Leaderboard

Popular Content

Showing content with the highest reputation on 05/05/23 in all areas

-

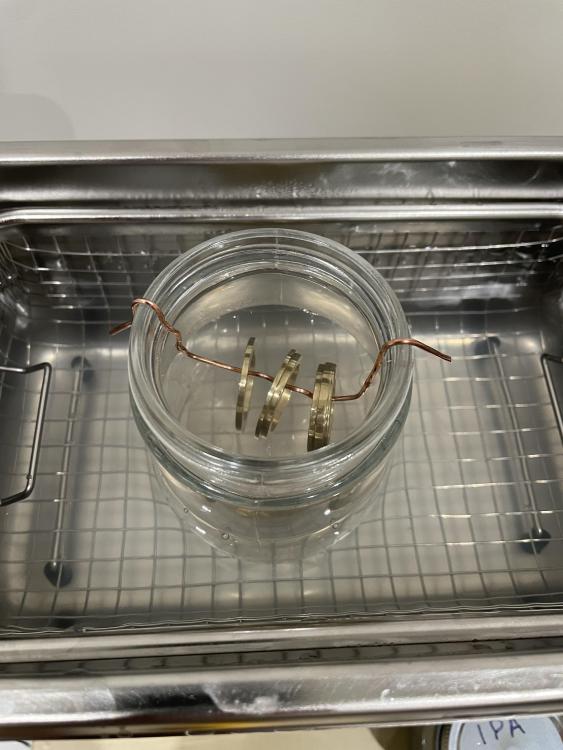

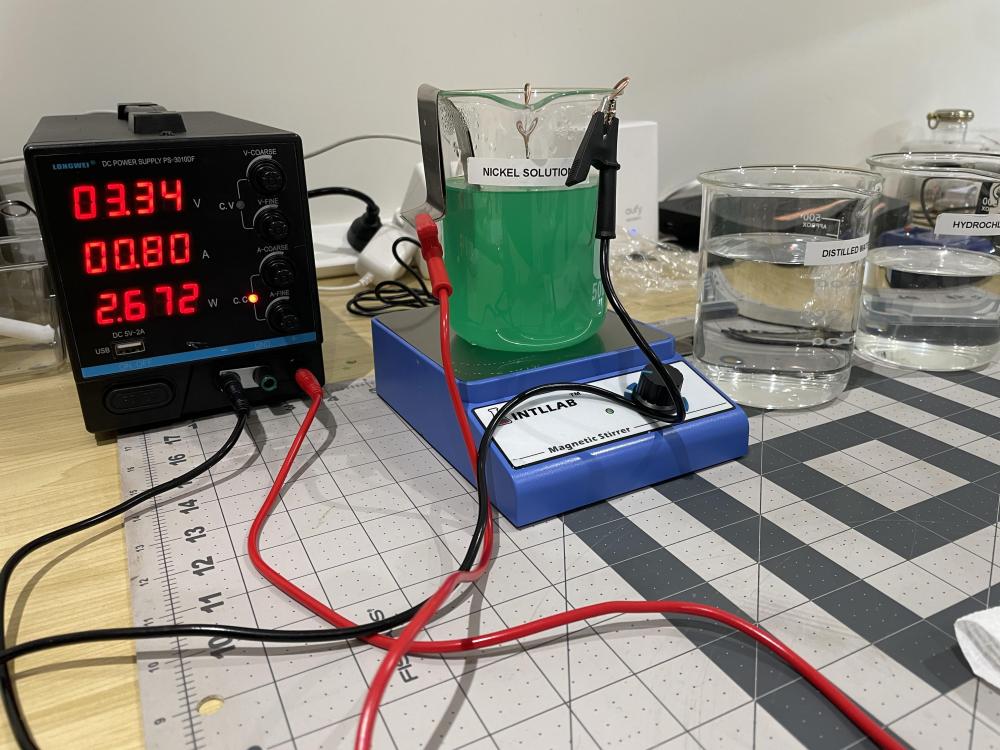

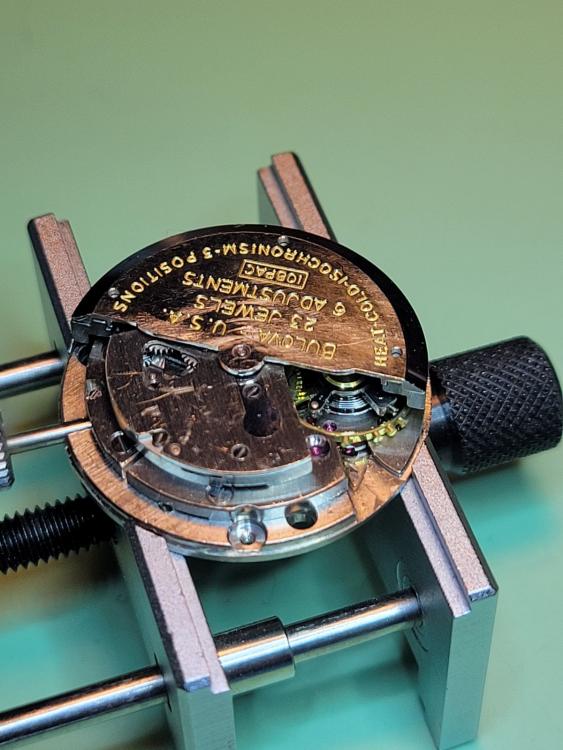

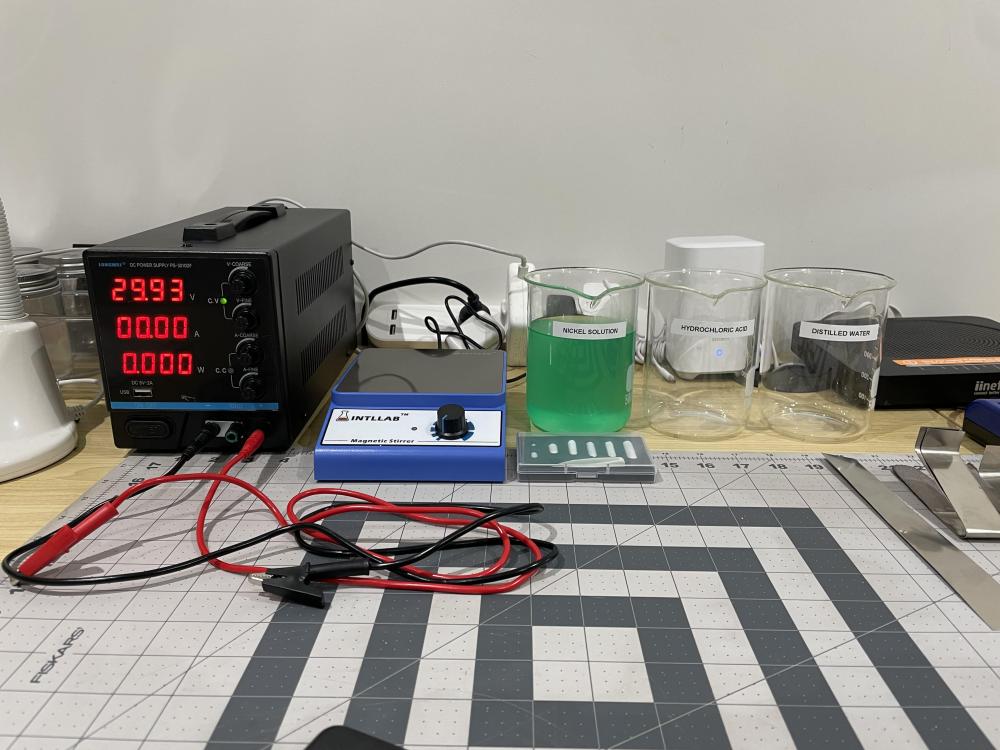

This week all the gear I needed to get started with Nickel plating arrived. A DC power power supply, magnetic stirrer, and nickel anode material. I made the Nickel liquid sulphate a couple of days ago and tried a piece brass rod. Seemed to work. Tonight I machined up a couple of dummy watch cases out of brass plus just a flat washer and set about cleaning and preparing them. The first piece I did with the following settings: First was 5v at 1A for 15 mins. Turned out ok. Plating was dull but polished up fine. second, slightly thicker and more reminiscent of a watch case I did at 6v at 1A - no good. Possibly not clean enough. I rebuffed and polished the nickel