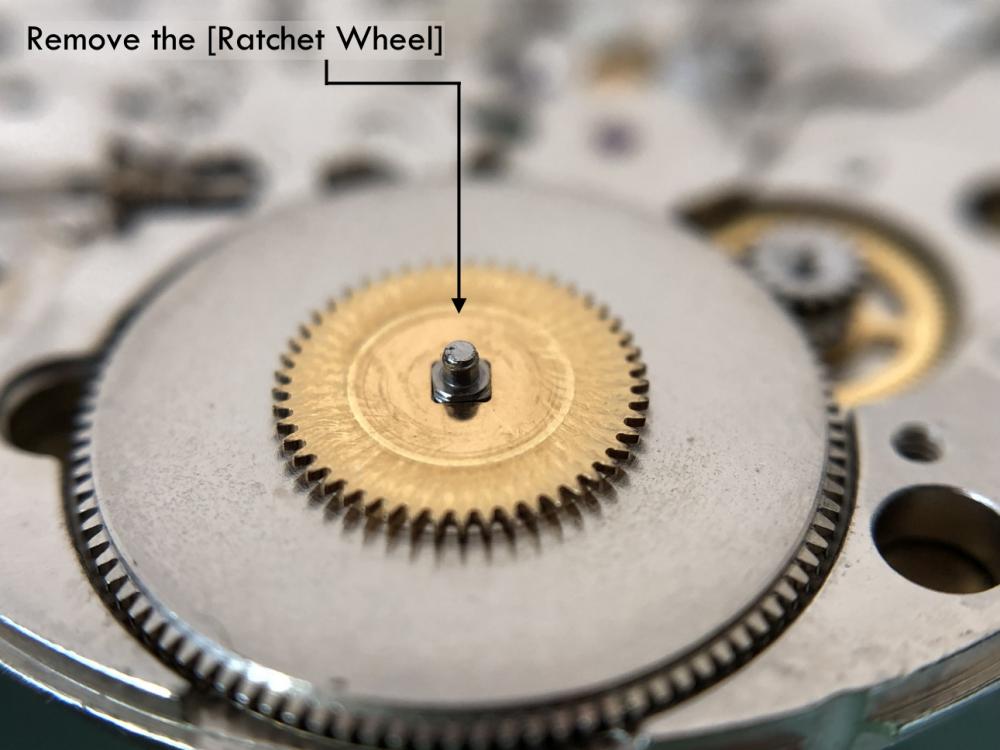

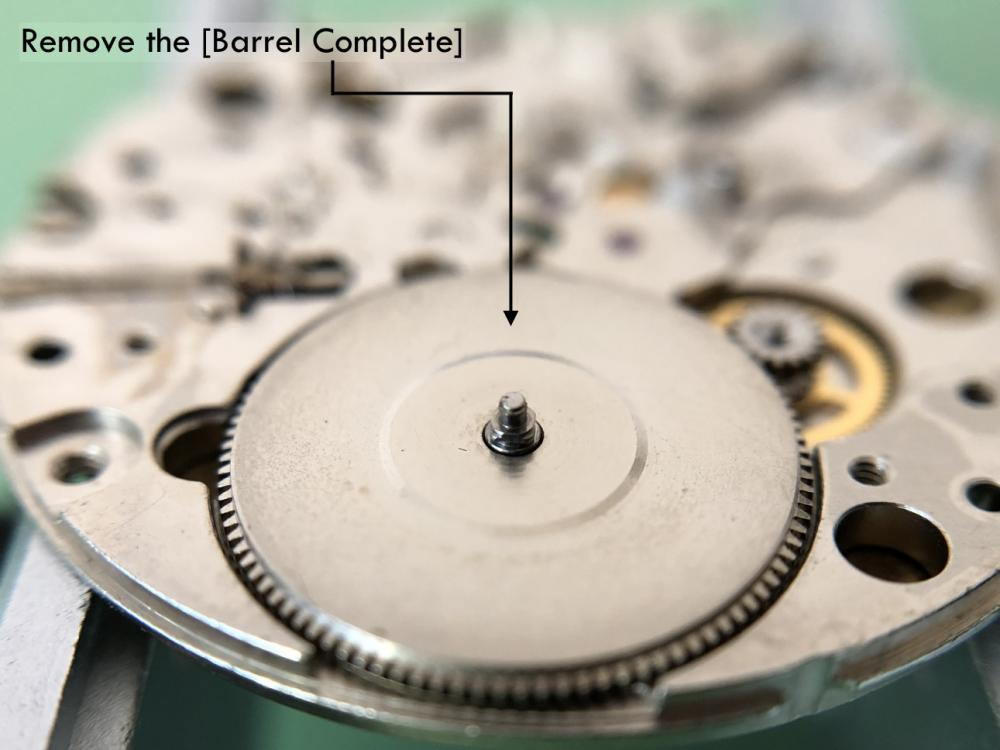

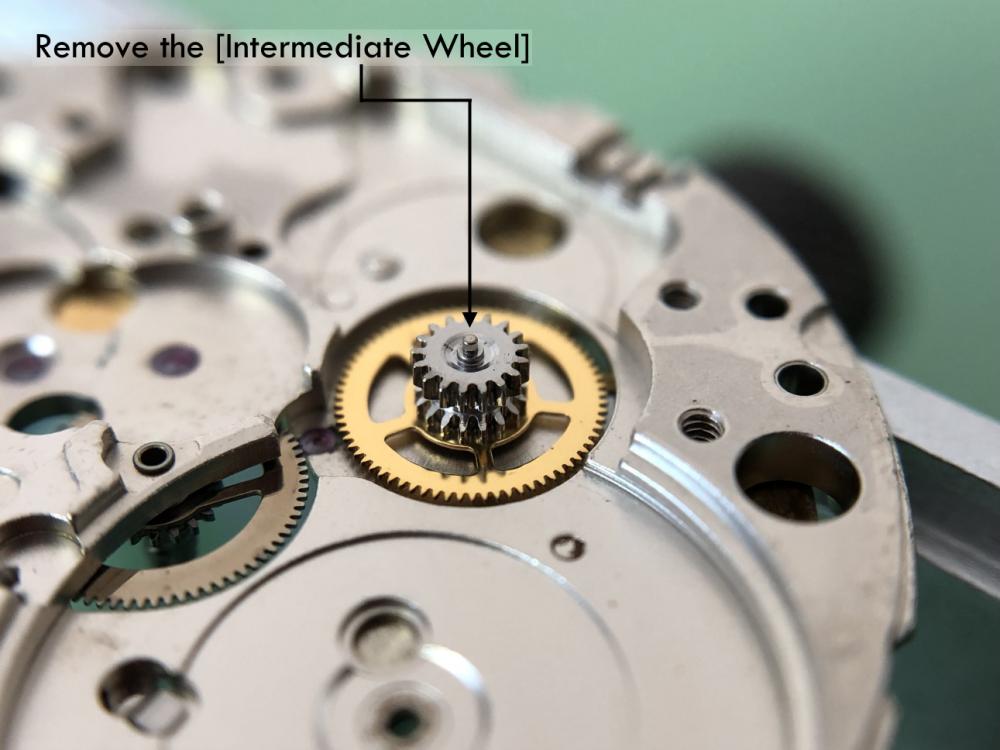

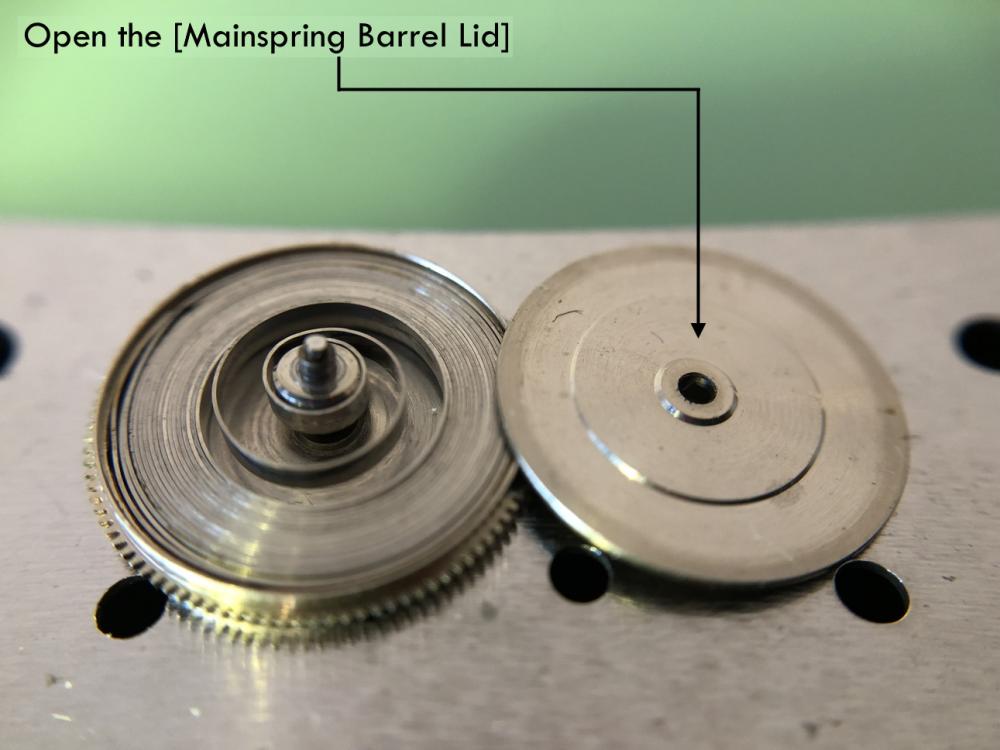

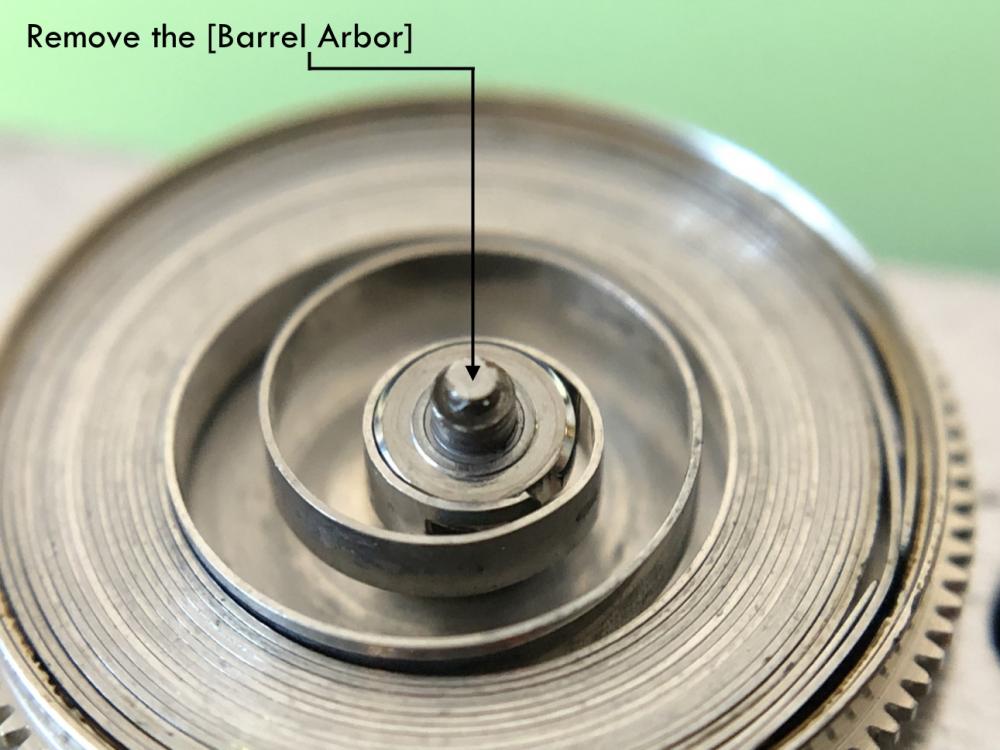

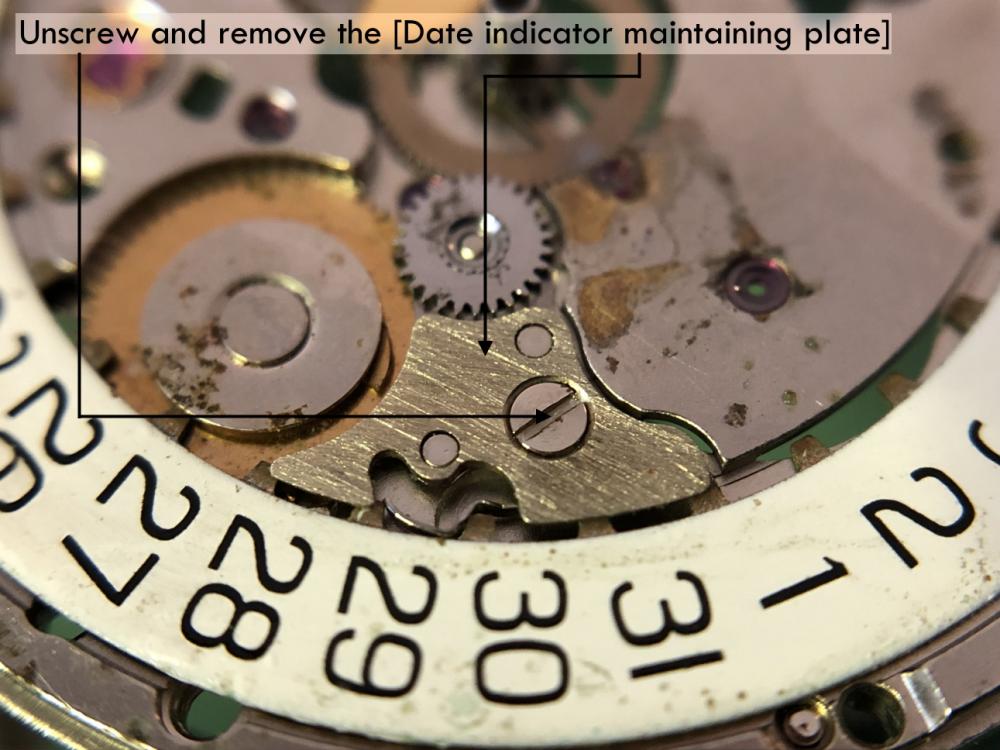

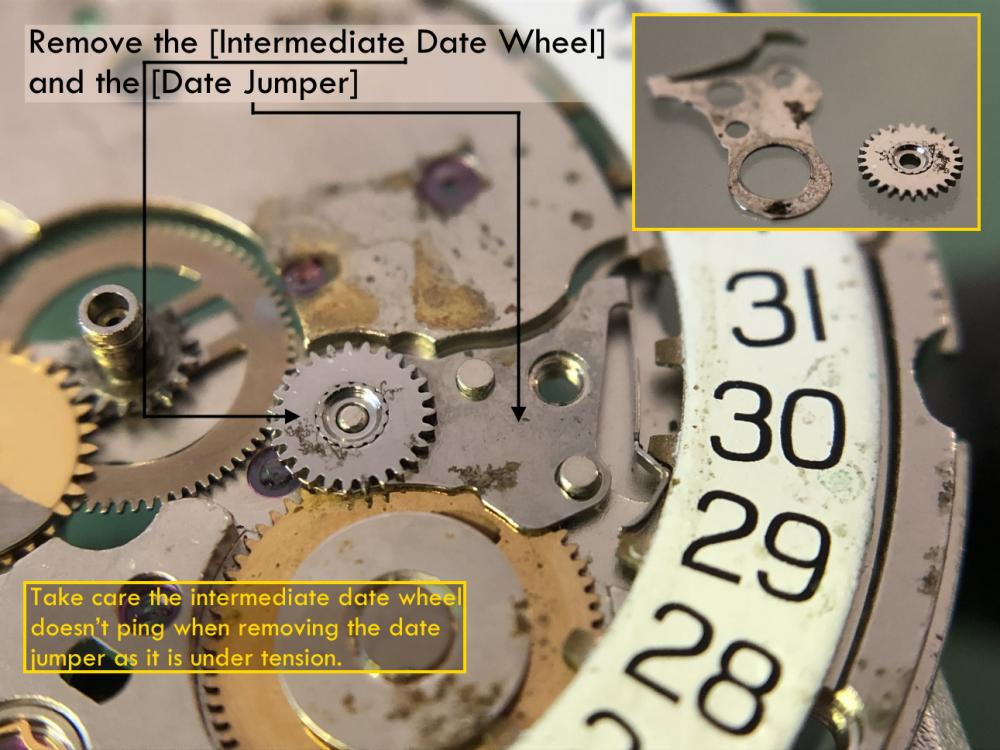

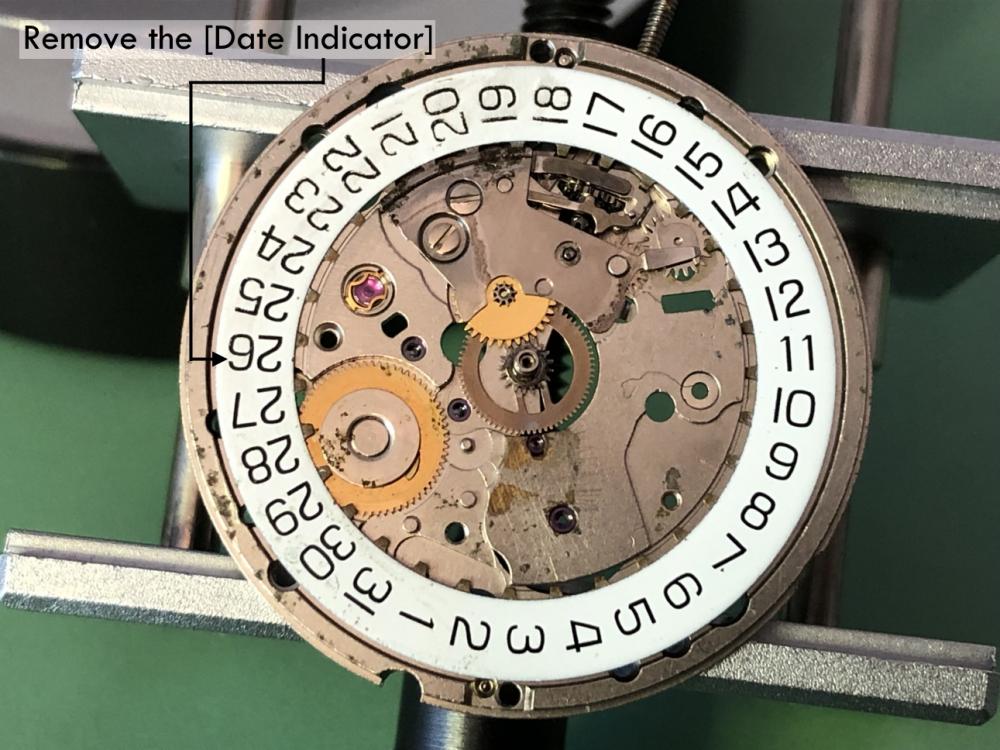

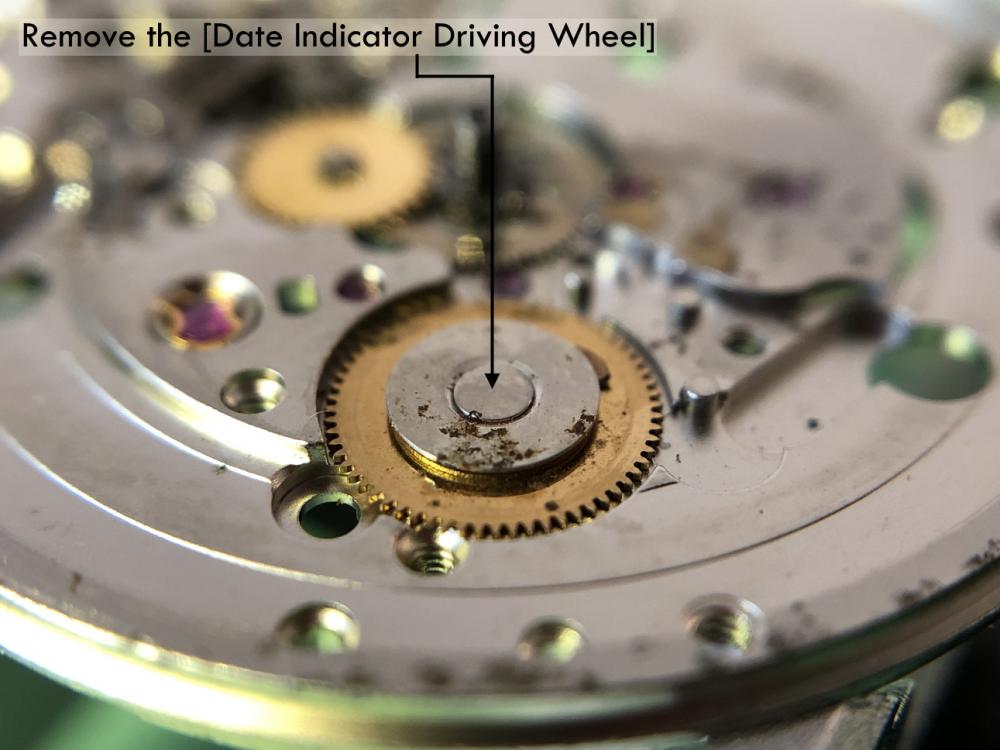

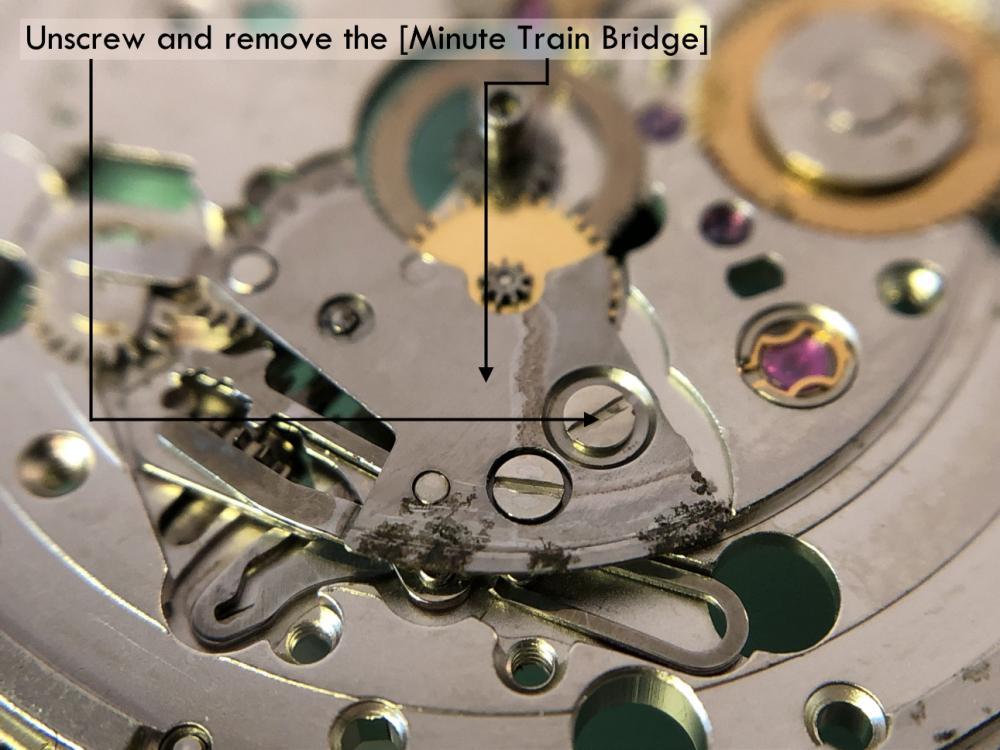

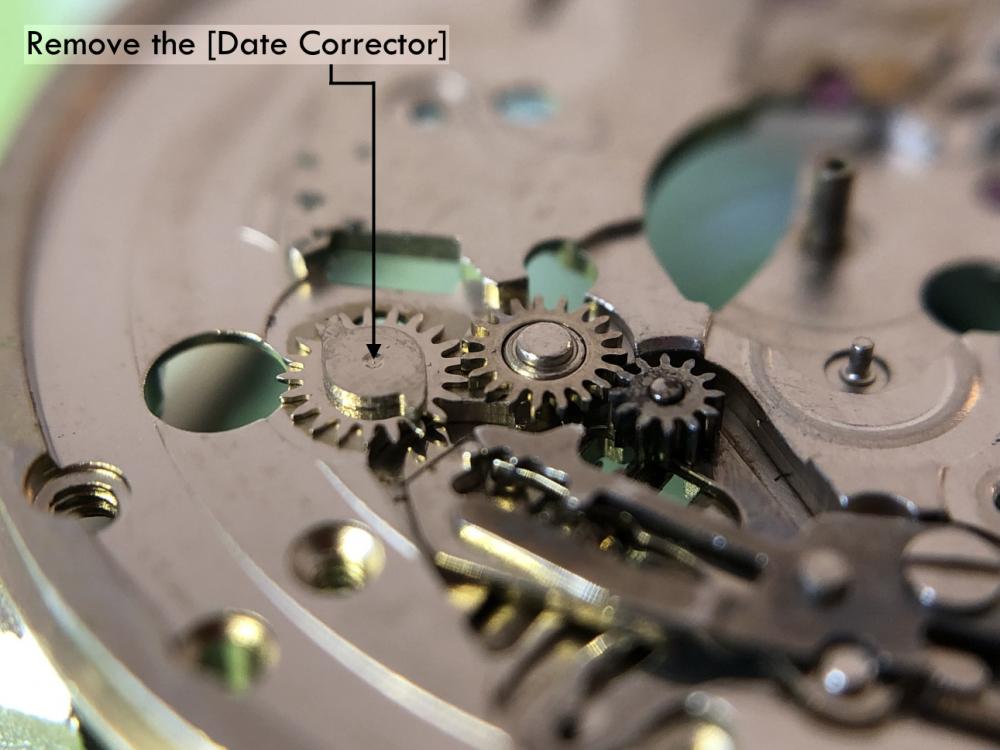

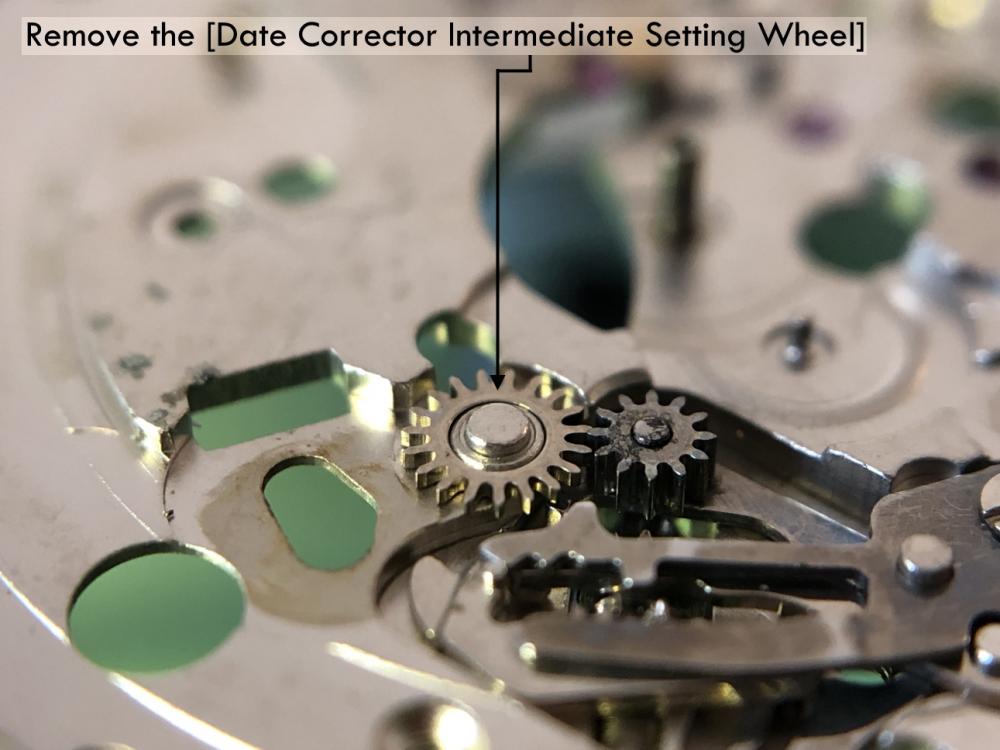

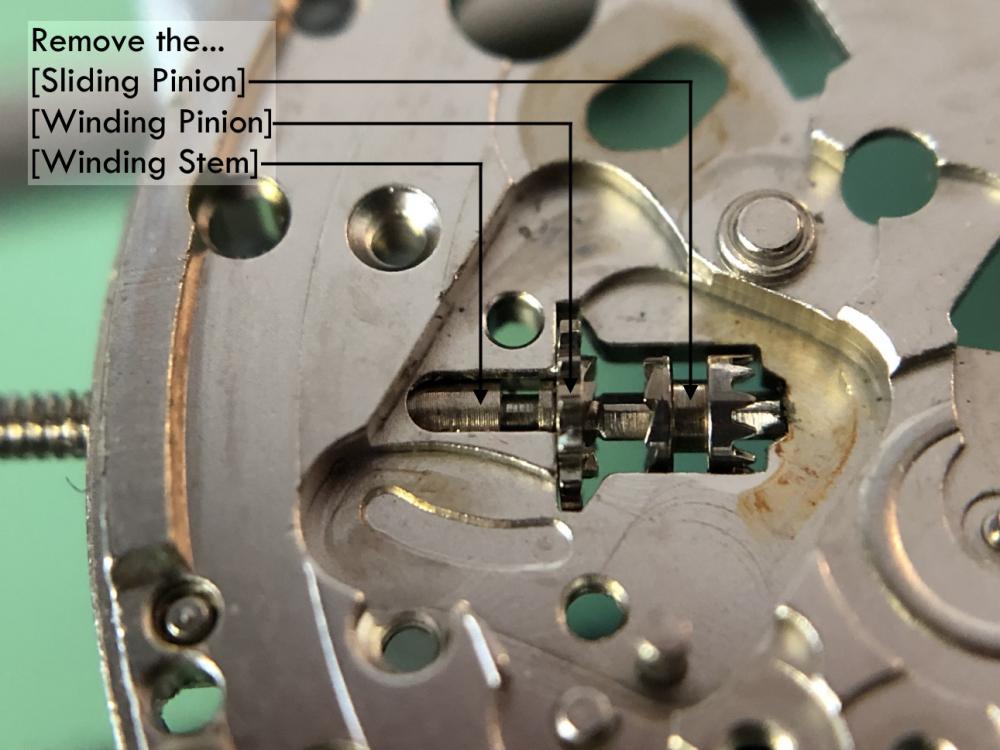

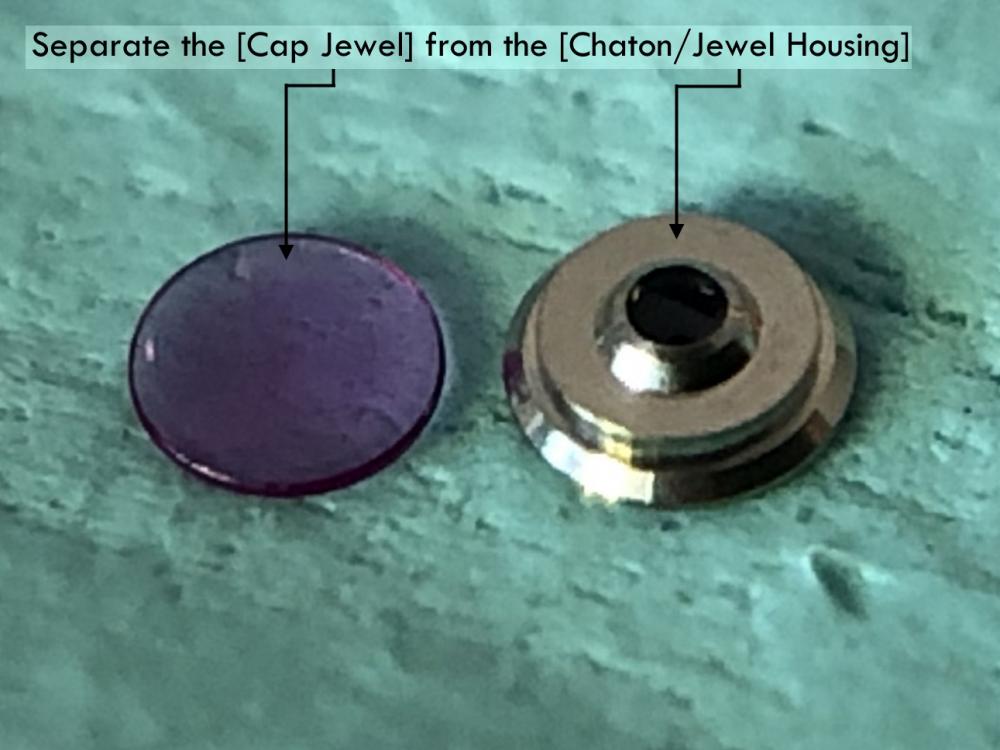

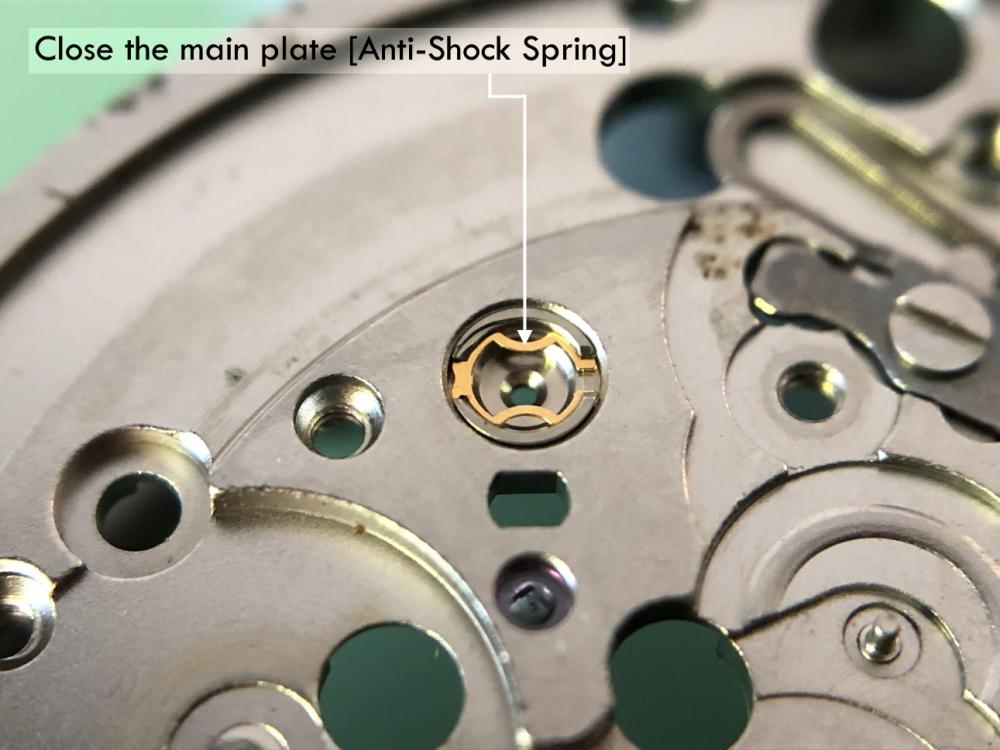

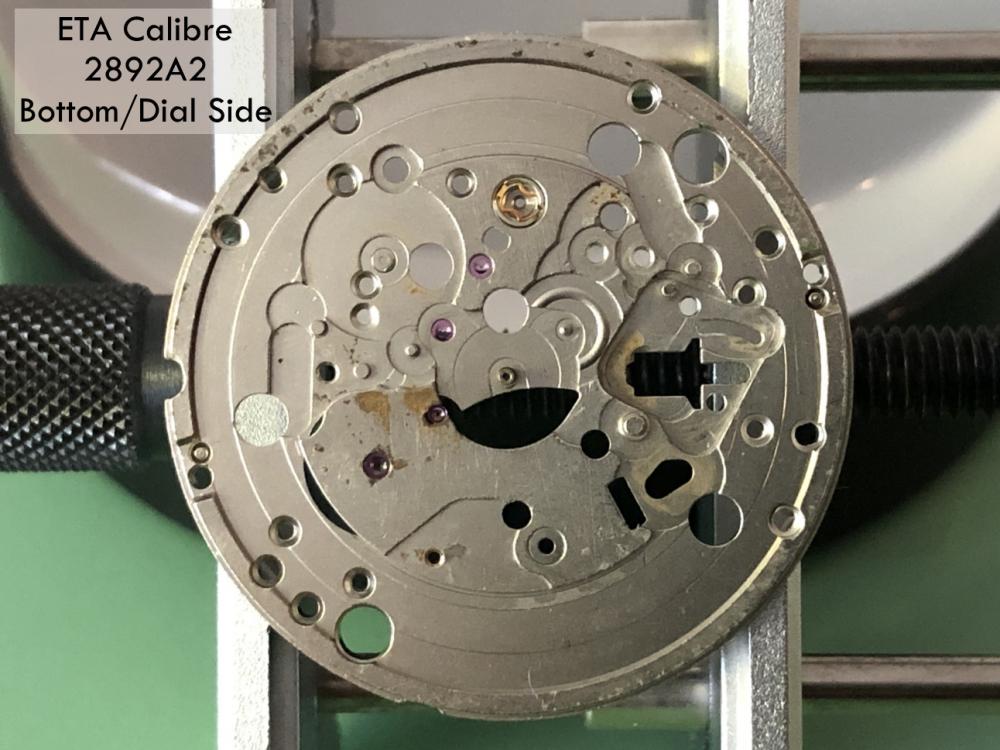

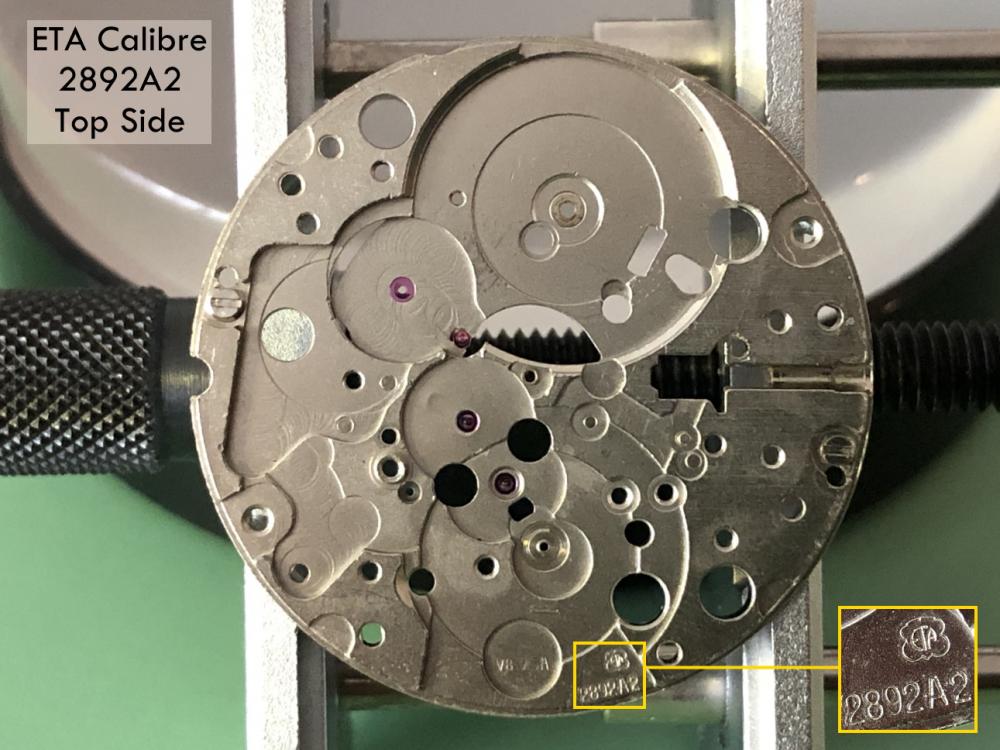

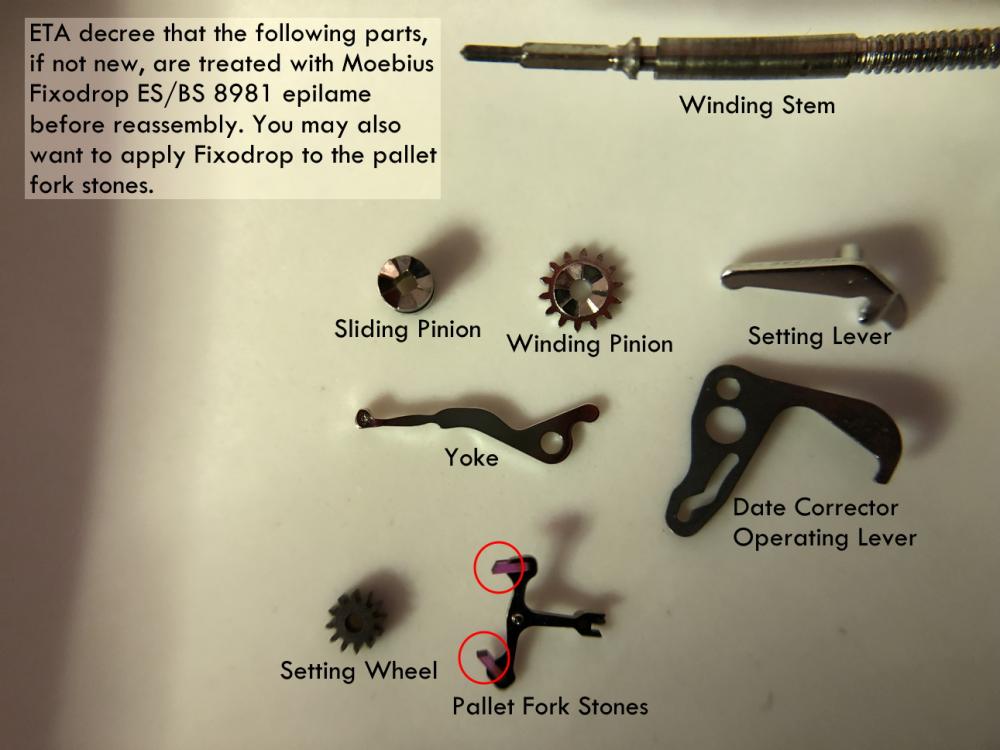

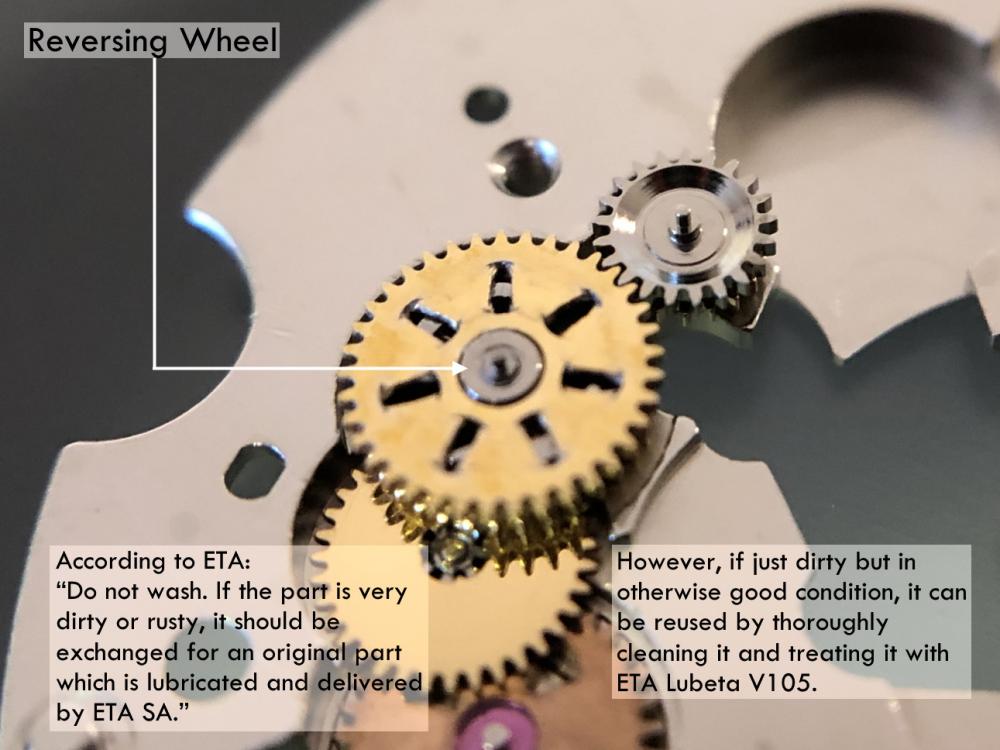

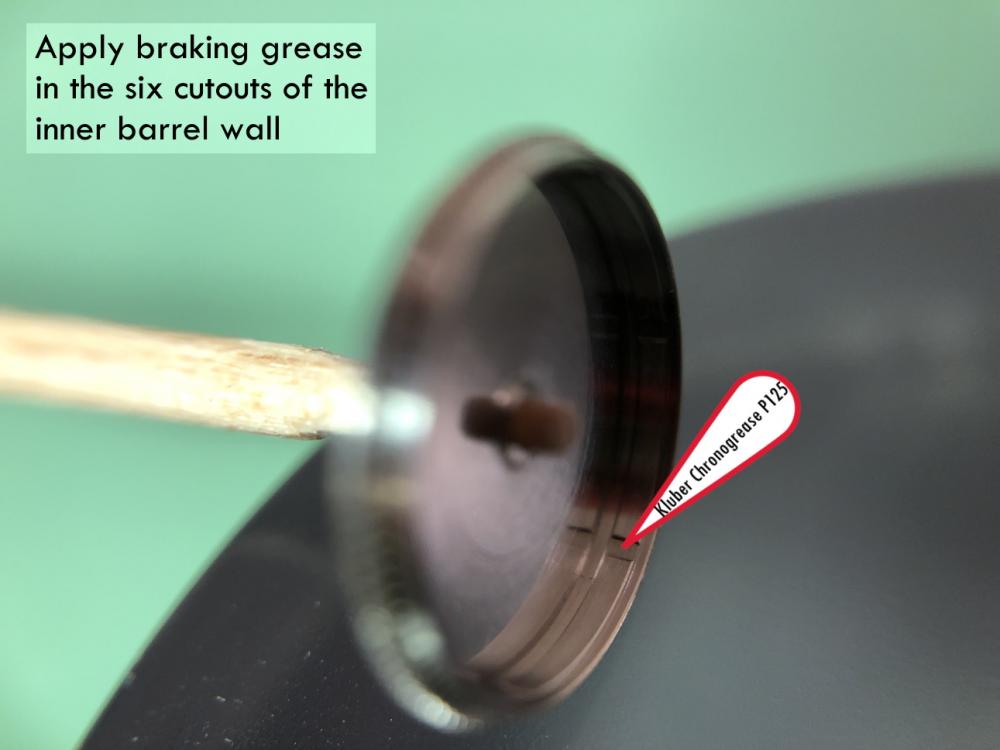

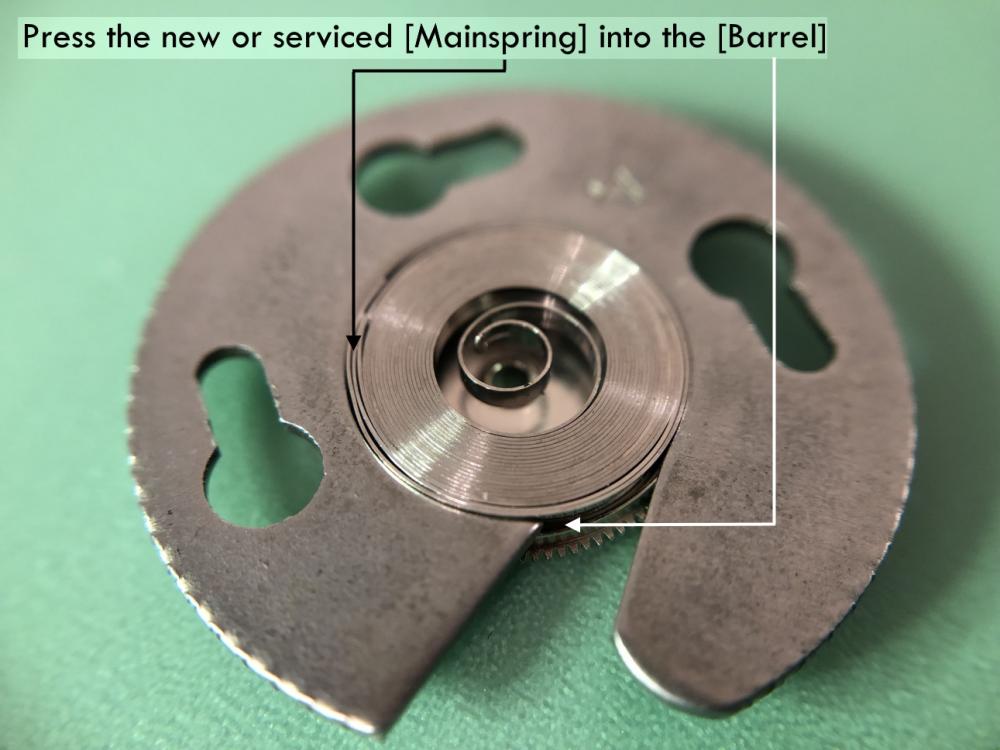

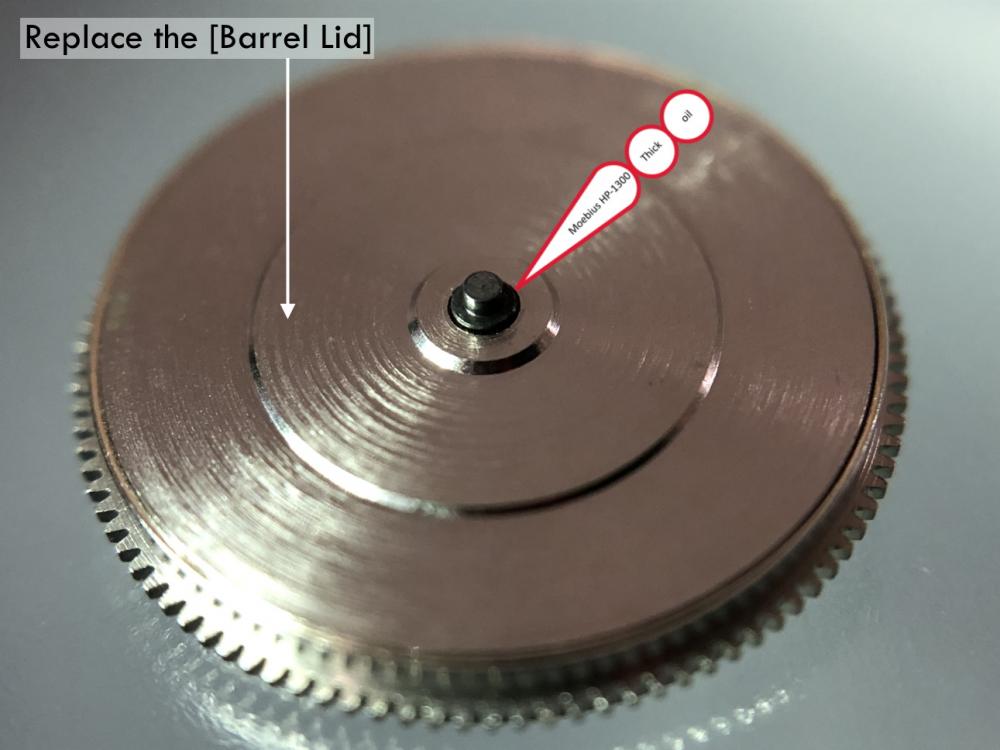

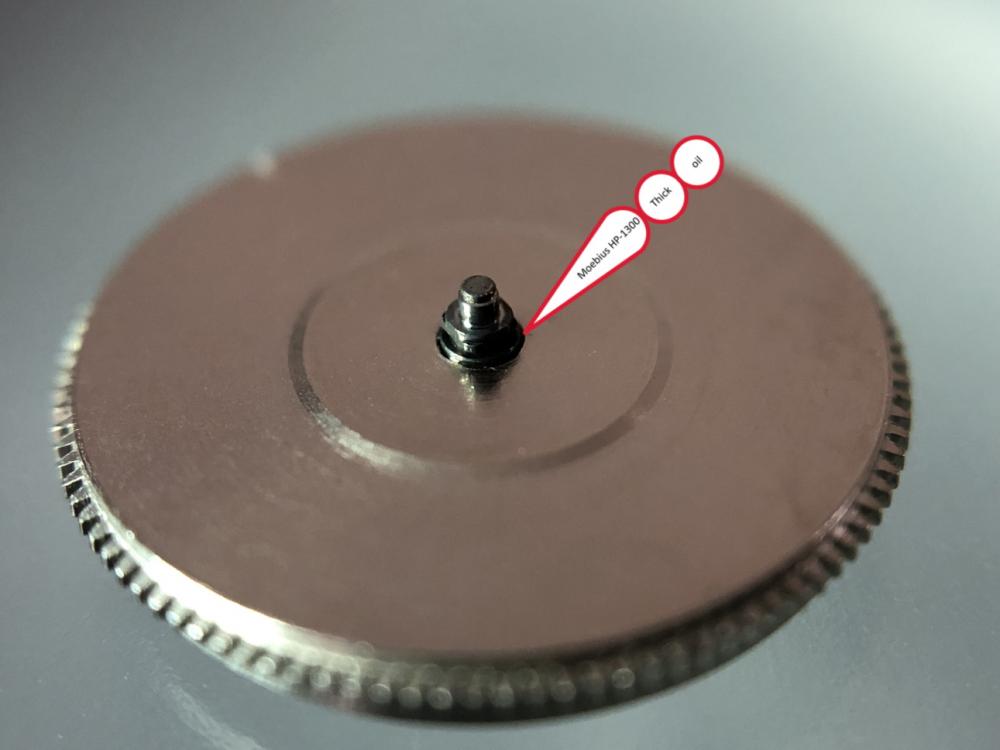

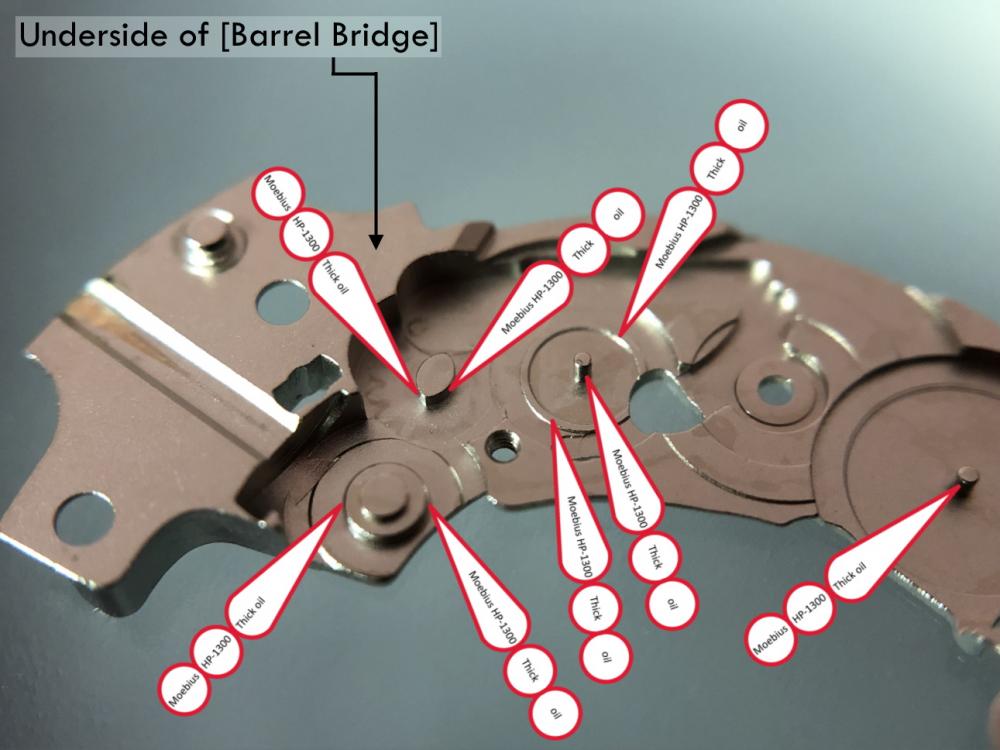

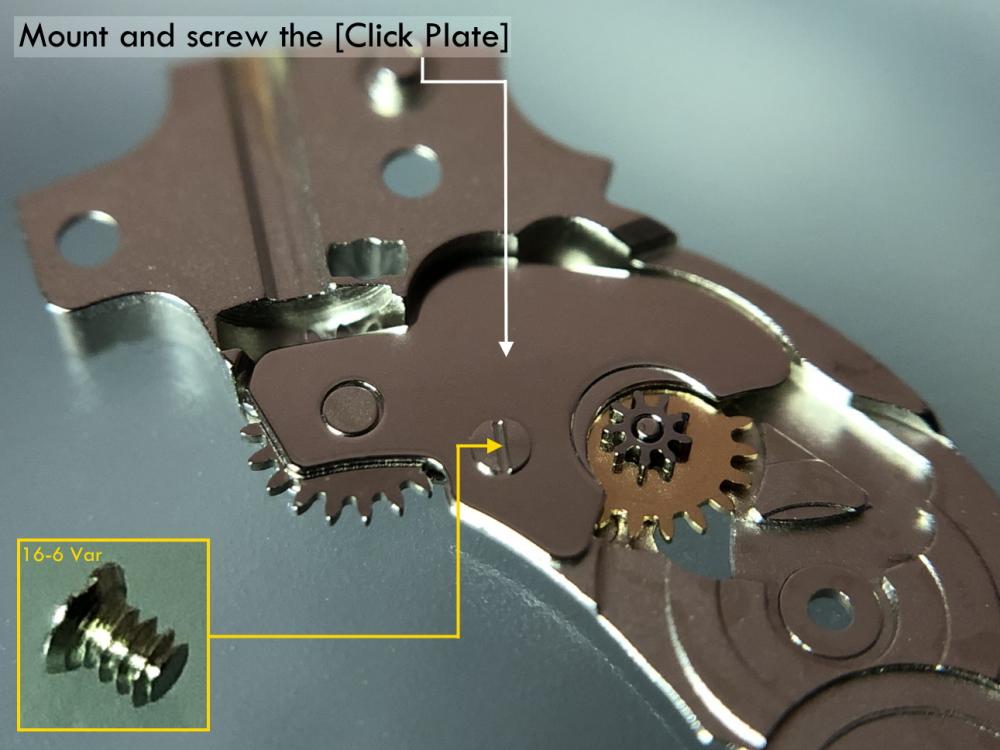

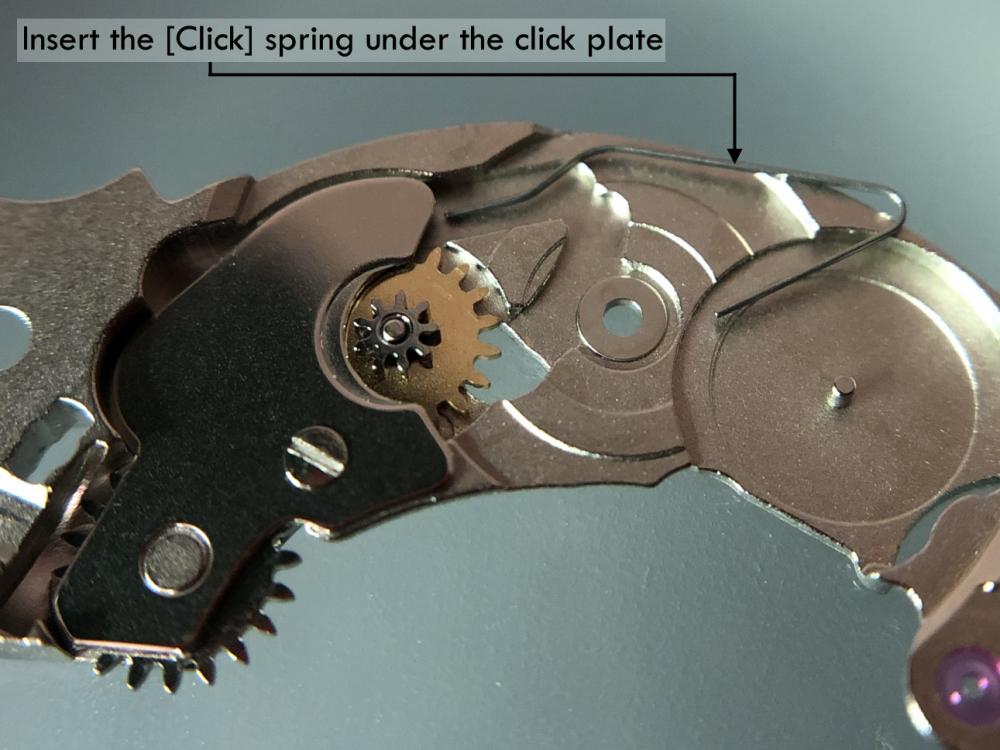

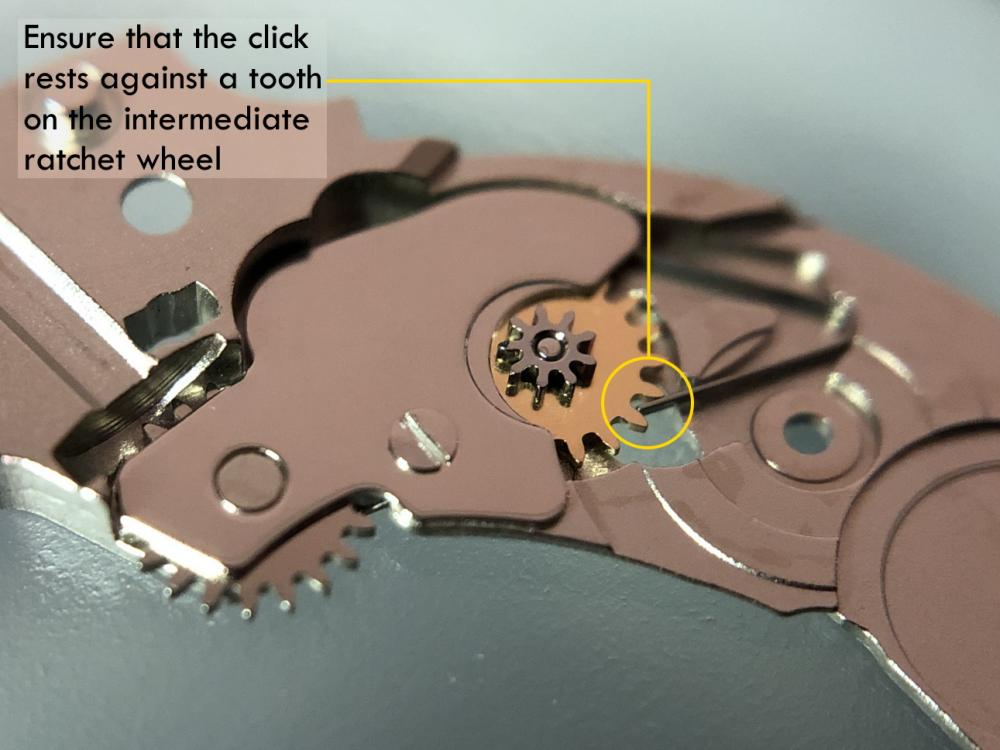

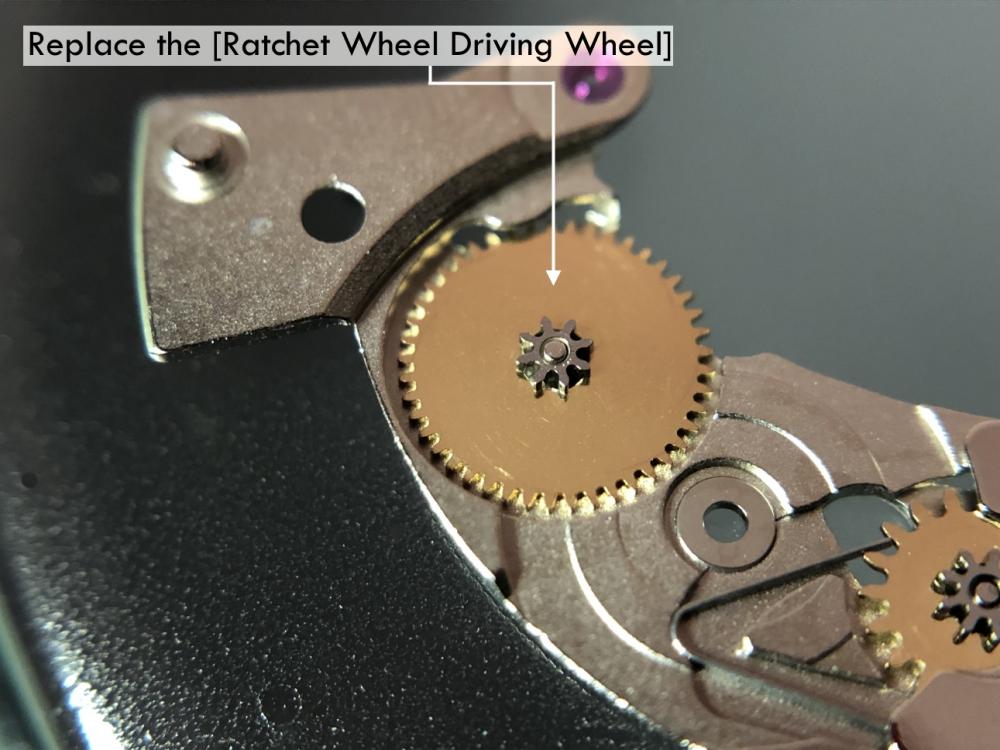

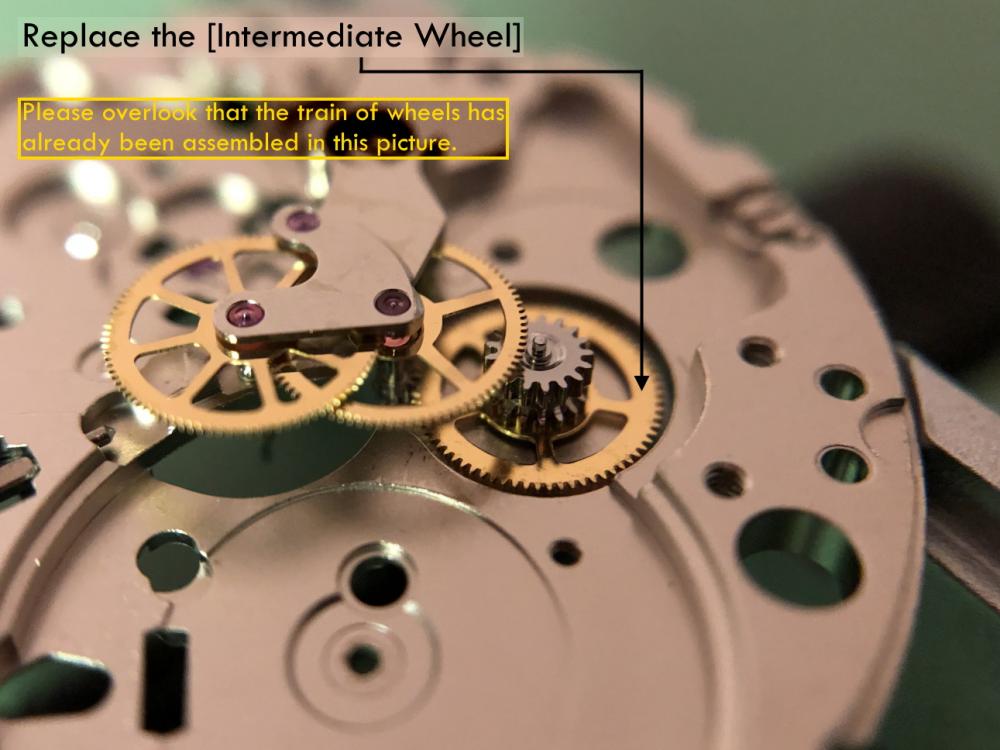

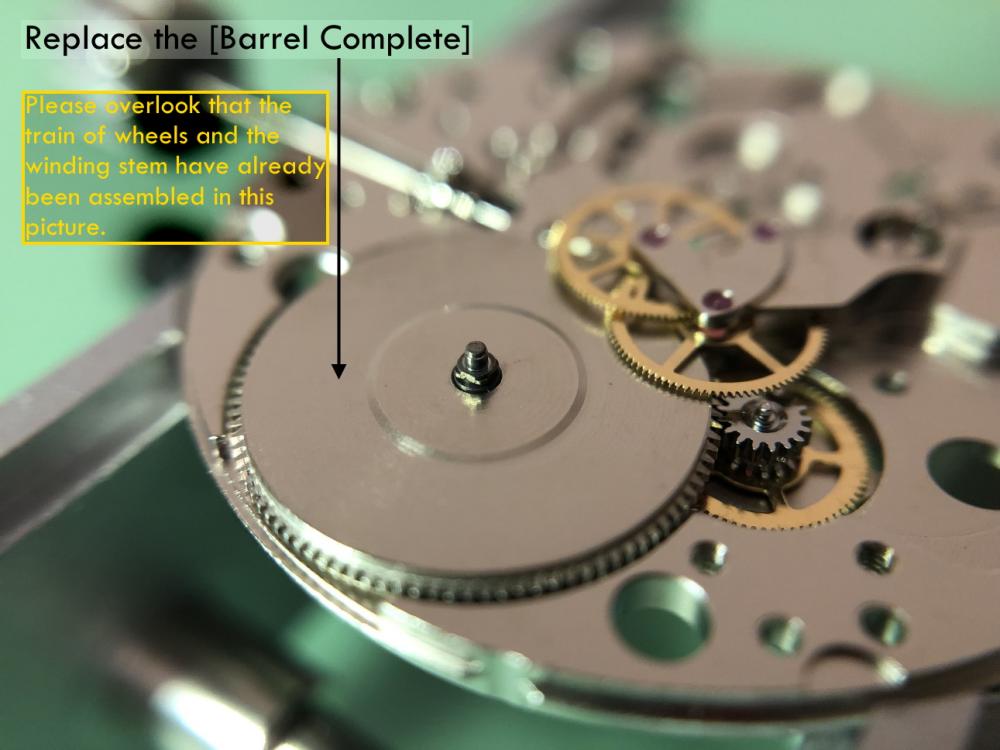

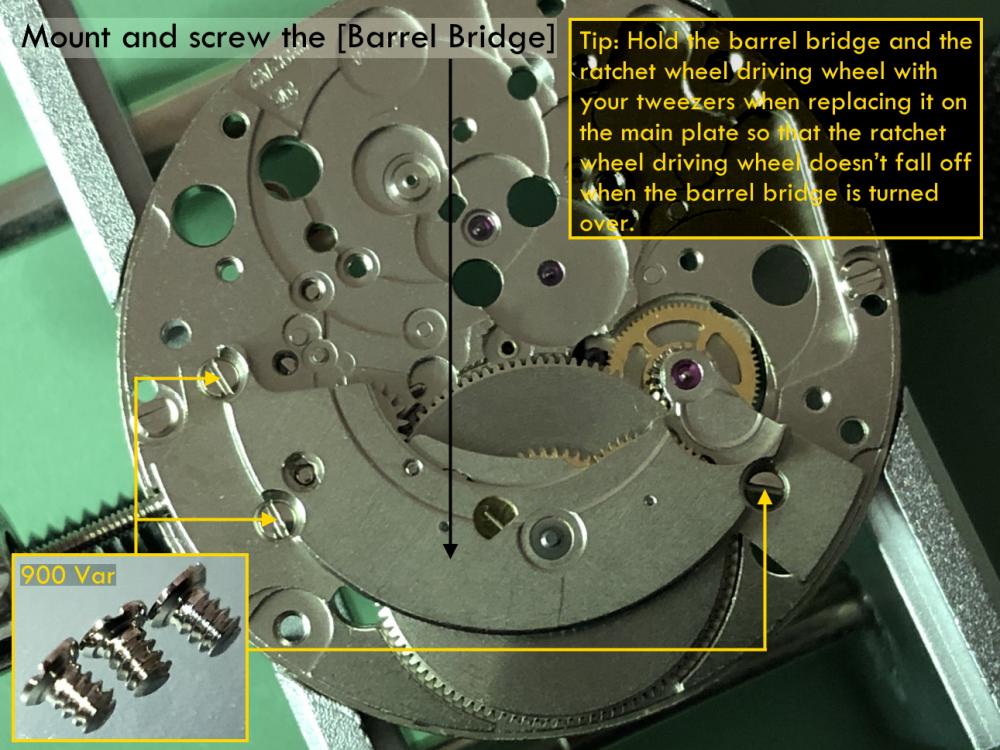

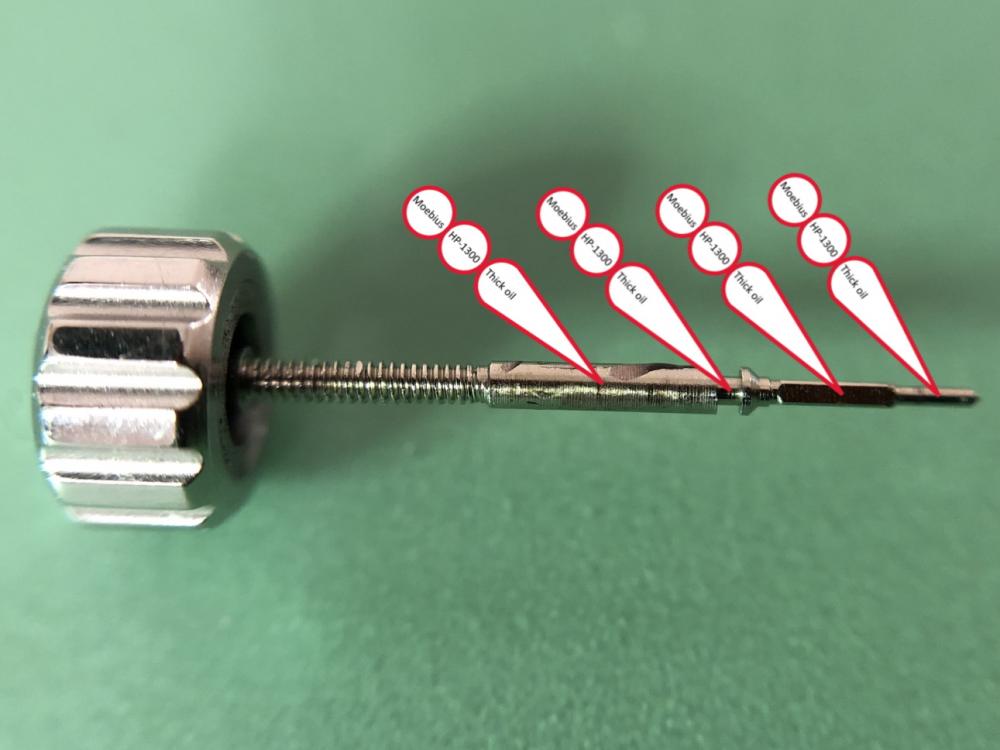

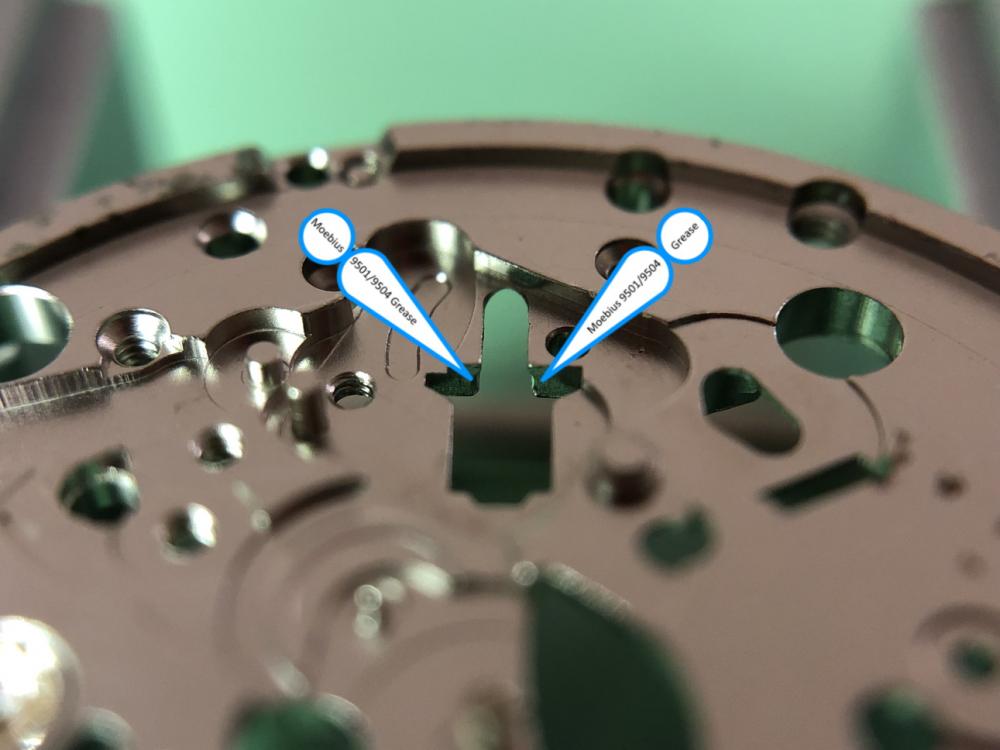

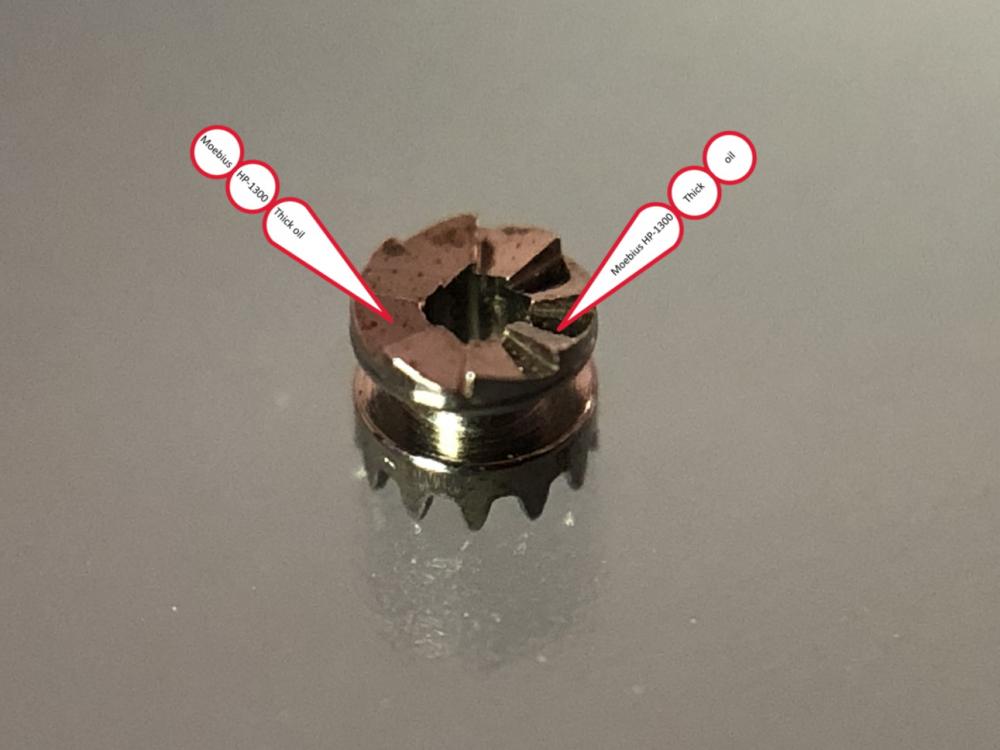

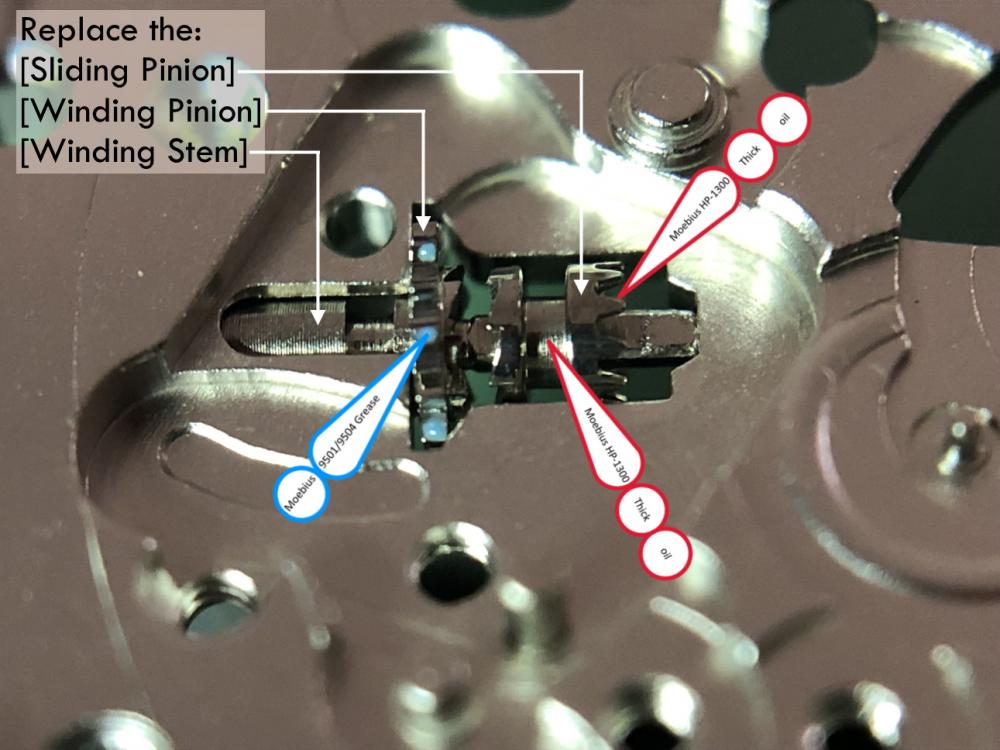

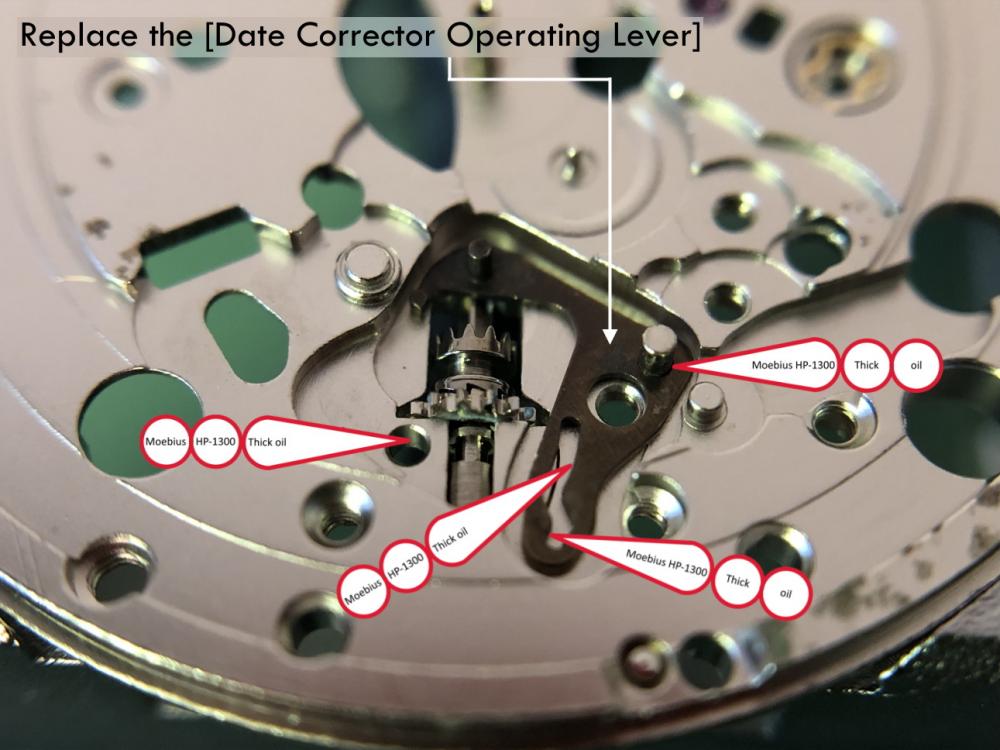

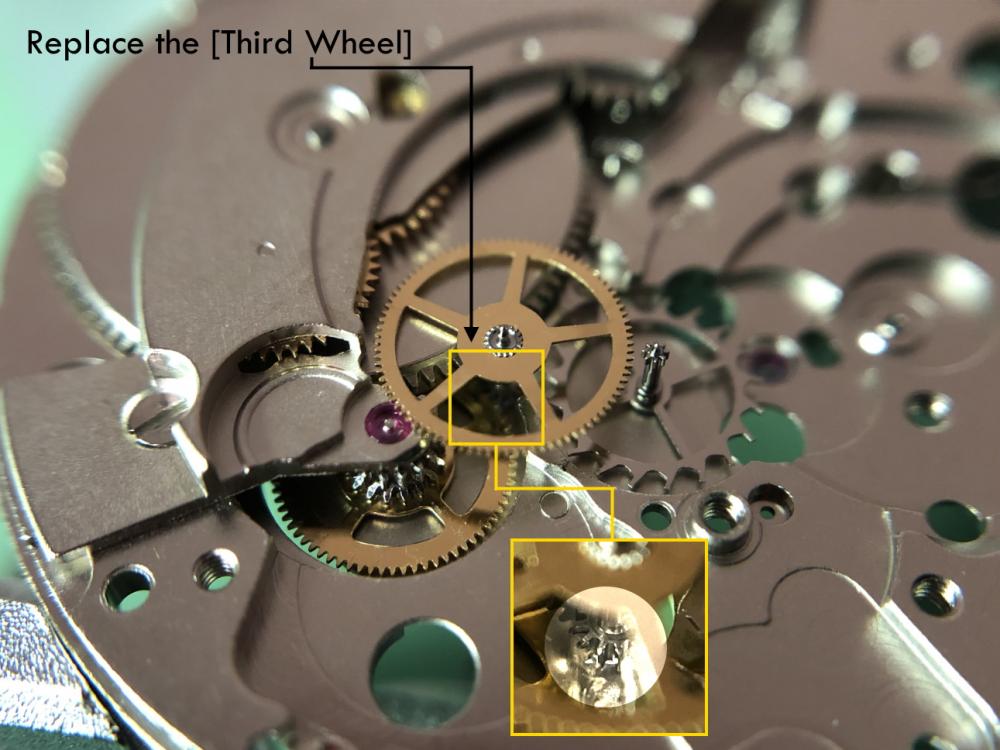

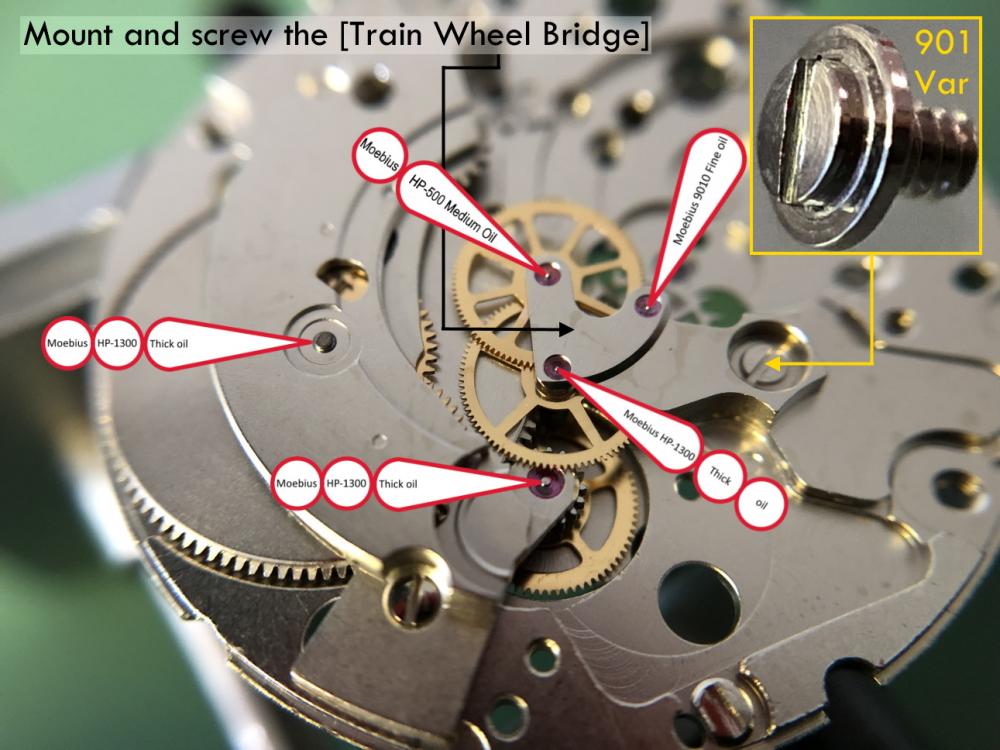

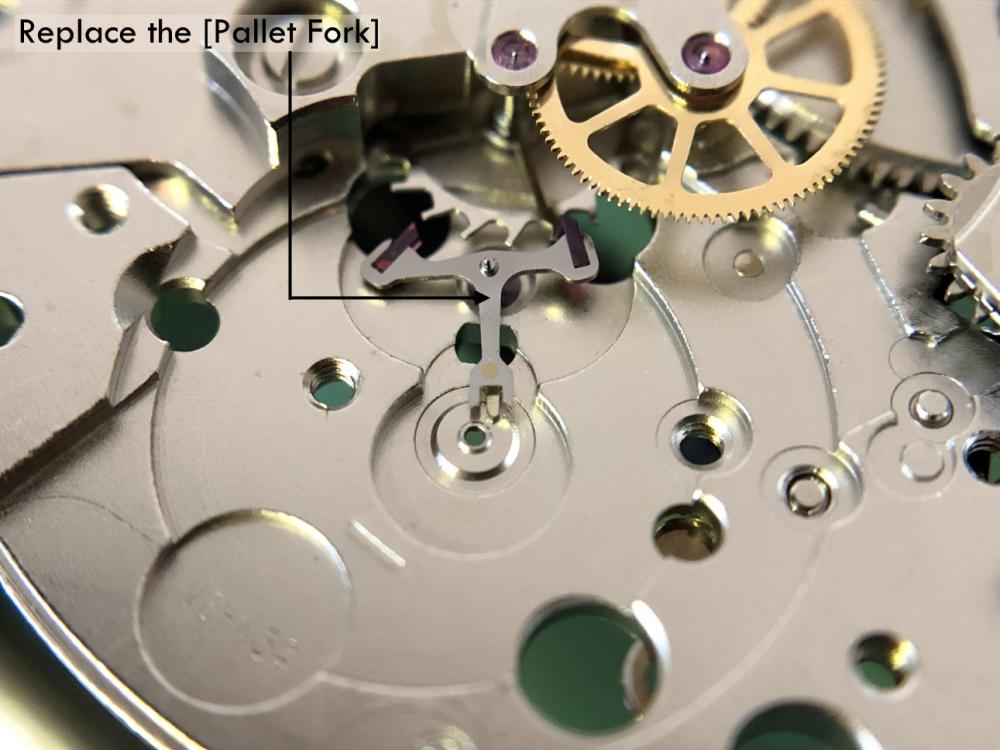

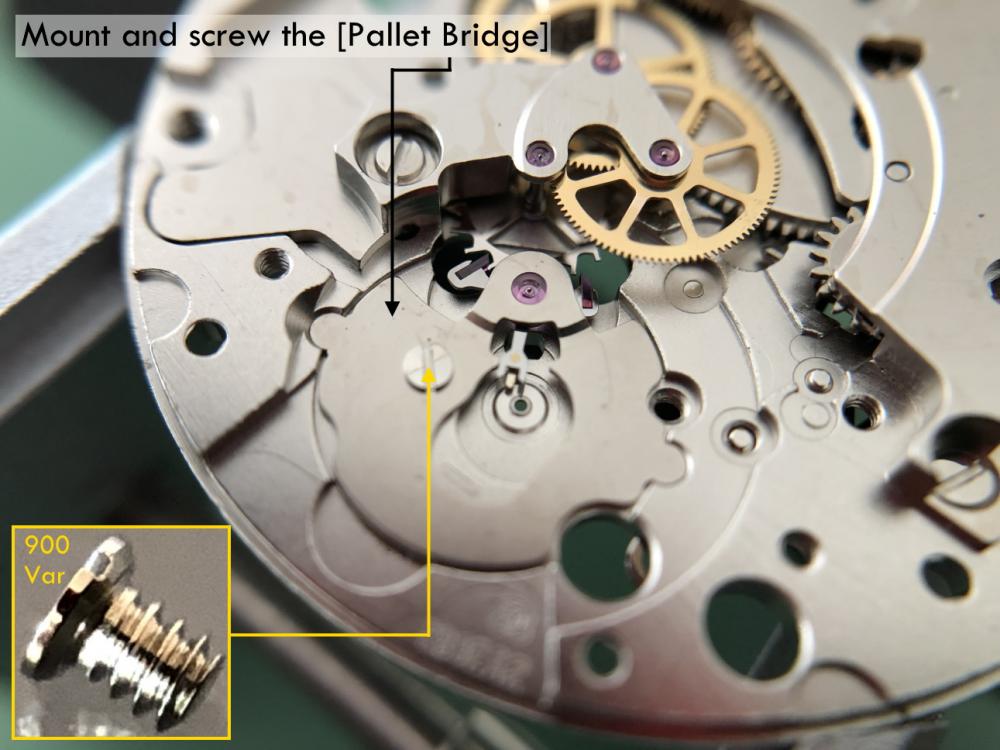

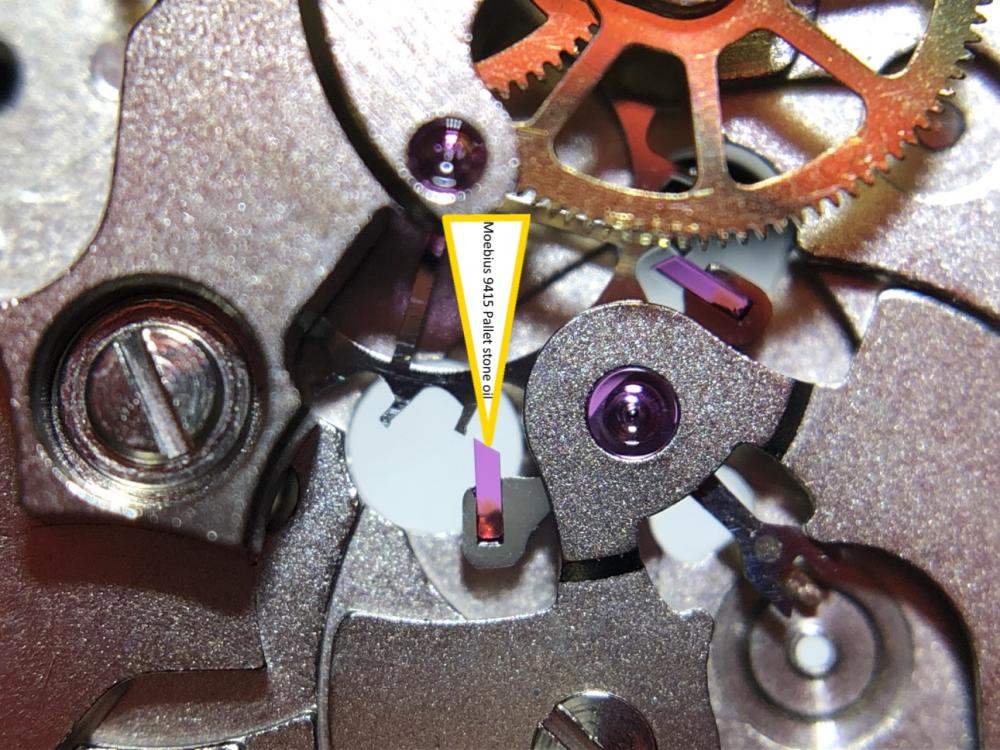

