Leaderboard

Popular Content

Showing content with the highest reputation on 11/20/19 in all areas

-

The height adjustment on all double roller rests is iffy at best. Files are like dogs, they might bite end off a sausage or wolf the whole thing down. With a double roller rest, if it isn't perfectly parallel to the lathe bed you have a tapered square. If it isn't perfectly adjusted for height you have an oversize or undersize square. With a single roller it's easy. You turn the diameter for the square to the diameter for the winding pinion. You turn the diameter for the front pivot to the square section of the winding square. You don't turn to the length of the winding pinion- just the square. Single roller rest, file until you just hit the pivot diameter. Index, repeat 4x. Now finish the pivot and the rest of the stem. With a single roller you can flip the rest at any time and measure what you're doing if you mistrust the pivot as guide. With a microscope you also see if you are tapering (possible with either single or double roller- there's no panacea) and correct. Your eyes are incredibly accurate for spotting tapers. I usually cut the thread first, chuck on that and do the rest. Harden, temper, deblue with a bristle brush and white (steel) paste in the lathe holding the stem in a pinvice then clean up the thread and detent slot, burnish the pivot and large diameter that rides the plate/bridge. The brush usually cleans up the file marks on the square plenty. You want a 6 or 8 cut file for that. 8 best for the finish strokes.4 points

-

I was first in my class in hairsprings and have saved many considered "gone" but that one is GONE, and I'm the biggest optimist you'll meet. Even the best old dude from the Vallee de Joux would not even consider it.3 points

-

You may have noticed a few changes - I have removed the Gallery section and the CMS pages app from the site as it costs too much to 'rent' those modules with comparatively very little use by members - it just did not make sense to keep them going. I apologise if this inconveniences or annoys anybody but I think it is better to keep the core of this website to be a discussion forum. The WRT website is costing me a lot of money per month to run and I am making a few changes to help with that - there is a little income from eBay affiliate ads but not enough to cover the cost of hosting and some help from Patrons and for this we are very grateful. The site has over 30GB in uploaded media now!!! And the notification emails generated is quite high too - I have to use a separate company to handle this so that the site doesn't get email black-listed. One of these services suddenly and without notice stopped our service a few months ago and it was a few days before anybody even noticed (password reset emails were no longer working). I did manage to find a new email provider and things have been running smoothly ever since. Getting back to the uploaded media, as mentioned it's over 30GB and this covers images in topics going back several years. I do back this up every night and I backup the site database every hour in order to protect the content should we ever have a disaster I have a Synology NAS here in the office which has a full backup on and I also keep a backup offsite on a cloud service. I have also decided to use Amazon Cloudfront to host all the uploaded media. I am in the process of migrating this content over and you may notice broken images for a very short period during the migration. But ultimately this will maintain and even improve performance of the site. Anyway, all being said, this is a fantastic community and I am fully committed to continuing with it's administration, keeping our little corner of the net alive - Just a little update to let you know what's happening -2 points

-

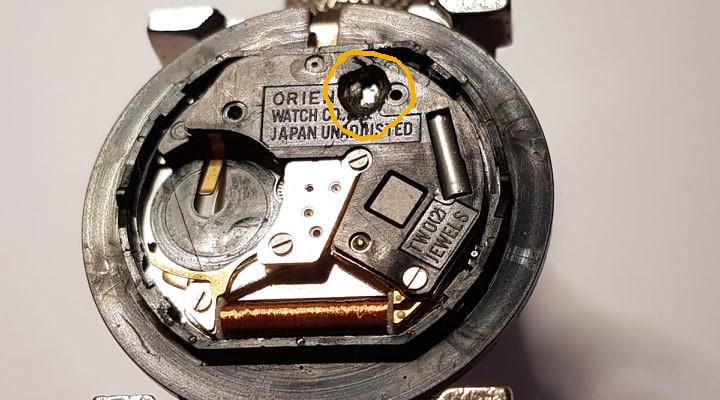

Could be that the contact to signal stem position to the IC is not working.2 points

-

Got this 1950's Timex Mercury running and relumed hands with new second hand. Seems to be keeping good time also. Sent from my SM-G975F using Tapatalk1 point

-

1 point

-

1 point

-

1 point

-

An explanation for the mirror image numerals: http://www.wernersflyingwatches.com/products_ProID_14.html1 point

-

You mean this? (please excuse the poor picture) And it's missing two more which I have sent to a fellow member for his joy. My frustration is that for most of these I did the damage while trying to correct just minor imperfection, typically the outer coil distance. I went to the bends of the dog leg but made it worse each time. Now I am more or less able to correct the above working only on the end arc like Master Nickelsilver recently explained. And I finish the work while it's running, observing how it breaths and trying to make that even. I think that an HS that keeps good shape while running is always better.1 point

-

Measure Twice, 12L14 is also called leaded stock and is generally used to make turned shafts. It machines beautifully and leaves a nice finish but it is almost impossible to weld. It can be hardened.1 point

-

1 point

-

1 point

-

1 point

-

As mentioned above, normally a roller rest is used. There are two main types, one with two rollers that straddle the work, the other is a single roller. I prefer the latter, as it's easier to measure what's going on. All watch lathes that I'm aware of have at least a 60 hole index in the headstock pulley, so easy to index 4 places. In Switzerland the standard steel for turned parts is Sandvik 20AP. It's a high carbon (about 1%) steel, with a tiny bit of lead for machinability. There is a major metal supplier here that has their "copy" of 20AP, Klein Metals with their LAW 100 Pb, and both Sandvik and Klein have come out with non-leaded steels with similar qualities as there's a push against lead anywhere. These steels are not that dissimilar to O1 which is the most common steel used in the U.S. by all the watchmakers I know. For the rest of Europe I have no idea what designations would be easily found and similar to 20AP/O1. As for screws, they are definitely hardened and tempered in all cases when made of steel. Tempered to "blue".1 point

-

1 point

-

Yes - but you really need a roller rest and a lathe with index holes in the pulley wheel so you can turn accurately through 90 degrees1 point

-

1 point

-

Thank you, I will surely try it. Why I prefer the method that I mentioned above (water hardened, tempered to light blue stock): easy cutting on the lathe, has just the right strength and most of all: no danger to get a distorted staff after quenching - a slight bend can make hours of work worthless. Frank1 point

-

1 point

-

Good question :) I have this saved on my computer and i printed it out on the printer . Have you guys and girls seen it before ? .http://www.bhi.co.uk/Documents/certificate/Tech/PractLub.pdf1 point

.thumb.jpg.2b844895353ab5ea604c90f69e03ab3b.jpg)