off and did it again at 5v and 0.8A for 15 mins and it was good - but still dull out of the solution - polished up nice though. third piece was done the same to verify settings. All good. my solution is a bit cloudy, possibly the cheap vinegar or cheap salt! Well worth the exercise as I have a degree of confidence an actual case will plate. Oh and each piece I turned half way through to avoid shadowing. Very happy and will only get better. A few pics attached:3 points

-

3 points

-

I think we'll just have to accept that a really sharp blade is the quickest and easiest way to sharpen peg wood for those < 0.1mm pallet staff jewel holes and chaton holes. So, I just ordered these blades (same as in the picture) and a cutter for them on eBay from Japan. I'll try to remember to report back to this thread once I've tried it (delivery is 1 to 2 months)... eBay item numbers: 254266416996 and 2542624912172 points

-

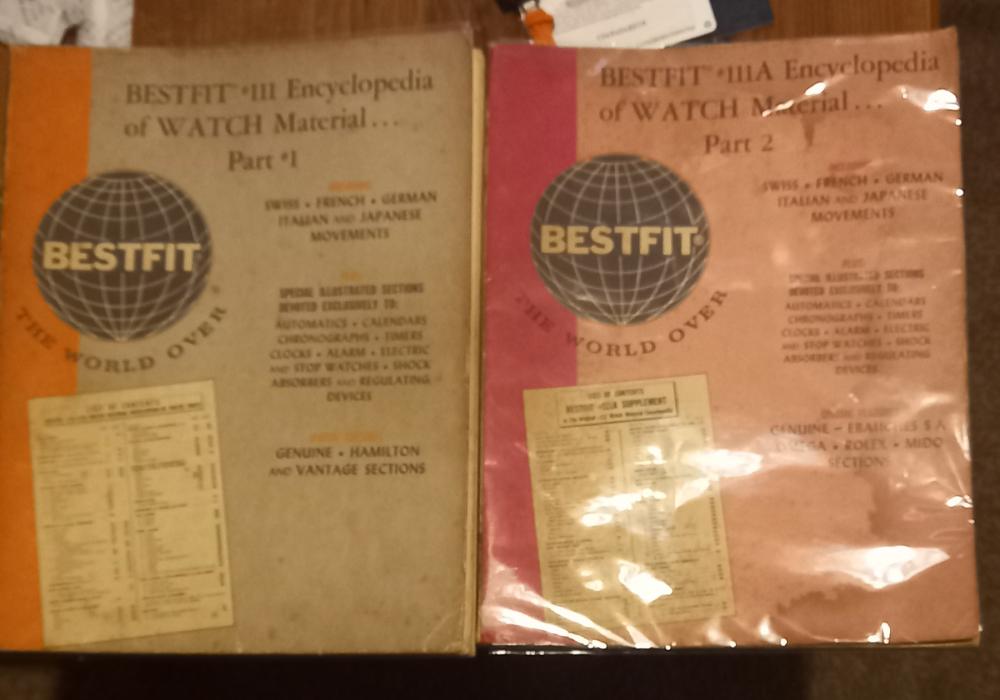

Been working hard last few weeks so it was time to treat myself to some tools etc. Some would call it random shite, i call it keeping myself content, and its a healthy fix as long as you dont get carried away. So i just wanted to show off my Bestfit encyclopedias. Been waiting ages to pick them up at a good price. Generally anywhere from 50-100 quid for both parts. These started at 20 and no one bid for them so well chuffed at that.. The Pdfs have been ok, quick to search through and take up no space at all but do have their drawbacks, a tenner to download them for starters for those that aren't in the know . But there is no substitute for sitting on the sofa with a cuppa in one hand and a good old fashioned book in the other. Any beginners looking on this post, these are a great reference guide and plenty of useful info besides. Behold the watch material legends !! "The Bestfit Books"2 points