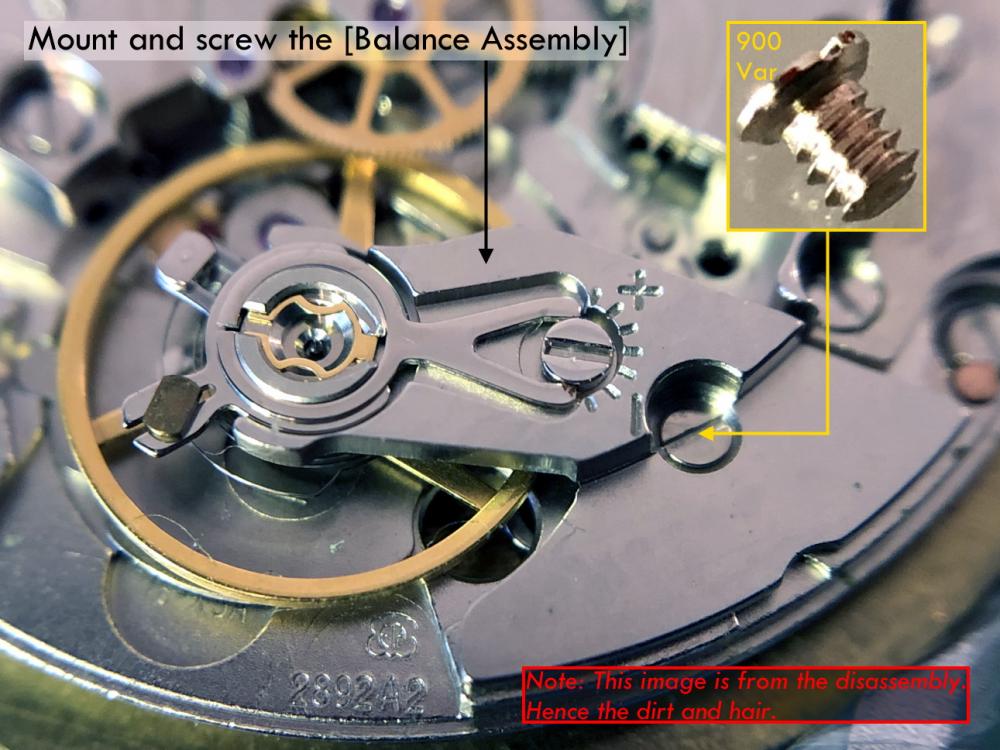

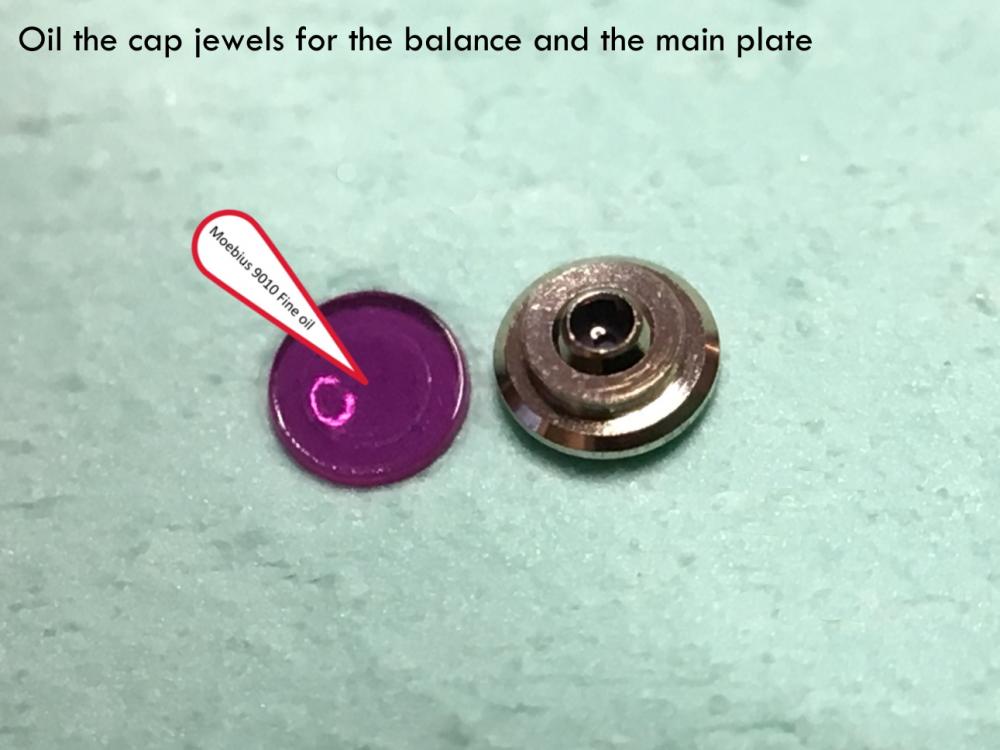

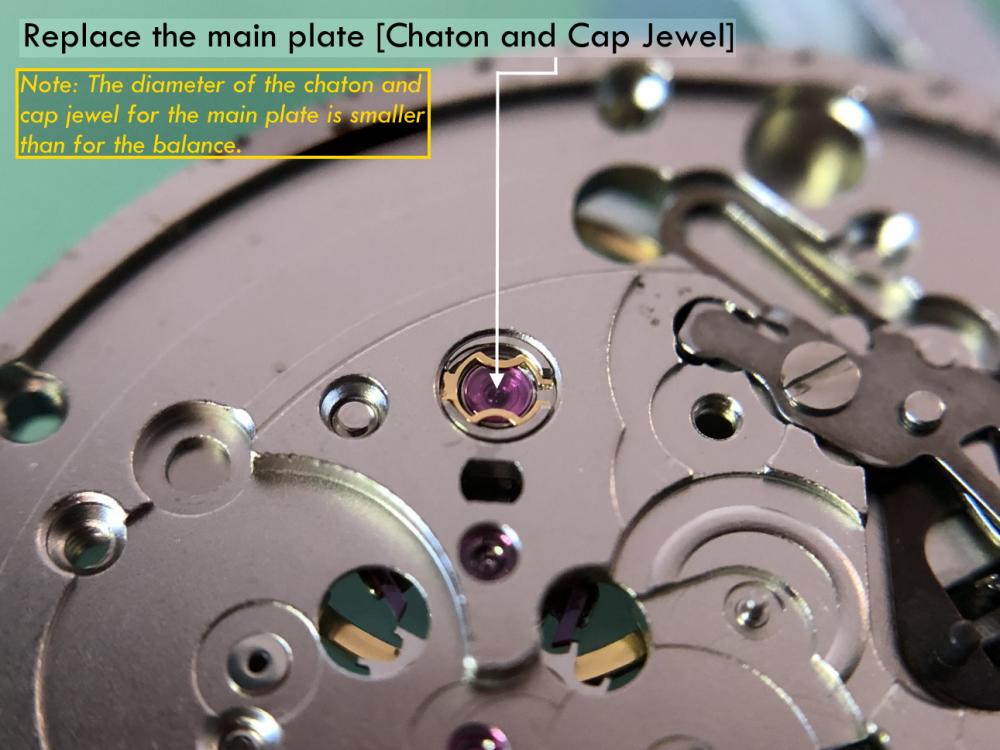

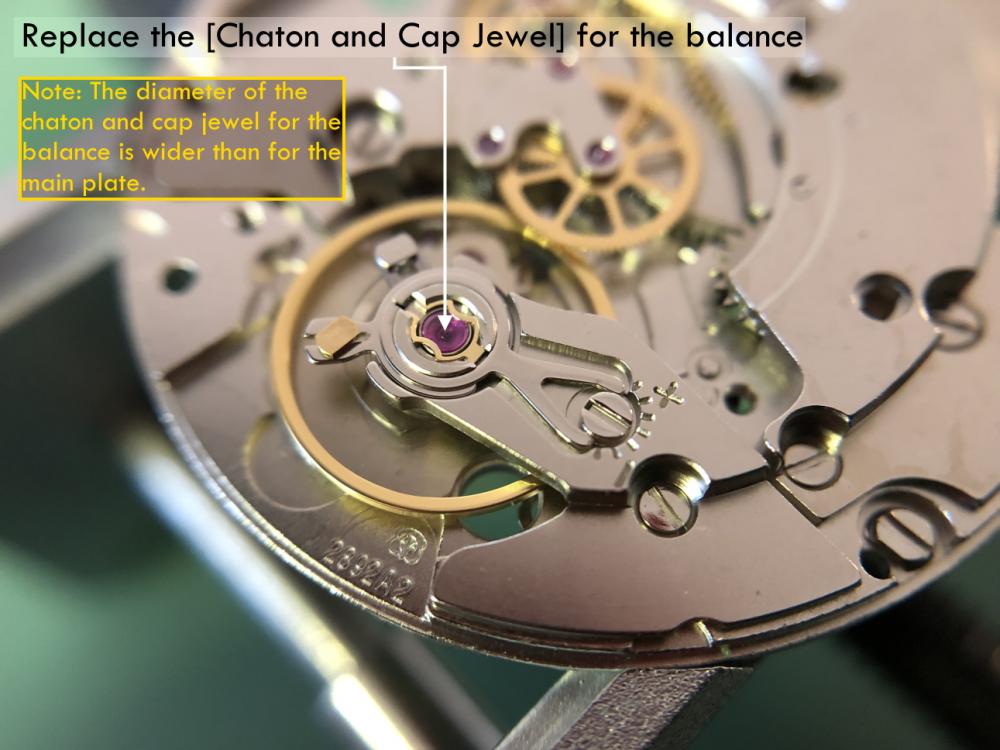

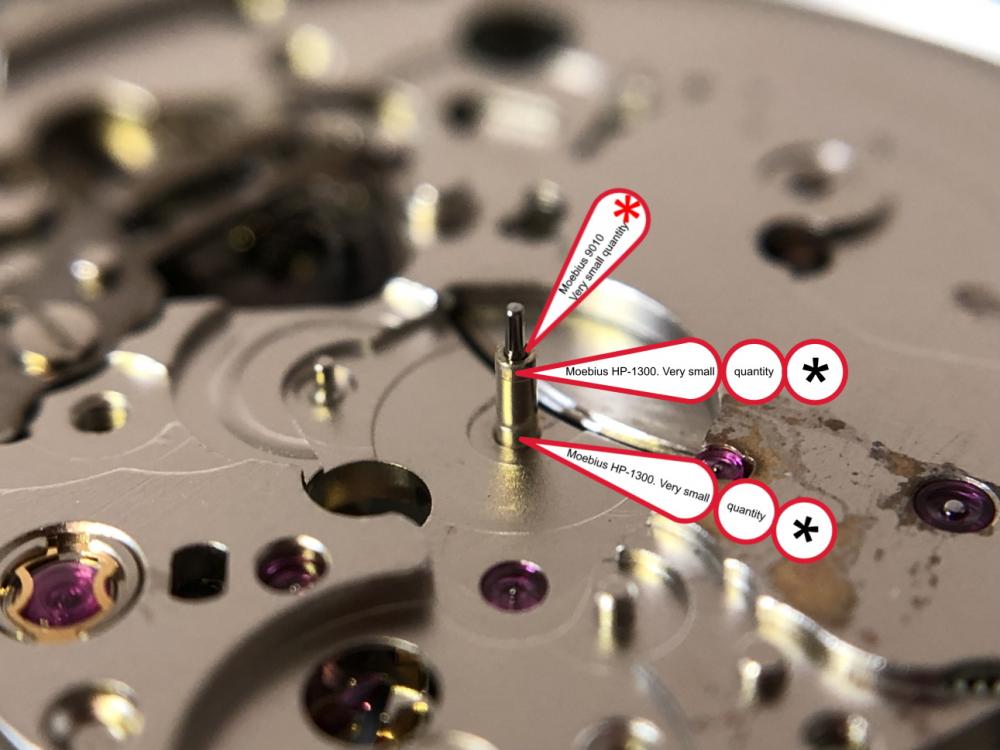

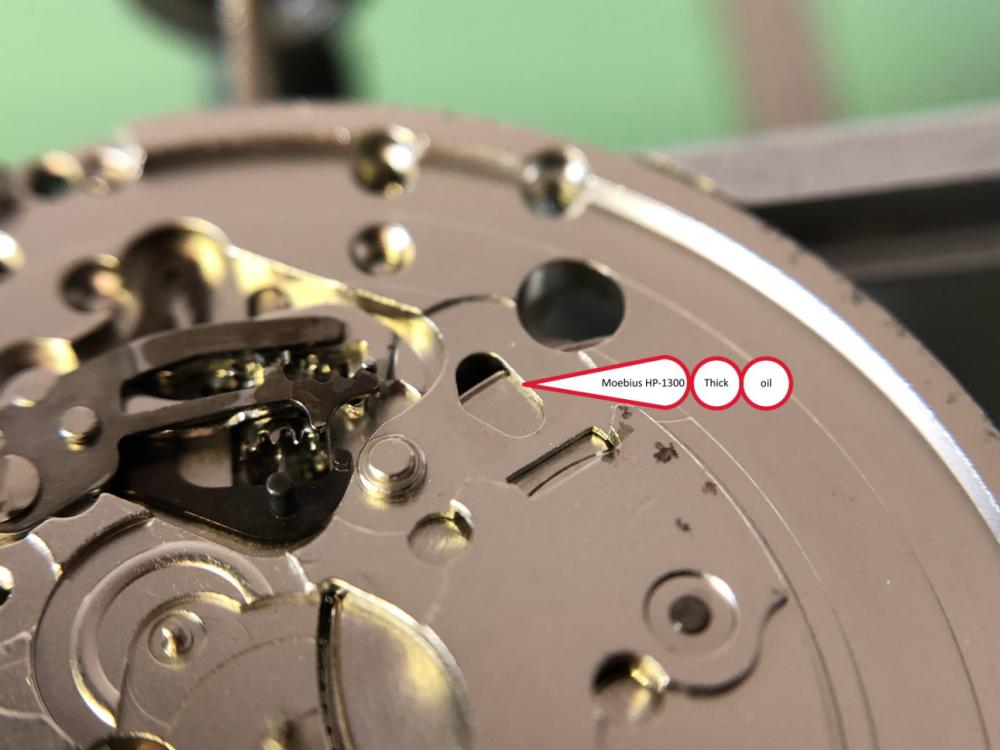

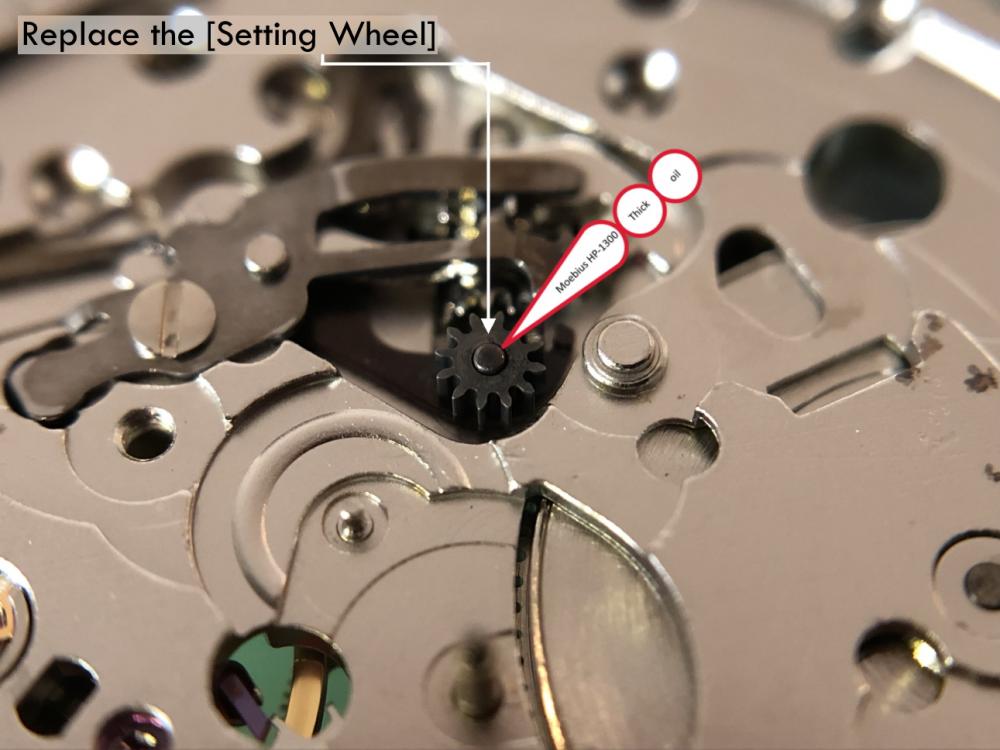

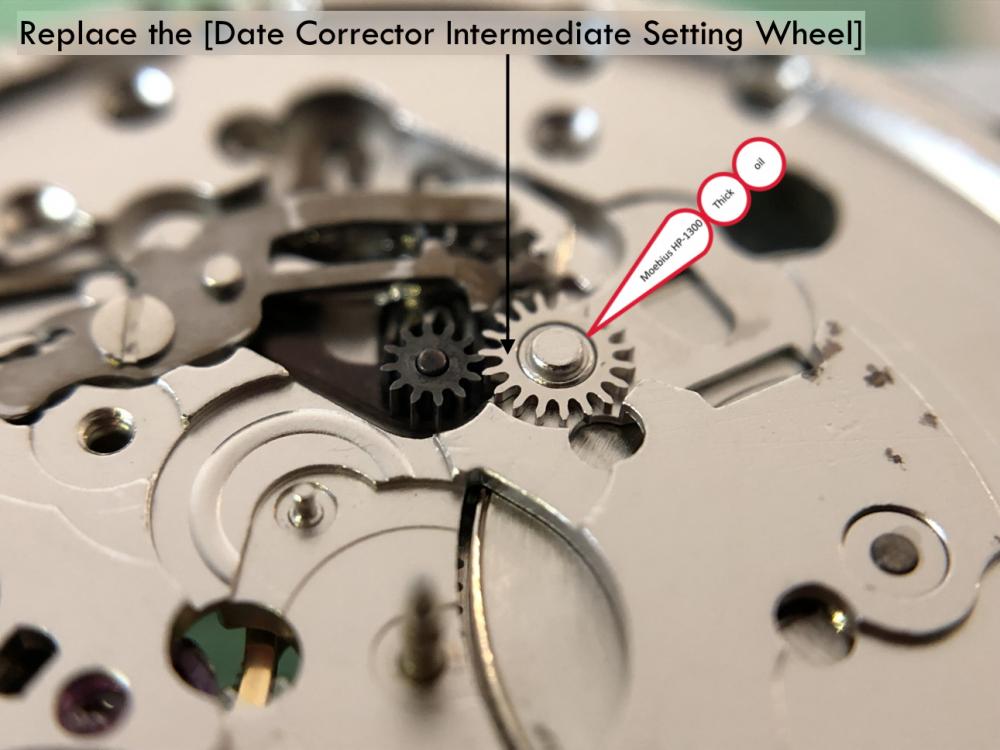

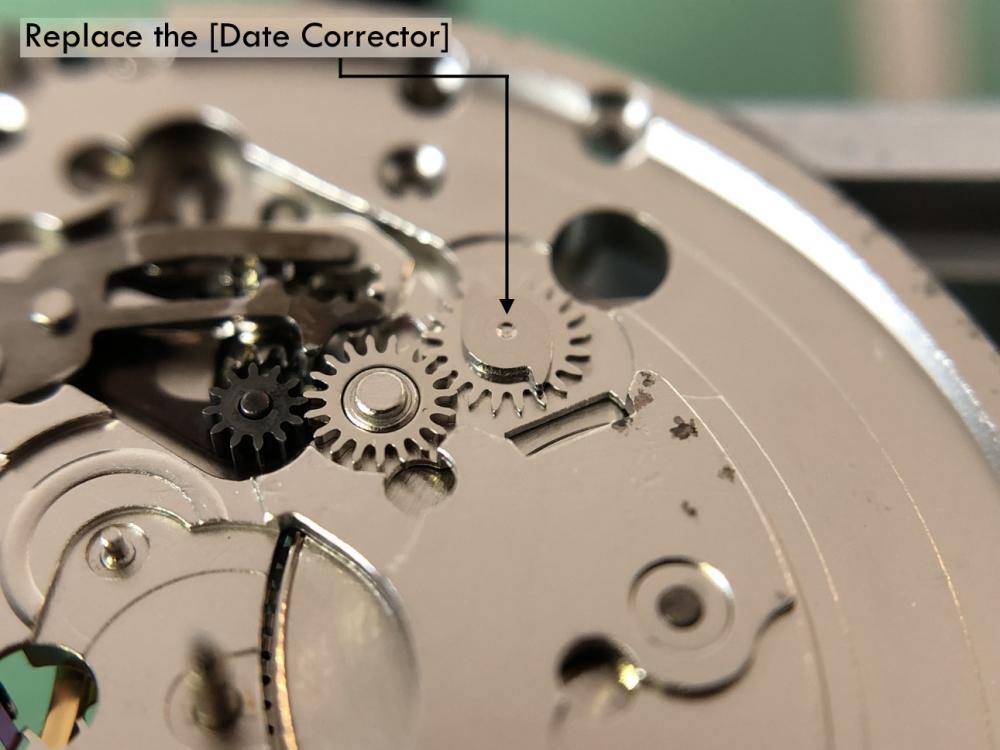

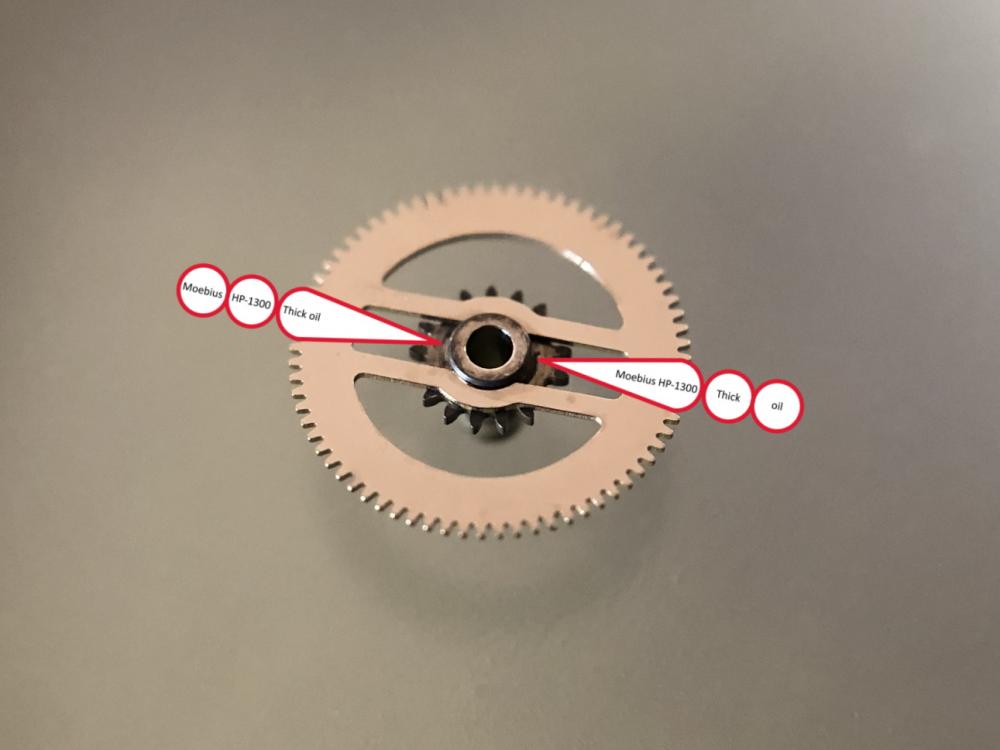

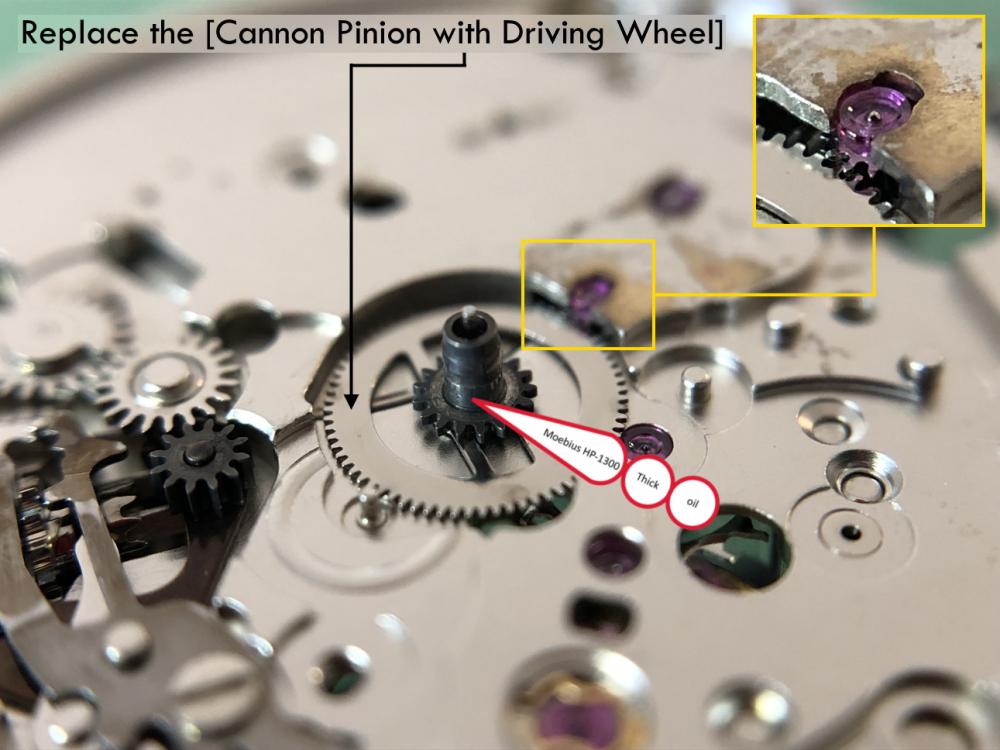

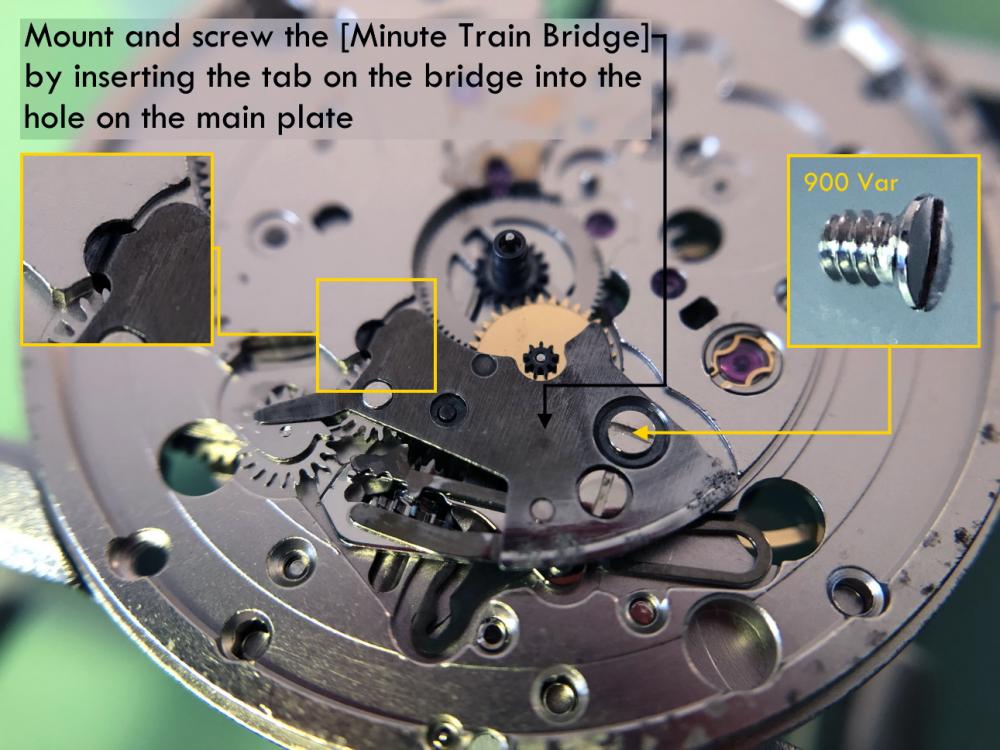

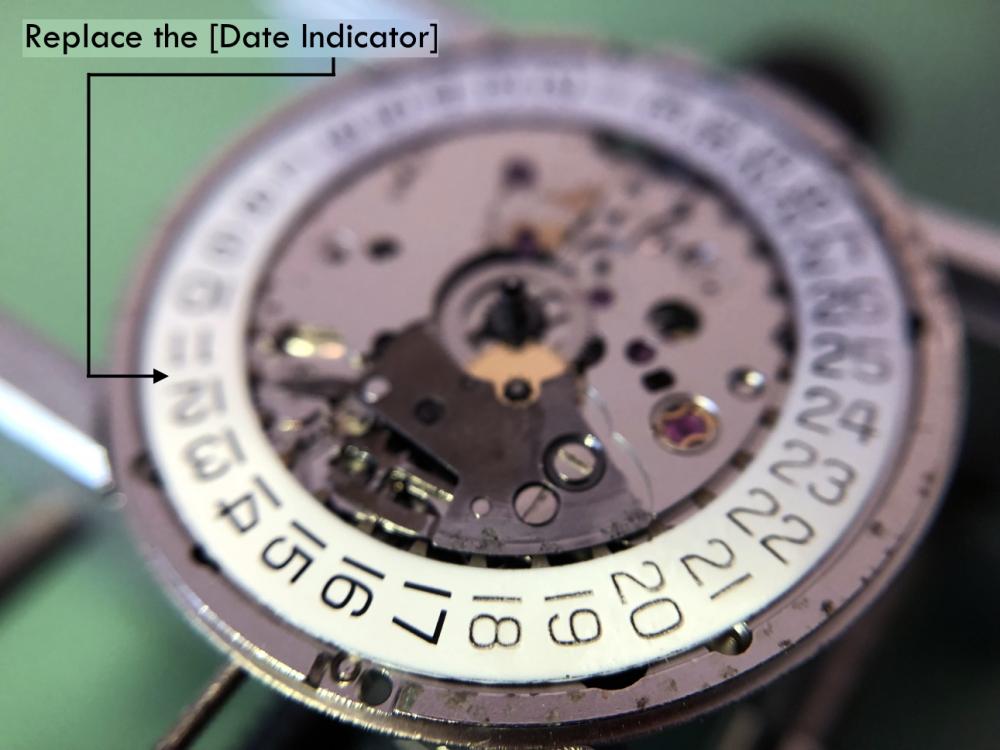

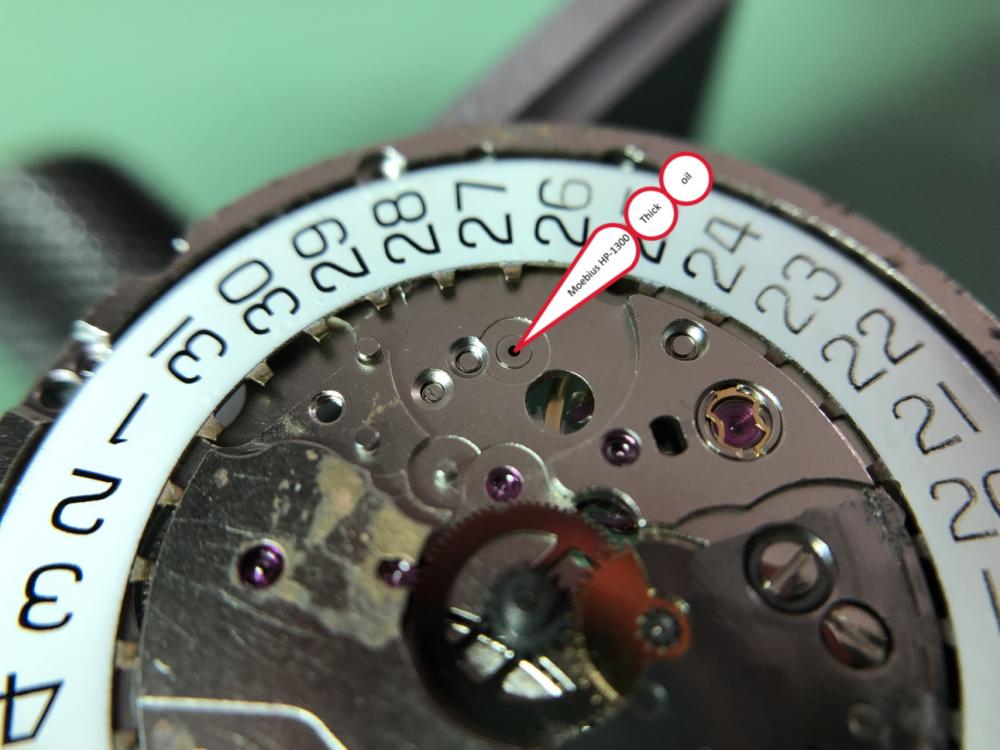

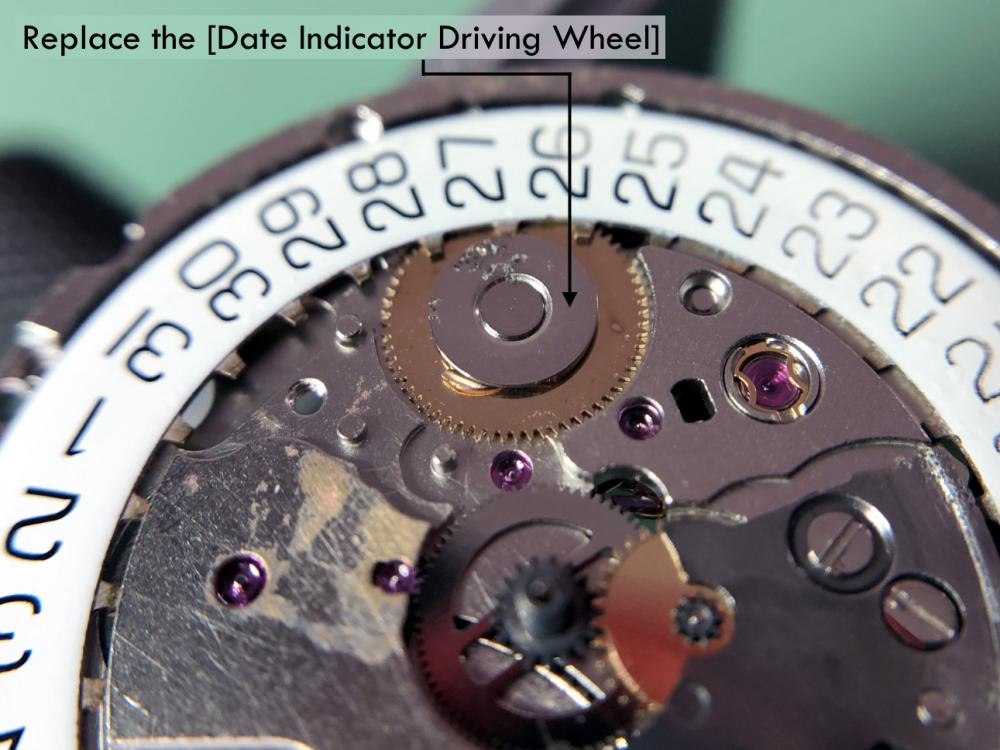

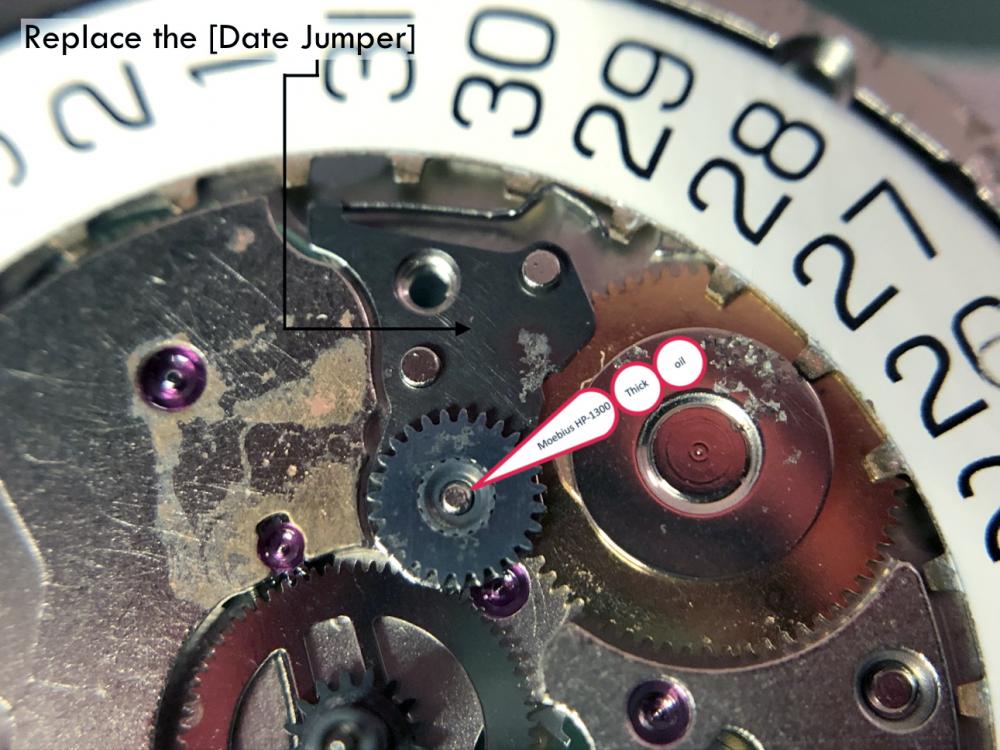

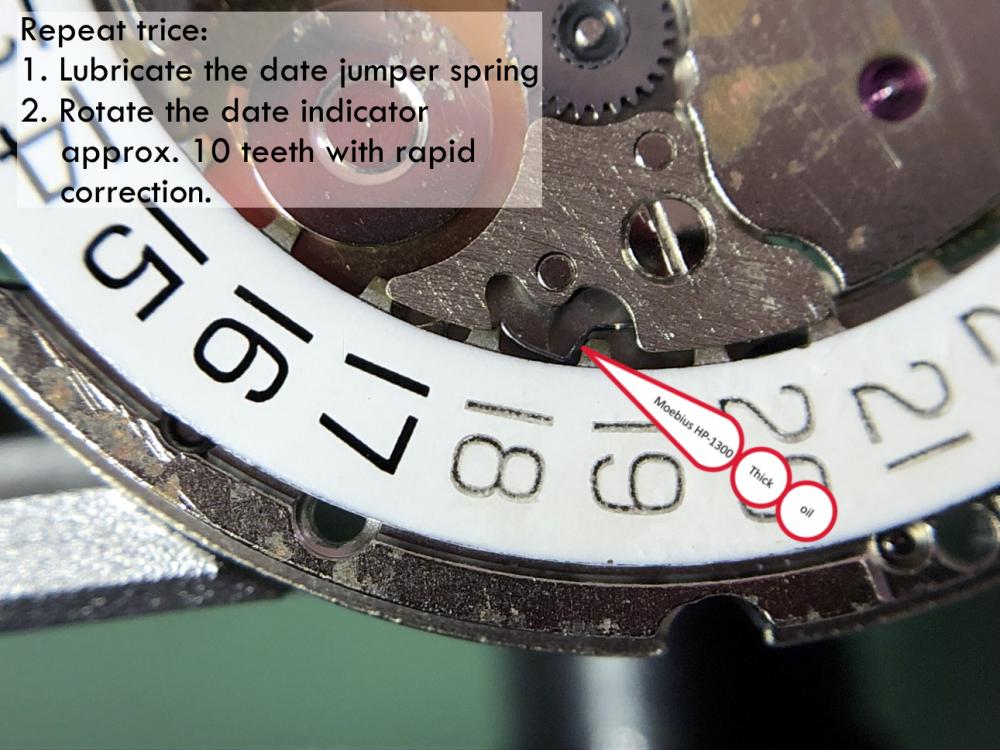

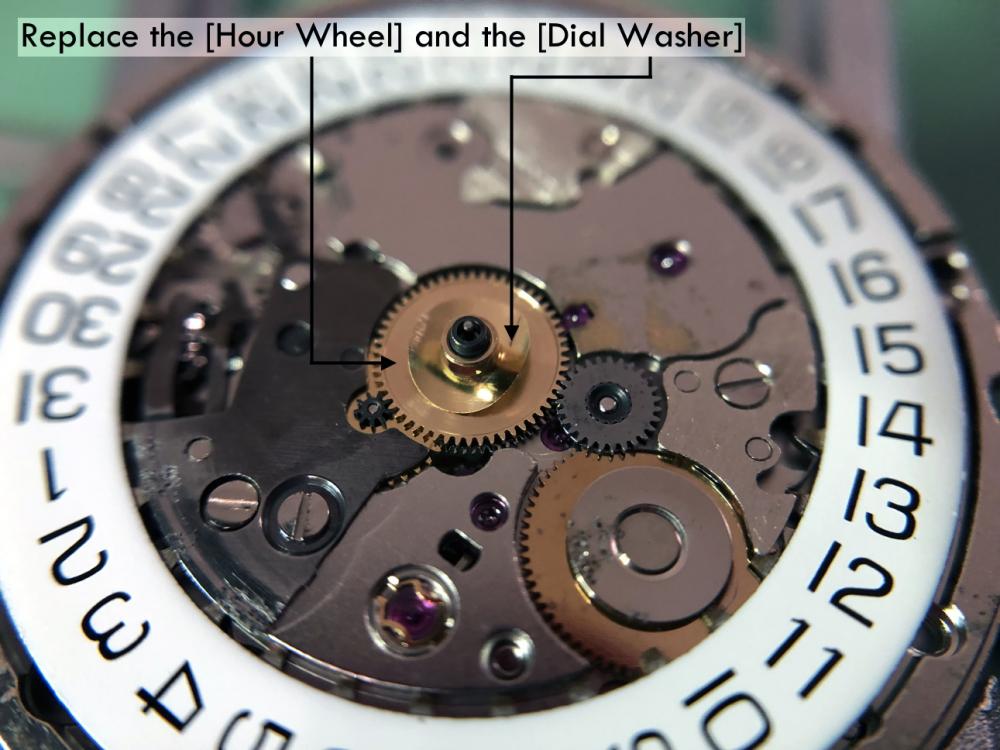

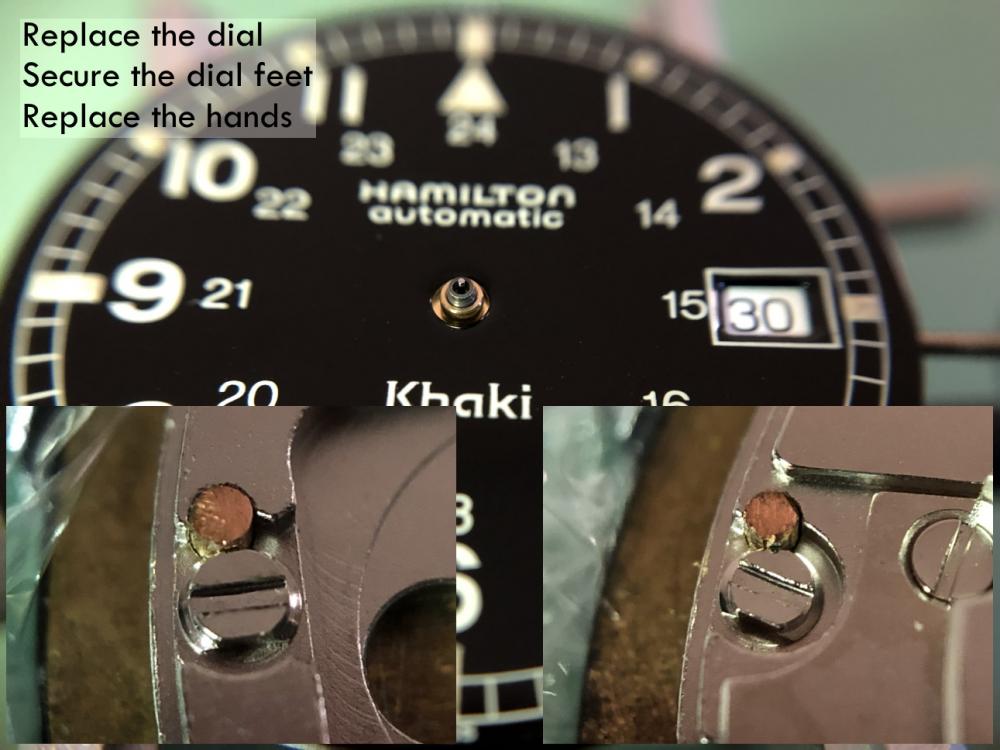

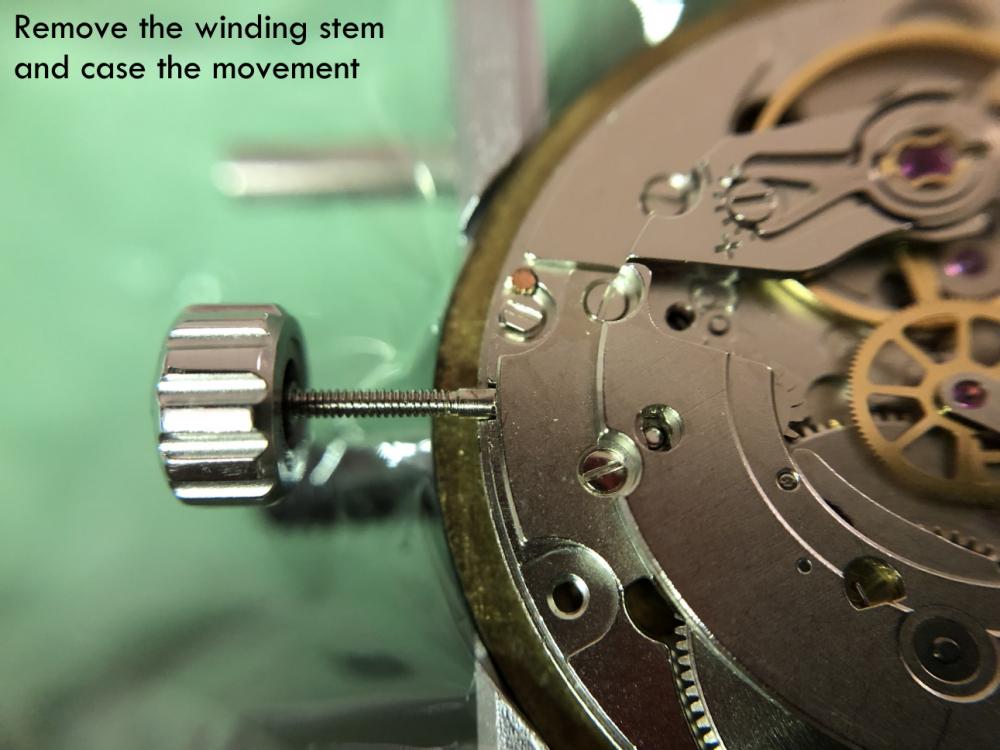

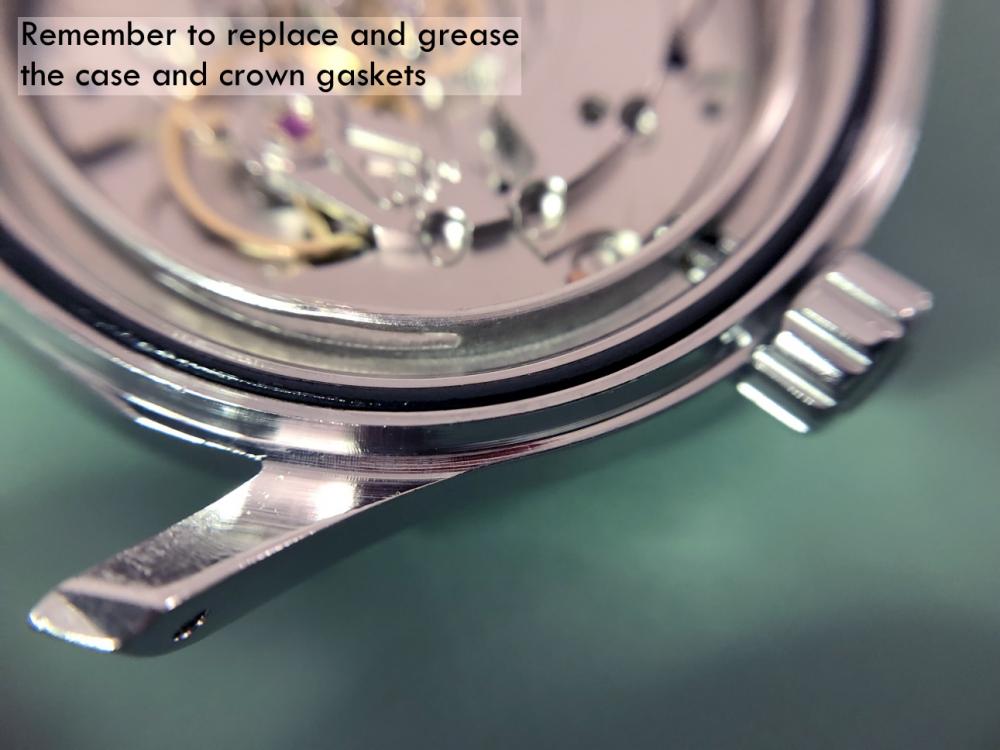

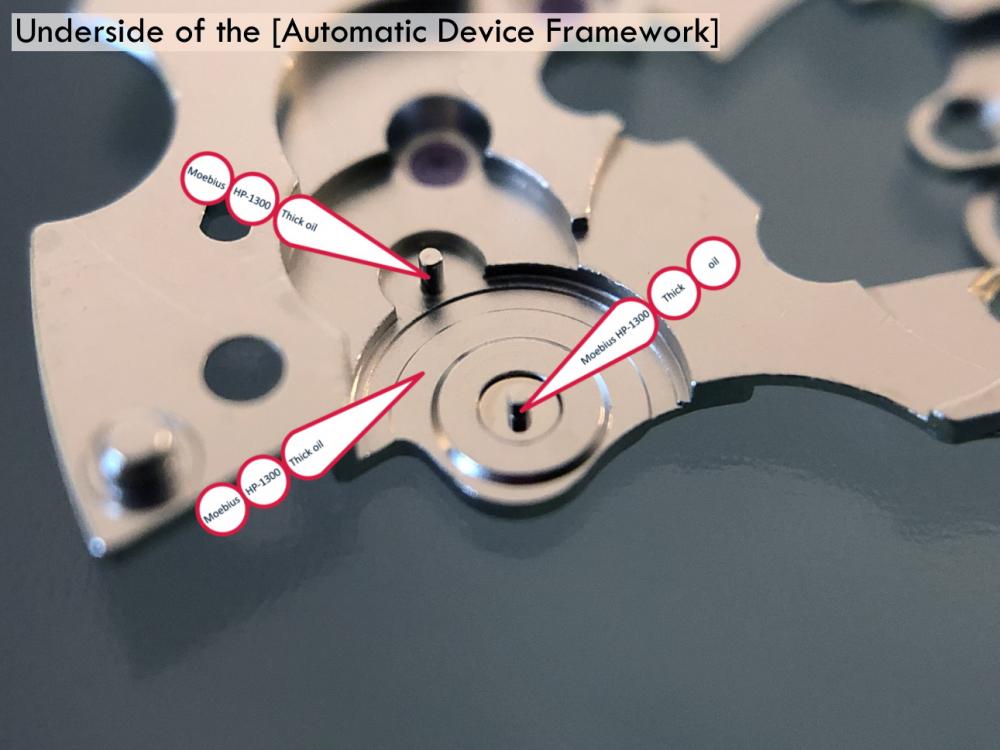

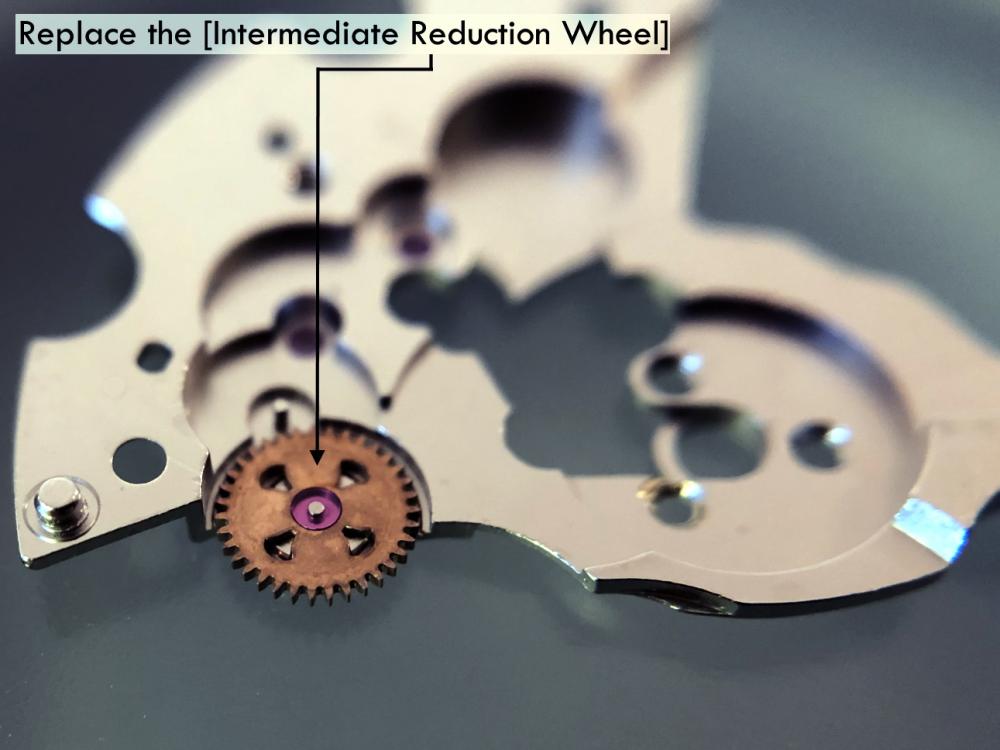

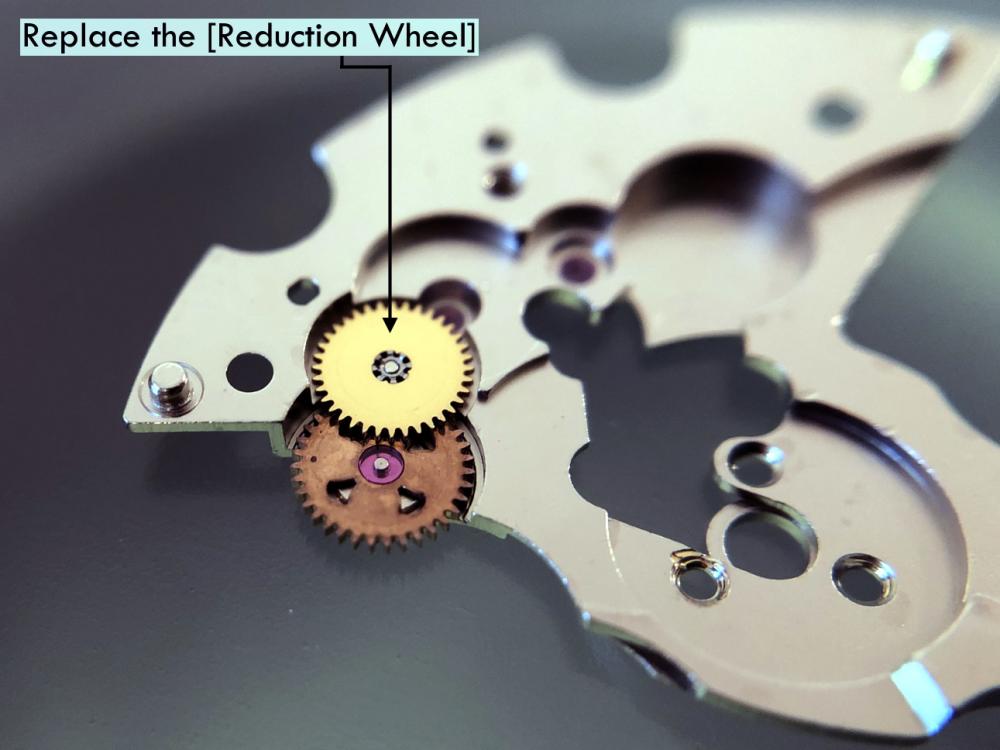

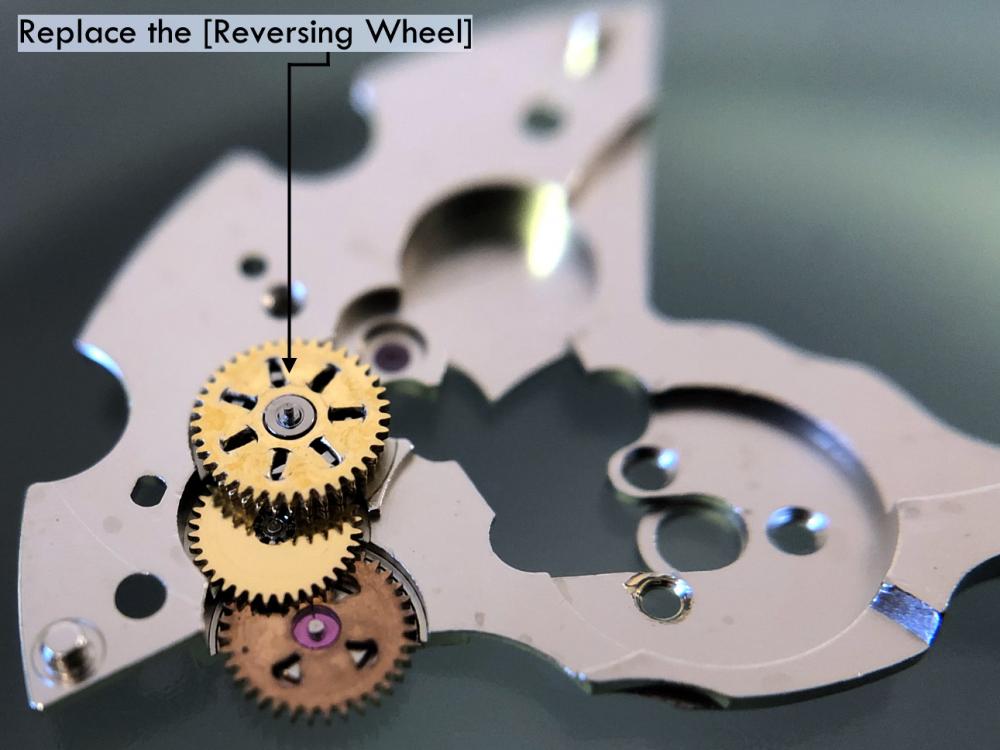

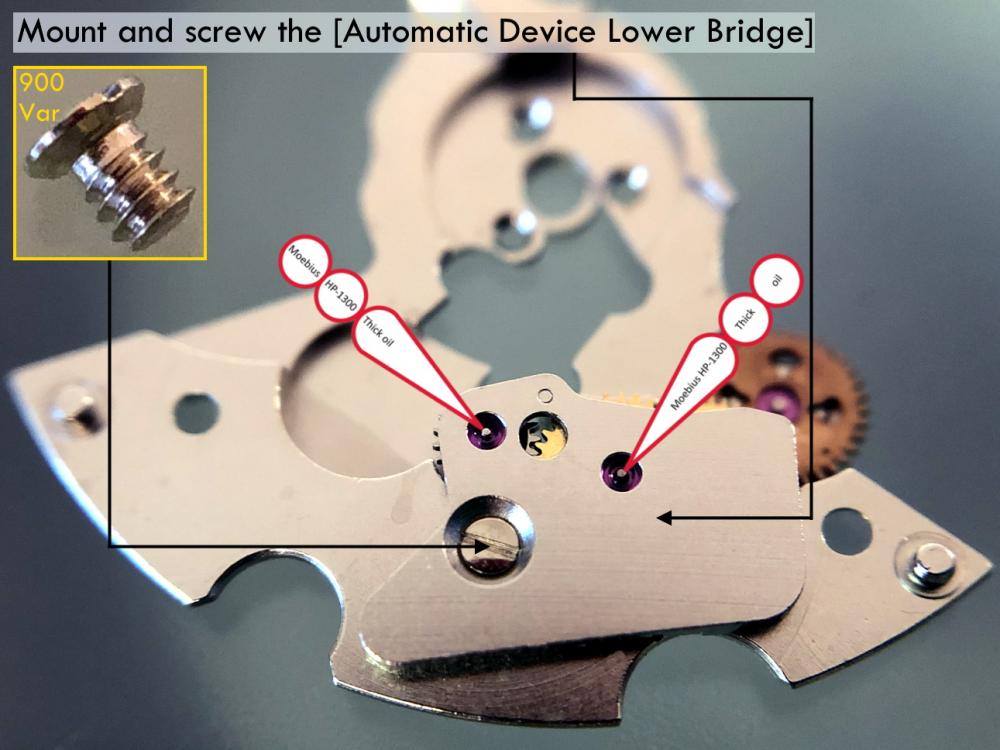

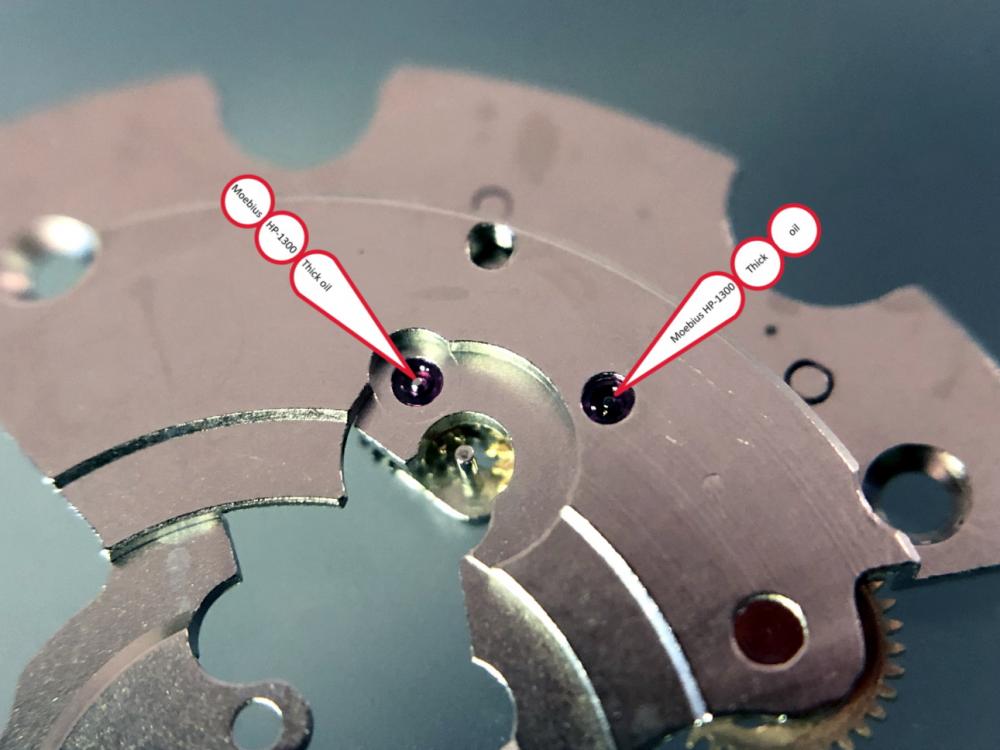

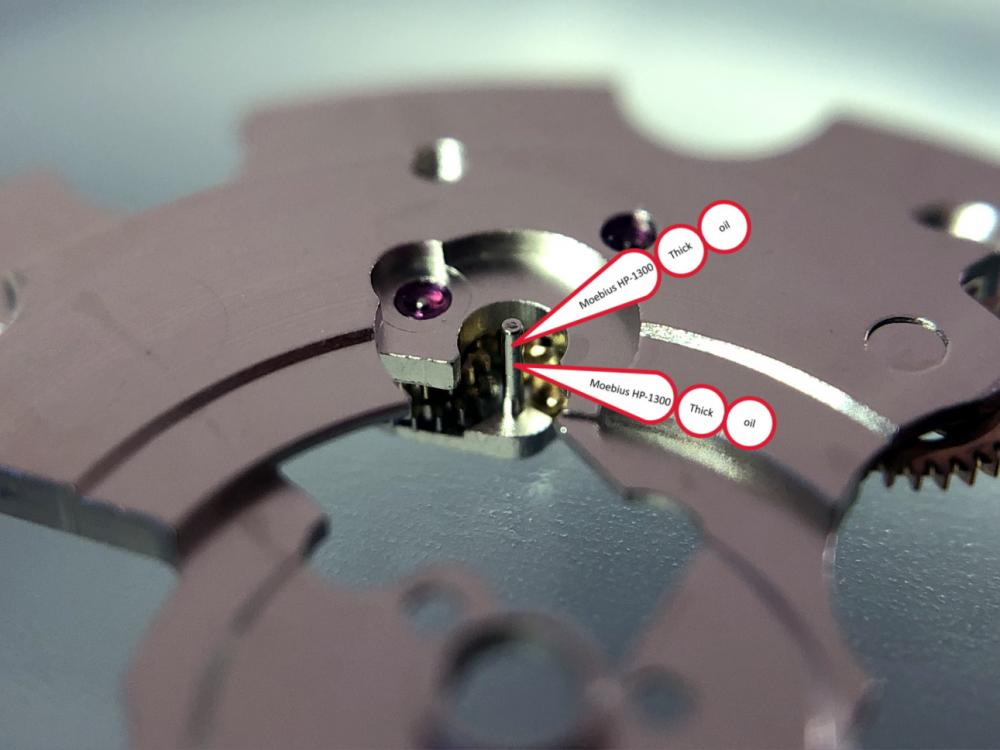

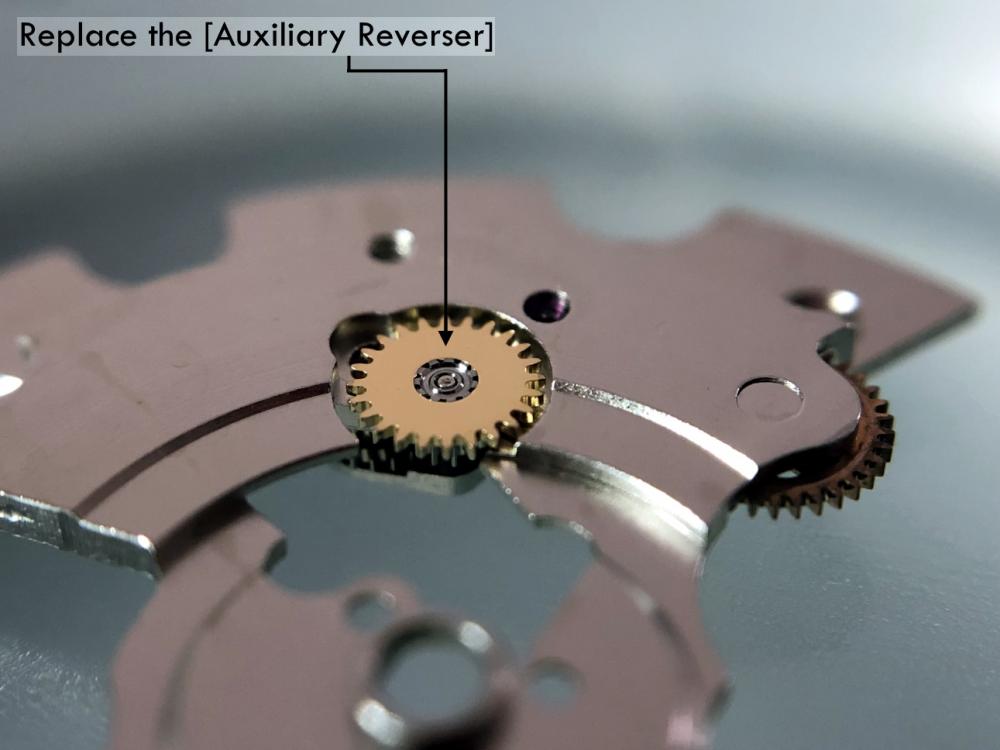

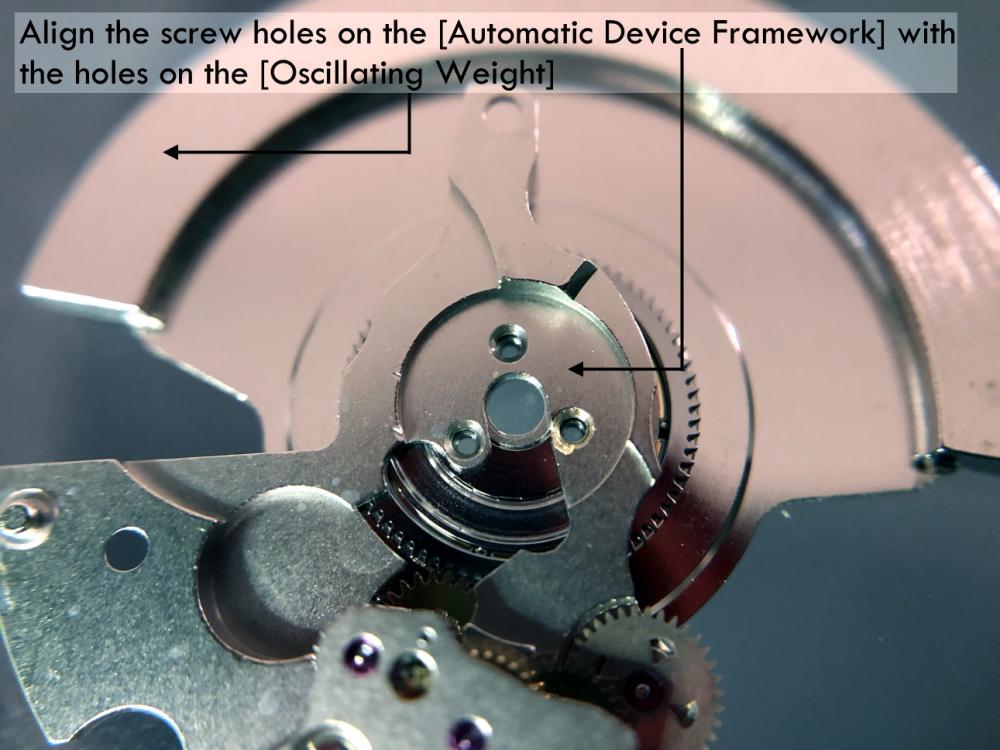

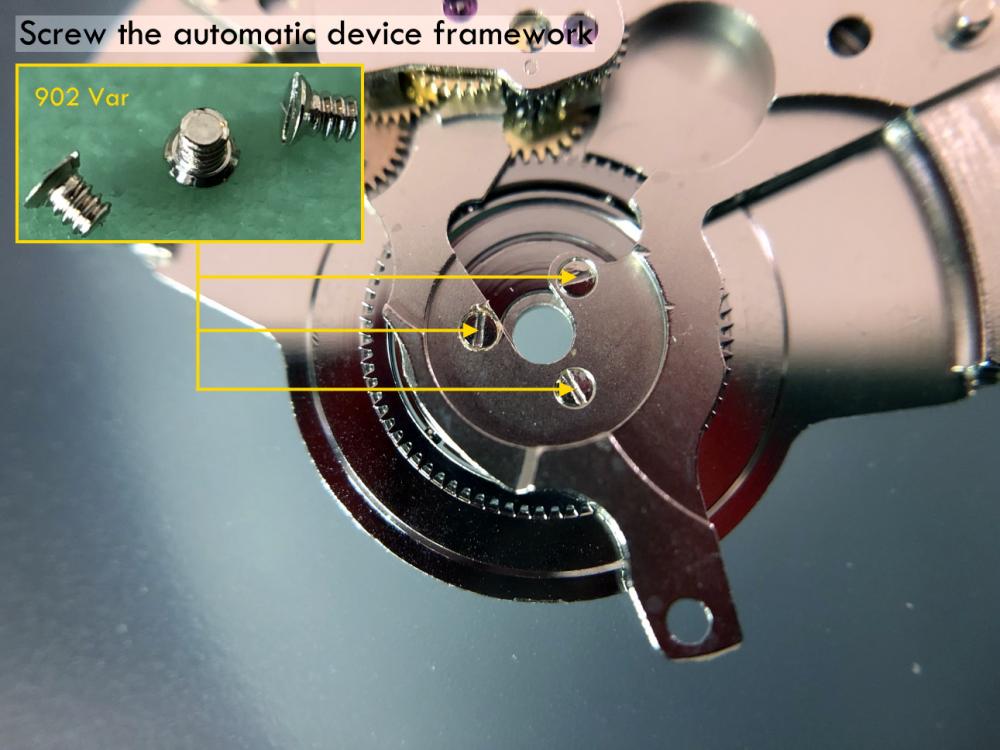

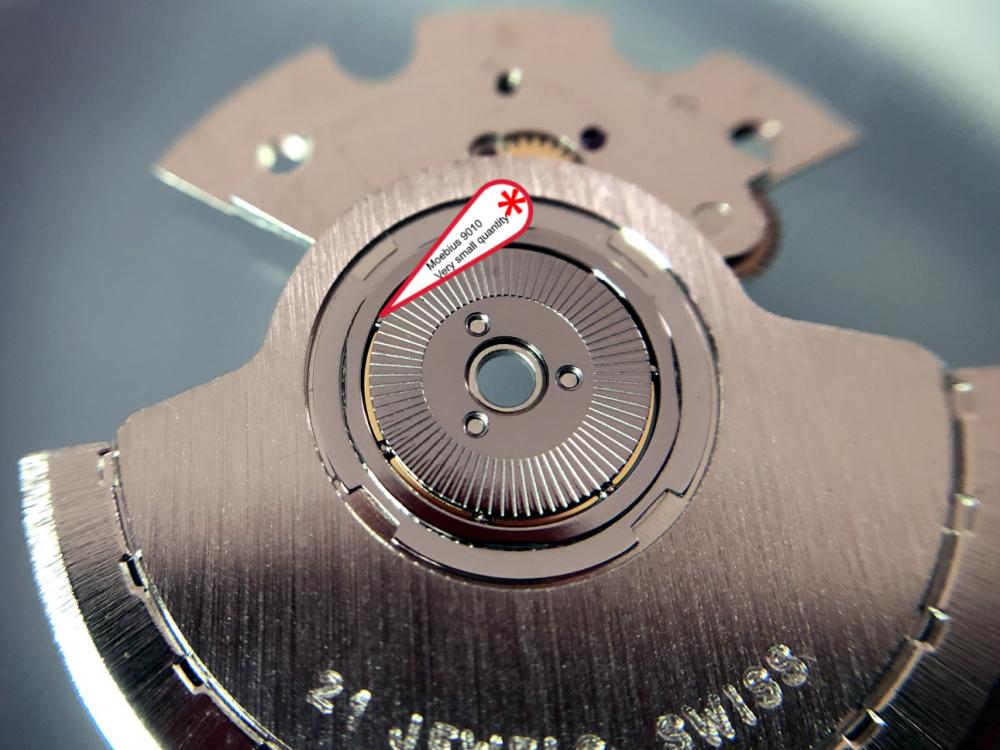

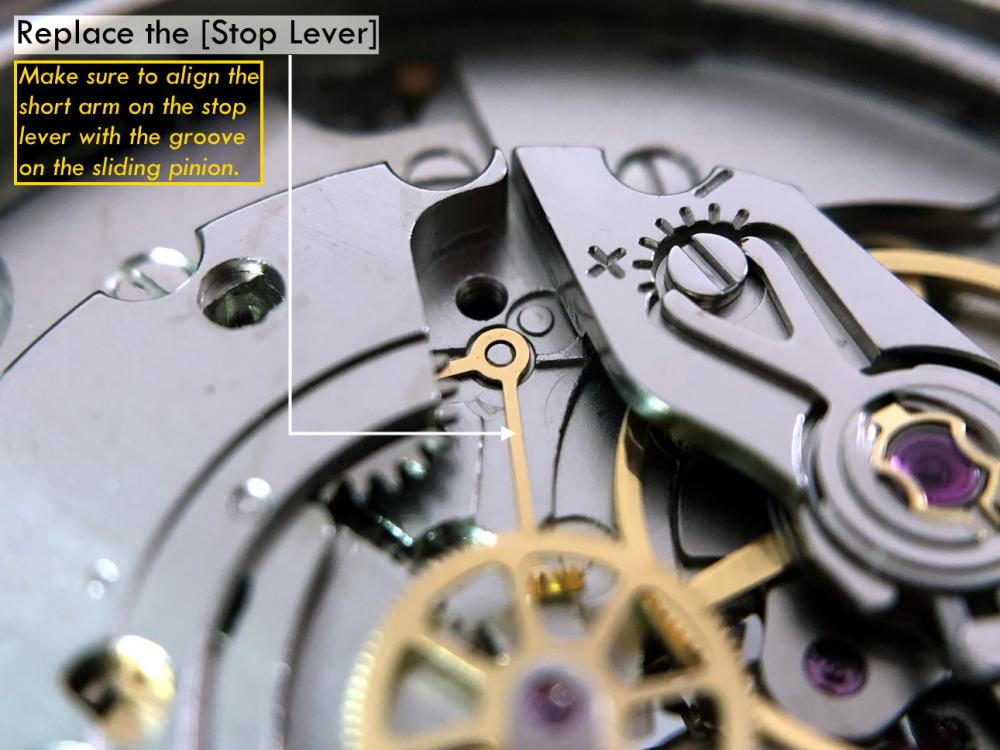

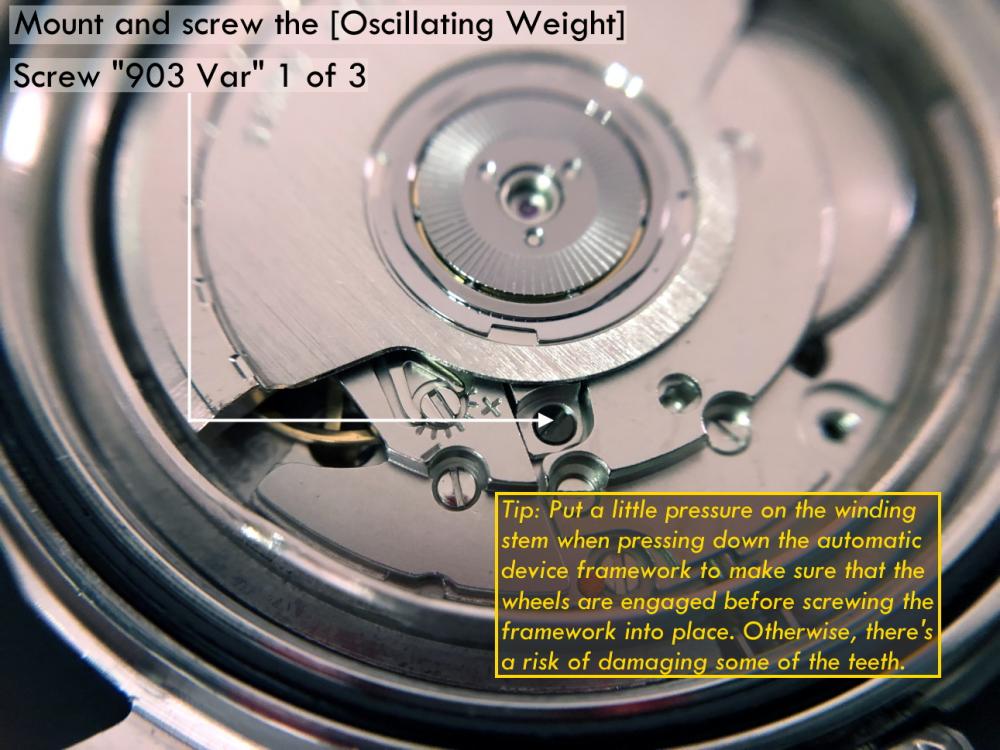

It is my impression that ETA's calibre 2892-A2 is usually found in more expensive watches and in luxury watches where oftentimes the movement has been modified. Mechanically, I don't think the 2892-A2 is superior to ETA’s classic 2824-2. Both movements have the same diameter (11 ½´´´ Ø 25.60 mm), the same frequency (28’800 