Leaderboard

Popular Content

Showing content with the highest reputation on 02/05/23 in all areas

-

Thats the sound of the CLICK, and hearing it (typical noise ) indicates ratchet wheel turns. Not winding indicates either a broken mainspring or disengaged arbour hook from mainspring eye. The barrel needs to be pulled/ lid removed to check its inside. Your watch is a variant of Ronda 1223 with alarm complication, thats what makes it collectable, not pricy so might not be worth a new mainspring if it needs that. A used mainspring which can be out of other variants as well is economical and you can do it yourself. We'll work with you to fix it, don't hesitate to ask questions please. Rgds3 points

-

One of the problems and watch repair is the assumption it's like automobile repair and detailed manuals are available for every single watch in the universe. Reality is if you're lucky you'll find a parts list. Really lucky the parts list might actually have pictures of the parts and then if you're extremely lucky there might exist some sort of technical documentation that you might actually build a get if you're lucky. Looks like you're extremely lucky or you're just lucky I remembered something to find you there is a link and I snipped out an image. So at the link you scroll to where you find that the second link that says 170 that switchers seeking. You'll find it's a complete service manual independently written on this particular watch. https://www.watchrepairtalk.com/topic/10501-custom-build-using-venus-170/2 points

-

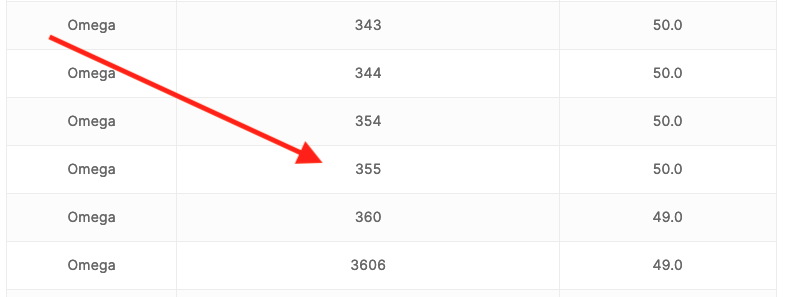

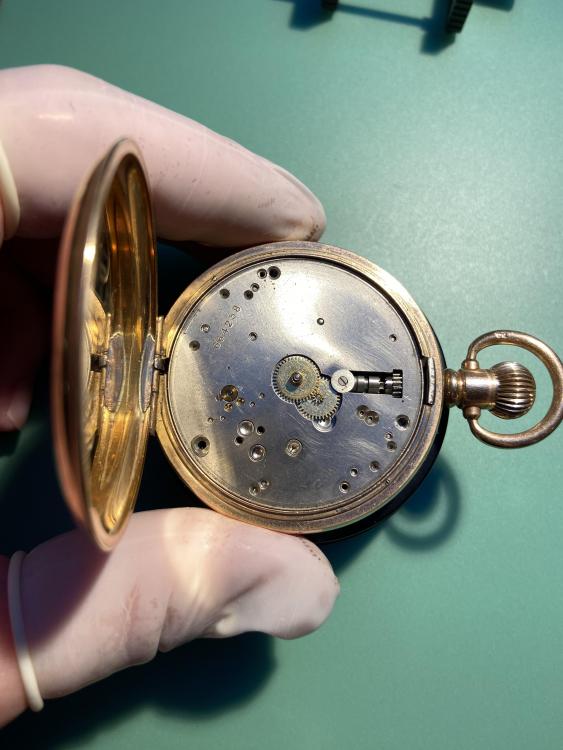

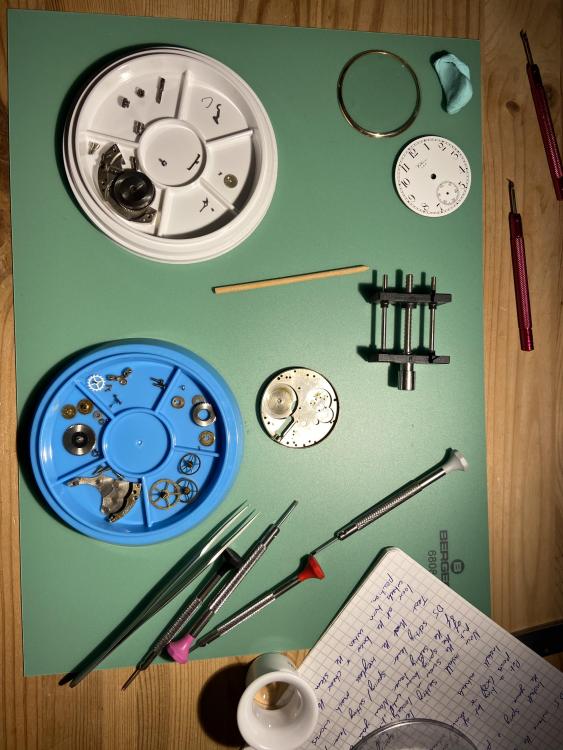

Yes, I've seen that list too. Perhaps in this list they didn't bother with the comma or the dot and describe it as a 355? Anyhow, it is indeed from this list where I took the assumed 50 degrees from Currently the movement is in parts and if in the meantime no info is found, I'll find the lift-angle via the 180 degrees amplitude timegrapher trick.2 points

-

1 point

-

1 point

-

