Leaderboard

Popular Content

Showing content with the highest reputation on 10/21/19 in all areas

-

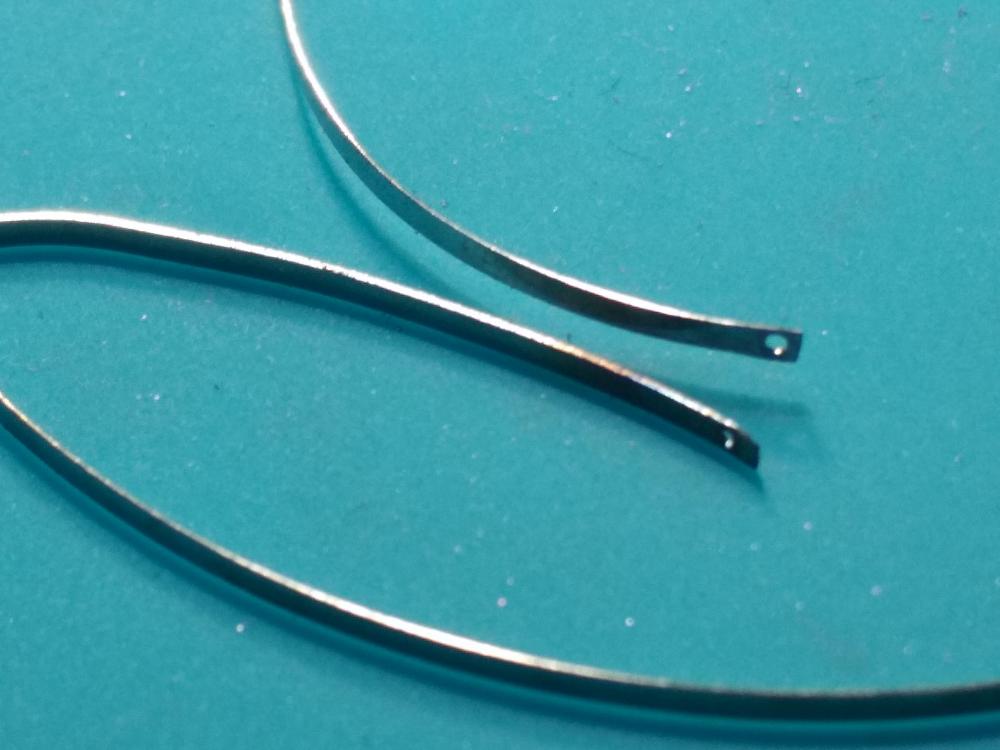

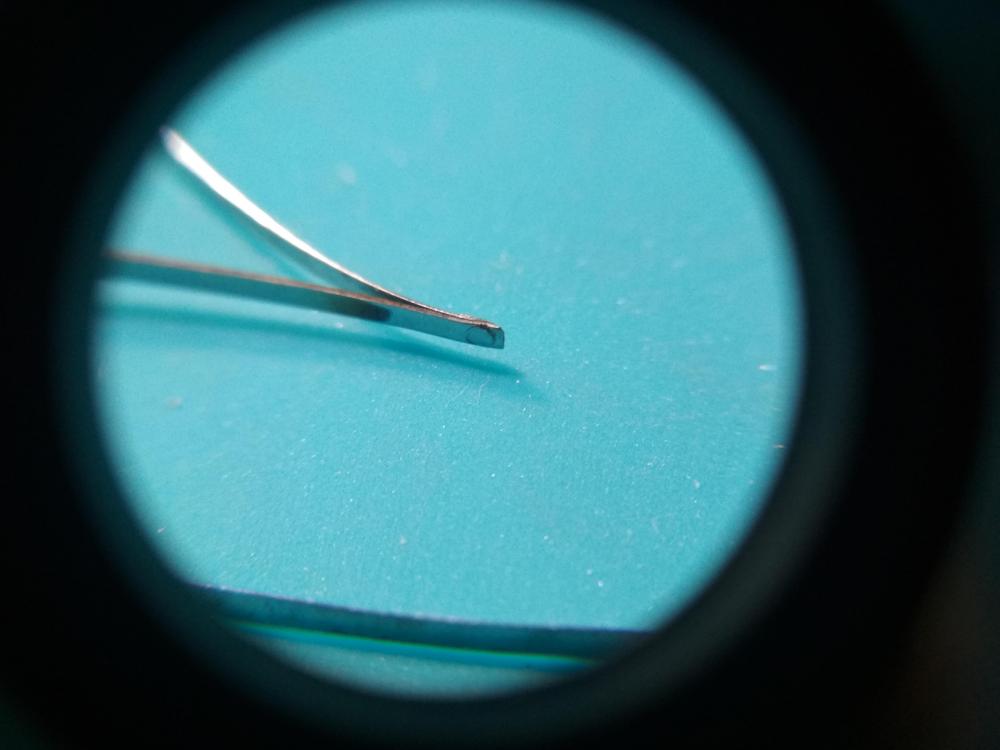

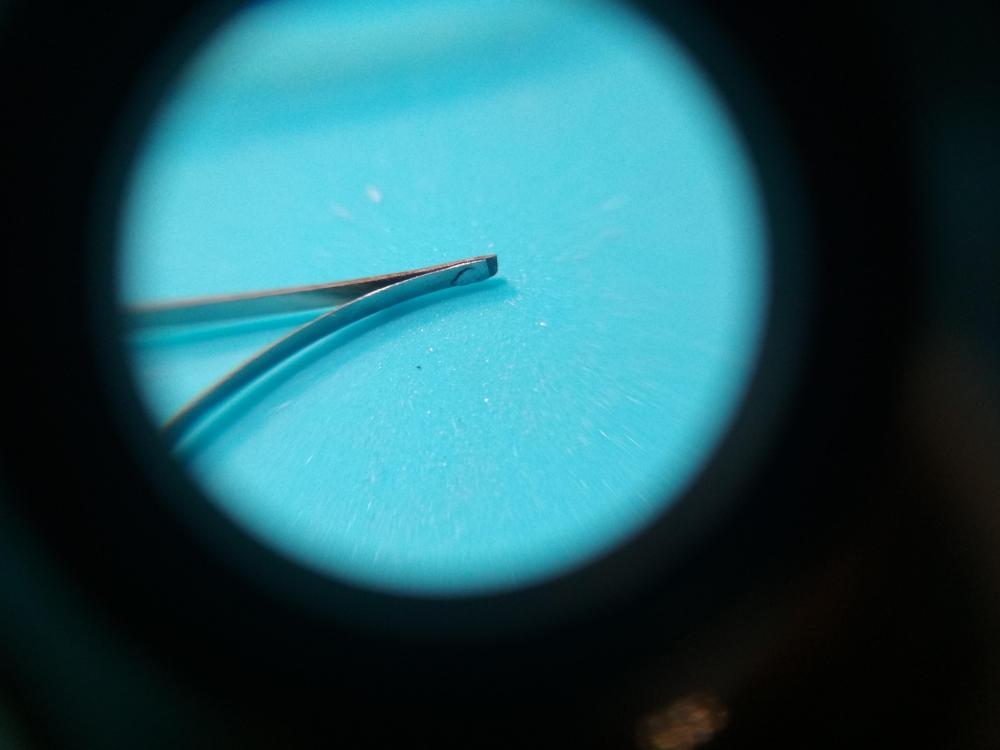

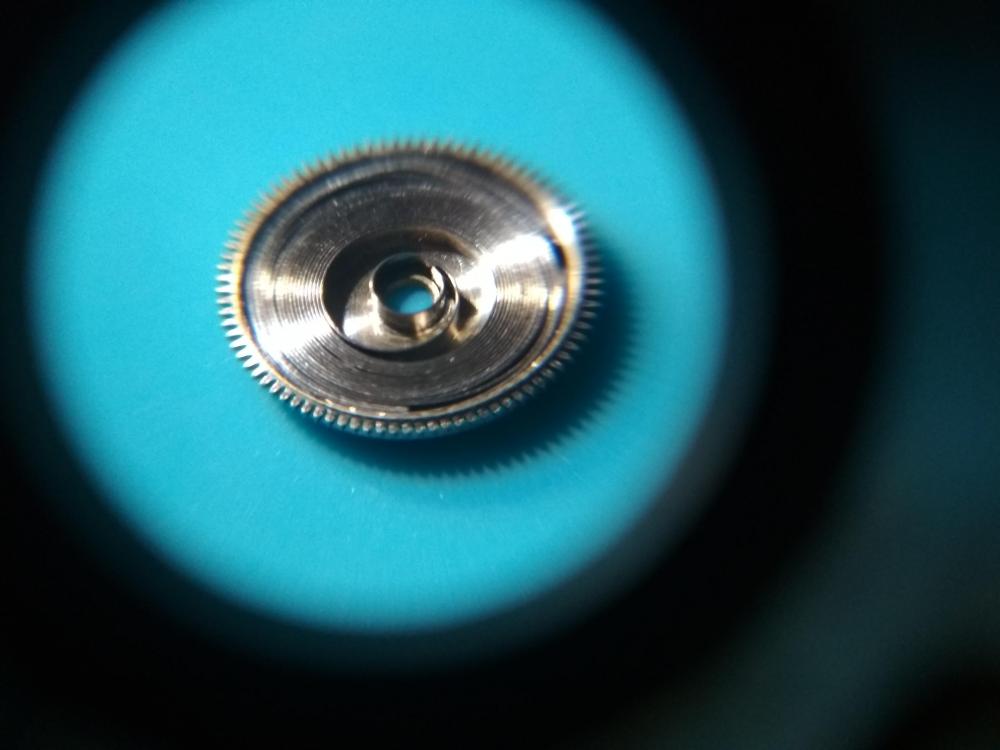

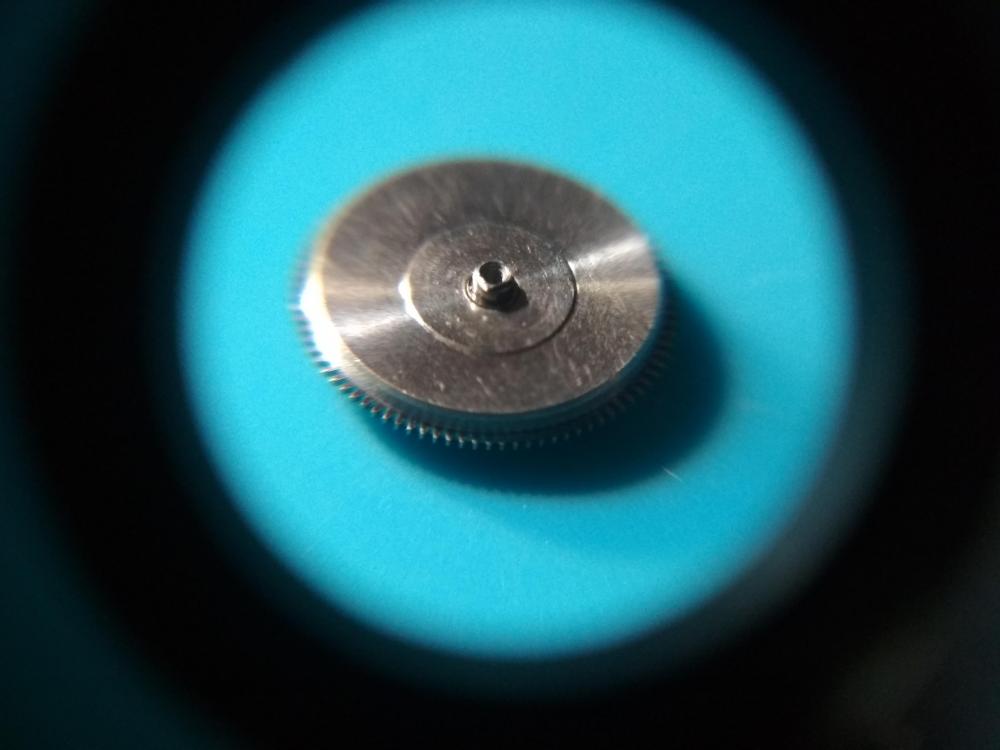

Had the head of screw strip off the mainspring barrel arbour. Tried to use a bergeon screw extractor and failed. So I set the arbour up in a lathe and graved a small cone center. Then I used circuit board drills and progressively drilled out the center. And after two broken bits, I finally got the insides loose. Then I went on my Stereo Microscope and picked out loose parts using rodico and a small pink screwdriver. All worked well. Now to find a new screw. The main mission was to replace a broken mainspring. And here is the broken mainspring. Sent from my iPhone using Tapatalk Pro5 points

-

2 points

-

Yes, it's pretty difficult to do it right. The radius position of the roller jewel is really critical as well as the safety roller diameter and its notch to pass the dart; should also make a shaped broach to make the hole for the roller jewel though a round hole can still work. It's easier of you have a measuring microscope and jig boring machine... If one had another to copy it would be much easier and probably doable without fancy machines to a decently functional level by someone skilled at fiddly work.2 points