A/h), and the same date complication. The decisive difference is the thickness where the 2892-A2 is one-millimetre thinner (3.6mm). That, combined with being a reliable and well-functioning movement, has made it popular for additional complications and alterations such as moon phase, power reserve display, co-axial escapement, chronograph modules from Dubois Depraz, and so on. The Swiss Sellita Calibre SW300-1 is, as far as I understand, an excellent clone of the 2892-A2. There is also a Chinese clone, the Seagull Calibre ST1812 (reviewed by @Markin the video “Chinese eta 2892-A2 Clone - Service and Review - Seagull ST1812”), and possibly others. Mark has made a playlist of videos that excellently demonstrate how to service the ETA 2892-A2 movement. The playlist is named: "Omega 2500 Co-Axial Stripdown and Service (ETA 2892-A2)" I recommend Mark’s playlist for several reasons. Among other things, he shows how to mount the barrel bridge safely and how to hold the minute train bridge with your tweezers to easily get it into place on the main plate (which I found a bit fiddly). In addition, he shows and compares the parts that are all too easy to mix up. One thing that is not shown in Mark's service video is that the Incabloc setting (chaton and cap jewel) for the balance and the main plate have different diameters. The main plate Incabloc setting diameter is smaller than that of the balance. The reason this is not shown in the video is probably that Mark removes, cleans, and lubricates the Incabloc settings one at a time after he reassembles the balance, so he wouldn’t notice. Anyway, don't mix up the two sets! Something that I appreciate about Mark's videos in general and that sets him apart from basically all