Leaderboard

Popular Content

Showing content with the highest reputation on 05/04/23 in Posts

-

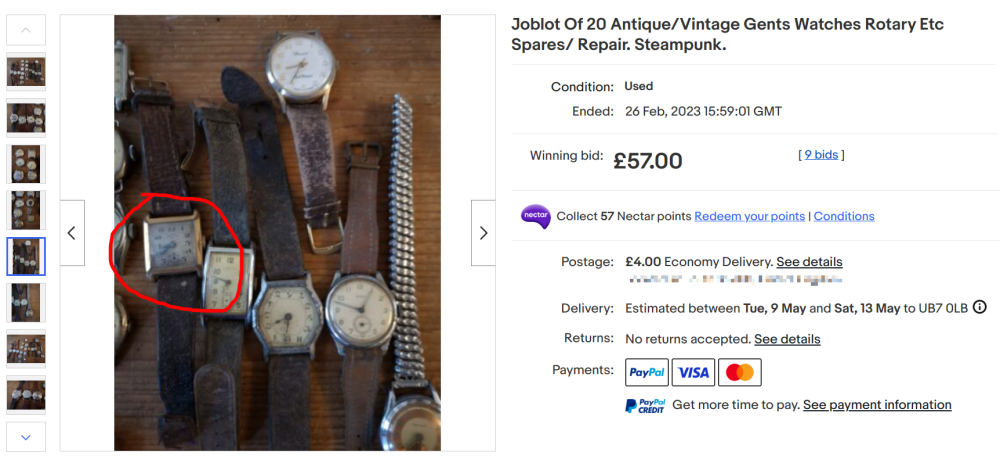

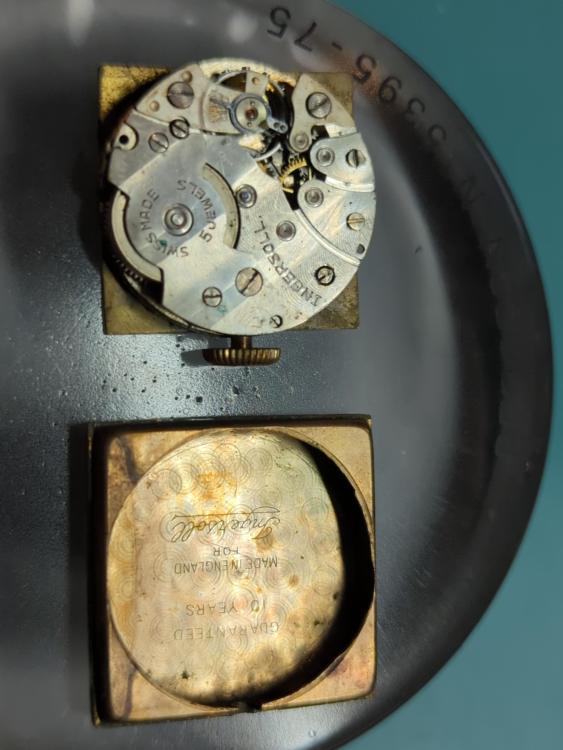

Another 404 watch brought back to life, this one is an Ingersol REX and was included in a batch of 20 others, making the average value £2.85: When it arrived it looked like this: And here it is when I finished: All in all the build went well and is 100% original, even the crystal (apart from the strap of course) and I'm very pleased with the results I'm not familiar with an Ingersol REX, I have some regular Ingersols, but never seen a REX version, so if anyone can shed some light on this it would be appreciated.5 points

-

You can lie all you want but as a dentist, we can tell whether you floss or not. When we ask whether you floss regularly, it's rhetorical.3 points

-

Hi, I don't know worn jewel holes, just damaged ones. But I knew many worn pivots. Usual sizes are: pivot under 0.2mm: jewel hole = pivot plus 1/100 mm pivot 0.2mm and more: jewel hole = pivot plus 2/100 mm Frank3 points

