Leaderboard

Popular Content

Showing content with the highest reputation on 04/26/22 in all areas

-

They're bolts, the slot is aesthetic, but they do go through the case and are fastened with nuts through the back.2 points

-

As a matter of interest, when I took it to an honest watch technician, all it needed was a cleaning. The gasket was fine, and the movement did not need to be replaced. I was lied to by the first shop I took it to.2 points

-

2 points

-

Well, you certainly can never have enough watches. That is one thing i have learned(; I have probably worked on at least 200-250 watches by now. Everything from Doxa, Timex, Lagonda to some nicer brands like Omega, Longines, Zenith and now recently some chronos. I would say that I am really good at standard mechanichal watches with simple complications such as date, day, automatic works and so on. I understand the basics. I am however a beginner on chronos. Ever since I bought my dream watch, a speedmaster, I have wanted to start servicing chronos. After About 3 chronos, all with landeron movements, I am starting to sort of get the hang of it! I started a small business out of this and recently launched a website. I wont advertise myself but since I have managed to sell many watches I have worked on I have managed to buy a nice arsenal of tools. Some really nice bergeon screwdrivers, Dumont tweezers of some different sizes, a nice vintage crystal press, a reaaaally nice Olympus microscope, a vintage Elma Super Elite if I remember the name correctly and all other basics. My personal watches are however few. I am very picky with what I wear. My favorite is my 2020 Speedmaster Sapphire sandwich which has been my dream watch since I was 13 so I saved up by selling watches and some other work and managed to buy one at 15. my second favorite is my modded Seiko skx031 from 2008 with some thin mercedes hands and a wonderful chromed-matted aluminum pepsi bezel. Of course I also wear my newly aquired vintage Ledian chrono from ~1950 with a newly serviced Landeron 48. lastly I have a Certina Blue Ribbon Volvo 50th anniversary from the seventies in absolutely incredible condition!2 points