other watch repairers on YouTube is that he doesn't continuously babble in his videos but mainly talks to make clarifications. I enjoy those segments of silence where I can just focus on the work being done. When I started my service, I decided to follow Mark's disassembly which worked perfectly. But for the assembly, I made up my mind to follow ETA's technical documentation to the letter. It turned out to be a mistake. In ETA's documentation, the assembly of the movement begins with the keyless works, then the train of wheels and then the barrel bridge. The crucial problem with this arrangement is that it is physically impossible to mount the barrel bridge if the train of wheels is already mounted. It is also very fiddly and difficult to baste the end of the winding stem into the winding pinion hole because the hole for the winding stem in the main plate is both open and tapered and therefore does not hold the winding stem. Mark takes a considerably more hands-on approach. He begins the assembly with the barrel bridge. He then mounts the keyless works whose constituent parts (the winding stem, the winding pinion, and the sliding pinion) are supported by the underside of the barrel bridge, making it considerably easier to get the keyless works in place. After I revised my strategy, this service walkthrough now follows Mark’s approach. It surprises me, but it seems like no watchmaker has proofread ETA's technical documentation. Alternatively, ETA follows an established practice and expects those using the documentation to understand that the assembly order in the document is not significant. I am also somewhat sceptical of ETA's recommendations regarding lubrication. Where we traditionally use grease, for example