-

I think I'd prefer the Robur (I like the control aspect) and I don't think there's anything the Bergeon can do that the Robur can't. I was meaning to get myself a Robur, but considering its price, especially the dies, I never got around to it. Eventually, I found a vintage Robur-style press for little money with wooden dies for non-armoured acrylic crystals and it works surprisingly well. Here's a picture of it.3 points

-

Well said, and that's my experience and opinion as well. It would seem you can pick up something good or interesting from all channels, even from the "idiots", although it's seldom worth the time to wait for those few and far between good or interesting things to show up. I guess you're right about that, but I get red rashes all over my body when I see someone slobber around with oil like that. After all, oiling is one of the most critical aspects of servicing a watch if we want it to work reliably for more than a few months. Well, I'd be more than shocked if that would turn out to be true, especially as all your watches are still working fine and since I know how serious and skilled you are. I wish I too could say that "all my watches I've done are still working fine". They're not I could have written that exact same sentence myself, and I'm 100 per cent sure none of us is servicing and repairing watches doing it in exactly the same way. Well, that's the commendable and rational approach, but sometimes I just can't help myself. If something is really bad, clearly wrong, or risks damaging the watch (like the oiling, or hammering out a balance staff in a staking set) I feel it's my privilege to be able to write a helping or suggesting comment about it, and I don't get too wound about it (except perhaps momentarily). Thanks for your input! Very readable, and I hope I didn't wind you up too much!3 points

-

Hi All, Just thought I would post a few pics of my restoration project of a Seiko 6119-8083 I picked up off ebay. It was pretty scuffed up but the dial looked ok and the seller had decent pictures of the movement. Once I opened it up the dial was indeed in near perfect condition and the lume was still going strong despite its age! I wanted to get this looking as "new" as possible so gave the case a bit of attention and popped in a new crystal. I only noticed after it had all gone together that the day-disc is offset; it does not feel loose so I suspect it was taken from another watch with a different crown position. Overall, Im really happy with it.2 points

-

one of the amusements I have with well this group is an obsession with material houses can only exist online. In the old days the used to be physical structures with real people. But for this group usually any attempt I have to convince people to seek out your physical real material houses falls on deaf ears because it's not online it doesn't exist. But the problem with being online is maybe they don't really exist? so for cousins they do have a help and support page which is actually quite amusing for reading. read the section on what if you're not a registered business that's quite interesting. https://www.cousinsuk.com/?section=helpAndSupportLoader then we have this link which is interesting it looks like cousins physically does exist they seem to have an address we should probably Google it and see if it is a actual building or just a field in the middle of no place. But notice what it says about contacting them well I would interpret that the main basically don't because were to make it really really hard to do that. https://www.cousinsuk.com/page/contactus this of course is the problem of online businesses do they really exist or not. Then yes at one time material houses were physical if you go look at cousins well for instance you look here. You can explore the company history were at one time it physically existed you could reach out to them but at some point in time they went all online they don't have to talk to customers anymore. Which makes the online people happy because it's not online it doesn't exist https://www.cousinsuk.com/history looks like they're still doing a little better than cousins because on the contact page they have an email address they also have a physical address and a form you can fill out that might actually go somewhere. But I can see their embracing the online attitude of don't even think of reaching out to us in any other way than this. noticing that @kd8tzc lives in the state of Ohio was wondering if there are any physical material houses there and here's sort of one. one other thing is cousins makes me nervous and you look at even like this notice the reference they are while the word professional. When a dealing online I don't think they discriminate against anyone but it does make you nervous when they say the word professional. I've actually seen some online material houses they won't deal with you unless they perceive somehow your professional and the trade. I know locally of the two material houses that we have one of them will sell your tools but won't sell watch material if you're a hobbyist and it has to do a tax reasons. The final sales tax on wholesale items is collected by the user in their business so if your watchmaker that's where the final taxes collected but in the case of tools year the final users so she charges taxed everybody. But it still brings him a problem of a lot of the material houses think there only dealing with the so-called professionals and they do a nice job of hiding from everybody else which explains why there's slowly all going out of business. At least a lot of them are because they become extremely hard to find. So at least below there is a phone number and you could physically go pick up things. Which means it is a problem you can at least yell and scream at somebody although yelling and screaming isn't the best approach usually. https://www.jewelerssupplies.com/2 points

