Leaderboard

Popular Content

Showing content with the highest reputation on 06/09/22 in all areas

-

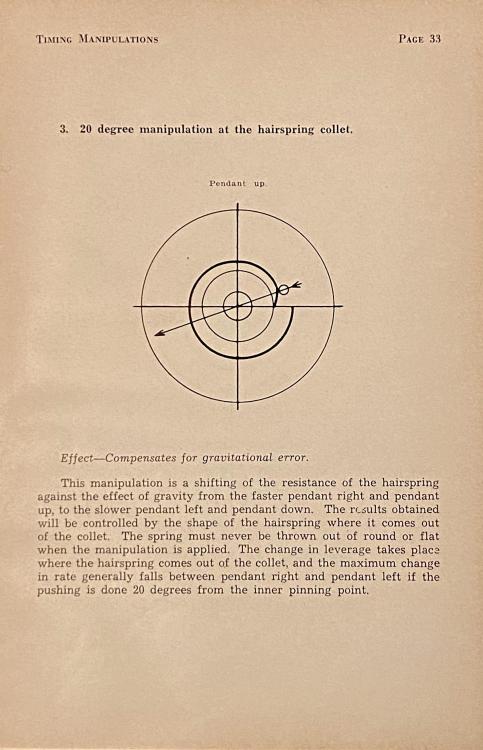

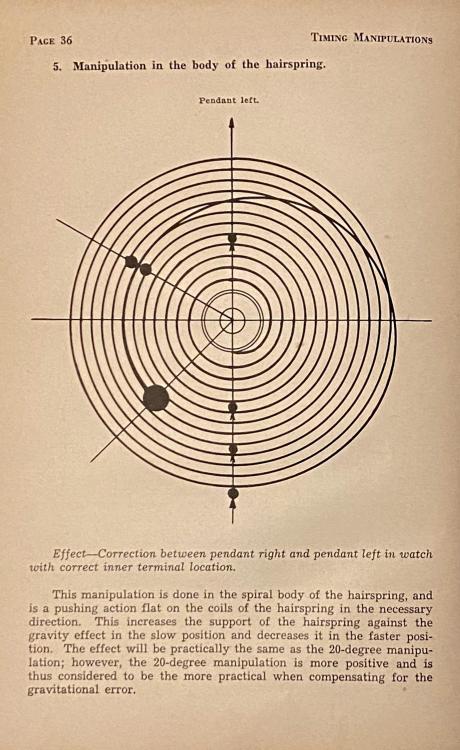

The thing with the regulating pins, is the basic logic is if you open them, the rate drops, and drops more as amplitude goes down. You could have them open enough that after 24 hours the spring is barely hitting them, so the rate goes way down. But if the spring isn't centered you can get very interesting results, including an increasing rate as amplitude goes down. Imagining a normal gap on the pins, if the spring favors strongly one side due to poor centering, the spring might pull away more at higher amp, and stay totally or almost totally in contact at lower amplitudes. As you change position, gravity is affecting the spring as well, and so in certain positions it might pull away still (your 12), but stay more in contact in the other ones, including the horizontal positions. This is just one possibility in your case. But the thing any school will hammer and hammer and hammer into students heads is before doing dynamic poising, every thing else must be perfect first. Otherwise, even if you had what looked like a clear poise issue, you can be embarking on a wild goose chase. I'm quite sure you can get your 24h delta lower, and without resorting to some of the techniques in the Hamilton book (which is a truly fantastic book). The pinning points, the way the hairspring leaves the collet, and the terminal curve on an ETA or Sellita has been intensely studied and should need no manipulation, and with the Etachron system you have a very easy way to get the hairspring really behaving top notch between the pins. It could be that in the end your best route is to do some dynamic poise, but do check and recheck and adjust any and everything else first.4 points

-

Check out here for a full video on screw head polishing and blueing including the use of the tool that you have.4 points