-

2 points

-

Not a watch, but a screw-head polishing tool. Offered on eBay as an auction, but the seemingly incomplete Lorch & Schmidt polishing set with a below mid-starting price got no bids, apart from my one in the last 5 seconds. However, only when enlarging the other sellers pictures, it seemed as if there were more collets hiding underneath the polishing disks and the polishing tool. This turned out to be the case. After quite some TLC of the parts and the wooden box, the set turned out to be like this; Less than 1/2 price than what these (be it fully complete) set are currently going for on eBay Three parts, for polishing screw-thread-ends, are missing ...... I can easily live with that2 points

-

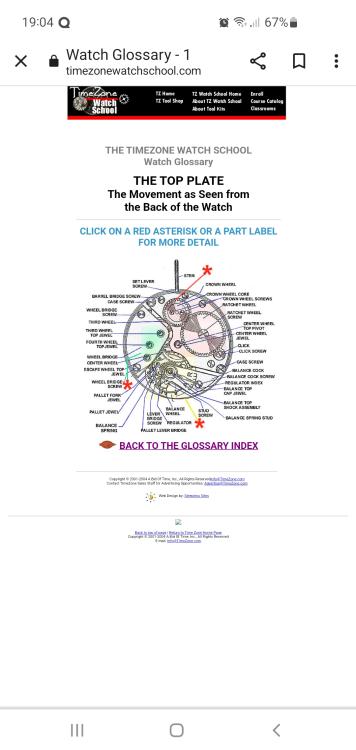

it depends upon where you're located and if you were influenced by any other location. For instance in the USA books by Henry B. Fried. for instance when I was in school the watch repairers manual was something we were required to have. Not sure if we actually used it as a textbook we had all sorts of other hand out some things but it was definitely a book we had. On the other hand some people of Swiss influence don't think for a much of Henry not quite sure why. I tend to be biased slightly because over the years I had met him a couple of times and had conversations with him a interesting person. https://www.amazon.com/Watch-Repairers-Manual-Henry-Fried/dp/1626549982 just think what the gold plating would've done to the shipping cost. that's an interesting quote I wonder if schools really are using it as the Bible? there is an interesting book and it is a training manual fortunately watch repair doesn't really necessarily evolve with time so older books are still perfectly valid https://archive.org/details/TM9-1575 then here's a book I've always liked and for that matter the author is done several other books which are interesting https://www.booksimonin.ch/en/5856-the-watch-repairers-manual.php#corps2 points

-

I have 2 of those kd, they are office stationary drawers. I have this 10 compartment size and one that has 6 drawers. Not cheap now as they are well built steel affairs but very handy for small tools. I lined out the bottoms with a rubber type flooring underlay, they fit under a desk easily. I would try an internet a search for secondhand office furniture in your area .2 points

-

Hi All, Just thought I would post a few pics of my restoration project of a Seiko 6119-8083 I picked up off ebay. It was pretty scuffed up but the dial looked ok and the seller had decent pictures of the movement. Once I opened it up the dial was indeed in near perfect condition and the lume was still going strong despite its age! I wanted to get this looking as "new" as possible so gave the case a bit of attention and popped in a new crystal. I only noticed after it had all gone together that the day-disc is offset; it does not feel loose so I suspect it was taken from another watch with a different crown position. Overall, Im really happy with it.2 points

-

2 points

-

I have an Omega 455 (I hate it !) which I work on when I've no other watches to play with. Being a small 'ladies' movement, 16mm dia, automatic + sweep second, it's all very tiny and fiddly. The hairspring is just too tiny to work on. The balance is only 6mm diameter, so everything needs to be spot on to get good amplitude - which I aren't. I've had this thing apart so many times looking for problems. I'm working through every pivot and jewel to find out where I'm losing power. This is the lower escape wheel jewel. Is that too much play, robbing me of amplitude ? I think probably yes. What is the general consensus on jewel hole wear - is there an industry standard recommendation ( @nickelsilver, @JohnR725, @praezis ) ? Maybe half the pivot width ?1 point