-

Good question. There is an informal "club" of low cost watches. Anything that costs £4.04 GBP or less (or a similar 404 of the local currency). Its not to be taken too seriously, so the rules are a fairly flexible. There is an entire thread on the subject, with some real surprises from the bargain bins of ebay and various flea markets and car boot sales around the world. Obviously there are some specimens that start off looking pretty sorry for themselves at these low prices, but that's half the fun of it. You can read all about the "404 club" here.2 points

-

I looked onlune at eBay too for a set before I got from Cousins, and even bid on a set. In horror once I checked out the Cousins web site I realised that a new set was far cheaper than the used set I had just bid on - fortunately someone (actually several people) came in and beat my bid and I saved a heap of cash by then getting the new set?!?! I also did the same with my Bergeon cannon pin remover tool, they are on eBay now (just looked) used for £174, but I got mine for £61.95 brand new from Cousins..... So now I always look at the new price before I assume the used ones is a bargain.2 points

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. You have hit the nail right on the head. I always advise those that are starting out to start with pocket watch movements and saying all that you have said. Stay away from Fusee pocket watch movements they are so different from the other types, don't bother with smiths or ingersoll, I know they are cheap but again different.2 points

-

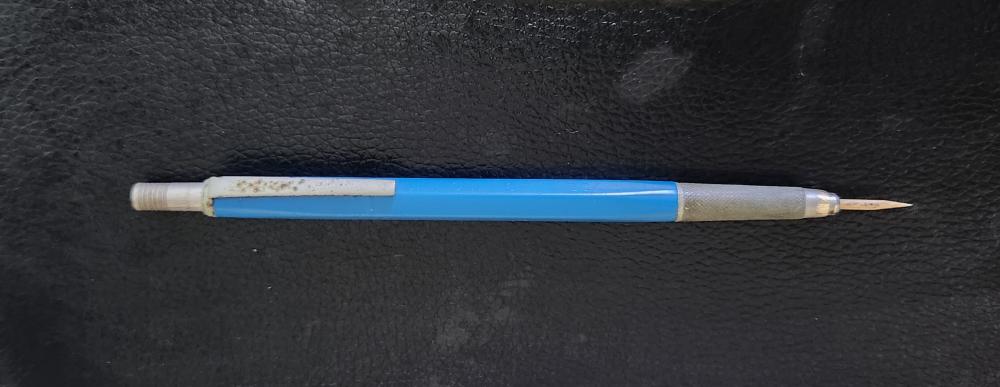

I have never enjoyed sharpening pegwood. I get wood chips all over the bench, floor, clothes and places you never even imagined. I recently found a mechanical pencil from my secondary school days. These dinosaurs use 2.0mm leads, which set me thinking.... Can I put a toothpick into it and stick it into my pencil sharpener to sharpen it? This is what I got. I just discovered that AliExpress still sells these antiques. I ordered a 3.0mm version for my pegwood.1 point

-

The smallest needles i use and can find are acupuncture needles at 0.18mm thats going to be around double the diameter of an average WW balance or escape wheel pivot with a jewel bearing hole a hundredth maybe 2 bigger. Possibly go through a big pocket watch pivot hole but there is no eye for threading. Yep definitely flogging a dead os, good thinking outside of the box though. My dentist once asked if I'd be ok to have some work done without any anesthetic to which i agreed. He said if i started to feel any pain just to raise my hand, i said no problem i shall raise it to just underneath your throat.1 point

