Leaderboard

Popular Content

Showing content with the highest reputation on 11/11/20 in all areas

-

Of the link is permissible, I’ll share it - buywatchparts.com. (I know, couldn’t believe the domain was available) I’m new to the online store thing, but have lots of ideas to improve and grow it in the future. If anyone does visit, any feedback on ways to improve it are always welcome!4 points

-

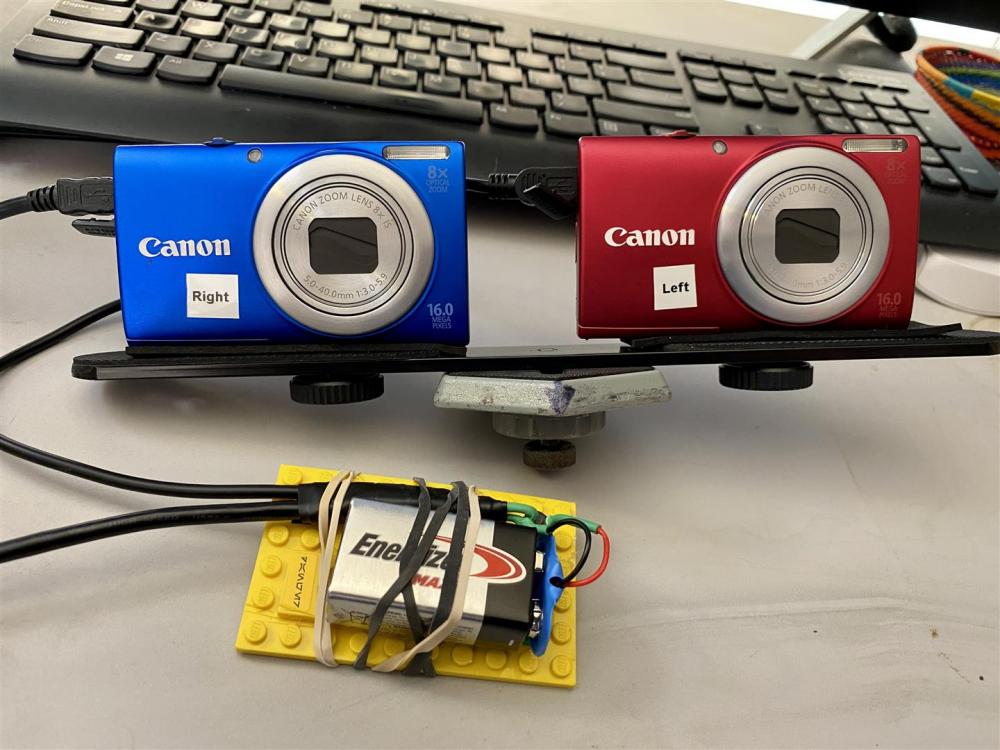

Hey everyone, here's a fun and affordable 3D photography side project. I really owe Andy Hull for giving me the inspiration and information I needed to pull this off! In addition to horology, I'm an avid photographer. I've been studying and practicing photography seriously for 20 years now, having bought my first real camera in 2000. If anyone is curious, the camera was a Canon Canonet QL17 GIII. Some of my work has been in galleries, and I'm a couple of classes away from completing a photography degree. When I became fascinated by photography, I wanted but couldn't afford a digital camera. I could afford a film camera, however, and I had free access to a nice darkroom between my law school classes at UC Davis. I learned how to process film and make silver-gelatin prints. Over the years, I've become a film snob. I embraced digital for macrophotography, but insisted on using real film when shooting people. Thanks to Andy, I've now embraced digital photography for 3D. For several years, I had been fascinated by 3D photography. I hadn't experimented with 3D photography much myself, because high quality 3D film cameras are expensive, require expensive slide film, and require a huge time investment to mount properly for viewing. I've shot a couple of rolls through Stereo Realist, ViewMaster, and Nishika cameras, but the cost and hassle were too much for me to fully embrace. Enter @AndyHull, who mentioned the "Canon Hack Development Kit" (CHDK) project to me. This is a super cool open source effort to significantly expand the capabilities of Canon point and shoot cameras. By using the CHDK, one can force old point and shoot cameras to shoot RAW files, show real-time over- and under-exposure, and execute scripts allowing for the cameras to take pictures on a programmed schedule or only after they detect movement, etc. I've barely scratched the surface of what CHDK can do -- It provides an incredible amount of power and flexibility. I purchased two new-old-stock Canon Powershot A4000IS cameras for $25/each from eBay. These cameras were released in 2012, but they work really well. Through the magic of CHDK, one can use a USB cable and a 5v power supply as a remote shutter release. In under 15 minutes, I used some LEGO bricks, a simple push button electrical switch, a couple of old USB-mini cables, and a battery to build a twin USB shutter release. CHDK does some additional magic to ensure that both cameras fire in a completely synchronized