-

1 point

-

Well, I think my spring used up all of it's lives as it broke at the arbor connector when I tried to get it out. Live and learn. Well, new spring on the way... ordered yesterday so I should get it tomorrow or Monday. Then I will get to play with trying to insert that one out of the package and not be able to play with the winder.1 point

-

That's the correct sized winder. If it's slipping off the hook on the winder I would confirm: 1. The inner coil of the mainspring is tight to the arbor when you insert the arbor. 2. Confirm the the hook on the winder is engaging the hole on the mainspring. I like to look under the microscope. 3. Confirm you are winding in the correct direction. Other than that I can't think of why the spring wouldn't wind into the winder.1 point

-

1 point

-

Well, I'll pass on the cuppa (give me an espresso any day though) but I am 100% with you. I love having digital books so you can quickly search, but having something to hold in your hands is priceless. Plus, you get all that old book smell goodness too!1 point

-

1 point

-

1 point

-

Maybe that's why some YouTubers use plenty of oil, it's nearly at it's use by date, so let's bang it on. Hehe.1 point

-

I thought I would post a few pics of how my setup has grown in 4 months. I started with the basics and I am graduallly acumulating more of the essentials. Today I mad emy first Nickel solution (liquid nickel sulphate). The carpet is a nightmare when droping screws and small parts but my neodyium magnet is awesome for rounding them up - parts will jump from 6 - 8 inches away! Anyway - enjoying the journey. Just thought I would share.1 point

-

I made it myself from a block of aluminium, and the staking block. I have milling machine in the garage (and a lathe), although I broke a small drill in one of the holes so I’m going to soak it in Alum powder when I find some!1 point

-

My question was posted just to make you think about the commercial BS there is in "shelf-life"1 point

-

Cool nice tool said the actress to the bishop . Strangley enough i was watching the same one being used on a video yesterday. CS Watch repairs .1 point

-

This same question has cropped up many times in the last year, in terms of synthetic oils what does the lubrication expiration date mean ? Mostly all it actually means is that watch lubrication manufacturers like mobius sell more watch lubrication. I would say hardly any of us here worry about it. I received an unopened 5ml bottle of 9010 in a job lot of tools, the container looks much older than a new container. Will i use it ? you betcha bottom dollar i will1 point

-

Speaking of braking grease. I believe I got the following from @nickelsilver a few years ago. "Moebius 8217 is the standard grease Kluber P125 is also a standard if a bit more high-tech grease. Then there is Moebius 8212, also known as Glissalube B, for aluminum barrels, and Moebius 8213, Glissalube A, for brass barrels. Easy to remember as the letter code matches the opposite metal."1 point

-

A slightly scruffy "La National" French cylinder pocket watch, with a nicely decorated main plate, is on its way. Its missing its crown, stem and bow, but otherwise looks complete. Hopefully with a little care and a clean and service, it should run. I probably have something suitable to replace the missing parts with. It came in 14 pence over the 404 club budget, but with inflation the way it is today, I think we may bend the rules and allow it in to the club.1 point

-

The back is stainless steel. The case is not. Use a razor blade to start the prying of the back. I won a bid on some levin collets and commented about it on a FB group. A guy said he was bidding against me. It happens.1 point

-

If it's a Wyler, there's a chance that it is a front-loader. I've worked on a couple of those. I would remove the bezel and crystal and see if the movement comes out the front. If not, then perhaps the back is difficult. Goodness knows, I thought my Glycine Compressor was practically impossible to open until I learned just the right spot to insert a slender knife blade. I'm not opening that one again for another five years, thank heaven. As to bidding against one of us unawares, that can happen. I'm sure most of us here understand it goes with the territory. Heck, if what you're bidding on is an old American pocket watch, you might be bidding against me, among others. Well, even if it is Swiss or English or German, I might still be among the other bidders. We can wish each other luck and hope for the best.1 point

-

Endless nights of search and research. Could not find an original one (the shape is quite specific), so then bought a hand full and picked the one that fits/looks the best, in my opinion. I chose this one: XAC 301.640 Sternkreuz.1 point

