Leaderboard

Popular Content

Showing content with the highest reputation on 07/09/15 in all areas

-

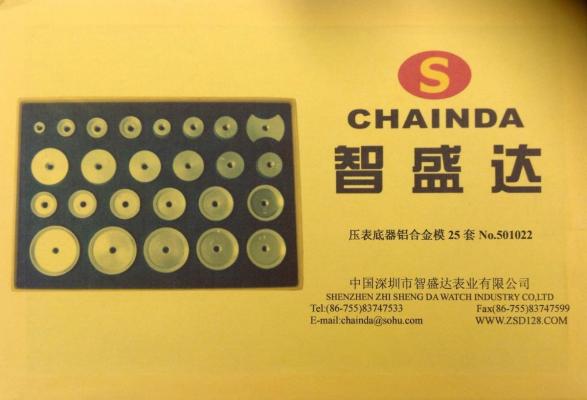

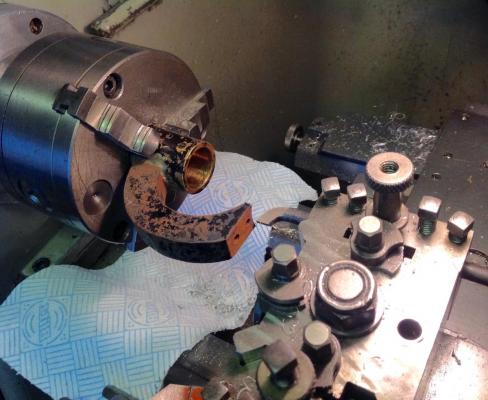

I purchased a cheap Chinese crystal press when I took up watch repairing/refurbishing a few years ago, this was one of the lever operated type with nylon dies. This has served me very well, but there are some jobs that a screw type of press is far better for because of the more sensitive control. Being a canny Scot, I kept an eye on eBay for a second hand Robur or Horotec and stumbled across this antique home made press for £14 delivered. The engineer in me immediately saw the potential, all it needed was stripped down, modified to take new dies and repainted. The other thing that was required was a set of new aluminium dies, so after a search on AliExpress I purchased these for £26 delivered from China. Right, down to business. (1) Modify the lower die holder to accept the 6mm threaded alloy dies. (2) Make an adaptor to fit the bottom of the ram with a 6mm thread to take the dies. (3) Machine the lower end of the pillar to give clearance for the largest die. (4) Accurise the dies to ensure that the faces are parallel. Many were slightly out of truth. (5) Remove paint and rust from press, paint and polish. (6) Reassemble. Total cost of complete set £40.................well pleased!2 points

-

Welcome to the forum Ray. That's very good advice from Anil. I would also check out every jewel to ensure there are no remnants of old oil that has hardened like varnish. This hardened oil expands when fresh oil is applied, and eventually grips the pinions. Clean the jewels with pegwood and check to make sure that end shake in the pinions is still present. A good way to check that everything is very free is to let down the mainspring, and remove the auto drive mechanism and click. Now remove the balance and escapement lever. With these parts removed, use a watchmakers puffer to blow the edge of the escapement wheel and it should drive the whole train easily.2 points

-

2 points

-

I would suspect the barrel pivots are worn, causing the barrel to tilt and jam. Scrutinize the barrel, is there any up down movement? Can the barrel be tilted (in relation to the mainplate)? Re running fast. A galloping movement is usually due to hairspring issues, if the coils touch each other this is what happens. Magnetized, oil and physically bent hairsprings may cause coils to touch. Remove the balance and lay it with the balance facing up. Inspect the coils, are they concentric without touching? The hairspring contacting other parts of the movement (main plate, pallet cock) also screws up the running, in this case the hairspring needs to be adjusted so that it is level. Anil2 points

