Leaderboard

Popular Content

Showing content with the highest reputation on 07/06/22 in all areas

-

3 points

-

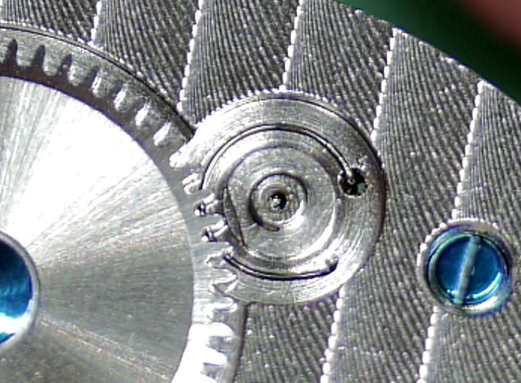

No. The elasticity of steel is its elasticity. It even doesn't really change with heat treatment, there the point of plastic deformation changes but up to that point its "springiness" remains the same. Heat treatment does change a lot of things though, and hairsprings from steel are 99.99999% of the time heat treated; if nothing else this avoids plastic deformation from simply removing and replacing the balance on the cock. But otherwise hairsprings don't get tired, and certainly don't decide to spring one way but not the other. If the balance oscillates freely with the fork out but not with the fork in, you have a problem with that interaction. If it doesn't oscillate freely with the fork out- not just move back and forth a few times, but oscillate freely- you have a problem with something on the balance.2 points

-

Hi Get hols of Ward Goodrich's book "Watchmakers lathe its use and abuse". Or De Carles book. As far as Gravers go its a personal choice, Usually tungsten carbide, and the shape prefered depends on the use the graver is being used for and the type of cut required.2 points

-

Haha. She sounds as though she has her head screwed on the right way round. You may not have tricked her, she probably just wants you to think that you did lol. She may just have worked out that you were the right one for her.2 points

-

Wow, you're right about the reviews on TrustPilot. I'm utterly surprised. My experience with CousinsUK is 1st class. As long as you are aware that the conditions are those of business-to-business and not business-to-consumer, there really shouldn't be anything to be surprised or disappointed about. EDIT: Cousins see themselves as a distributor. That is, you're really supposed to take your complaints to the manufacturer. Nevertheless, several times they have helped me out as a negotiator between me and the manufacturer. Really 1st class!2 points

-

I use a hand blower to remove most of the cleaner from the parts before the rinse. I believe one rinse is adequate. I dispose of the solutions after each watch. Make sure your oven is not too hot to melt the shellac !2 points

-

Hi When you say it doesnt move, is it stiff and sticky, does it oscillate if you give it a help with a brush, does it move at all. You have checked the train and thats ok and the pallet is ok . yes. Check the end shake on the balance for a little movement. also try powering down the watch removing the pallet and just fitting the balance whilst you work on it as this removes any outside influence, also check the balance pivots are not bent or broken. use a small artist brush or air puffer to oscillate the balance. If it oscillates ok check the beat it may be out.2 points

-

Other than the colour that looks identical to mine, so that's an excellent price. Regarding struggling to get your screwdrivers under it, just add a 0.5 Barlow lens, that will raise the head up enough to give plenty of room for drivers etc, I get about 8 inches of working space on mine with the Barlow fitted.2 points

-

1 point

-

interestingly more we did the exact same thing. I is set my password-protected off to a friend who remove the password I assume he kept a copy and I got my password removed copy back which is a lot nicer than having to remember stupid password.1 point

-

I took Kalanag's idea and ran with it. This works. One of the issues with the project is that the wound spring and housing does not sit inside the mainspring barrel before you press the plunger. This means the chances of the spring not seating well are high (as mentioned a few times in the thread). Kalanag's idea was to slightly eject the mainspring a tiny bit before trying to seat it in the barrel, now the spring can "set" in the bowl before you press the plunger. The chances of ejecting the spring too far and unleashing it are too great. I designed a "WinderSetBowl" to make this job foolproof. It is essentially one of Zero's barrel bowls, but set to be just 0.3mm deep. It should be sized to accommodate any winder in Zero's complete set. Instructions: After you remove the Winder Base from the Main Housing, place the housing in the "WinderSetBowl" and press the plunger. When you remove the housing, you'll notice the wound mainspring is now perfectly ejected exactly 0.3 mm. Now you can easily place it in the Barrel Bowl and eject the spring into the barrel. I am happy to place this in Thingiverse, but if Zero likes the idea, he is welcome to include it in his GitHub repository as part of his set. For now, if you would like, contact me and I'll email you the STL. I've already printed and tested this and it works great!1 point