-

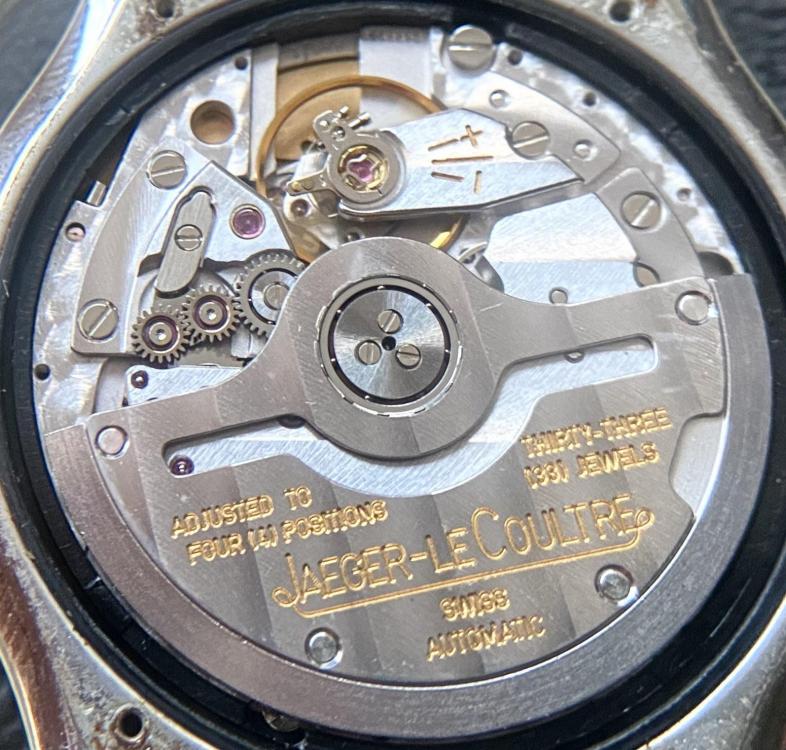

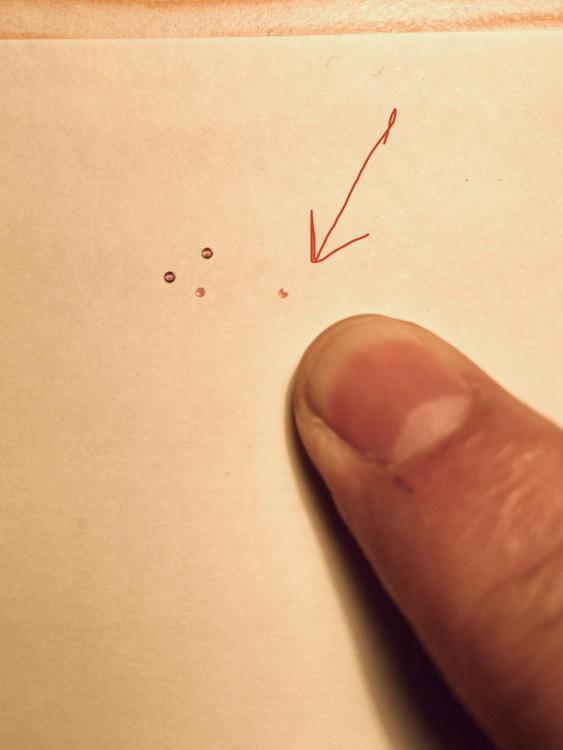

My JLC Heraion with caliber 889/1 needed a service. Having gained experience with several other (cheaper) watches I decided to try it myself. Being totally aware that I wouldn‘t get any spareparts if something might go wrong I was willing to let it serviced by JLC (about €800,-) if an accident should happen. Preparing my work I found a technical guide for the partially identical 928/2 at cousinsuk and a workthroug by the WatchGuy (AP Royal Oak with JLC 889/1). I designed a movement holder with a free CAD program and 3D printed it with my Ender 3. This holder supports the movement much better than my vice type holders. I didn‘t put me under time pressure in any way and just worked on the movement when I felt totally relaxed. A week later I had successfully disassembled the movement. Some screw hads unfortunately showed that I was not the first being inside this watch. The jewels of the fast reving wheels were totally dry and clean (!) showing that modern oils don‘t gum up but do eventually evaporate. I successfully cleaned the parts in pharmaceutical petroleum ether 40/60 and One Dip. The escape wheel and the pallet fork got epilamed. What happened to be the most challenging task was handling and oiling the super tiny capstones (0,9x0,12mm). One of them slipped out of my tweecers. My heart stood still for a moment. After hours of searching I gave up. I suspect the tiny particle landed on my clothes, skin or hair where it couldn‘t be seen. After some research I found that it is a standard KIF 508 which I could order with Boley. This time I was lucky For oiling the combined stones (fixed cap) of the escape wheel I found help in this forum. Meanwhile the watch is ticking healthy again and shows good results on the time grapher.1 point

-

Hello and good morning, Just to say I find the new background a lot easier and not so hard on the eyes. brilliant. And as regards the moving question which Mark quite rightly nipped in the bud, I think Old Hippys suggestion is probaby the right one. One cannot please every one but as said a compromise has to be found and informing the member his post was moved and why is a good compromise. I am sure that we all have faith in our Administrator and moderaters to find the solution and continue to provide a brilliant forum which is open minded and informative. Thank you Gentlemen your work is appreciated.1 point

-

Speedtimerkollection.com in europe is a mine of second user bits as is welwynwatchparts.co.uk always worth a look when hunting spares. good to have them on your system.1 point

-

He showed the grease pot where definitely „8207“ was written on in one of his videos. Kalle always repeats his credo that there ist no best method and that every watchmaker should follow that procedure that gives him the best results. Oops Paul was faster1 point

-

Yep it was 8207, he showed a closeup of the bottle he was using and the number was clearly visible.1 point