-

If you have a window at a decent level in the room arrange your work bench to that. Don't have carpet on the floor, a light colour flooring is best. Make sure the walls are light in colour, Your bench need to be high so that you do not have to sit hunched over when repairing, an adjustable comfortable seat is a must. A good bench light make sure it doesn't cast a shadow over the work space. Try to arrange things such as tools around you so you do not have to keep getting up. Have something like wood beading around your bench to stop stuff from rolling off. You will need plenty of power sockets so try and keep the wiring out of the way. The more light you have the better. If you are going to clean watches/clocks in the room make sure you have good ventilation. This hopefully will help you. One last thing no matter how big your workshop is it will never be big enough.1 point

-

I would expect that it would come with the colored part oriented so that the spring goes in as it should, but regardless you would just position it so that the spring is orientated the same way you showed it in the barrel, CCW. I've had springs come with neither side colored and you just pop it in the way it should go. EDIT: I mixed this post up with your other post, I assume it's for the same mainspring.1 point

-

LOL! Definitely got a little lucky. The freedom to experiment with things like that is part of what makes 404s so great!1 point

-

https://www.andrewsofficefurniture.com/15-drawer-bisley-multi-drawer-cabinet-black google reverse image search..1 point

-

Perhaps thsts whst it means but more so it shows mickey can sell.1 point

-

I wonder if the word "Voumard" on the ratchet wheel is any kind of a clue? I have heard of Voumard watches but didn't know if they used in-house movements or not. However a quick search on Ranfft credits them with at least two in-house movements, although nothing like this one, but then Ranfft isn't an exhaustive list of everything that has ever been made. Sadly Google isn't coming up with very much that helps. This sounds like a Roskopf design often found in pin lever movements. I think I read somewhere that Roskopf was the inventor of the pin pallet movement, but I may have that wrong.1 point

-

1 point

-

Typical wristwatch escape wheel pivot is around 0.1mm, similar or smaller for pallet fork. Definitely too small for a needle and thread, and too small for machine sharpened peg wood. I use a standard snap-off cutter, but use the extra sharp NT Black blades- really makes a difference on peg wood. Also, different pieces of peg wood even from the same batch sharpen up differently. I have old stock peg wood and new stuff from Horotec, some pieces are great, some so-so, no real difference between the 30yo stuff or new.1 point

-

Escape wheel, pallet pivots must be about 0.1-0.2 mm? What could you find small enough to go though that ?1 point

-

Thank you all for the welcome and excellent advice so far. The hunt for a movement is on! Since I’ve been hunting vintage watches I’m getting good at sleuthing on eBay.1 point