-

A couple of finished items here for the diy old pillar drill rotary wash. Still honing things for the wash baskets, but this is what i've come up with so far. Parts list :- 3 small round sealable tubs £1.50p for the 3. 1 larger tub that holds 2 of the smaller tubs 79p. 3 bolts with nuts and washers inc. Mdf big washers made with holesaw, shed items. 1 pill box container 29p. 3 mini mesh baskets, had those already. 1 lid from tuperwear cup, kitchen cupboard. 1 mealworm tub from the mother in law . 1 2kg dumbell weight from my gym stock of around 2 1/2 tonne. This gives me 1 segmented single basket that will do 1 possibly 2 movements. The larger tub carries 2 lots of this so potentially 4 watch movements. The mealworm tub and weight is for hazard intervention protection. Sources. :- kitchen, shed, home gym, watchroom, the range, poundland and home bargains, oh and the mother in law . Well under £4.04p for the wash baskets, maybe was eligible to have posted all this there.3 points

-

This is purely visual. I'm a pretty good regleur, but I work with a guy who is amazing, and the absolute number one "trick" he has is to true and center everything up just like in school. Check the centering with no power. The spring should be centered and not touching either pin. Give it a wiggle and see that it bounces back and forth. Tweak at stud to center, twist pin block to open and close.3 points