-

Ask Kalle, I'm sure he has an answer. I'm curious too if his aversion to ultrasonics is due to the 2k+ price increase on the ACA900 cleaning machine with ultrasonic. Or one of his mentors who cut his teeth prior to commonplace electric motors told him "it's bad". US has been the defacto cleaning method for watches for 60+ years. He also epilames the whole pallet fork. 40 years ago was ok, from 20 years ago not ok. Why? "They" figured out it was better to just do the stones. YT is great, but it's not all great content1 point

-

1 point

-

1 point

-

I’d say that’s a fairly avcurate estimation. Ever since I started watchmaking I have been tinkering with watches more or less every day when I have been at home. Some days more than others of course but I find it extremely calming and a great way of passing some time(: i but a lot of non working watches on auction sites and sell them there too for a small profit allowing me to always buy new tools wothout losing money.1 point

-

1 point

-

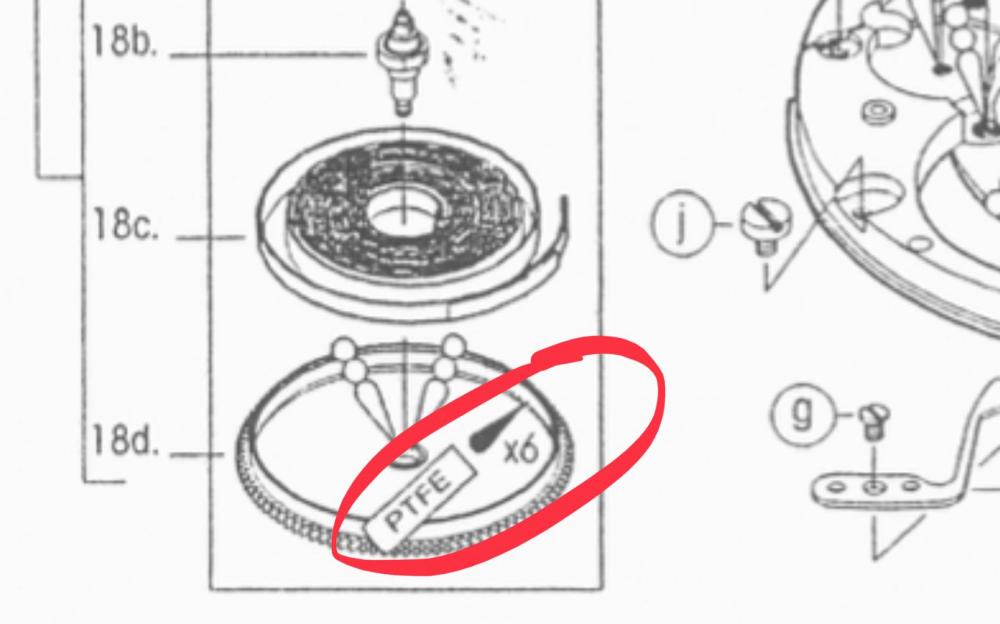

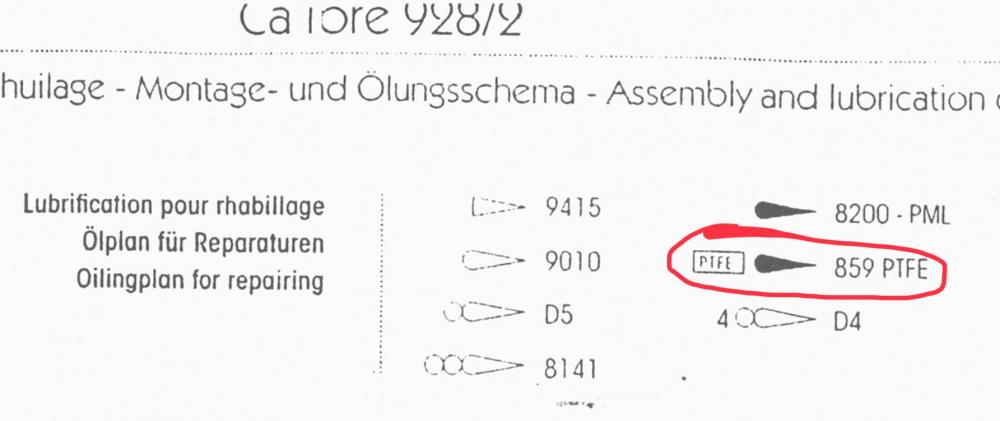

nickelsilver, I highly respect your knowledge! Please tell me, why 8207 is wrong when it seems to work well in a professional workshop. I‘m confused about the braking grease discussion. The technical literatur of JLC recommends the clock oil „859 + PTFE“ for this application. This is also not specified as a braking grease and lets me assume, that each thick grease with a dry lubricant additive (graphite, PTFE, MoS2) should work. I once used Molykote DX (PTFE) in a rlx 3135 clone and got 42h power reserve. Eventually I will test an automatic watch with different barrel wall lubrications and report here1 point

-

Haha yes it's extremely accurate but only twice a day. My guess is the seller was just a little bit shy on the truth. Its kind of nice looking though in a dodgy non genuine wasted some money kind of way. Nice bit of shellac as well, I could french polish two mousemen sideboards with that.1 point

-

Apparently this is typical of the Mumbai Specials If it works think yourself lucky but don't panic it won't work for long. I have been know to pick up the odd cheap one, £10 max just to get a movement for spares for another watch I was working on. I think there is a watch conspiracy on eBay, sellers selling watches that have a hidden history and end up not working then under another of their many user names sell you a movement so you have some spares to put the first one right. Mind you its not just the Mumbai sellers doing this, over the last year I have bought quite a few watches and movements on eBay, mainly from