Leaderboard

Popular Content

Showing content with the highest reputation on 06/18/19 in all areas

-

Hi all, I've finally put my foot through the door of the world of chronographs, and I got an excellent deal on a gold cased Luxor chronograph with a Landeron 248 movement. The dial looks perfect, so perfect at such a price I assume it was either redialed or a miracle occurred when my offer was accepted. The only flaw to the watch is the second recorder resets to about 1 -2 minutes past 12, every time. I thought initially the second hand just needed adjustment, until I noticed the minute recorder will advance a minute when the second recorder crosses midnight exactly, but still resets at 1-2 past 12. This means a recorded minute is actually 58ish seconds. So adjusting the second hand won't solve this problem, and I'm very curious what about this movement syncs these two registers. If anyone has advice, it would be appreciated.2 points

-

2 points

-

First of all my apologies for not having documented the disassembling, but the watch arrived in a terrible condition and I stripped it down right away to get rid of all that dirt. If you have worked on some watches yet and think about entering the chronograph world with a 7734 let me give you 3 advices: Do it! The 7734 is a solid construction and not too complicated. Take your time and watch all the 6 parts of Mark's Venus 175-service on youtube. Of course the Venus is a column wheel system, but the basic movement is very similar and also on the chrono layer you can learn a lot especially about lubrication: https://www.youtube.com/watch?v=EI3T-IR3AgM Download the 7734 service manual. A lot of information here: https://strela-watch.de/valjoux-7734-7733-7736-technical-documentation/ Here we go. Some 8200 for the barrel and the new mainspring goes in (got it from cousins - what I'm gonna do after Brexit? ). The complete barrel. Some D5 for the arbor. Putting in the wheels and the bridges. Lubrication: 9010 for the escape wheel and the second wheel, D5 for all others. The keyless works. 9501 for the stem and the gears. D5 for the wheels and the lever axis, 9501 for the contact points of levers and springs. The click spring. D5 for the click and the crown wheel, 9501 for the contact point of click and its spring. Finally the ratchet wheel goes in. The pallets go back in, no lubrication for the pivots. Lubricating the balance jewels with 9010. The balance back in. The escape wheel and the pallets got epilame so I let run the movement with dry pallets for some minutes. After that 941 for the pallets (work from the dial side through the window). Now I start with the chronograph. First the bridge and the spring for the levers go in. Fly back lever goes in with some D5. Operating lever, again D5 for the axis. A little bit tricky, you must upline the integrated spring with the upper lever first (9501 for the contact area). The second pictures shows the final layering. The sliding gear goes in, D5 for the lever axis, no lubrication for the wheel! At this point I forgot to put in the minute recorder runner (no lubrication). You should install it here, later its going to be more difficult. The blocking lever (D5) returns. Some 9501 for the contact area to the sliding gear. The blocking lever spring. Be very careful, this one isn't just a flyer, its a damned Lockheed SR-71 Blackbird. The friction spring (gets a drop of 9010). The chronograph runner and its bridge (9010 for the long pivot and the jewel in the bridge). The minute recorder jumper, no lubrication. The hammer. D5 for the axis, 9010 for the lever ends that hit the hearts, 9501 for the contact areas to the sliding gear, fly back lever, operating lever, jumper. The hammer cam jumper. Before installing the clutch give 9010 to the pivots of the coupling wheel. D5 to the lever axis. The spring. 9501 for the contact point. Finally line up the driving wheel with the coupling wheel and the chrono layer is complete again! The dial side. Some 9501 and the cannon pinion goes in. Hour wheel with D5. The dial rest with its 3 screws. The date indicator. The date indicator driving wheel with some D5. The jumper with D5 to its axis. As there was no lubrication described in the manual between disc/jumper or disc/wheel and the parts looked well polished I didn’t lubricate. It works - let’s see how long. The guard with 2 screws. Finally the spring. The dial comes back and is secured with its 2 screws from the side. While disassembling I put the little hands into seperate trays to prevent mixing them up. Now I turned the crown in the setting position exactly to the point when the date switches and put on the hour hand to 12. Positioning the chrono-hand exactly on zero was that tricky that I forgot to take a pic. New springs and gaskets for the pushers. Unfortunatly I’m not good in restoring cases. So just refreshing the brushing a bit and some cape cod work. The movement back in the case and secured with 2 screws. A new gasket for the caseback and here we are. Thank you for watching.1 point

-

I think you can just remove the hand and set it at zero when in reset position. If that doesn't do it there's a laundry list of potential issues, on which books have been written. Try that and if you still have a problem it can be addressed.1 point

-

Looks like they broke the original spring and just put the pieces back to hold the endstone in place. As far as i know it should be a Kif Protechoc spring .1 point