-

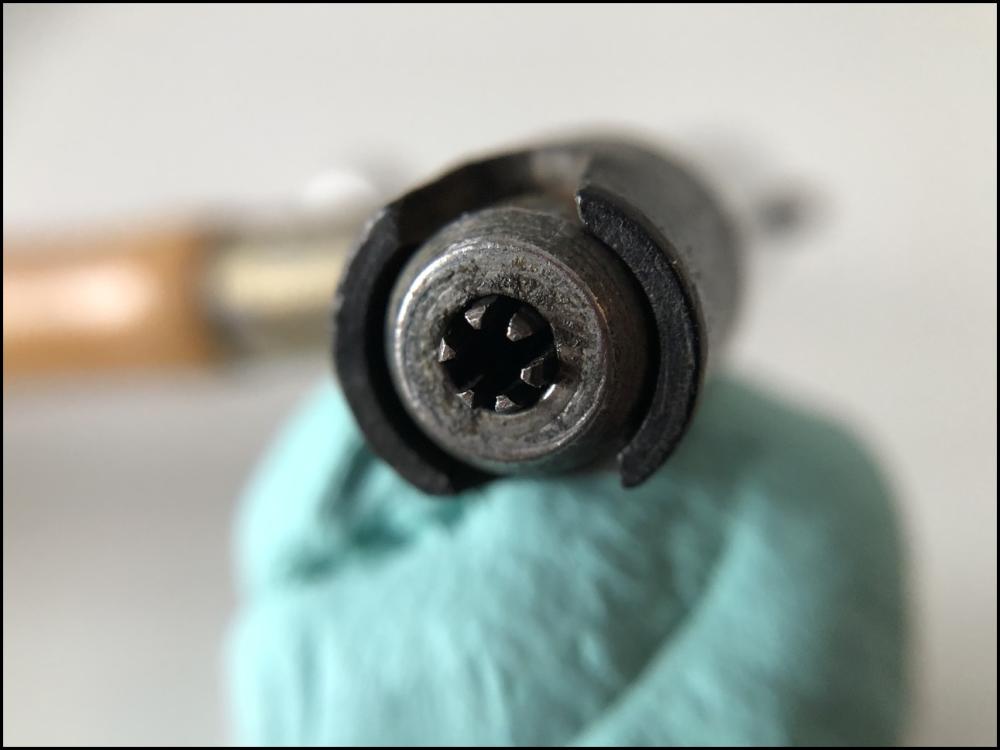

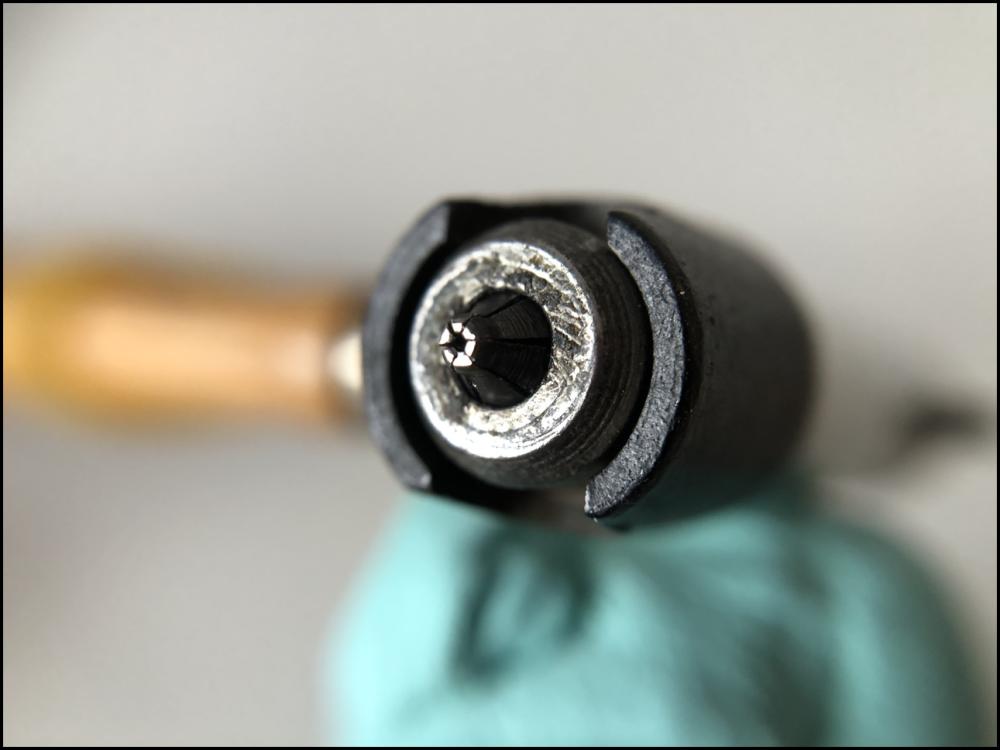

Unfortunately, the current Bergeon cannon pinion remover can only remove rather large cannon pinions. "Can lift cannon pinions diameter Ø1.20 to Ø1.80mm" I got one of those from Cousins too, but at the time I bought mine (years ago), the ad said that it could lift cannon pinions of any size (which it couldn't) and when complaining about this Cousins, to my surprise, accepted a return. Eventually, I got a vintage remover on eBay that can lift cannon pinions of any size and it's one of my most appreciated tools. Pictures below:1 point