manner, within 1/1000s of each other. Here's my original rig. Please note that a 9V battery wasn't an ideal choice, and I've switched to a 5V battery. I mounted my two Powershot A4000IS cameras close to each other on a "stereo bar," but I got even better results by using epoxy to glue these two cameras together. Here's v2 of my rig. It produces better results, although I do need to rotate all of the left shots 180 degrees while processing. Combined with Adobe Lightroom and some really powerful free software called "Stereo Photo Maker" (SDM), it's trivially easy to produce 3D stereo pairs that look great. It's possible to see the 3D effect in these stereo pairs with one's naked eyes through the "crosseyed" or "parallel" viewing techniques. These methods give me a headache and are really hard to teach others to do, but the good news is that there are inexpensive and effective 3D viewers available. I'm using the "OWL" and "Lite OWL" designed by Brian May. My wife was really blown away by the 3D effect. My total cost was well under $100 and a couple of hours of time to build a super high quality 3D stereophotography rig: Canon A4000IS #1: $25 Canon A4000IS #2: $25 Battery, USB cables, and electronic switch: ~$10 OWL Viewer: $20 CHDK and Stereo Photo Maker: $0 Total: ~$80 I shot a model last Friday, and am really happy with how well my 3D rig performed! Thanks @AndyHull! First good stereo pair (Parallel Eye). I've since improved my processing technique to ensure that the colors match better. Here's a Parallel-Eye shot from my recent photoshoot. I'm really happy with these results! If anyone would like to see the full (uncensored) photoshoot, please send me a DM and I'll send the link.2 points

-

Hello all, Amateur watch enthusiast here, been tinkering with watches for ten years or so, but have started taking it much more seriously the past year or so (including Mark's GREAT course). Always looking forward to learning more, and willing to share any info I can! Also, as an aside, been buying watchmaker estates for a decade or so, and have decided to begin making my inventory available to others (No way I'll ever use 1% of it myself). Although a very slow process, I do have several thousand parts inventoried including quite a selection Bestfit balance staffs, Timex Stems and crowns, and many other items available. I have a huge collection of parts and tools to add to the site (years of work), so if I see someone needing a part, I'll chime in if I happen to have it. Not sure if I can list the site here, so will not post the URL, but feel free to PM me if interested).2 points

-

@AndyHull I jest of course.... I admire your optimism and enthusiasm in even contemplating such a hair spring. I would go so far as to suggest that the two halves may be successfully reunited using a granny knot with no noticeable detrimental impact on its current performance. ??2 points