-

have you ever looked at the lubrication chart found that the link below? as a rather interesting line on the bottom of the chart where it makes a reference to which of those oils you should be using and where. it just a peculiar line of sometimes use one and sometimes use the other. https://www.moebius-lubricants.ch/en/products/oils1 point

-

To get it in beat you will have to bend the crutch. Are you sure all the teeth on the escape wheel are good and no sign of wear, no burr on the ends and the pivots and pivot holes are all good. It might be due to it not having the correct pendulum. If all is good I wouldn't worry about it. Use this to get the right length for the pendulum it will save you doing all the math. https://theindex.nawcc.org/CalcPendulumLength.php1 point

-

For me the two go-tos are Levin Practical Benchwork for Horologists, and Gazeley Watch and Clock Making and Repairing. Those don't teach you how to work on watches, but are packed with useful info on doing the actual work (and a lot of "making"). For really basic instruction, there the Chicago School of Watchmaking course text, which can be found to download, and the Joseph Bulova School of Watchmaking course book, which is in print, available here or can be downloaded here (it's nice to have an actual book though).1 point

-

1 point

-

Was thinking about fishing 2 lb mono-filament or copper winding wire 0.1mm I did look at guitar wire, but the thinnest I could fine was high E of 0.008" = 0.203 mm, so not a good candidate1 point

-

A beard whisker is about the right size to poke through a jewel hole. Organic and low carbon footprint.1 point

-

1 point

-

1 point

-

Got a set of tiny screwdrivers today and the third smallest was just the right size to turn this screw. Just to be safe I turned it counter-clockwise to see if it would move and it did but that made the watch faster so I turned it in the clockwise direction to move the watch back to just a little slower than it was. I did a thing! Yay! Thanks for the confidence boost.1 point

-

Jewels aren't 100% impenetrable. I have seen dimple drilled into end stone by damaged balance pivot, where a piece of pivot-end had chipped off, the half still intact had done drilled the dimple. So I guess we can't rule out wear on jewel hole by worn pivots.1 point

-

I know it's the obsession of this group but is amplitude really that important more important than keeping good time? What sort of amplitude are you aiming for for instance there is the timing specs from Omega what sort of timing amplitude are they expecting? Notice there only concerned about the amplitude at the end of 24 hours 170°. They are in real life concerned about timekeeping not amplitude. another problem conceivably could run into is something this tiny is lubrication will be critical. I remember when I was in school the instructor is using an organic oil for the super tiny ladies watches. From the lubrication specifications I've seen usually organic oils do have better properties for reducing friction but consider the worse it everything else. then yes I went back and looked at your video I think it looks better than the Rolex video that someone gave me as it was flopping around considerably more than this. Oh and then there is the other little problem jewel wearing out or pivot wearing out?1 point