-

OK people are going to throw rocks at me now....... but the dial was an etched metal with no lacquer etc, so I used water on a cotton bud, carefully rolling it and it cleaned it a little without any damage and I noticed that the numbers were surviving, then I used some IPA, and again everything survived..... then I used some silver polish paste in one corner and and it came up great with no damage, so I thought "what the heck" and did the whole dial in silver polish and this is how it turned out. I decided to stop there and not get the belt sander out. I took it in small steps and would definitely not recommend hitting a modern dial with anything other than water, but I got away with it in this old dial... this time.1 point

-

People's crazy ideas have made them millions over the years. Watchfoss might have you flogging a dead os, annnywaay must go i have an email to send to the UK patent office.1 point

-

What did you use to clean the dial? It looks great! Well, the whole thing looks great. Nice!1 point

-

Welcome! Indeed, pocket watches are the way to go when you're new. The classic choice is the ETA/Unitas 6497 or ETA/Unitas 6498 or a clone (but make sure it has an Incabloc shock setting - easier to handle anti-shock springs) and if you get one of those, then eBay is full of options for cases, dials, and hands should you later want to build your own wristwatch. Here's an example: https://www.ebay.com/itm/2851053452081 point

-

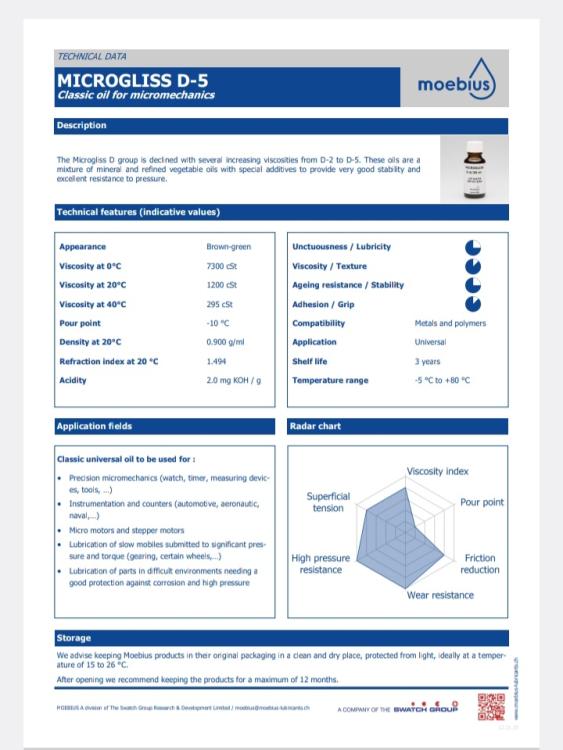

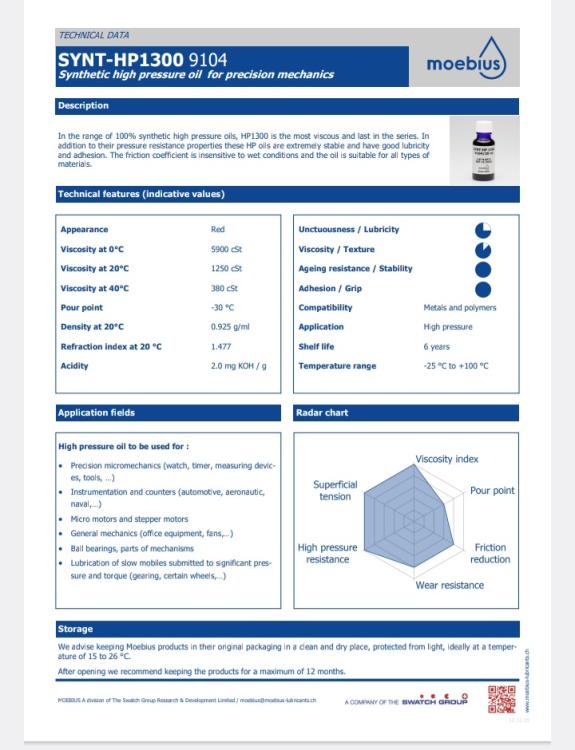

The PDF Mark linked to is excellent. Worth noticing perhaps is that for most (all?) of their movements, ETA has now replaced D5 with HP-1300. Not sure if that's a better oil, but at least you can get a 2mm bottle for £17.55 (CousinsUK) rather than a 20ml bottle of D5 for £26.95. 2ml will last for years and years unless you're a pro. Just thought I'd mention it.1 point

-

1 point

-

1 point

-

SG$ 219.43 | Watchmaker tools professional welding and repair of watch dial feet stem apparatus for soldering dial feet Simple and practical https://a.aliexpress.com/_mtk0MhI Sorry about that. My mentor gave me his old dial foot repair machine. It was so simple inside that I'm sure @LittleWatchShop can cobble one in an afternoon. It comprise a 12V lead acid battery, a 12V 10A motor controller and a carbon rod. I promised to show the insides of it in another post. I should really clear my bench and get down to it.1 point

-

Scott I wear the housebrick (Magnifying Glass Loupe LED Light Adjustable Headband Visor Magnifier Loupe - 3rd reply above). For me though, many is the time I do not notice having it on. I put in on just after I have placed the watch in my component tray in the working box. I always use the LED, relying on rechargeable batteries. I think my head is thicker than yours. No headaches. Except for trying to get better amplitude.1 point