-

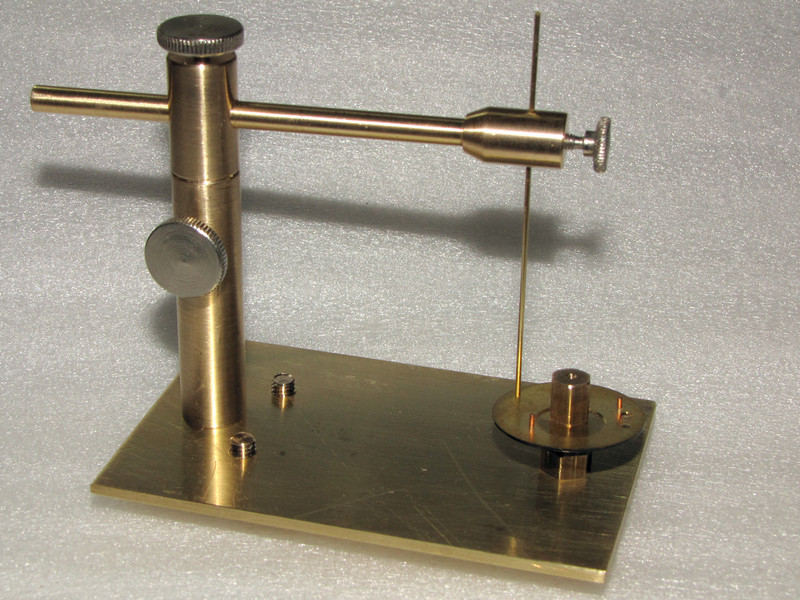

I'm currently looking as well, and came across this thread doing my due diligence searching. The last post is intriguing... We could absolutely make a spring winder, and any other tool needed, at or above "swiss" quality, with relative ease. Reverse-engineer the bits that must be; make improvements where necessary*, and let the other details fall where they may (make it look cool!). I just made some rack handle ferrules for long-obsolete audio gear for someone, and I had a local shop quote large quantities of these parts. I can help facilitate a project but I don't have time to do all the measurements and drawings to get them done. I can review the drawings to ensure what is needed to actually make them is there. My suggestion is to take some low-hanging fruit (such as 3135 and/or 2824) and do a good drawing of that, and I'll work out the pricing on it. If we want to move forward, I'm in to help. *One are of improvement is modularity. The Swiss winders al have the crank dedicated to each winder. Is that necessary? I doubt it. For 20 sizes you probably need at most five crank handles.2 points

-

1 point

-

Just like to say a big thank you to all 3 respondents - very much appreciated from Lurch. Followed the advice to the letter and 'hey presto'. Also, decided to remove the Ratchet Wheel for good measure just to make sure the Click is not broken. Took the photos below in case they assist anyone else with a similar problem.1 point

-

1 point

-

Hi Bernie The detent will fit on the post nearer the date ring with the nose in the ring teeth exactly how the spring fits, just a guess, between the other post and the detent tensioning the detent into the ring the plate will hold them all together. Attached the FE tech sheet for you. FE 233-60, 233-66, 233-67A.pdf1 point

-

FE 233-66 got date complication. If memory serves me right, ORIS used FE or cupillard 233 in its vintage manual wind, the movement should be rare and sought after, worth a look in ebay to get an idea.1 point

-

Thanks for the replies they are much appreciated - I did wonder about the main spring but as the dial is not in great condition I don't intend to turn this into a working watch it is not that important. I have though made some progress in the last 3 or 4 hours, the position and orientation of the main central gear is obvious, I think it is for the minute hand - one of the gears in the train has an extended shaft so this goes in the position for the seconds sub dial so the third gear must go in between - the last position can only be for the escapement wheel, it took a while to work out which way up the escapement wheel and middle gear went and after a 30-40min struggle the top bridge finally dropped on and the gears all meshed, after spending some time working out which way to install the spring and spring winding arbor into the barrel, I found that I couldn't juggle the main spring barrel into place and should have installed the main spring barrel first. I guessing there are plenty of forum members that have been there and done that. I'm at the stage where the gear train is assembled, main spring and the two gears that go with it are on and the pawl that holds the main spring in tension is in place, but I can't find a spring for the pawl, there is a very small bit of bent wire only a few mm long - it may be the spring I'll have to study it for a while and see if it will fit. I'll give it a rest for now it's getting late and I don't want to push my luck. There are no identifying marks on the movement - just 15 jewels swiss made, the dial is marked GALA - I suspect it is a radium dial, it does not glow after being in bright sunlight for 10 or so mins. I did spend a whole evening the other day on bidfun-db looking at movements but there is just so many I gave up.1 point