-

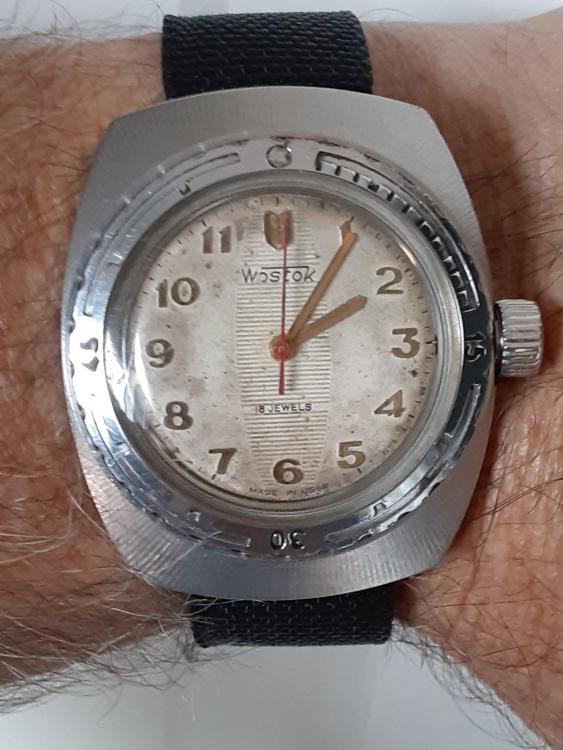

Hello all, Guillaume from France, aged 44, I have discovered Mark's videos on YouTube and I am obviously a big fan now. I own automatic and mechanic watches (around 15 by now). I started a few months ago to build my own watches from parts sourced here and there. I have made two at the moment :-) 3 others are in progress and I ambition finally to create/manufacture my own dials ! Thanks for indulgence for a "beginner" Guillaume1 point

-

The Slava 2414 twin barrel got a bath today. From stone dead and fully wound, to >260 degrees and around -30s/day currently. I'll let it settle overnight and do the final regulate, adjust and tidy up any remaining fine scratches on the crystal tomorrow. An interesting movement. One thing worthy of note is this comment on ranfft.de The keyless work is a little fiddly, but not that bad, but in my opinion you are more likely to encounter flying spring action from the date disk than anything else when stripping and cleaning.1 point

-

1 point

-

Just lift slightly the tip of the holding lever at the top. BTW we have a section here where it's considered polite to introduce oneself even before asking questions.1 point

-

I'm assuming that the other 3 links in your photo have all been through the sanding process and are ready for polishing? In which case you need to spend a lot more time on each grade of paper; there is no way that that is the finish from a 9 micron lapping film, you still have the finish from the 600 or even 400 showing through. In hand finishing there is absolutely no substitute for patience. You will need to go back to at least the 1200 or maybe an 800 and rework the surface until you have a uniform finish that is only as deep as the 800 can make it, there should be no evidence of any deeper scratches. Then move to the next finest grade and do the same, and so on. By the time you get to a 9 micron film the end result should look almost polished in its own right; there should be no evidence of the brushed finish in your photo, and no visible scratches. You also need to be careful to clean the bracelet in between each grade of paper, preferably by flushing with water, to ensure that there are no particles of the coarser abrasive left behind that can wreak havoc with the end result. Also make sure that the mop that you polish with is clean and uncontaminated. If in doubt use a new mop and never use the same mop for different grades. Best of luck.1 point

-

1 point

-

de Carles book cover this also. i had a problem with a roller jewel. the hole that it "slips into" was too large. and it sliped back from the fork. the clearence is critical !! i think i would bail out. (army air corps "when in doubt - bail out"). vin1 point

-

OP, what sequence of grits are you using? Start and something rough enough to get rid of the biggest scratch and work your way up to 2000 or finer, then polish1 point

-

Ouch, I can imagine the air might of turned blue for a few seconds after the roller broke. Archie Perkin's book details how to make a roller, but its a big difference between reading how to do it and actually doing it, I've certainly never tried to make one before.1 point

-

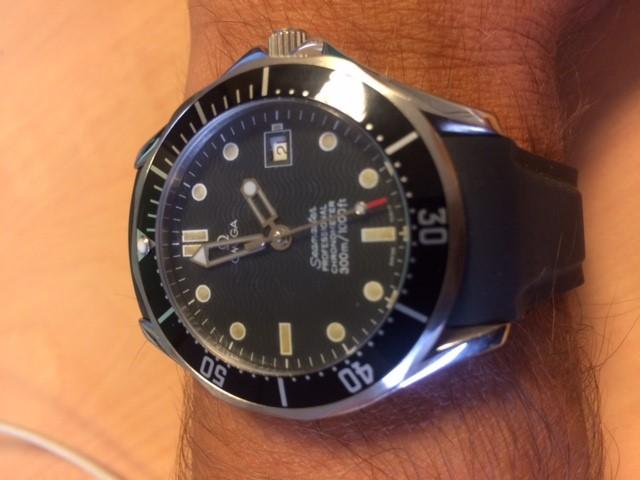

Seiko Timer on a miserable day. The light looks like just before sunset. Horrible! This is the only forum that messes around with Imgur links. It looks like I used a potato to take the pic. Here's the direct link https://i.imgur.com/sYMenRf.jpg1 point