Are we talking about a plate jewel or some other jewel? Then for plate jewels usually what you do is put it in and check for end shake. If you don't have enough because the jeweling tool has micrometer adjustments you adjusted a hair and push the jewel a little more easily get proper end shake. Then at the link below Is all sorts of interesting things to download. But for this discussion scroll down to the section titled Joseph School of Watch Making. You'll notice there's a section on putting in jewels but rather than just download the section you can download the entire book. Sooner or later you're going to need other information in the book anyway. https://www.mybulova.com/vintage-bulova-catalogs1 point

-

Both of these are excellent things to have. Then ideally you want both of them not one or the other. The micrometer is just good for all kinds of things not just pivots. The pivot gauge is nice because often times people measure the pivot and will pick a jewel it's too tight. Where we drop it into a hole you can see if it feels right you basically get a better feel for whether the hole sizes going to be correct or not.1 point

-

If it's a chronograph you're probably screwed. Usually anything that's delicate and breakable which would be what a chronograph Has whatever was breakable was broken a long time ago and there's no more spare parts left. Which is unfortunately why when you look at eBay you'll see watches disassembled for the parts because the parts are worth way more than the movement itself is worth.1 point

-

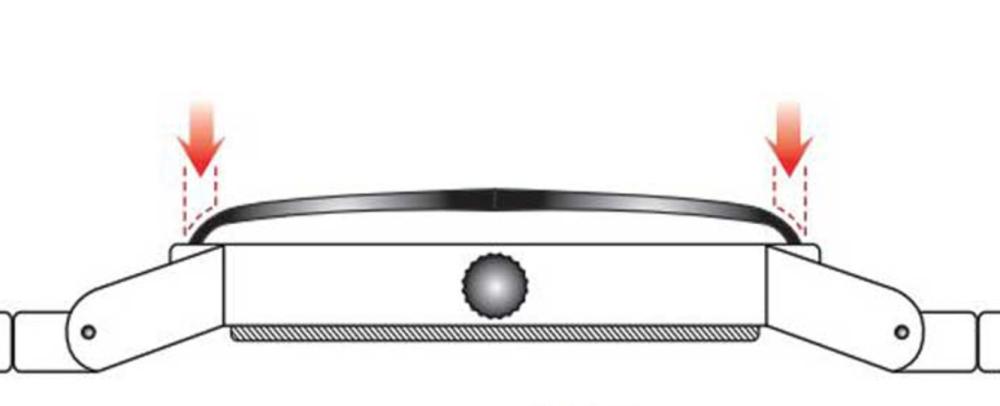

I've seen people claim that the ball used for removing screw backs can remove Rolex backs but if the back is on really tight you do need the tool. Another thing the use rather than superglue is epoxy. The interesting thing with epoxy is that if you drop the back a pot of boiling water then there is no problem taking off whatever's glued together. I learned that trick from the material house the used it before removing crystals that were epoxy in the epoxy basically gets soft.1 point