-

And finally, the last one. (Although many more can be found by scouring the Internet.) this purports to be. Mark VI-C (I think). Now go on, look at it and tell me that this machine is not where Elma got their idea from! I just wonder if either the original patent that National took out on the machine ran out, or, if National allowed others to freely license the basic design?1 point

-

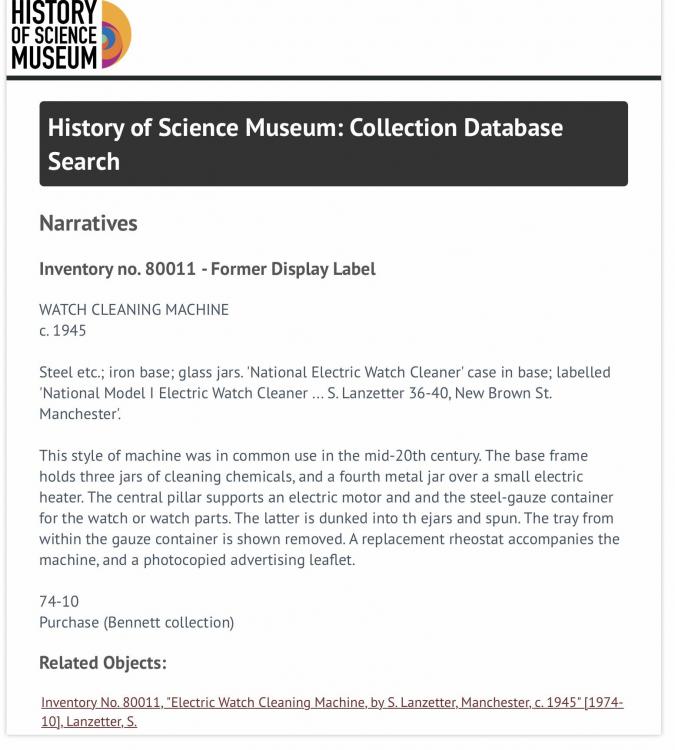

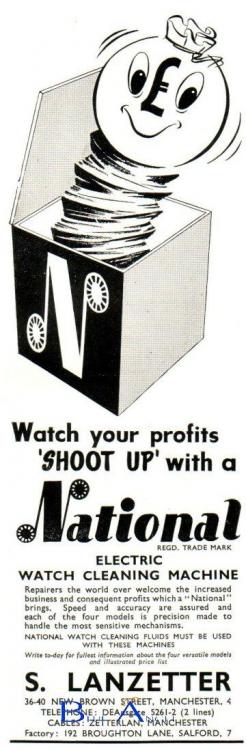

I have been doing a little research into these fine old machines and found some useful background. The National brand was used by the company S.Lanzetter of Manchester. That much can be found out easily by simply reading the information on the makers’s plate. It seems that S.Lanzetter was one of the key members of the Jewish watch making and jewellers community in Manchester from around the turn of the 19th century. At the time, they were a very well known watchmaker’s materials and machinery supplier, and also responsible in their own right for patenting some key items. Such as this particular style of watch cleaning machine ( and other variants) from around 1945, electric soldering machines, and watch crystal cutting/grinding machines. i managed to find a reference to a National Watch Cleaning machine that is retained in the UK’s History of Science Museum. I have included their extract for the item below. It describes the typical layout and functionality of this type of machine perfectly and mentions a spare rheostat, that seems to have been supplied with the exhibit. I would be interested to know which company copied what, as the original Elma machines were pretty much identical, and it gets me thinking if the National, as well as later National designs, pre-dated them all? Who knows... What I have further identified were other versions of what the manufacturer refers to as their “Model 1”. I have seen what appears to be later versions of model one that have an additional switch, which I presume isolates the rheostat and thus provides a proper off switch, rather than just relying on the rheostat being set to minimum (as mine is). A further version of the model 1 additionally has a small indicator lamp on the rheostat housing, indicating if the heater is switched on. Again, mine does not have that. This leads me to assume that my model 1 is one of the early versions, which perhaps dates it to between 1945 to 1950. As this makes my machine likely to be around 60 to 70 years old - I feel like I am restoring something quite special, even though it is quite an ordinary machine. I have also found an old advert for the National brand(as applied at the time) which may be an example of the advertising copy, as referred to in the science museum entry. This is really “of its time” and a delightful reminder of the whimsical advertising style, typical of the 1940’s and 50’s.1 point

-

1 point

-

No I'm sure these are mercury its a very good quality french clock I dont think they are replacement mercury vials I may put them in some slightly warm water and see if that helps. Thats the problem they only seem to be readily available in America and I think it would be illegal to try and import mercury via the postal service into England and they are also very expensive.1 point

-

From what I see the clock is a genuine French Four Glass. Mercury can solidify only with extreme cold. Myself I have never come across these what I will call dummy type pendulums. It would probably be best to replace them. I don’t think here in the UK you can post mercury.1 point