-

That's correct. Multiple iterations on the same movement, superseding each other without a much to make it obvious. It's been a while, but I had two version of the same 7s26 watch; one I bought in college, and the other was replaced by insurance when the first was destroyed in a car wreck. The first, I think, was an A or B, and the second was a C. For sentimental reasons I wanted to fix the original, and figured I'd use parts from the second to fix the problem. I ran into exactly what you did. I ultimately ended up using the case and hands, and got an aftermarket dial, domed sapphire crystal, and a new NH38 (I think that's the one without a date). Now it's my "shop watch" for when I'm working on things I don't want to subject my daily driver to. I recall the _/A/B/C iterations are noted on the rotor, or maybe on the main plate somewhere if you know to look. Maybe it's because of what I learned with the Seiko, but I've not run into that particular issue with any other movements for whatever that's worth.1 point

-

It's all about researching or asking, in this case even Seiko enthusiasts know that 7S26 has been made in three versions, A B and C, that also has been discussed many times here. Below a parts compatibility sheet shared by myself. https://docs.google.com/spreadsheets/d/e/2PACX-1vRN2UULQKTfKmhRStZhDdIOIQrqd6sPB-g6x2SKyQQjOvTBjG_7TQXQhAT4f1WqAX5QAPkIimi-3jqd/pubhtml Note if you aim for a sure repair the best option is to buy a brand new complete NH36 movement. That will give you manual winding, seconds hacking, and plenty of spare parte from the old one, for little money on top.1 point

-

just a little clarification here. I've seen that people new to watch repair don't realize there's something else is going on. So let's look at what the Swiss do at least what they used to do currently they do have unique numbers for every single part. But previously they had a numbering system where in setting using a name they use a number. So I've seen this happen with people new to watch repair is you look at a tech sheets you'll see a part number for a balance staff for instance annual The order one and be very confused by it's not the right part at all. So I snipped out a couple images explain a little about that show you the pictures. So by using a number rather than a word you can get by with packets with just a number on it because the packets of watch parts tend to be really tiny it also means a number is universal where every language would use the same number for the same part but obviously their language it's a different word you can't print all the words on pack in a parts. Then you end up with the American companies as in C with Elgin they had lots of variations for the same part because the watch you fall over time and that's an entirely different numbering system or scheme than what the Swiss are doing. oh and then the other thing shown below is even with the Swiss one part might be our wheel but they are wheel could have different heights to it. This is where people in the material house get really frustrated because people don't often give enough information and then you end up with the wrong parts than your unhappy with the material house is unhappy with you. This is also why typically a lot of watch material houses won't do business with hobbyists are amateurs because they have no idea at all how to order parts although that's not unique to hobbyists one of the local material houses got very frustrated with everybody including professionals it would tend to tell them how stupid they were because they didn't understand how to run their material house. They had acquired a material house and started to material business which lasted a few years before it went out of business mainly because he didn't understand how complicated the material house business is. Oh and then the other thing about the numbering scheme that is actually several different schemes. Says not like universal a part number may be identical to all systems. Which also means when other material houses absorb other material houses they usually will not integrated into their system because it's too confusing so unfortunately Swiss American part numbering schemes for watch parts are confusing and as you're finding out lead to why doesn't my part fits when I have the right part number.1 point

-

Thanks Guys! That's why I purchased a job lot of junk to practice on. Hopefully I won't be a fumble-fingered beginner for the rest of my life!1 point

-

When you pull the stem out, some part of the keyless are free to jump out of position, you will then have a mess that can easily engage the minute train or date change mech or helplessly stuck somewhere, in which case, you have no choice but to get to the keyless and set every part right. Weasol is trying and hoping for the best senario, he needs more data. Regs1 point