-

Hello Mike, welcome to the WRT forum. You are brave to plan attacking such good grade movement, couple of cheap pieces would be better choice to pratice on, best to get you two movements of same caliber to save on spare parts too. Rgds1 point

-

Type into google what is the best type of lacquer for brass and it will come up with many brand names and I hope you can find one near you. Lacquer for wood is no good for brass. I don't think you will ever get the colour to match the dial, going by the photo it looks something from off white to a very silver almost grey looking. You might have to mix and match.1 point

-

All good suggestions as to the cause tiktok. The keyless works and added complication of the alarm looks somewhat tricky compared to anything basic. So take your time and plenty of close clear photos before the removal of each component, especially any spring postions and their orientation. Also make notes to supplement these.1 point

-

Hi the mark suggests its a Ronda 1223-12. with the back off and watching the ratchet wheel when you turn the crown does the ratchet wheel turn if so as Kalanag said points to a mainspring. If it does not and the keyless work just grinds your problem lies within the keyless work. ie crown wheel etc. A parts /tech sheet can be found on cousins uk documentdownloads. for some reason the one I have will not upload.1 point

-

Thanks for letting me join the group. Like many I found this addictive hobby through watching Mark's videos & Then signed up for his online training courses. I'm about to retire and so buying up a bunch of tools while I can still afford to!1 point

-

I was thinking because the age isn't super vintage it may be best fit does have it listed. So what online and looked and they do have a 35.5 and it gives some part numbers so I went back to the bestfit book the civic you get dimensions for those part numbers and sort of. Then there's a minor mistake in the fingerprint system is says 33.5 but it's supposed to be 35.5 so if your fingerprint matches the 35.5 in the image then all the parts should be right. It looks like the 35.5 shares parts 39.5 which is helpful if you decide to break a pivot and you need a balance staff I was thinking about it I went to the watch stem site and did get you stem dimensions that's another way to verify your watches just to measure the stem size and see if that corresponds. Of course it still is not going to get you technical data comes technical data didn't exist back then because there was no cheap relatively cheap timing machines.1 point

-

1 point

-

1 point

-

1 point

-

Indeed, I'm certain that I paid quite a bit more than that for the one I purchased.1 point

-

1 point

-

Depends on the model. Looking at the Tudor website the model ranges that do not state "chronometer" or "officially certified" are the Ranger, Tudor Royal, 1926, and Clair De Rose. LWS's watch looks similar to the styling in the 1926 range, although the current range appears to feature at least some numerals on the dials, I can't see one that is batons only, so the jury is still out.1 point

-

If you're looking for someplace to buy crystals here's somebody who Should be able to help http://whitescrystals.com/1 point

-

I do know that some of the companies will look up the serial number of your watch but you have to give them a little money but let's Google and see what we find we find a link like this https://www.vintagemasters.eu/omega-serial-numbers-check-and-verify/ Then you can go here but it's unhelpful as you need to go to an Omega boutique and they can look up your authenticity and yes I'm sure it's my costume little money https://www.omegawatches.com/en-us/customer-service/certificates-and-extracts Then it looks like they have some boutiques in Denmark. https://www.omegawatches.com/en-us/store/country/denmark I like I've said this before I've seen this come up with Omega's where any of the vintage pocket watches are doesn't seem to be any way to find anything out on them other than I think the first two numbers are size reference. Because typically only get parts listings if parts were available. If you are searching for a balance staff it would be helpful to have the dimensions because often times you will find that they use the same balance staff for several different watches. How do curiosity has looking in the bestfit book more Omega pocket watches and they have clocks listed a couple of those they don't actually say the word of pocket watch and they don't seem to have anything big enough to be a pocket watch. So basically we just need of vintage material Log before bestfit1 point