-

3 points

-

I used long nose pliers. This type doesn't have containment rings.2 points

-

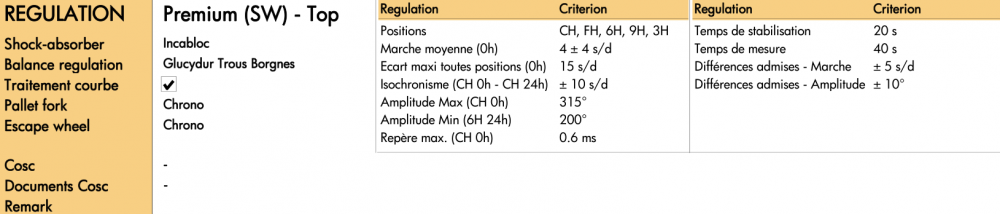

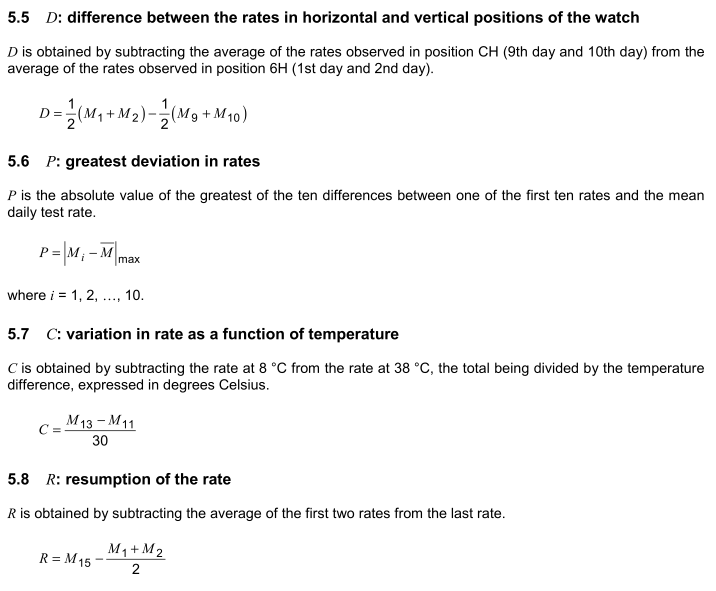

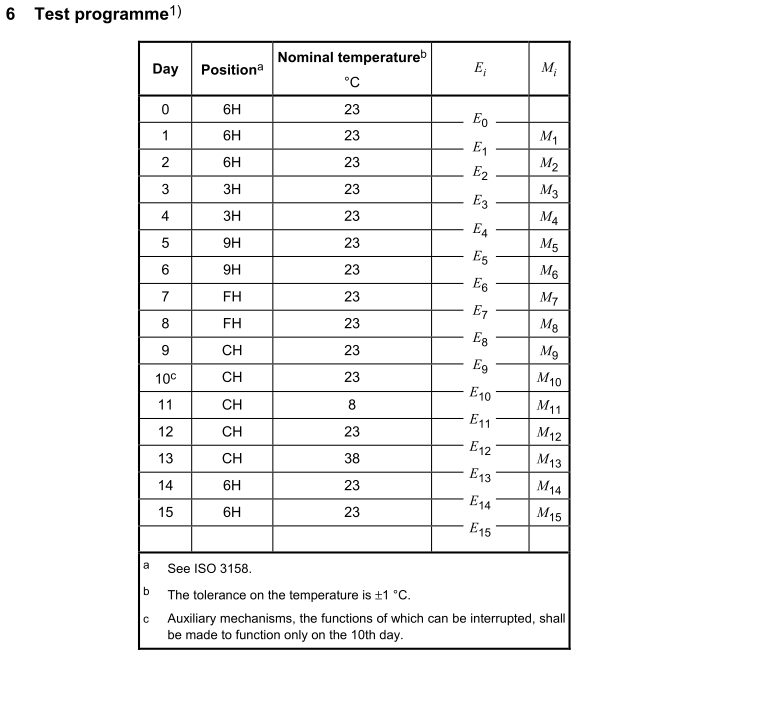

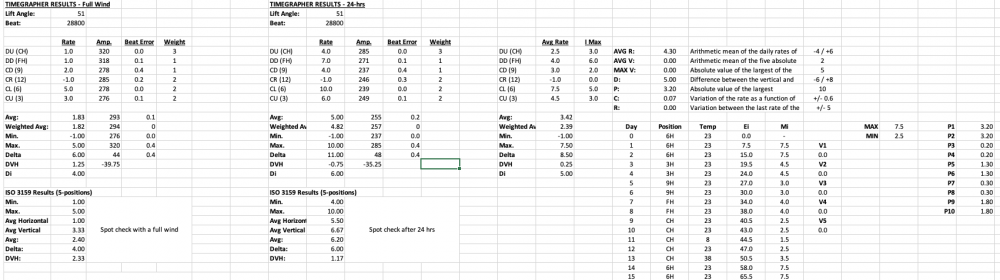

Precision adjustment for isochronism and positional error, so what's the question? First, the landscape of what I'm working on. I have a number of Sellita SW300-1 movements, Premium (Top) grade execution with chronometer grade pallet fork, escape wheel, and 5-position regulation to +/-4 s/d. Attached is the technical cut sheet for reference. I am working on fine tuning the adjustment of these movements in preparation to undergo chronometer certification, ISO3159 testing. For reference, the testing protocols: Out of the box, the movements are very good. In fact, as an automatic movement that will maintain a near full power reserve over the course of a day while wearing, these will perform exceptionally well. I have been using an MTG-9900A to test each movement at full wind and half wind with a 6-position 20-second stabilization and 40-second timing period protocol. With these numbers, I am capturing the instantaneous rates at 0 and 24, determining the average beat rate for each position, the isochronism for each position, and able to use these numbers to predict the approximate performance when the movement undergoes ISO3159 testing protocol. Here's an example of my data: So what's bugging me? Like I said, I'm very satisfied with the performance of this movement. On the wrist, it will time very good. Even undergoing ISO3159, it appears it will pass. To give myself some margin of error, I should slow the average rate down 1.5 s/d using the average rate between 0 and 24. Why? Because the test is 24hrs in each position so isochronism matters even though the reality of wearing an automatic doesn't matter as much. What's bothering me is the positional error between 6H and 12H. At full wind it is a 6-sec delta, at half wind that is exacerbated to an 11-sec delta. Because of the relative consistency between the other positions this suggests to me the balance needs dynamic poising or inherent to the design of an SW300-1 is a gravitational issue. Keep in mind these are factory fresh, top grade movements that, and I confirmed with Sellita, have been dynamically poised in factory. I will test out the theory of dynamic poising to eliminate the delta between 6H and 12H. But should the issue persist (and I think it will since I am seeing this delta on a number of the movements), I believe it is likely a center of gravity issue with the hairspring. Finally arriving at my question, how do you modify the hairspring to shift the center of gravity? Looking at Hmilton's book on hairspring manipulations, he recommends a slight tweak to the hairspring at the collet pinning point. However, the SW300-1 collet and pinning design simply does not allow for one to access the start of the coil in the same way it is accessible in a vintage movement. His next advice is to adjust the coil at the other pinning point. But his example is an overcoil, not a flat hairspring. How would I go about making a gravitational adjustment to the flat hairspring at the outer pinning point? And in doing so, how to I determine the direction of the manipulation, eg. opening the arc moves the center down, etc? Perhaps the question is moot considering the movements will wear well, the issue is an error between 6H and 12H and since 12H is not factored into ISO3159, maybe it's all a moot point. In any event, I'd still like to learn more about these kinds of precision adjustments to compensate for very small changes to increase the accuracy of a movement. Brochure_technique-SW300-1_2.pdf1 point