European sellers and not one of them has been an honest unadulterated watch, all once stripped clearly had a hidden history, even those claimed to be virgin watches that they have owned from new, once stripped had clear signs of someone having a fiddle at some time in there watch past, damaged screw heads, scratches from a lest than careful stripdown, parts from a gold watch in a silver watch etc. I do enjoy some of their descriptions like for example a new never been worn watch that in the description had the case and back replaced because it was rusty, a strap replaced with an after market one because the original was scratched, the dial repainted because the old one was water damaged but still insist its brand new and unworn. Just treat watches you buy from that region as potential parts watches. You a search on YouTube there are videos showing the conditions in the backstreet watch Shops that would make you cringe, with buckets full of parts just sitting in the open in their dirty and dusty shop and a stack a mile high of boxes of repainted dials, with the watch assembler just putting movements together with old junk quality tools and not a drop of watch oil anywhere to be seen.1 point

-

I would like to thank WW and JohnR for your wonderful links and advice. This is truly a amazing forum you all do the watchmaking Hobbyist a wonderful service, people in this family of watchmakers a great service. I can't wait for a time when I can repay the depth of knowledge that is given freely. again big thank you1 point

-

1 point

-

Same for me and everyone else I would guess. Looks pretty nice (I like it) but I would have preferred the old black on white as it makes it easier to edit text. Selected text now turns blue, and it's difficult to see.1 point

-

That’s a lovely pocket watch, I’m always jealous of the American movements as it’s so much easier to find parts. My collection of English and Swiss movements are such a pain to find parts. A very old watchmaker once told me to wear even my broken pocket watches and if anyone asks the time just look surprised and remark ‘oh it must have stopped’1 point

-

Hello T I would take a look at the Ranfft web site (google Ranfft seiko 7019) and you will get a page on the seiko including all the family generations which may also contain the parts you need as a donor. fron what I looked at the 7009A is compatible., so it may widen your search and opertunity for bits. To that end I have attached the sheets for the 7019 and the 7009A so you may compare the parts and numbers. hope you dind it usefull cheers. 599_Seiko7019A (1).pdf 277_Seiko7009A (6).pdf1 point