-

@nickelsilver Thank you for further explanation Exactly this is what I meant with the "180 degrees amplitude timegrapher trick". Perhaps it was just my illusion that Omega, everything they ever produced, was well documented by them; guess not An illusion less, an experience wiser Everybody, thank you for your time & help1 point

-

I was referring to the guideline for testing if a spring is "set". The spring looks a little long. I'm wondering if it would be possible to cut off 2 or 3 coils then anneal and reshape the cut end. But looking at the coil, it should be able to take a lot more than "two or three" winds. I think the problem lies elsewhere.1 point

-

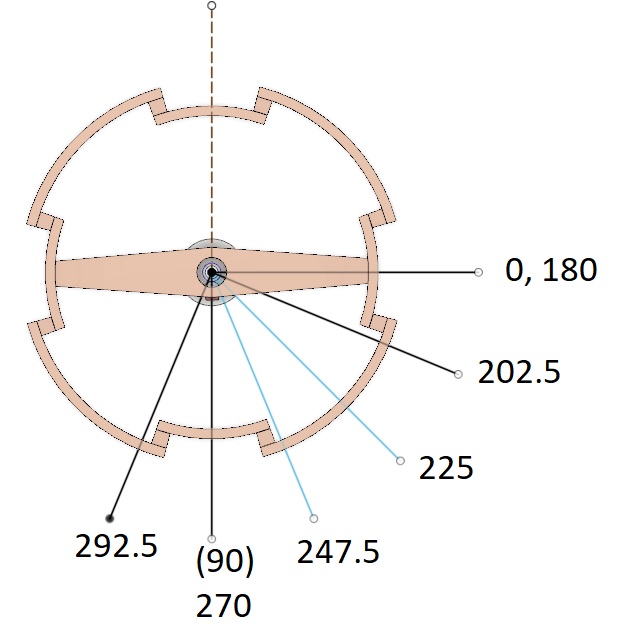

You will encounter many watches with an unknown lift angle. The best thing to do is to learn to see the amplitude by looking at the balance arms. It's very easy with a 2 arm balance: from unwound, wind a tiny bit, just until the arms are coming right over the pallet fork, this is 90 degrees. Continue until the arms are switching places, this is 180 degrees. From there it's a matter of visualizing the further degrees; if it makes it to the arms directly over the pallet fork that's another 90 degrees, so you're at 270. Halfway there, another 45 degrees, so you're at 225. It's not too hard to divide a 90 degree quadrant into 4ths, you're in the realm of 20 degrees there (22.5). I've found that the listed lift angle is off by several degrees or more just double checking the balance visually.1 point

-

1 point

-

Hi NEW. A nice little hand full there for the right price, well done1 point

-

Hi as Mikepilk stated I have attached the tech/parts sheet for you 923_Venus 170.pdf1 point

-

1 point

-

Limit ‘junior’ model w/Revue cal 56. A little pricey for 404 but it was a no reserve auction non-runner I won for 8 GBP. The mis-threaded case back was fixed with a glued flange nut. Cleaned up and new main later it is running fine but a little fast. I may fiddle a bit with it later but the wife wants it and may not care it’s a minute off by days end…1 point

-

As @xyzzy suggested, I just soldered a lead to SPK (GND) and R3 (tricky!) and managed to feed it 5V from my power supply. The voltage at C1 is still about 0.3V. I put the meter in one of the lines to read to current, which appeared zero, or close to it (I need to solder the connectors on my test leads, they are cheap rubbish, so I was getting fluctuating results). It may never work, but at least I'm getting some enjoyment and learning something from the testing I am an engineer (aero) but feel totally stupid and clueless chasing electrons around !1 point

-

1 point

-

1973 Bulova model 11636-8W with an 11AOACB movement on (I believe) the original bracelet. This one looks to be the same as the Ambassador model but was sold overseas and lacks the "Ambassador" model name on the dial. I didn't think I would have a hope in hell of finding a new crystal so I was lucky that it polished up nicely.1 point