-

Scratches are scratches, you can do a lot with polishing but the goal with starting with a rougher abrasive like sandpaper (and then removing those scratches, and then those, and so forth) is to minimize distortion of the case shape. You can insist with the buffing wheel and get out some pretty serious marks but you round over edges and muck things up pretty fast. The blue 3M is 9 micron as I recall, which is an excellent place to stop prior to buffing.1 point

-

You'd be way ahead if you'd have taken off the roller, which you knew, so no empathy here! (We all take shortcuts that bite us in the butt sometimes)1 point

-

I should have. Now I have a major repair. And I was so so close Sent from my iPhone using Tapatalk Pro1 point

-

Thanks for the input @anilv, much appreciated! BTW, I happened to mention you in my latest video. Hope that was OK! It’s no longer a practical problem, but out of sheer curiosity I’ve given this a lot of thought and I’m still leaning towards my own of idea, although I’m still humble. I can’t see that there’s anything wrong with the click works or any other parts of the keyless works. To support my theory, as well, is the fact that after having replaced the worn-out winding pinion and clutch wheel, manual winding works perfectly. Not only is it more efficient (of course), but the mainspring has never unwound uncontrollably after the replacement of the winding pinion and the clutch wheel. So, for anyone interested here’s my “final take” on this, although I am of course still very interested in alternative ideas as my goal is to understand what’s truly happening! While reading; assume that the cogs on the winding pinion and the clutch wheel are worn-out and slipping against one another once enough tension has built in the mainspring by manual winding. So, as tension is peaking between the winding pinion and the crown wheel the click piece will be disengaged and the tip of the click piece and a tip of a crown wheel tooth will be opposite one another. At this very moment a slip between the cogs of the clutch wheel and the winding pinion occurs and the crown wheel, unnaturally, with a snap and tremendous speed, rolls back in a clockwise direction into the position it came from. As well, at this point the ratchet wheel exerts a lot of pressure on the crown wheel pushing it in the direction of the click. I believe that the combination of this event and force makes the crown wheel slide ever so little in the direction of the click, and in the process the crown wheel becomes weakened in its ability to keep the ratchet wheel teeth from slipping on the crown wheel teeth, and once this process has started it’s a point of no return. The ratchet wheel begins to spin in an anticlockwise direction with such an extreme speed and force that the crown wheel is unable to engage it again, even after the click has engaged the crown wheel. Hence the mainspring unwinds uncontrollably. One objection to the above reasoning could be that this should also happen when we manually wind the watch through the winding crown and stem and quickly release our fingers from the winding crown. However, the speed with which we’re able to release the winding crown with our fingers could never match that of the cogs of the winding pinion and clutch wheel slipping against one other. That is, no matter how fast we release the fingers from the winding crown, the force from our fingers will make the crown wheel teeth roll back into the click in a controlled manner keeping the ratchet wheel teeth engaged with the crown wheel teeth. Well, JM2C!1 point

-

Hello, I want ot show you my way to repair broken slipping end of the automatic mainspring. 1. Firstly I drilled mainspring and slipping end with 0,3mm driller. 2. I made the rivet 3. Mainspring and end riveted 4. Clinching the rivet with pliers 5. Rivet grinding with file and water paper 6. Mainspring installed in barrel 7. Completed. I have checked if it works well. I have 9 full turns of arbor before mainspring starts to slip at the barrel wall. I think it is quite good. Some service manual says that 8,5 turns is a good result. What do you think - is it good way to repair this malfunction?1 point

-

Works on this project are done. Here're the results below. It's my second project of the 8110A movement. I am very impressed about japanese design and engineering. What was done: - dissambly movement, cleaning, oiling - repaint bezel and fit new glass - repaint all hands -relume hands - new gaskets and springs for the pushers - new signed crown - little case polishing - assemble Now it's time to enjoy and wear it on the wrist. I'm verry happy cause this watch is small timepiece which fits to my narrow wrist just fantastic. Cheers1 point

-

1 point