-

Ideally when you're starting watch repair it would start with something that's less complicated. The classic thing that we recommend does the Chinese clone of the 6497. A larger basic watch that you can practice on and it's running because you're purchasing a brand-new. This way in the midst of taken apart and putting it back together if it quits running it makes it easy to point the finger at whose problem is that. Versus starting with a watch that wasn't running thinking you can fix it and then deciding it still can't be fixed because you didn't have the skills in the first place versus mysterious breakages along the way. Then there's the other problem of if this is its original Swiss watch is always the likelihood that things might not actually interchange. Plus the clone watches tend to just have problems. Because whoever cloned it usually cloned it at a much lower cost and they didn't really mean for somebody to be repairing it down the road you can end up with issues Out of curiosity what country do you live in?1 point

-

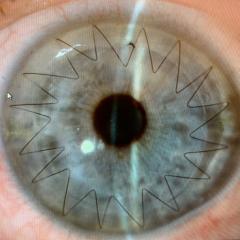

Thank you for the welcomes. I understand that this is a horology and not an eye forum but I have something that would be of special interest to Nucejoe and his family. Attached is a photo I have used in teaching to demonstrate a rejection line in a corneal transplant that is referred to as a Khoudadoust line. Something for your relatives to be proud of.1 point

-

1 point

-

Well...it is about the journey, not the destination. I show the progress here in this figure, but there is a problem. The dimension for the balance beam hole specified did not work for my balance. Probably been wallered out over the years of repairs. Instead of 120, I get 133. Discovered that AFTER the cut. I can save it by going back to the pivot and working inward.1 point