-

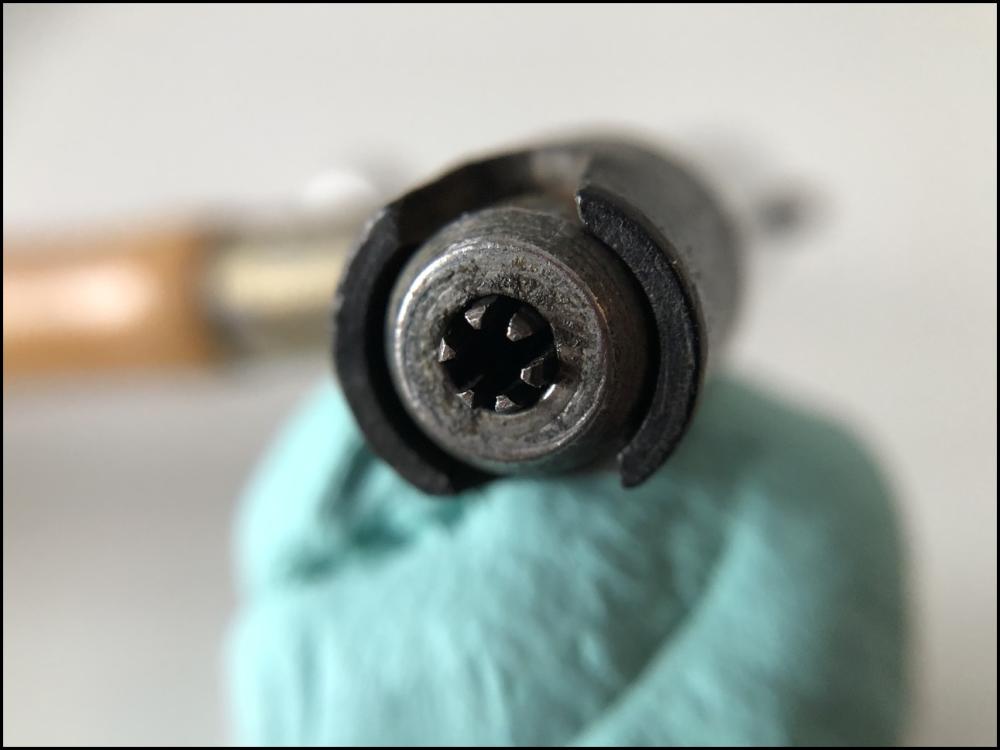

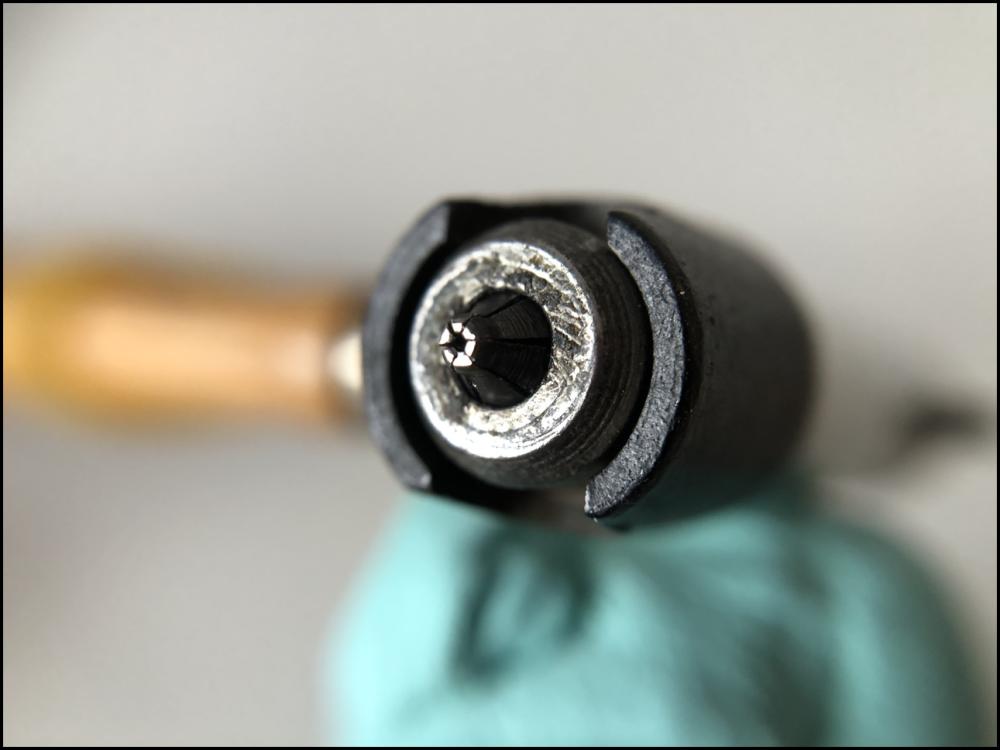

Unfortunately, the current Bergeon cannon pinion remover can only remove rather large cannon pinions. "Can lift cannon pinions diameter Ø1.20 to Ø1.80mm" I got one of those from Cousins too, but at the time I bought mine (years ago), the ad said that it could lift cannon pinions of any size (which it couldn't) and when complaining about this Cousins, to my surprise, accepted a return. Eventually, I got a vintage remover on eBay that can lift cannon pinions of any size and it's one of my most appreciated tools. Pictures below:1 point