-

1 point

-

Well a challenge and no mistake, wish you well, If the spring is from an automatic and has a bridle the barrel wall is greased in approx three places to allow the spring to slip on the full wind, the spring its self when installed I have seen advocated three drops of oil on the spring .that will capilliary spread through the spring when wound. good luck.1 point

-

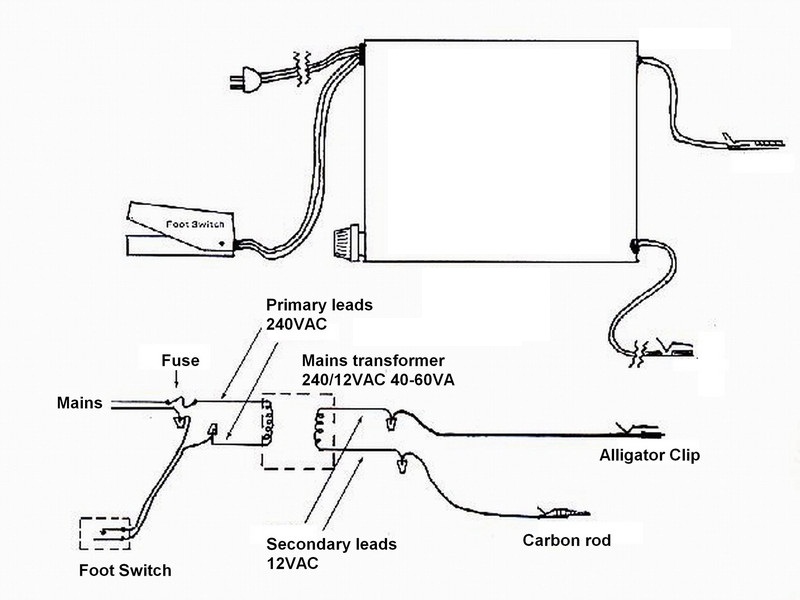

Hi Hector It is infact quite a simple yet effective design, The power input through the two jacks at the back left +ve and -ve. The posative has an in line fuse and is connected to the jack (red) on the right into which plugs the carbon rod(salvaged from batteries) . The Negative connects to the post and table where the dial is fitted via a switch and a power indicator is fitted across the out puts. So when the dial is on the plate and screwed down the dial wire is positioned in the top rail onto the dial with flux and a solder chip the carbon rob is applied and the power swiched on. The rod completes the circuit and an arc forms at the joint melting the solder. It takes a little practice in determining the length of the power application. If I can find the origional design I will post it.1 point

-

I snipped out something from the guideline for using the message board and I'm guessing you should really talk to Mark it's his message board he probably wouldn't mind if you asked him but I would ask first. Then I'm giving you a link to a cryptic discussion. as far as having a section for selling stuff it did exist briefly some of us actually witnessed and saw it but it's gone now. It's cryptically explained that the discussion below. https://www.watchrepairtalk.com/topic/16265-advanced-members-club-did-i-dream-it/1 point

-

I believe the part you are looking at is the micro adjuster for the regulator. It allows you to adjust the regulator by turning the screw in it, and keeps pressure on the regulator to keep it from moving once adjusted.1 point