-

I also think the problem may be in the balance-hairspring. Try checking the watch in different positions on the bench. If watch runs fine say dial up and gains time dial down you might look for a cracked jewel. Another problem could be in the placement of the hairspring stud in its holder. If the spring is a bit high or low the spring could be coming in contact with either the balance bridge or arms on the balance itself and it's possible that it could only show up when changing position of the watch. If anyone is curious as to why I say this I recently had to replace a hairspring on a ladies Omega 484 and when I checked it on machine dial up it ran fine but went crazy dial down. If I remember right the hairspring was making a slight contact with the balance bridge. Spring was not bent so I thought well maybe I just pushed stud up too far when I installed balance. Pushed it down a hair and problem went away. A 484 is a pretty small movement and I had to look at it under 20x microscope to see it rubbing the balance bridge. Charles K2 points

-

For me finding the reason for a fault & fixing that fault. A real sense of achievement :woohoo-jumping-smiley-emoticon:2 points

-

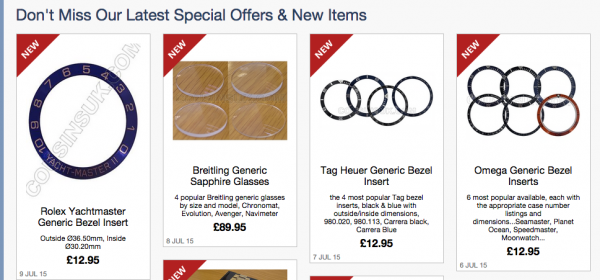

This makes me both sad and encouraged at the same time. Sad because it really could be the end of an era where independent watch repairers can look after customers in a professional manner by providing quality repairs using genuine parts. Slightly encouraged because it seems that generic parts may allow watch owners some choice in the matter of who repairs their watches. It's not ideal but at least it is something. A client of mine told me they recently got quoted £1200 for a service, and some case parts on their branded watch from the authorised service centre (I won't say which brand because that's not the point). If I can't get genuine parts any longer I will always recommend that the client sends their watch to someone who can, but if I can suggest an alternative using generic parts and saving them hundreds (yes hundreds) of pounds then I have no moral problem with that - as long as the owner knows that generic parts are being used. The watch houses want to take choice away from the watch owners. It's nice to see that in a round about way the choice has not been fully taken. It's the tip of the iceberg but it's a start. And it is something we predicted quite some time back - if Switzerland won't supply the parts, China will! Now the question is going to be about quality I suppose.1 point

-

This is going to be very interesting! 3000 days to travel almost 3 billion miles. Can't wait for the images. Http://seeplutonow.com/ I wonder what other milestones will be reached in my lifetime?1 point

-

Very nice set-up. Couldn't help noticing the tiles on the wall is it the kitchen or the bathroom? :)1 point

-

We know all too well in the car & bike world OEM parts are not necessarily the best, but nearly always the most expensive. Agreed there is a fair bit of rubbish out there but quite a lot of good stuff too - just do your homework. As Clockboy pointed out the response from Smersh err Spectre err Swatch & others will range from inferiority issues to dire warnings about pianos falling on your head should you fit a generic bezel or similar. As ever the market will decide.....1 point

-

I predicted just this when the whole Swatch policy was first announced and confirmed. Not that such a prediction is exactly rocket science - anyone with half an eye on the market knows that, when a vacuum is created, something will emerge to fill it!1 point

-

1 point

-

Thank you for all your replies. Charles had it on the money! I had previously raised the hairspring stud upwards a little, and when I returned it to flush with the top of the balance cock the problem was sorted. It is now keeping good time for a movement made about 1940. Like a ladies watch, the AS984 is a small one so another step in the learning process. Clearly, any timekeeping difficulty has to highlight the balance to be investigated first. I'm looking forward to seeing my sister-in-law's face when she sees her late father's watch running. By the way, isn't working on someone else's watch nerve-wracking compared to your first throw-away one! I am trying to attach a couple of pics of the watch, wish me luck! Frank.1 point

-

1 point

-

Welcome aboard Irish. There are a lot of good people on here willing to help out when they can. It doesn't matter whether you just want to tinker, or get into the serious side of watch repair, as long as you enjoy what you are doing. I'll go and clean out the corner to make it more comfortable for you! :)1 point