-

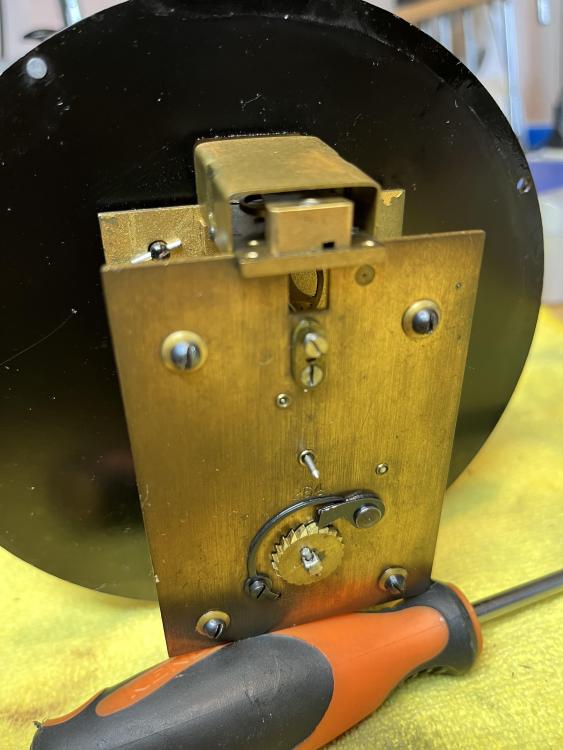

When it comes to the sound of the tick this can depend on the type of construction and size of the case. It is an alarm with a 24 hour dial. Looks like the stop alarm is the button above the hand set.1 point

-

The setting wheel seems to be upside down. Try turning it over.1 point

-

Thanks guys! This kind of discussion is why I come here. Absolutely fascinating!1 point

-

Mine has a knurled screw to shut off the alarm. It does so by pushing down a spring bar against a wheel in the chime train. And yes the ticking sound from this clock is really loud. Probably amplified by the sound box.1 point

-

Thank you! Are there rules of thumb for reading the data? For instance, if rates in pendant position gain over 24hrs, increase the opening at the pins. Is there something similar for deciphering to which side the hairspring may not be centered?1 point

-

12H = 12-o'clock up or crown right In this position, the regulating arm is pointed at approximately 1:30 which makes the etachron regulating pins almost parallel to the ground when rotated to close the pins.1 point