in the keyless works, ETA chooses mainly oil (HP-1300). I guess that ETA treats all parts of the movement with epilame (Fixodrop) and that oil may then be a better alternative. For better or for worse, my service walkthrough follows ETA's lubrication recommendations. As usual, I would like to remind those of you with no previous experience in watch servicing that this service walkthrough should not be seen as a tutorial on how to service a watch movement. A lot of tools, consumables, training and know-how are required to succeed. Fortunately, there are several excellent resources and watchmaking schools online. When looking through the pictures you’ll see that a few screws and plates are either marred or have pits and grooves in them. None of this is my doing but is either the result of rust (that I removed) or the doings of a less scrupulous repairer than myself. Finally, someone may ask, “Why to bother to do a service walkthrough with pictures when there is such an excellent video?" The main answer to the question is that I find it interesting and fun, and I see it as a complement to Mark's service video. Using this walkthrough, you can quickly scroll through the pictures to read what the different parts are called and where and in what order they should go, what the screws to be used look like, and to read ETA's lubrication recommendations. So, I hope you’ll find this ETA 2892-A2 service walkthrough useful, now or in the future. *** ETA Calibre 2892-A2 Disassembly *** ' *** ETA Calibre 2892-A2 Assembly ***5 points

-

This is a Roskopf type movement. They need extra long springs that are hard to get today. The usual mainspring calculation does not work here. Frank2 points

-

2 points

-