-

outstanding progress has been made. You'll notice in this discussion you asked the question sort of? So when you start the discussion off is I have a poising issue and that is not really a question it say I have a problem and it's the poise issue. So now that the balance wheel conceivably is more poised you found that it didn't fix the issue. You will note that I did not discourage you from fixing the poise issue because it's a good learning exercise but it probably isn't the reason you have a loss of amplitude. in a somewhat random order of where the problem could or could not be as far as timekeeping issues go look at sure regulator pins how far apart are they? If you have dramatic amplitude changes and unless you were free sprung balance like Rolex typically has you have regulator pins a necessary evil. the problem is the farther the pins are a part the greater the effect will be with amplitude variations. This is usually the most likely thing that causes a timekeeping issue is the regulator pins and amplitude. Now amplitude a variety of things can be going on here especially with the new balance staff. Especially one that had issues. Ideally balance pivots on the end are supposed to be barely curved and of course polished the entire pivot needs to be shiny and polished. The reason why it's not a nice round shape is you want to equalize the resistance so the end of the pivot that would have the least now has more to hopefully make it more equal when the staff is resting on its sides. So conceivably your NZ are pivots are two round but before we worry about that we need to actually figure out what the real problem is. Then I believe in the very beginning you set a pivot was worn and if you have a worn pivot conceivably you have jewels that have issues. As hard a sapphire is they're not perfect you could have a cracked jewel or some other issue. That would cause a dramatic decrease in amplitude. Then? Just as I thought I'm repeating something that was already suggested you way up above by nice job. So you could have pivot and or jewel issues and seeing as how you had a warning pivot originally it makes it very likely. Other things that affect amplitude is of the hairspring isn't perfectly flat if it's touching the balance arms and it won't always touch consistently somet.mes only touch when it's in one position or something. So now we have to go back to being a detective and figuring out what the real problem is it was very likely not poise but it still had a nice lesson and hopefully it keeps better time once we figure out what this amplitude problem is1 point

-

There are laser printers which will print white. Unfortunately I don't have access to one, but your local print shop might. https://www.ebay.co.uk/itm/WHITE-Toners-Drums-for-OKI-Printers-OKI-5-6-7-8-9-C-Series-Printers-UK-Reman/181771981574?var=480717594441&hash=item2a52745306:g:OcsAAOSwstxVduov You can also get white toner, and use it in a conventional laser printer. https://www.ebay.co.uk/itm/4000-PAGE-SOLID-GHOST-WHITE-TONER-REFILL-FOR-HP-PRINTERS/124284721602?hash=item1ceff259c2:g:CnoAAOSw7CJZ5Dap I haven't inspected this particular can of worms very carefully, but I suspect it would be possible to heat-transfer the toner from a substrate to the dial.1 point

-

For the English watches, a Whitworth nut is required to be superglued on... Or it won't open.1 point

-

this is an unfortunate problem of anything from China ranging from very good to very undesirable. This is where it be really nice to physically go and see the product that you're buying and look at it and hold it in your hand which unfortunately is hard to do online. Because online they seem to all use the same picture and not necessarily sell the item that's in the picture.1 point

-

I’m not convinced that a poise issue alone would lead to a drop in amplitude such as what is described in the original post.1 point

-

"How to refit (Seiko) Etachron" - often asked, you should use the search function. There is a section with pictures in the attached document. 7S26C_36C.pdf1 point

-

That red coil is actually a small hydrogen bomb. “it has a very loud alarm.”1 point

-

1 point

-

Performance over the long haul is where synthetics shine. Less oxidation (drying out) and inherently more slippery than natural carbon chains. More consistent batch to batch as well. I have some snake oil which I market for turntables and tape deck oiling, that performs exceptionally well there. I use it on pocket watches too. I have recently used it on a dial indicator mechanism that was acting up, which probably could have used 9010 in stead, but it is working better than ever now. That is unjeweled, which may be why. But wrist watches, I stick with the usual suspects. Did you see my post about finding pure linseed oil, almond oil (and other oils) at the art supply store? It is used for making oil based paints, but I know traditionally these types of oils were used for lubrication as well. Despite the art store mark-up, still much less than Mobius... They might be fun to play with as well.1 point