-

Looks great Geo, nice work. It reminds me that I bought a press very similar to yours meaning to convert it to take various dies I already have. You've inspired me to have another look at it, although I'll have to try and figure out a way to do it without the use of any similar equipment :). Not that easy when you're not particularly mechanically minded! Thanks for sharing. Stephen1 point

-

That's me too. And when the reading on the timegrapher is perfect after fine tuning the hairspring. Sent from my iPad using Tapatalk1 point

-

I think someone here mentioned a similar problem and discovered his magnetic anti-rheumatism bracelet was causing the problem!1 point

-

#98..thanks. Yes it's not impossible but this would only make sense for a really rare watch. Anil1 point

-

I envy you Steven, I, like you, discovered this site through Mark's videos. I retired after 32 years in R & D from Alcoa (the aluminum co.) and really enjoyed learning a wide variety of disciplines. Two years later (2012) I took a job at a jewelry store where I learned some basic watch repair (no mechanical watches). I'd like to get into mechanical but, home life makes it difficult. My last two years while working, I enrolled at the Art Institute of Pittsburgh - online. I was involved in interactive multimedia and web design. I was amazed to find that so much psychology goes into designing. Even something as simple basic as typography has many subtleties that influence the audience. Unfortunately, I had to drop out because of work responsibilities. Through my training at the Art Institute I can appreciate what goes into video production. Of all the different videos that I've seen regarding watch repair, Mark's are the best. He gives me confidence to continue learning. His editing is spot on. I hope Mark gets rewarded for all his generous efforts. I envy you Steven. You had the good fortune to get into the repair business long ago. Had I known how rewarding this is, I would have pursued this when I was young. Welcome, Dave1 point

-

1 point

-

That's an odd one Frank, I would have expected the watch to loose time if it had been the cannon pinion. I'm sure the problem is to do with the balance. If you have demagnetised it, try removing it and give it a good wash in lighter fluid to make sure there is no oil contamination.1 point

-

It could gain in time if you turn the watch upside down on the bench ?Try putting it on the bench in different angels and see if it gain time or loose time . If so you will need to find a medium setting . I don't think its a loose cannon pinion .It would loose time then .1 point

-

I've been looking on youtube and I have found this very good video on how to set up a Longcase Clock (grandfather clock) this is an antique not modern with a Westminster movement. I would like to say I have no connection with this person or his business. It is good it's the way I would go about the procedure and simply explained. I'm trying to add a little more to the clock forum page. Link1 point

-

Hello. Having just discovered these forums after looking over some of Mark's great videos and though I should take the opportunity to join up and introduce myself. I'm just starting to get into watch repair as a hobby and am mostly interested in working on old manual wind movements. As a starting point I've picked up a few cheap watches that are in need of servicing. Hopefully they won't end up destroyed along the way. My professional background (and other hobby) is in embedded software and electronics. I'm fairly hands on and have done quite a lot of fine soldering work under magnification. Hopefully some of these skills will be transferrable. At this stage I'm in the process of acquiring enough tools and oils so I can perform the basic clean and service work required. I also picked up this cool toy a while ago that I hope might help out in the hobby. It's a head mounted stereo microscope that was originally designed for surgeons and dentists. It quality unit with apochromatic optics, a good depth of field and working distance. It is able to auto focus and can zoom from 3.2x - 9.0x. It also has a co-axial light source and built in video camera. It was quite cheap but was missing the control box that drives everything. Fortunately I have been able to reverse engineer enough of the inner working to enable the auto focus and control the zoom. Mark's videos have been extremely informative and there seems to be some very generous people here who are willing share their knowledge with others. I'm sure I'll be here with many questions once the screws start flying. - Cheers, Tex1 point

-

Getting the balance swinging after major surgery, or finding a part on the floor after 15 minutes looking1 point

-

When a customer would say I've had this watch or clock repaired, I've taken it back many times and it still doesn't work. When you repair the fault and knowing it is going to be satisfactory. That would be one of my best feelings, because you know next time the person wants something repaired there more likely to bring it to you then to take it elsewhere.1 point

-

1 point