-

When you restart it do you give it a shake and does it then run again ok and stops always in the same spot, It still might be some debris in the movement or has been found before a bit of the bumper spring broken off and wandering about the movement . I think the best thing to do if you are confident enough is to get it de cased and run it under a cover (wine glass) and when it stops again have a look round for debris, bent or broken tooth on the train wheels. If it hasn't been serviced at all its best to do that as well, as it may have a broken mainspring also.1 point

-

And the 0.7 Barlow with give even more room but you may find the head it now too high to use, useful if you can stand your scope on a lower bench, or you have one of those fancy adjustable height benches like the one IKEA Sells, but for me and my workbench 0.5 is perfect. And yes it screws on the bottom lens set where the ring light clamps, if you have one that is Here is my little setup Showing around 8 inches to the bottom of the original lens set with the Barlow lens fitted which is hidden by the ring light.1 point

-

If you are inexperienced, it is very easy to install the balance in a "overbanked" condition. The roller jewel or possibly finger (in your case) must be installed beyond the direction/side the pallet fork is pointing in. If this doesn't make sense to you and you can't find a visual reference, let us know and I'm sure one of us can come up with a photo that explains it better. Shane Hold the balancecock over the movement so that the wheel is set with the rooler on the correct side. Once the pivot is in place (without tripping the fork), rotate the arm until its in its position and set it on its locating pins. We can get better photos but that's all I have before coffee. Shane1 point

-

Jumping in. Yes the Barlow lens screws in as a last lens before the viewing table. hth Tom1 point

-

1 point

-

I remember donkeys years one I was working on the s/p according to the book was wrong I made a note of it in the book. It is more then likely the same thing has happened to you. Nice to know you have sorted it and the clock is working well.1 point

-

Hey Ian, I am also just starting out. The loupe was what I used to begin with but I do not have that special eye muscle to make it stay in my eye socket. I tried the ones with the wire around my neck and I find that the working distance is not ideal. So I got one of these. I got it from taobao, and it worked out to be about USD 120. I can adjust both eyes (left and right distance) and also the diopter so it accommodates for my myopia I can use them without glasses. I also learned that I am not really supposed to smash my eyes to the padded eye pieces, more like hover a little above them. I can get better working distance, although I still struggle with my screw drivers to get under the scope. I can give you the link if you want, but it is not in English. Good luck!1 point

-

1 point

-

Hello Lotus, Welcome to the WRT forum. I'm not very familiar with vintage Timex watches however I found this YT video that may help you with that model. I'm sure there are many others who will chime in to help you if this video doesn't answer your questions. Best of luck to you on your journey into this hobby.1 point

-

Please read through this thread. The movement does come out the front.1 point

-

1 point

-

Hi all - I live in the north central USA. I've worn watches since my parents gave me a little manual wind Timex for my 7th birthday, but the pandemic turned me from "a guy with this or that quartz watch until it breaks" into "a watch guy." Occasionally browsing watch review videos led me to Mark's mesmerizing repair videos, which led me to watching probably 300 hours of his and other watch service videos. A few months back I finally took an 8 hour course with a local watchmaker to service a ST36/6497 clone movement and assemble a watch, in hopes of getting some hands-on practice before attempting to fix a broken HMT frankenwatch. (I succeeded! even replaced its crystal after ruining the original with isopropyl alcohol) And eventually to attempt service on my malfunctioning Vostok. I managed to disassemble the grinding automatic wind on a very cheap Tongji-based watch to lubricate it, and want to work on a couple more junk automatics before tackling the Vostok I actually care about. Ultimately I'd like to be restoring pocket watches, but I've already discovered I'll need to learn to replace a balance staff to really open up that realm, with its requisite equipment investment. I already have a time consuming day job, time consuming chores, and already have somewhat time consuming practice & performance commitments as an amateur musician, but there's still a free hour in the week so I've gotta make some tiny machines tick tick tick. I look forward to participating here - I promise to research as much as I can before asking novice questions, but I am a novice and I've got a million questions. Cheers!1 point

-

Great introduction! Welcome to the forum - I think you'll find the place to be pretty knowledgeable so, ask away!1 point

-

Clock is running great! Got the 10th edition of the T book and have done some comparisons. I believe my clock is plate 1574A. It appears identical to 1579 except for the suspension spring size and length.1 point