-

OK people are going to throw rocks at me now....... but the dial was an etched metal with no lacquer etc, so I used water on a cotton bud, carefully rolling it and it cleaned it a little without any damage and I noticed that the numbers were surviving, then I used some IPA, and again everything survived..... then I used some silver polish paste in one corner and and it came up great with no damage, so I thought "what the heck" and did the whole dial in silver polish and this is how it turned out. I decided to stop there and not get the belt sander out. I took it in small steps and would definitely not recommend hitting a modern dial with anything other than water, but I got away with it in this old dial... this time.1 point

-

SG$ 219.43 | Watchmaker tools professional welding and repair of watch dial feet stem apparatus for soldering dial feet Simple and practical https://a.aliexpress.com/_mtk0MhI Sorry about that. My mentor gave me his old dial foot repair machine. It was so simple inside that I'm sure @LittleWatchShop can cobble one in an afternoon. It comprise a 12V lead acid battery, a 12V 10A motor controller and a carbon rod. I promised to show the insides of it in another post. I should really clear my bench and get down to it.1 point

-

Hi, I'm building my setup at the moment. What holder is that you are using for your screw drivers? I bought a wood one with metal holes and its not very good because the metal scratches the sides of the drivers.1 point

-

1 point

-

Scott I wear the housebrick (Magnifying Glass Loupe LED Light Adjustable Headband Visor Magnifier Loupe - 3rd reply above). For me though, many is the time I do not notice having it on. I put in on just after I have placed the watch in my component tray in the working box. I always use the LED, relying on rechargeable batteries. I think my head is thicker than yours. No headaches. Except for trying to get better amplitude.1 point

-

Thank you. But I think I want to redo the top brush finish... But yeah looks very nice. Now I'm afraid to ware it now. Also I guess I was lucky to find a nearly new bezel. About the size. I would say that it's not that big actually. Well depends what you compare it with.1 point

-

1 point

-

If the lume is not flaking off, leave well alone. Preserve the vintage character and enjoy it for what it is.1 point

-

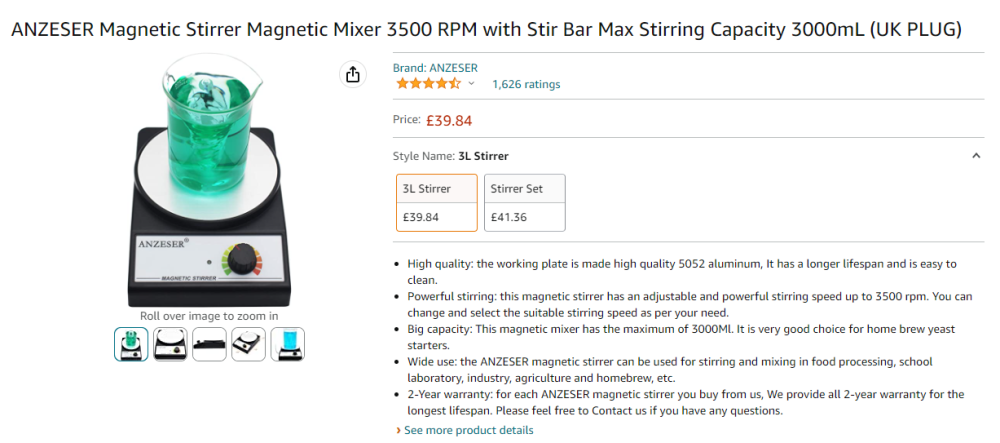

I have fairly good results with a home made nickel plate solution, but I think you need to be concentrating on maintaining constant amperage not voltage. When creating the plating solution I keep my amperage at 3.0A, but when plating I keep it at 0.1A - low and slow for plating a watch case seems to do the trick. You may also want to invest in a magnetic stirrer, they are relatively cheap and the agitation they create prevents bubbles forming on the watch case, and where there are bubbles there is no plating solution and then you get patchy plating. Here is the one I use: Also, remember to turn the watch case every so often so that each side faces the electrode and you get an even plate.1 point

.thumb.jpg.f1a29a0f2bbf72f94295583bed5078e9.jpg)