-

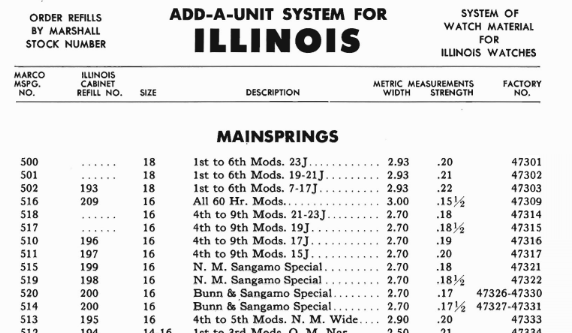

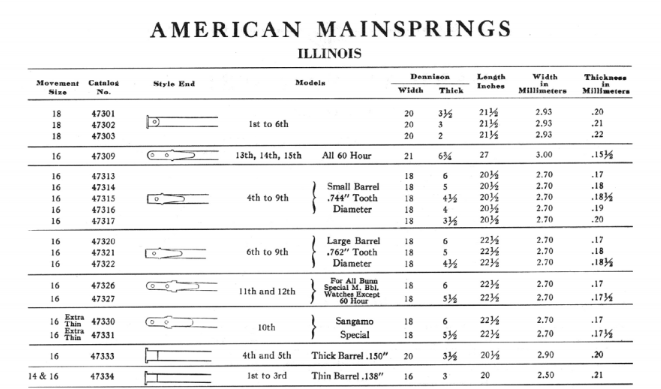

I'm not sure if it has a technical term but basically it's a cascading failure. According to Elgin the reason why this occurs is because somebody touched the mainspring with their hands. The bad chemicals in your hand react with the steel and cause rust and that causes fractures and then the spring breaks. The other problem is the metallurgy may not a been the very best at the time the spring was made except? I've seen the exact same thing happen to a Rolex watch with a modern spring that was covered with rust. Athletic basically when I wound up nice and tight one coil just one place breaks and the break ripples right across the whole spring. There are liquid rust removers some specifically designed for horology that will remove the rust. Typically there time-limited if you leave it into long it might turn all the steel parts blacked that's very undesirable. I think some people on this group recommend Coca-Cola because the acid in that is equivalent to the rust removing chemical and I think I've heard other people use strong tea As supposedly that will take rust off but I've never tried either. I have tried the liquid rust remover that I bought a long time ago and it did take the rust off. They hairspring doesn't look as bad as some I've seen if you do take the rust off the hairsprings been compromised so it won't be perfect but considering the rest of the watch study pretty good can you get a new hairspring may be? Elgin hairsprings were premade but matchstick each balance wheel we can probably figure out which one it is and then you'll still have to match it. In other words even if we had the exact replacement you'll have to play with timing screws to get the balance to match the hairspring For the balance wheel how much lathe work do you do? You could replace just the pivots if you're really skilled. Otherwise it replace the entire balance staff. Or if you a time machine you can go back in time I get a balance completes because we get a balance complete now you have to cannibalize something else to get it probably or if somebody sells you one off of eBay they've already cannibalize the watch for you. But on pocket watches swapping parts isn't necessarily what you want to do is a do not necessarily interchange. For instance when you change the balance staff like for instance http://www.elginwatchparts.com/ If you go to the link above and enter in your number 417 we get a parts list with problems? Microphone off Balance staff as you can see we get a part number and a warning note? Staff number 869 and something they don't have they refer you to something else? This is because there's almost always variations especially with Elgin staffs variations will be by pivots size always for almost every single staff and then the be other variations. Good news is the only have three different balance staffs just different pivots sizes. Apparently this watch came as either a single roller or a double roller in the staffs the same. Then the balance jewel is sort of easy it's held in with two screws. Take the two screws out push it from the inside pushing out there is a end stone now come off separate and then the hole jewel. At the website above you can get a part number and of course with the part number you also need the size corresponding to the pivots size of your staff. If you had access to modern jeweling tools you to just smash out the hole jewel agreement out from modern jewel and put that in. Then I really can't tell From the pictures how badly rusted the Canon pinion is it may just clean up in the same solution you can use with the hairspring. Then you can try this place for your watch parts https://www.daveswatchparts.com/index.html For mainsprings I usually get them for my local material house but everyone else said recommend eBay. You can usually always find American pocket watch mainsprings on eBay. Balance staff be purchased at the link above you may have to ask otherwise eBay would be a good source again. It's amazing how much American material can be found on eBay in the US especially Elgin.1 point

-

Was there one screw here or two screws? Sometimes the crown wheel is a left-handed screw and it's not always marked as left-handed. But looking at the walk-through that I found it looks like there's supposed to be two screws https://www.watchrepairtalk.com/topic/2309-eta-7750-service-walkthrough-the-industry-standard-chronograph/ Then it worst-case if the screw won't come out providing we can get all of the steel parts off the plate that it's in we can dissolve it out which is what I've usually done for Broken screws that don't want to come out. Sometimes when they break you can still unscrew them if you're careful sometimes there out far enough you grapple with the pin vice other times dissolving was the way to work for me but you can't have any other steel Pieces on that part or They will disappear also1 point

-

Ahh the joy of old pocket watches, eBay will be the answer to most of your problems. That and time and Patience I have repaired jobs and I’ve waited years for parts to show up. Keep cleaning the hairspring you may get it clean, but I do sometimes see hairsprings come on sale. The main spring you should be able to buy from Cousins, the balance staff you will probably have to make yourself. Keep an eye out for donor watches on eBay you might find everything you need.1 point

-

Hi. For getting screw out that have just snapped and are not rusted in I have so for been lucky that the bit left in the plate just simply unscrews just using the end of a suitabley sized screwdriver to tease it out. Obviously that rarely works if the crew snapped because the threads were rusted solid. There is a Bergeon tool that grips the screw between two pins and the plate is then rotated to unscrew the broken bit. For a Bergeon tool it's not overly expensive and it's available from the Chinese factory for a lot less, I have seen it for around £35 and there is a cheaper Chinese version that's about £15 but that used miniature end mills to grip the screw which may be a little too brittle to function reliably. .1 point

-

If as you suspect its been glued/loctited a little heat will release the glue but not too much heat. as you warm it up keep tyring to move it.1 point

-

Yikes! I wonder how that mainspring failed like that? I'm also working on a couple of old Elgins. I would think that the easiest way to solve your issues would be to find a donor movement. I more closely examining my first grade 313, I've also detected damaged jewels and rust on the hairspring. I'm going to follow this to see what the experts have to say.1 point