-

Great, best to check the obvious thins first. Is it running ok now.1 point

-

How powerful is your ultrasonic? 10 mins is probably more than enough. I use 5 mins for cleaning, and 3 for rinsing. Yes, lighter fluid does leave a residue, you should use IPA for rinsing. When I used IPA I did 3 mins in the ultrasonic, and just 1 min for pallet and balance. Do NOT worry about dissolving old shellac ! After years of using refined Naphtha, IPA, I switched this year to proper cleaners - Elma WF Pro cleaner and Elma Suprol Pro rinse. I got the Elma as you can buy it in 2.5L size, so not too expensive, and it will last me years. (For each watch I use about 40ml of fluid in a glass beaker sat in the ultrasonic. So the total cost of cleaning+rinsing is about £1 per watch) The WF Pro cleans much better than naphtha, and leaves parts shining. And with the rinse there's no need to worry about dissolving shellac.1 point

-

The first thing to check is the clearance of the sweep seconds, It may have been catching the batons (hour markers) or the other hands. If the stem wasn't secure the movement may have moved slightly, did you check that the movement was secured with its clamps/screws as if the stem screw was loose ther may be a loose screw or other debris in the movement. Was the second hand only attended to or was it cleaned etc. attaches is the tec/parts sheet 1367_Omega 354 (2).pdf1 point

-

Well I now appear to have a working display on my Hi Fi amp (aka my Yamaha DSP -A970 Digital Sound Field Processing Amplifier). My cheap from China display works. There are however, still a couple of issues I need to resolve. The original display has slightly different dimensions, so I am thinking of 3d printing an adaptor for it. It is currently fitted with one screw, some tape and a tie wrap. Its perfectly secure of course. Also the backlight supply needs wired to the original switched supply, as currently the backlight remains on, even when the amp goes in to standby. I may also check the old display as it may only be a failed tungsten filament backlight that is making that unusable, in which case an LED or two might fix that, and I can re-fit the original with no 3d printed adaptor required.1 point

-

If you want to "restore it to its original glory" and replace the bezel, I would replace the lume and paint the seconds hand.1 point

-

Keeping with the somewhat rambling and completely off topic nature of this thread, I got a spare moment to work on my HiFi project. I started with the rebadged Akai R470 - Memorex SCT-88 tape deck. This was a bit of a mess when it arrived. Both belts had gone, and the tape counter belt had reverted to a thick black non polymerized goop, which had to be removed before I could even think about fixing any of the other issues. This is the ebay listing picture for comparison. It also had a broken clip in the transport mechanism which caused some weird load and eject problems, but that was a relatively easy fix with some supeglue and baking soda. After a fair bit of cleaning and lubricating and some cosmetic work to make it look clean and presentable enough to sit in the living room, it plays perfectly and looks almost new. After a little effort, I can now sit and listen to some of the large collection of tapes we still have lying around. Interestingly when I took a quick trawl round the local charity shops the other day, not a single one of them (and we have quite a few charity shops here), not one, had any cassette tapes. CDs, VHS tapes, Mini-disks, 78s, LPs, 45s, you name it, they were there, but not a single cassette tape. Very strange. I think I'll probably tackle the record deck next, then the amp. I'll keep you all posted with any progress I make.1 point

-

Finding cases which fit is very difficult, unless you find one for that specific model, and even then it might not fit. I bought a NOS case for a specific ETA movement, and it didn't fit properly because of the dial size. I had to make a spacer. So, your chances are not great, unless you can find a cheap scrapper with the same movement.1 point

-

Think you are correct. It's just that I'm excited by the very new hobby. Something that I am able to achieve something with. Regards Ross1 point

-

Lol. Seriously Ross, it could be cheaper and a lot less hassle buying watches that have the movement cased. Depending on your choice of genre. Uncased are fantastic for practicing your skills on and the odd little gem that you might come across is always worth a bit more time and effort to get it on your wrist..1 point

-

Welcome to the forum! Many of the videos we watch on YT show a complete watch service in under an hour - not very realistic. There's a new YouTuber with a focus on new hobbyists. Maybe take a look at the first couple he's posted.1 point

.thumb.jpg.da7cf64dbc0fd210b861bfa04208e204.jpg)

.thumb.jpg.1f325095e7b3dca91b4047a996909652.jpg)