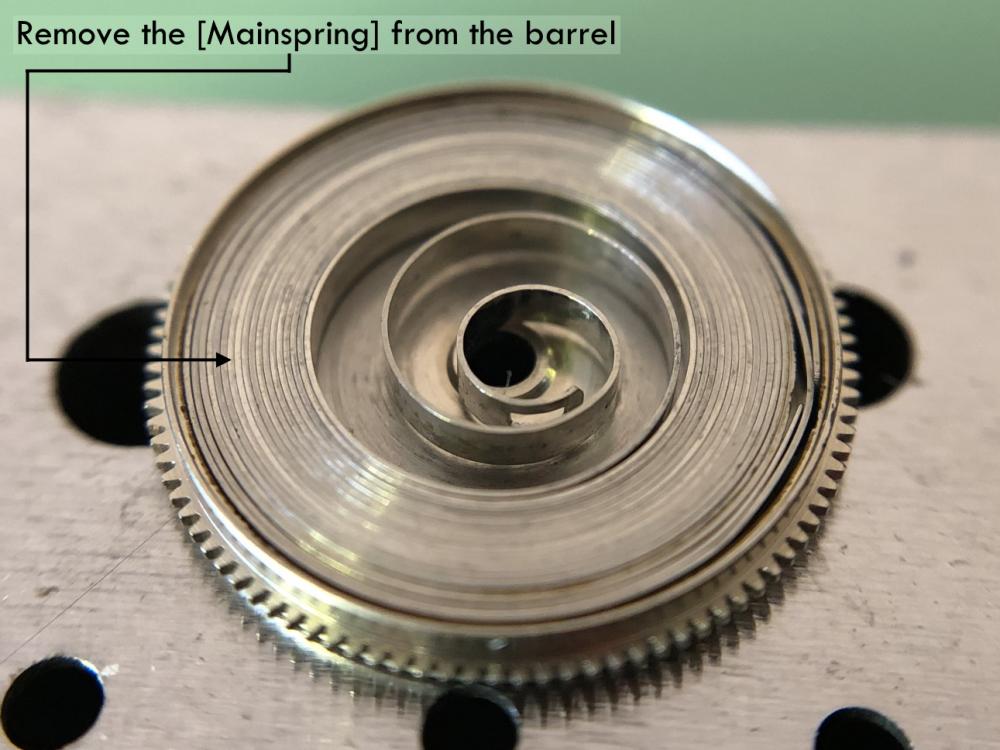

Depending upon whose literature look at the mainspring is supposed to be dry. Only the breaking grease and the harbor is to be lubricated. That's because either the materials the mainspring are magically self lubricating or they've applied some sort of dry invisible lubricant but supposedly they're not supposed to be lubricated. Out of curiosity what did you find inside? In other words was it ~sticky dirty grease or was it dry or what The problem is generalizations. Some of the mainspring barrels that are not meant to be opened my understanding is if you open them you probably will destroy them. Rolex for instance now is a mainspring barrel that cannot be open it's meant to be replaced and we will never see the replacement. Others older sometimes they can be open sometimes they can't. Then ones like this look like a normal barrel with just a cautionary morning. As is almost everything in watch repair that is not necessarily a universal rule of how to handle the situation. Not sure that's quite a correct statement. I don't think the limiting themselves to just the independent watchmaker perhaps. Suppose for instance your watchmaker working for somebody who has Swatch group access in other words you are a chosen one how to Swatch group feel about you? In other words you're not one of those evil independent people your authorized but authorized for what exactly? In the case of Omega you have to be at the right level to access technical literature. You can't see the service bulletins unless somebody is authorized at that level. You can typically order some casings stuff but a lot of that you can see the price but you can order. So even for Swatch group access you still have to be at the