-

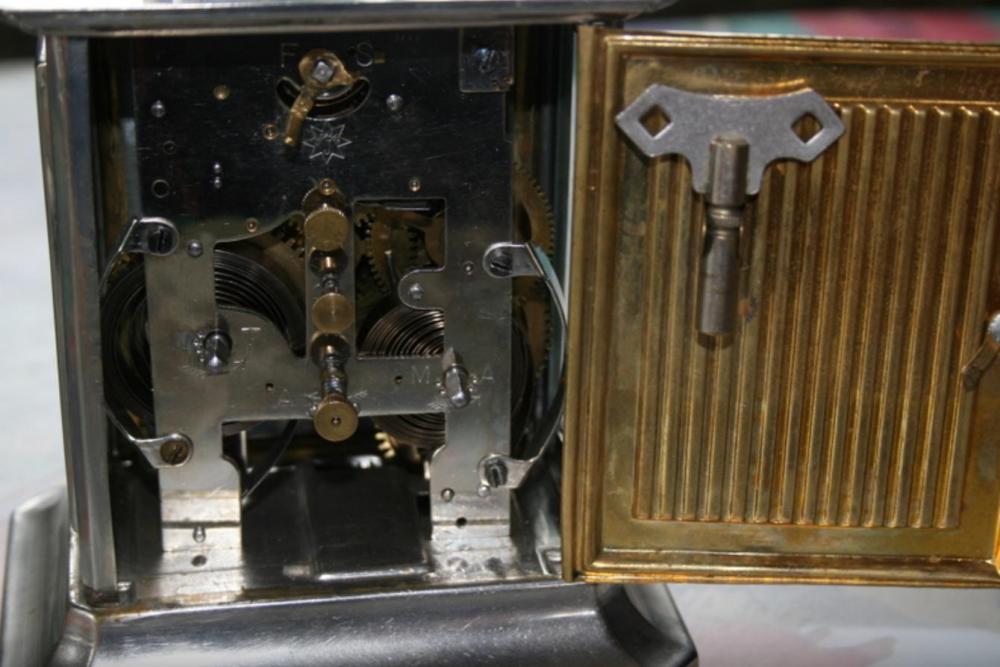

Here a few pics + a vid of the ships clocks. Both movements were identical Smiths but I could only get one of the platforms to run successfully (so far). However the customer only wanted one returned which had the readable dial. Both clocks I found with the same fault with the mainsprings that had been wound so tight they had ripped the end holes. Although I could have repaired the springs I purchased a new spring. A very simple movement with platform escapements so a straight forward repair/ service. However worth noting I cleaned the platforms by running them through my watch cleaning machine first and then stripped the platforms removed the jewels and soaked in a degreaser. Despite this under inspection with my microscope there were still significant and stubborn deposits of dried oil on the jewels so further rubbing with pegwood was required.. The runner had to be set on almost max gain to achieve good time. I did notice this how it had been set before so perhaps the h/s is a touch short. Smiths platform movement Cleaning the cases one completed. Used Priory concentrated cleaner followed by liquid brass. Overwound indeed Very simple movement being assembled1 point

-

1 point

-

Mine supposed to be a Mauthe according to the seller but the mark on the dial is that of HAC. Both were from Germany.1 point

-

A translated citation from my second link: „…these movements and case shapes were produced by almost all German watch factories from about 1900 to 1940. With a variety of options: bell, music box, everything that somehow makes noise and shows the purpose of the clock: A toy clock to learn what a clock is and what you can use it for. In the specified time to find in almost every middle-class household to explain a clock to the offspring… …About the movement itself: Who exactly brought this species to the market first, you will probably never find out. Junghans has claimed this, but it speaks against the fact that these movements were sold in exactly this design by BADUF, Kienzle, Mauthe, Schatz and many others. To my knowledge, Junghans has never issued licenses for replicas (exceptions confirm the rule). Also, these works are knitted quite simply…cheap sheet metal anchor escapement, lantern drives and very coarse gears. In addition, open main springs, very short running time of max. 36h. The housing is made of sheet iron and not particularly thickly nickel-plated. Please look at the aperture on the front with caution. Very thinly pressed brass sheet. The dial is made of cardboard and likes to disintegrate over time.“1 point