-

Thank you WW and NEW I did write a long long reply but deleted it so I didn't look BLUNT just to keep the friends I've made on this wonderful forum1 point

-

Hi T the bestway to store a balance is to lie it on its back with the balance upside down on the cock and cover with a glass. There are all manner of balance holders , some good some bad. If you are adjusting the collet , the tool shown and suitably modified aka Hector's post so the balance is held on the device and the post adjusted to support the balance and get the spring to lie in its horizontal plane at rest. I dont think the balance springs of today are as soft as those in the past. The damage is done when the balance is left hanging with no support for an extended period. The safest and cheapest way is to put it on its back.1 point

-

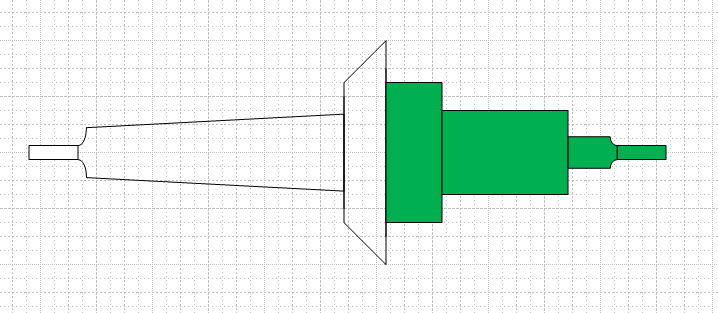

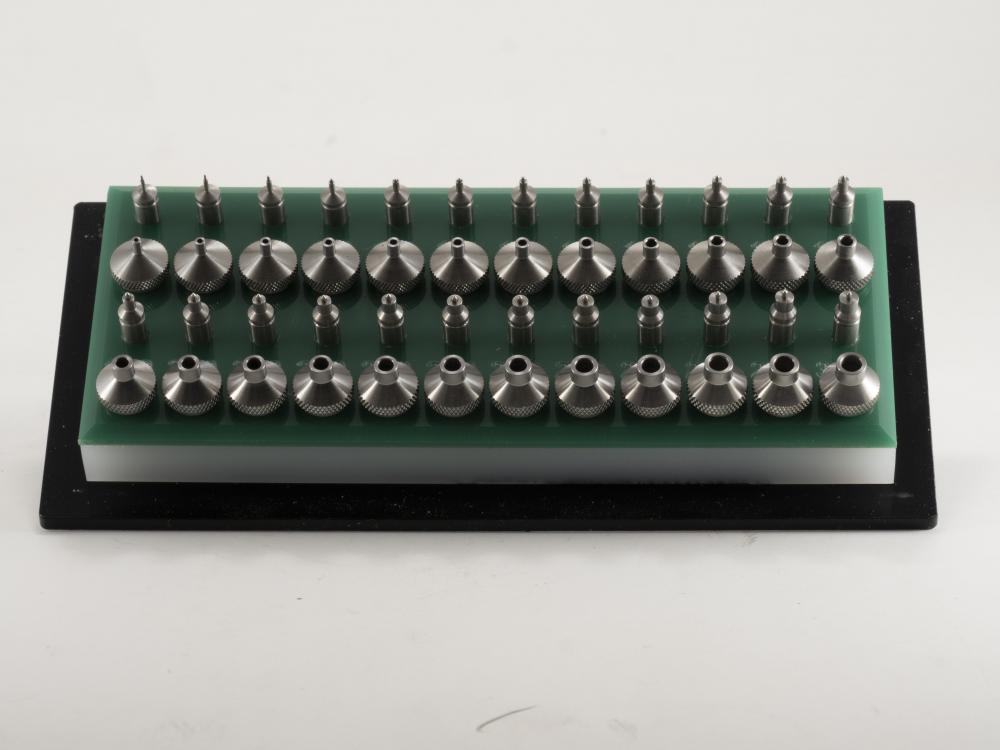

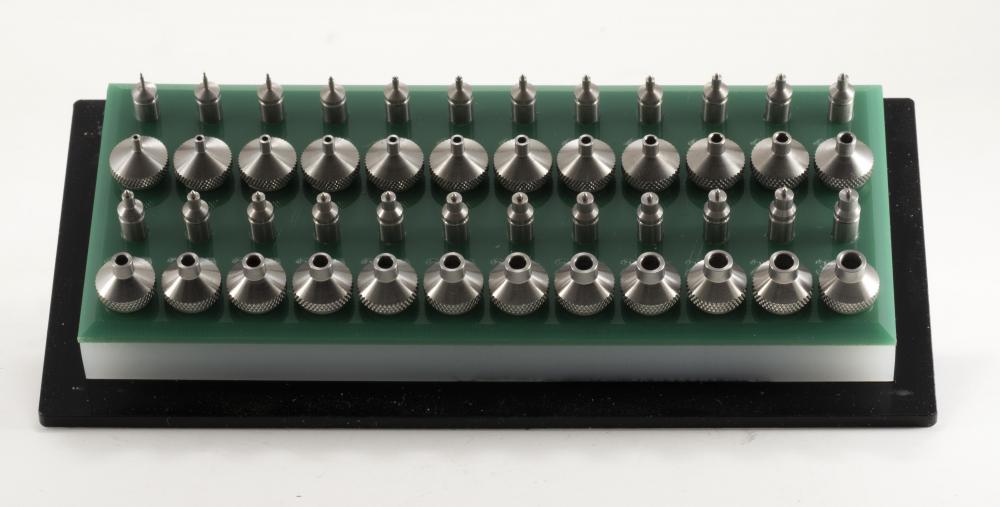

Hi all Time for the next tool in this series This time is the good old Jewelling tool Seen before on the forum but still well worth a second look here. Again from Aliexpress for £117 for the tool and a nice selection of 24 pushers and anvils which are all well made and seem to do what they are supposed to do, https://www.aliexpress.com/item/4000261581571.html?spm=a2g0o.order_list.0.0.119c1802OtQ8wu Obviously a clone of the well known Horia tool but a well made tool none the less and at a fraction of the originals asking price. Not used it in anger yet but have used it a couple of times to adjust end shake and that function was performed faultlessly so doubt a jewel replacement will be an issue for this tool either, once a replacement jewel has been found that is. Thanks for following this thread. Paul1 point

-

1 point

-

When I have needed to move a post I always message the member explaining the reason and wait for an OK. That is I think the polite way to go.1 point