right level or for instance the last time I looked at Longines Let your sure it look like I had full access to everything all the technical bulletins number one through over 100 so they weren't necessarily as stringent as Omega. But the last time I was there there is no technical literature left. But a lot of that stuff was vintage and I think the trimming away a lot of vintage stuff. Some of the other Swatch group cites the literature is extremely poor to nonexistent. So I don't think it's just the independent That Swatch group is trying to stomp out I think they're trying to stomp out all watchmakers.2 points

-

Okay here's the problem with things like this do you really have to take it out? Some of it depends upon how you clean your watches for instance at work we have a really expensive cleaning machine that would clean this without disassembly but if you thought a bottle of lubrication was expensive were not even going go into how expensive the machine at work as to so I wouldn't normally worry about taking it off. Then there's the other problem even if you can get the screw out you may find that it's stripped that's why somebody broke the screwdriver tip in the first place they jammed in a screw and called it quits and now no one will ever take it out so if you can make it work without taking it apart you just save yourself a lot of problem.2 points

-

2 points

-

Another phenomenal walk-through from you The clarity of the pictures, the "take-you-by-the-hand" approach & sequence, the additional descriptions (think of the amount of work involved!); everything is "second-to-none" !!! I would say, currently the best walk-through kid in town Excellent stuff A stiff competitor with Mark's video's2 points