-

It's a pinned topic, all the most used tools have one. And this very thread is a great candidate to be merged there.1 point

-

For that full authentic look, I would cork... https://www.ebay.co.uk/itm/Natural-Cork-Dining-Table-Placemats-Coaster-Trivet-Drinks-Mats-Surface-Protector/292834814624?_trkparms=aid%3D555017%26algo%3DPL.CASSINI%26ao%3D1%26asc%3D20170907081254%26meid%3Dc263661ca14641aa940435dac72c1951%26pid%3D100281%26rk%3D2%26rkt%3D12%26%26itm%3D292834814624&_trksid=p2045573.c100281.m3567 .. however plastic (a nylon cutting board, cut to size maybe), as that might be less inclined to get stained, would be my second choice.1 point

-

Read this page. https://www.medfordclock.com/merc.htm and here you can but the fake ones http://www.m-p.co.uk/muk/parts/pendulums-french.htm1 point

-

Are you sure its a real mercury pendulum? I've heard of cheaper clocks having fake mercury pendulums, could it be the pendulum was taken apart and put together incorrectly with the pretend mercury parts upside down? The whole point of mercury is it is liquid and flows freely as Old Hippy says1 point

-

I have no problems with mine. you had one or are you speaking with the usual prejudice about Asian tools? Another type I recommend is the Aluminum one withe the screw in between pillars. No need to spend big money or go hunting vintage when it comes to decent tools.1 point

-

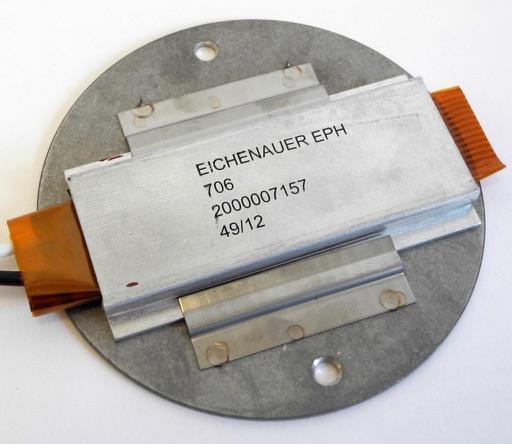

With the PTC Heating Element arrived, it was time for some metal bashing. Actually, it briefly got a bit more "high tech" that that. I needed to try and replicate the Elma Heater, based upon what the Elma spare part heater looks like from catalogue pictures. A quick estimation on my part seemed to indicate a mounting plate size of around 90mm diameter (the element being 75mm on it's long side). Where to sort it from? A quick conversation with an old work-mate turned up the opportunity for a catch-up and a bit of "metal bashing" for the cost of a light lunch. A bit of mild steel around 1.5mm think was run through his laser/plasma cutter in no time and I had my mounting plate. Once back home, it was drilled to attach the heating element. So that job done, now to mount it in the machine. In my opinion, it's not a bad replication of the original Elma spare part and I cannot imagine that it would be any less efficient. SO - if you cannot get hold of the Elma Heating element, all you need is a relatively cheap PTC Heating element, and a good mate with around £35,000's worth of plasma cutter!1 point

-

You really cannot skimp on a watch fitting glass tool. You need to have one that you can trust and get the repair done without worrying about is it going to work. The cheap tools will not do a good job, they do not fit properly, and they break, not lined up and will not last long. Buy the best and it will last a lifetime. I had many including the Robur. It is necessary have tool.1 point

-

Eagerly waiting for this old Omega Seamaster Cosmic 2000 to arrive. This is going to be my new project. I heard the cases are open though. Verzonden vanaf mijn iPhone met Tapatalk1 point

-

These (Indian) presses nearly all are poorly bored: axis of upper and lower die are neither same nor parallel. That makes problems like you had. Better go for used pro presses as advised before. Frank1 point

-

Not a complete watch ... Just a dial but a really nice old 5500 one Envoyé de mon Moto G (5) Plus en utilisant Tapatalk1 point

-

Its actually quite an attractive piece, though all those extra rocks in there might make it a tad heavier than strictly necessary.1 point

-

1 point

-

This is one type I had. https://www.cousinsuk.com/category/press-dies-robur expensive used for fitting tension ring glasses As near as I can find of another type I had for tension ring and flat This very good glass lift and fitting tool for high dome glasses Beware of cheap Chinese types. You know they won’t last because of the price. Good tools will last you a lifetime.1 point

-

I don't think it's really needed to spend more that 50 on a glass/case press. I've upgrade from a cheap one to this http://www.watch-tool.de/html/second_hand.php?id=0111gm It's strong, heavy and works very well. There is also another from the same seller which is cheaper and should work good because the pillars are lined up with the pressing point.1 point

.thumb.jpg.f706ad06f89a2f338f71a3d0a9822d69.jpg)