-

1 point

-

Looks like a Junghans (Germany): http://deerbe.com/unt/38417-junghans_reisewecker_mit_walzenspielwerk_um_ca_1900.html https://uhrforum.de/threads/junghans-offiziersuhr-reisewecker-mit-spielwerk.300676/ https://www.uhrenwerkstattforum.de/t816f28-Junghans-Wecker.html https://www.willhaben.at/iad/kaufen-und-verkaufen/d/antike-uhr-standuhr-zum-aufziehen-wecker-569262609/1 point

-

1 point

-

1 point

-

When a book is properly digitized (and bestfit files are like that), it's done by Optical Character Recognition, so they are fully searchable. That means one can surely find all occurrences of a given word in much less time.1 point

-

It works really well, but i have nothing to make a comparison with. The pillar drill can only revolve one way so i may need to find a way to create more turbulence inside the tub.1 point

-

How about using the lid and the top part from the base - but using a brass mesh dome? I figured that brass mesh could be formed around a rounded wooden block, then snipped to size, maybe some strips cut out of the sides and solder joined in order to get the correct circumference, then epoxied to the remaining top part of the base.. possibly with a brass mesh divider soldered across it too. Edited to add: Cleaning machines basically make the fluid flow along/past/through the watch parts. Your basket will allow fluid in, but it doesn't look so likely to have much flow - possibly less than forcibly dunking and lifting the basket (based on the small holes in the basket).. so the fluid may stay somewhat stationary within each compartment once it reaches speed.1 point

-

Well done! Have you tested if the fluid agitation is comparable to that of a mesh basket?1 point

-

When hardening it's good to protect the part from direct flame. This is often done by wrapping in iron wire and coating with pure soap, or sometimes borax, or sometimes a commercial anti-scale powder (a great one is available from gunsmith supplier Brownell's). I have a slightly different technique, using 20mm iron tubes on a handle, in which the part is placed the tube then filled with fine wood charcoal powder. Whatever the technique, even heating and avoidance of oxygen is the goal. The part, when at proper temperature, is then quenched. For blueing his method is very good. I also put the part (which when done with the above anti-scale measures should be a clean grey, otherwise the black scale must be cleaned off to see the color change [and it should be clean of oil]) on brass fillings in a pan, over an alcohol flame. From the quench the steel is at its maximum hardness, and is very brittle. Heating to a lower temperature is called tempering, and blue is pretty much the standard color for watch components. The steel changes color at different temperatures, from a light straw to brown, then purple, dark blue, blue, light blue, then almost grey again. For a cutting tool you would temper to straw. Using the pan with filings helps ensure an even heating, and prolongs the process so that the temperature reaches into the part as well. For parts larger than watch-size you would need to do it in an oven for a specific amount of time for a given cross section. The thread pitches on the Habegger rolling dies are the modern standard pitches according to NIHS. If you look at the Asco Schurch catalog, on the taps pages, they list the pitch for each diameter- as well as the tap drill size for both steel and brass which is great. From memory, the Martin B (Bourgeaux) plates are quite close to the modern norm in pitch for a given diameter. Also from memory, the L or Latard plates are slightly finer pitch. As a bit of trivia- and this is from my observation, not a book, the Martin B holes correspond to the seemingly oddly-backward "tap size" for watch stems.1 point

-

Just for the record, the latest formulations of lighter fluids may contain some percentage of ethanol, since they are often little more than unleaded petrol (or gasoline if you prefer), and there is a trend to "green" up automotive fuels by adding "green" plant sourced ethanol. It might be worth trying them to see if they also dissolve shellac. Unleaded petrol without ethanol, should have little if any effect on shellac. I suspect you would need to leave the shellac in the ethanol enhanced petrol for a fairly long period, since the percentage of ethanol is relatively low (around 10% to 15%)1 point