-

6119 are my favourite, easy to work on and the only problem with these is they are so reliable that they do not get scheduled maintenance. Most of the wear I see is in the barrel pivots so check this. Apart from water damage, any other wear or damage is due to previous mishandling, I have come across several watches where the hairspring needed tweaking. The big balance helps with good timekeeping compared to later models. I don't like the the 7xxx range as they are cheaply built. Anilv2 points

-

I have a neighbor that is always texting and asking me questions about this or that. I always reply with a google search that she could have done herself. Nowadays, I just send her this. So, here, read this. And also this. And, BTW, you are the perfect one to answer your question. You have before you a scientific experiment--old (really old), and new! Put a couple of drops of each on a clean glass plate and set it vertically and see if gravity affects them both the same. Look at the color of each and compare. Grab a watch out of your box-o-watches and lubricate it with the old stuff and let us know if it is running a year from now. Maybe there is a simple DIY way to measure viscosity (I would have to google that)--better than my simple glass method. My bet is on the old stuff being as good as the new stuff. I use 50 year old Elgin oil myself.1 point

-

Thanks for the to this useful document Nickelsilver The ly is 8 3/4"' i think of this as the lady's( LY) .Also TY 10 1/2 "' the RY had 2 versions of the 13"' caliber 144 and 649 Empire the 649 is shock protected1 point

-

The Generale Ressorts book shows a 13"' (ligne) Smiths movement, which this one is, as using a spring 1.60 x 0.135 x 660 in a ring 14.5mm diameter. 0.17 seems really thick for a 13"' movement, but it is a pin lever (and not a very tall spring), and GR does have some errors in the book. It's not uncommon to find springs far off the original size that have been used in the past to get the watch going, which might explain the height difference. For a spring that should work according to your measurements Cousins has GR ref 3398 1.30 x 0.17 x 520 x15, which should be fine (and cheap at 7 pounds).1 point

-

Wow that was a read on therories of spring sizes. Which one did you use . Barrel diameter, arbor diameter, rule if thirds , rule of half reamaining spring space etc etc.1 point

-

So instead of updating the technical document, ETA decided to adjust the barrel bridge. It seems drastic, to say the least. On the other hand, it is common to start with the train of wheels on many movements, so perhaps they reasoned that it was a more long-term solution in line with what is customary. Who knows! I think it is a very wise decision that I will also follow in the future. After all, why deviate from a proven method that we know works!? I looked through all my pictures to see if I could find a picture of the intermediate reduction wheel from the other side but couldn't find one. I'm guessing that the other side looks at least somewhat different, otherwise, I would have taken a picture of it. Anyway, good to know and be aware of! So do I as explained in the assembly section of the walkthrough. I anticipated that I would have done that on this movement as it was in pretty rough shape. I even got the specialist tool for unlocking the bolt on the rotor that Mark demonstrates in the video "How to replace rotor bearing on an automatic watch. Valjoux 7750 + 2892-A2. Watch repair tutorials." However, the play was just fine so I didn't get any use for the tool this time.1 point

-

I actually nearly wrote self servicing Watchmakers, amateurs, enthusiasts, hobbyists, just about everyone that is not in a position to fit under their umbrella. Lets restrict parts shall we and also any literature that helps anyone fit the parts that they manage to aquire by scraping whats left in the bottom of the barrel. Then when we've done all of that lets release watches that cause their unknowingly (unknowing that swatch are asses) public into camping out side of releasing shops early hours of the morning, to pay good money for total crap. Yes lets do that people of swatcherland. Oh i forgot youve already done it. Cheers Gert for mentioning swatch , you know it screws with my blood pressure, i used to like you .1 point

-

I found some pictures so you can see the missing arm and other styles that have different arm arrangements. Usually the arm stays with the tool because it's held in place with the screw. In one of the pictures there's something on the left-hand side it's a bit fuzzy though. At the end of it is a slot that slot goes over the rim of the balance wheel allowing you to straighten out your balance wheel and true things. Typically that gets separated from the caliper and is never seen again. Which is why When you typically find the truing calipers you will not find that because nobody associates that with the truing caliper.1 point

-

Hi You forgot < self interested , trade protective, why because they can and are protected by the EU although not a member.1 point

-

Dont get me started Gert . Greedy , selfish, manipulative, devious, arrogant, uncompromising, lack of decent moral and compassion. Too late, shall i continue ?1 point

-

There are 2 different end nibs. The nibs with the holes that allow the pivots of a balance staff to pass through safely. This end is for straightening out a balance wheel (truing), the staff stays on the wheel. If you look closely inside the nibs at this end you will see a very small convex shape for the cone of a staff to fit into. This transfers the pressure to a meatier part of the staff and prevents the pivots from breaking off while manipulating the balance wheel to straightness with your fingers. Unfortunately on this one the index and carrier arm are missing, this is what gives you the visuals to straighten out, the 2 fastening screws are still there though so you should be able to manufacture the parts needed to complete the tool. The other set of nibs have no holes, this side of the calipers is for poising the balance wheel (finding an unbalance in the wheel ie. it's heavy spots). Good calipers will have jewelled nibs here with a lightly loaded sprung pin behind the jewel for the pivot to press up against. Cheaper ones will have just a shallow recess in the nib to hold the pivots, be careful not to bend the pivots when bringing the nibs together on the cheaper version.1 point

-

1 point

-

1 point

-

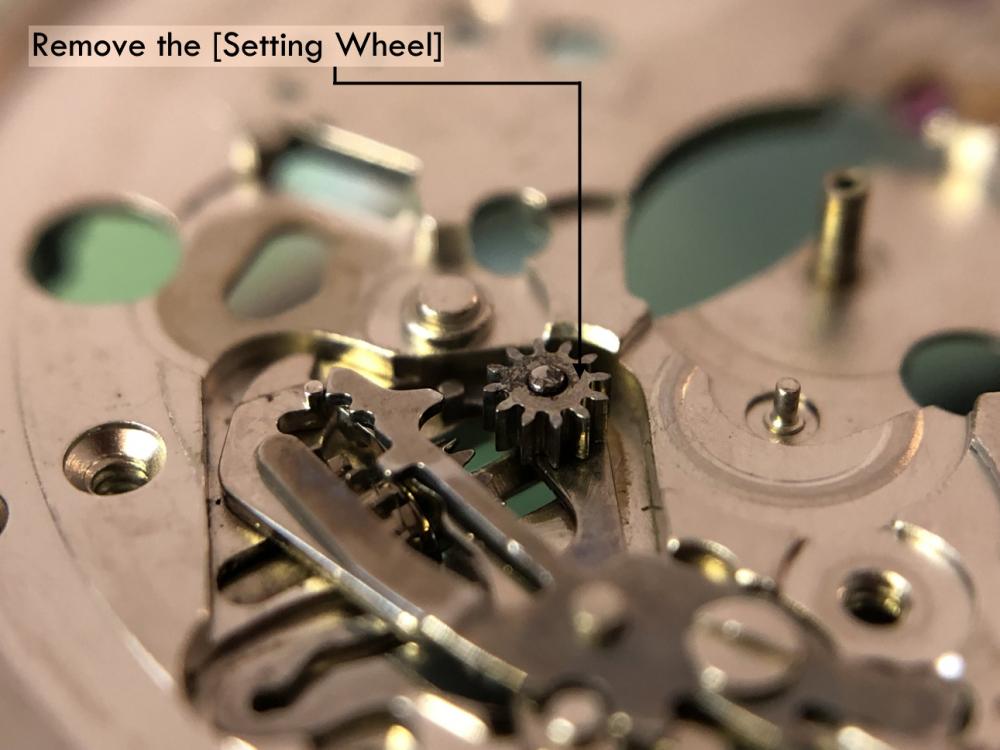

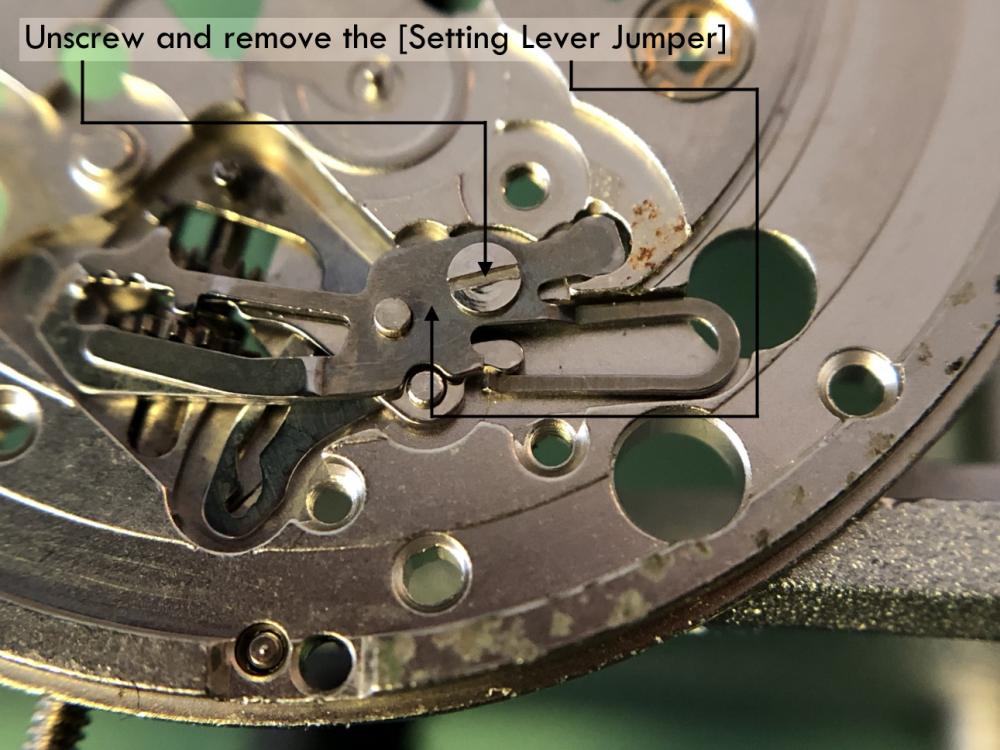

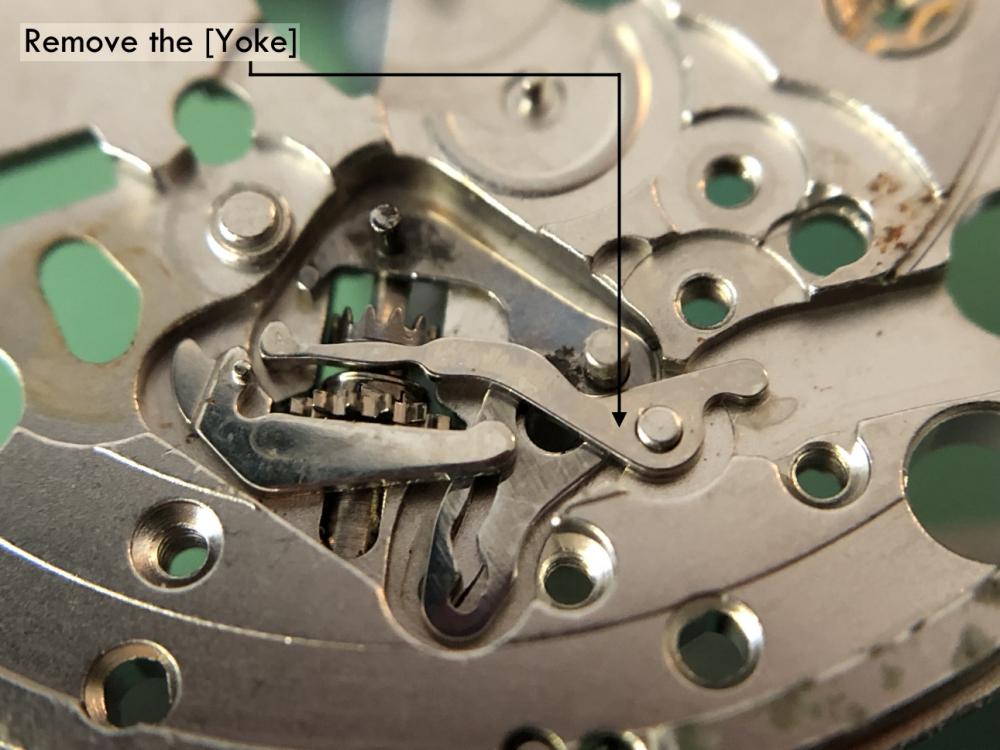

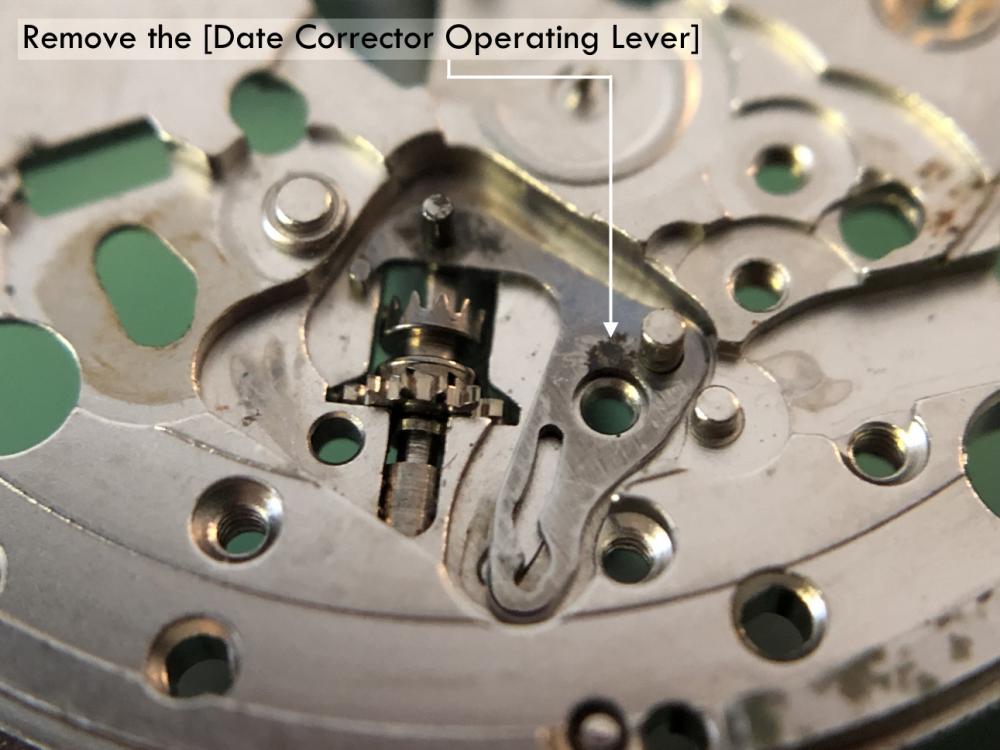

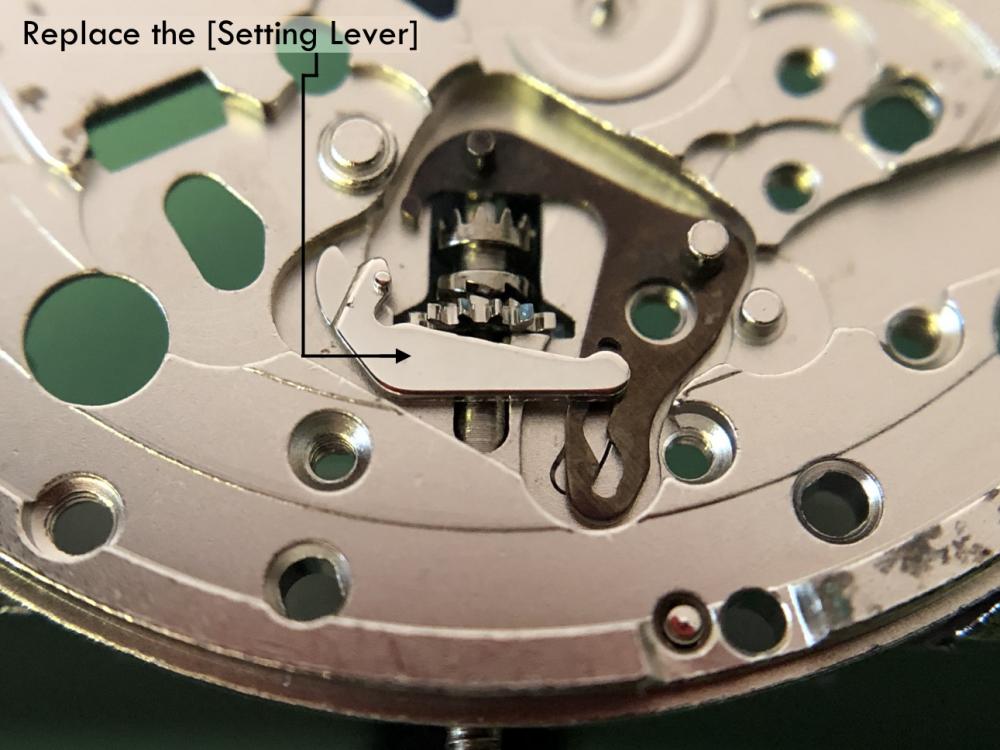

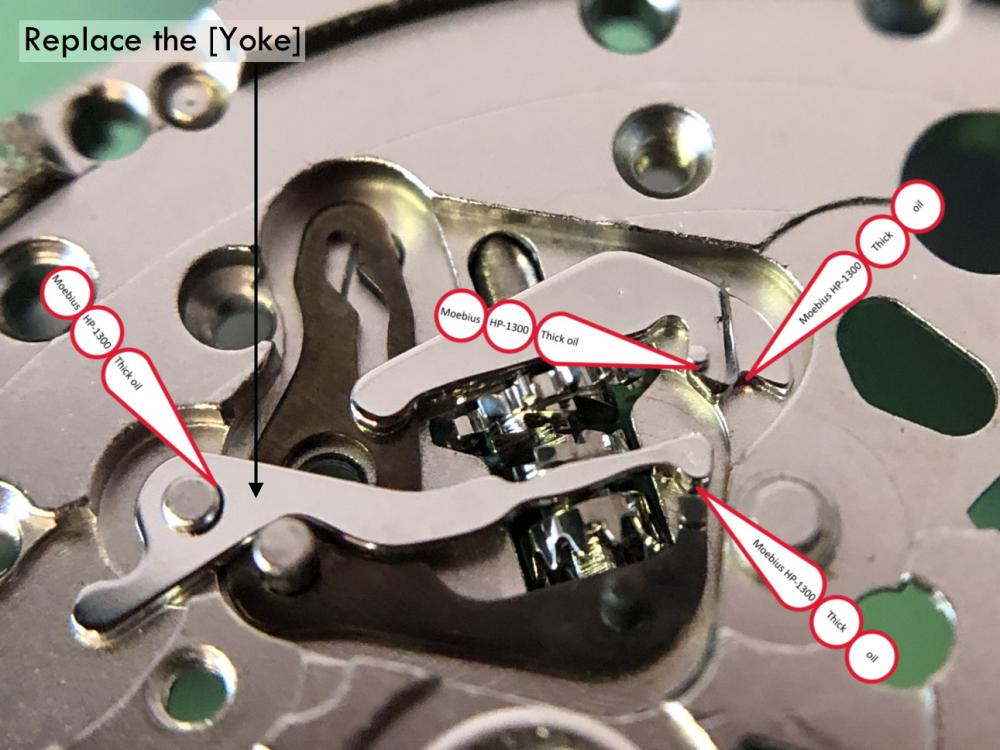

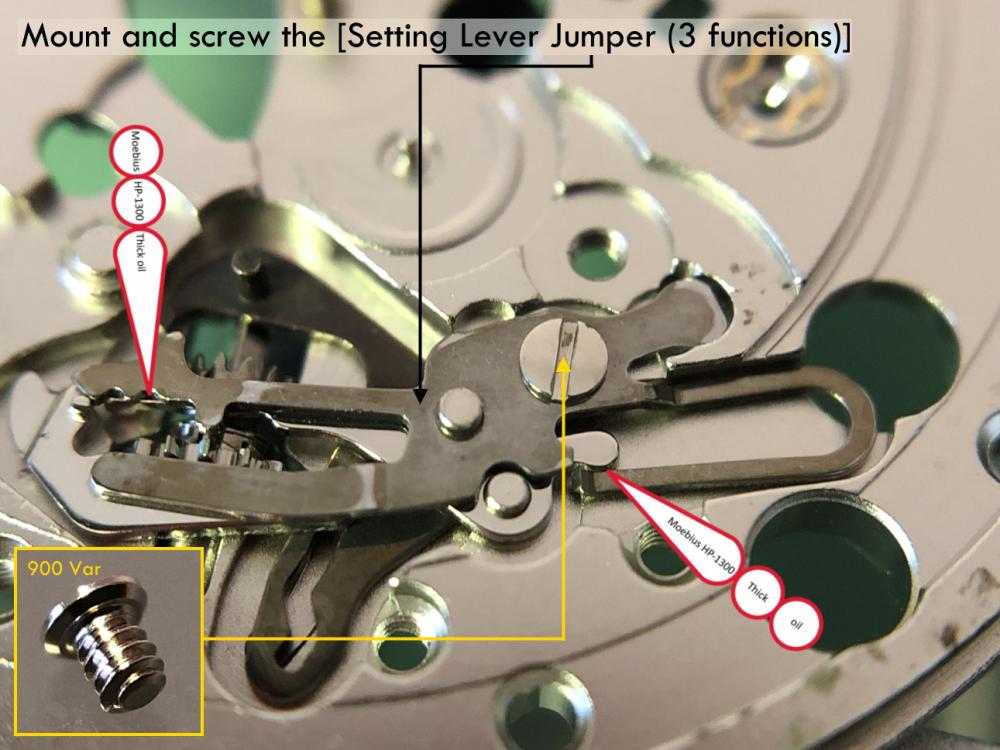

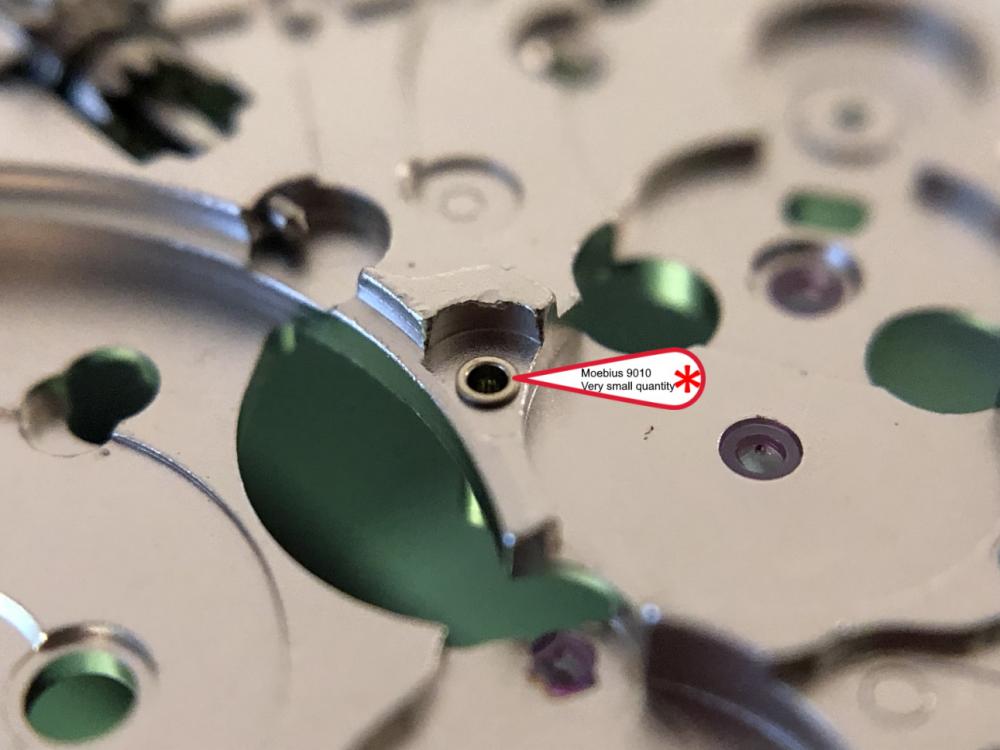

Second Seiko service! The keyless works were messed up. It showed up with a busted stem. The new stem would not insert, so I knew something was wrong. The setting lever jumper was bent upward and disengaged. Other than the dealing with diashock and kif, it was a pretty uneventful service of the movement. Well...it did take me close to an hour to service the mainspring. I realize now that I had the teeth on my winder closed too much, so as I got close to the end, it was binding. Lesson learned. I was having trouble getting the stem in. First time, I knocked the setting lever jumper off track. I took it off and did another bend' Had an issue with the casing but it was my own fault--not paying attention. Trimmed down the stem and installed a new crown. Seems to be working fine. This watch has been worked on before...perhaps several times. That second hand does not look genuine...maybe replaced during a previous service? Dunno.1 point

-

I was able to locate a new old-stock Nike band for my WC0053 thru www.parsecent.com. I confirmed with customer service that this they had the black rubber strap via email, so I went ahead and ordered the strap. I had spoken with Hope @ 309-689-6531 ext. 11. I've attached the images that she had sent to me too.1 point

-

I have the first 3 tools. They are for setting jewels. The 1st and 2nd are called pallet warmers. They are used for holding the pallet fork in place with the jewels and warmed over an alcohol burner to melt the shellac and secure the jewels to the pallet fork. I have used both of them before and I prefer the 1st one. The 3rd tool is a roller jewel warmer. I haven't had to use it yet. The 4th tool.... no idea. Sorry.1 point

-

1 point

-

There are a bunch of them on thingiverse and one of these days I may get round to making one.... https://www.thingiverse.com/search?q=useless+machine&page=1&type=things&sort=relevant ... although I may not tell my wife what I'm doing. I wouldn't want to confirm her suspicions about my uselessness.1 point

-

I don't find them very difficult at all, but I suppose it's because the majority of the movements I began learning on were Seiko's. Lots of 6309's, 6119's, 7006's, and 5606's. Speaking frankly, I'm a big Seiko fanboy! Value for money I think they are tough to beat, and some of their dials are simply stunning. They break down the keyless works into just a couple of parts. Their 'magic lever' system for the auto winding is so simple it's brilliant. I'm a fan. You can definitely tell they really thought it out and simplified it for mass production, but they are still capable of keeping excellent time.1 point

-

Unless it’s crimped shut, you can open it, provided you have the means to properly install the MS again. There was this whole “unbreakable” phase the industry adopted when it developed modern steel mainsprings. And parts were easily accessible. No one at the time would’ve thought there would be a “Swatch” group that would try to kill off independent repair. I should add that I’m working on a Longines L989.2 movement now - extremely rare twin barrelled marvel from the late 80’s. Only tackle what you feel confident you can replace if you screw up. Know your limits.1 point