-

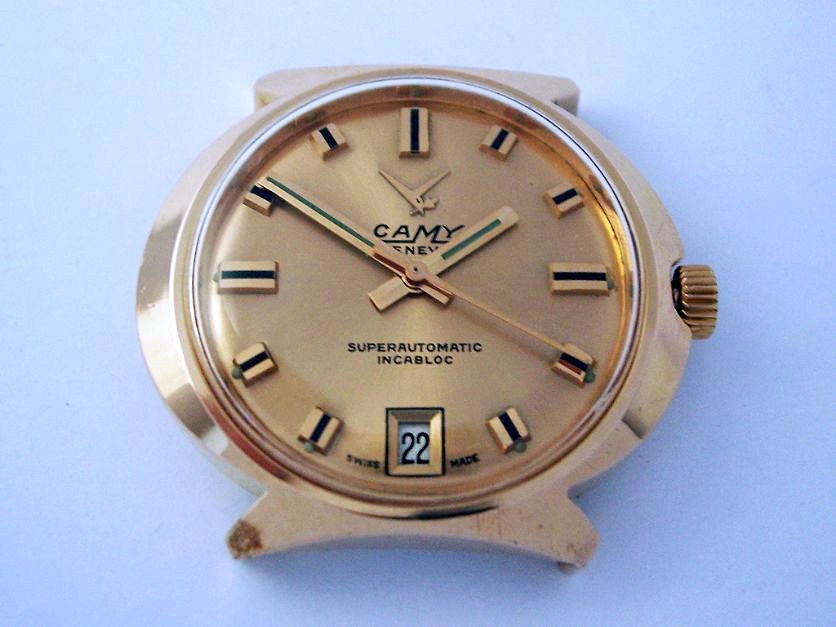

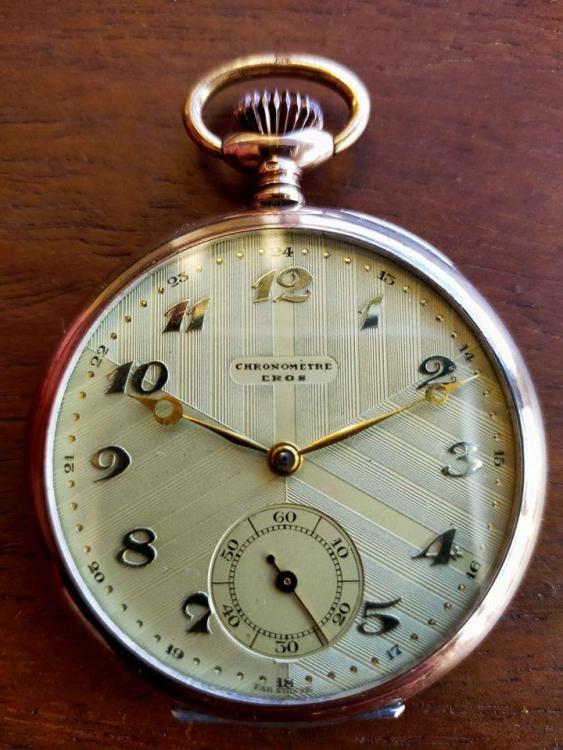

I found this on one of my vintage watch Facebook pages. Probably have to wait for ten days or so as I'm in the US and it's coming from the UK. That dial is amazing. I also love the gold hands and numbers with a silver case. I'm 73 and SHOULD stop collecting and start selling my collection as my daughter wants so that she doesn't have to deal with it but being addicted and all I can't stop. Lol.. Plus I have many watches in a drawer in my watch work bench to be serviced.1 point

-

Oh dear...thats not good. A bit of advice.. whenever you get stuck, stop and think about it. In the first instance you had a problem figuring out which way the pallet fork went in. Your next step should be to observe how the pallet fork interacts with the other parts.. in this case the escape wheel and balance-wheel. The escape wheel end will not help you but if you had looked on the underside of the balance you would have notice the roller jewel and you would then realize that there's only one way the pallet-fork will go as there is a centre-pin on the pallet-fork (called the guard pin) which would interfere with the roller jewel if the pallet fork is installed upside down. In the second instance, you would realize by now that the roller jewel is the one giving motion to the pallet fork, as such it needs to be in the middle of the pallet fork arms. If it does not swing freely you need to eliminate probably reasons it doesn't ..is the balance in the pivots? Is the roller jewel in the fork? It is important to always analyze why something does not go well, you WILL get better at this but you need to consciously do this in the beginning. It will become second nature after a while. I hope the above doesn't too much like a lecture but if you don't develop the habit of thinking through problems you will end up being more frustrated and the end result is a mangled hair-spring. As always...good luck! Anilv1 point

.thumb.jpg.91aeb08765b4f2b7f0fc10182999bcc2.jpg)