-

1 point

-

That is one of the barrels that separates from the edge, not from the top or bottom. I like to use a sharp razor and a screwdriver as leverage, but you must be VERY careful when doing it this way not to mark up the side walls of the barrel. With a light touch and steady hand they will separate. Here's one on a 7006A (same barrel as a 7009A) I did the other day.1 point

-

Due to the persistence of some friends of mine, I finished making my first ever watch repair video. Talk about a learning curve! I have zero experience with filming, editing, etc., so this has been quite the undertaking. I wanted to make very detailed videos, so I made the first video (on a Seiko 6139-6005 'Pogue') solely about the disassembly process. It ended up being almost 28 minutes long, but I think it went into detail on some things that I hope someone out there will find useful. It's rough, lol, and you can tell my inexperience creating videos, but I think that the technical info is solid. It's been a fun process. I'll remember not to drink a bottle of Coke before filming the next one. Shaky hands at first, haha! I would really appreciate any feedback you may have. If there’s something I can do to make the video better either with filming, editing, or otherwise I would like to hear your thoughts. I am limited by only having one regular camera and a microscope camera, but I think it turned out OK considering my lack of experience. It really taught me to appreciate the quality of videos that Mark has created. I didn't realize just how much work was involved in creating something presentable. Kudos to him!1 point

-

The follow up 2nd video has been uploaded. I had quite the difficult time trying to film close ups of the jeweling work, but I think it came out well enough. In case you watched the first video, here's a link to the part 2 - Repair & Assembly. There were a few things that I left out of the video, but 99% of the rebuild is there. I won't put them all on here moving forward. It is not my intent to use this forum as a platform to promote my own content, but I do greatly value the opinions of those on here who have much more experience than I do, and appreciate any feedback you may have. I'm not trying to be a YouTube star, I already have a steady job! I just figured that anyone who may have watched the 'Part 1 - Disassembly' video might want to see the watch completed. I figured I'd post this one so you can at least get some closure, haha!! I think I made a better video on this 2nd attempt, at least from an editing standpoint.1 point

-

1 point

-

1 point

-

I've just been doing that exact job this morning - pegging pallet and escape wheel holes Just getting the tip sharp enough to go in the pallet hole is difficult, then it immediately breaks, and start again argghh0 points