-

This advice in the light of my personal experience made me thinking about an apron „Even if you think you are not the apron type, I would strongly advocate the use of one, unless you wish to spend most of your time under the bench with a torch and magnetic strip…Bulldog clips are used to secure the bottom part of your apron to the edge of the bench or table you will be working at, to create the safety net mentioned earlier. “ (Excerpt from: Maintaining and Repairing Mechanical Watches by Mark W Wiles)1 point

-

The most important thing is practise. One has to learn controlling the force applied by the fingers. Better to drop a screw than to shoot it away. I grip the screws on the threads only to be safe.1 point

-

I continue my search for interesting books and recently received this book. Unlike some of the older reprints (Practical Watch Repairing by Donald de Carle originally published in 1946 or The Watch Repairer's Manual by Henry B. Fried originally published in 1949 but updated in 1961) this one was copyrighted in 2016, so it is up-to-date as far as tools, oils, time graphers, suppliers, etc... The author approaches his presentation targeting the hobbyist rather than the aspiring watchmaker. In my opinion there's a difference in the approach. Like Mark's online courseware, this book references a simple Unitas/ETA 6497 movement (or the Seagull ST25 which is relatively large, cheap and available). I highly recommend this book for the beginner who has yet to pay for any other instruction but who is looking for more than watching 1 hour YouTube videos hoping to pick things up by watching.1 point

-

Thanks @Paul80 for doing the test. There are some that say it makes no difference, then there are some (like me) that have had a bad experience. Elsewhere I mention that I think it’s more a difference in the type of Shellac than IPA but I obviously don’t know for sure. I just keep Shellac away from IPA, then I know I’m safe. One dip isn’t THAT expensive when you consider the price of damaged parts, so I stick to that for pallet forks or other sensitive parts.1 point

-

For a balance staff I find I'm as fast making a new one as repivoting; also, with repivoting there are several pitfalls that can turn the job sour and you're left with a useless staff, so you end up making it anyway. I would always make a full drawing before either. Technically, a properly done repivoting is as good as original, there's no reason it would fail or perform less well. For trickier parts like a pinion, it is usually far faster and easier to repivot than remake. Doing a correct repivoting of a balance staff isn't easier than making a whole staff, it's just possibly quicker, but in my experience not really unless it's an ultra high grade staff (or marine chronometer or something). Getting the staff running perfectly true to drill, drilling a truly concentric hole that is straight and to proper depth, making the plug with the correct friction fit, fitting the plug, then turning the plug to final size and form and length, finally finishing off in the Jacot*- there are a lot of skills wrapped up there. *using the Jacot you really find out if your plug was fitted correctly!1 point

-

This should be the caliber in your watch: Soprod 9035 The differential function seems to be realised by a planetary gear set which keeps the construction flat.1 point

-

Gumming up and stopping/ slowing down does seem better than grinding to a holt with the associated damage. No doubt many will disagree.1 point

-

What makes Daniel's book interesting is he tells how to make things found in watches. In other words if you need to replace a missing component very likely he tells you how to make the component. Here's an interesting website and an interesting book on the website. You can either look at it or scroll down and downloaded in a variety of formats it's free. What makes it also interesting despite when it was written not really a lot has changed it's still a very useful book for learning watch repair. https://archive.org/details/TM9-1575 Then on the same website there is some other watch company stuff sometimes it's hard to find it looks like they have way more Waltham stuff. .https://archive.org/search.php?query=Waltham watch Then here's a really good book the older editions tend to be better because they cover doing more Like making things versus just replacing them but still each edition is good. The Swiss watch repairer's manual H. Jendritzki Here's a link to what happens when you get obsessed with George's book.Roger has a really interesting story is that a lecture once we talked about how he went to meet Georgia was quite amusing. Fortunately he was obsessed and he came back a year later. https://www.youtube.com/user/rwsmithwatches/featured1 point