-

Closing this thread - we are going to have an internal discussion on this and see if we can come up with a compromise.1 point

-

Cleaned up the thread a bit as it was going seriously off-topic - out of respect for the OP and other people who follow this thread - remember, emails are sent to all subscribed to this thread after you post and they might not be interested in personal conversations - those can be executed via PM1 point

-

Unfortunately, it appears the delta between CL and CR is here to stay. For some reason, when I rotate the regulator stud, the inner prong contacts the hairspring, but there is still a gap between the hairspring and the outer prong. Further rotation of the regulator stud doesn’t help. Interestingly, if I rotate the regulator stud even more so that the hairspring doesn’t bounce between the prongs of the regulator stud, the amplitude isn’t affected, but when I push the regulator arm closer to the hairspring stud, the amplitude suddenly drops from 290 to 180 suddenly at a certain point. I suspect there’s a slight twist in the terminal curve somewhere, since this isn’t supposed to happen...1 point

-

I just asked a friend who does work for AP, he's not in the shop and can't remember exactly but around 3 minutes he said. He checks the forks anyway and puts new shellac if/as needed. With my old Greiner machine that distilled, the manual recommends 30 seconds for the balance and fork in freshly distilled (and very warm) alcohol, then the rest of the parts go in and get rinsed for 10-15 seconds in the same alco bath, the bath gets dumped, and once it refills after about 6 minutes, that's it. The only time I ever had an issue with shellac dissolving in the Greiner was if I left the fork in for quite some time. Depends on the age of the shellac too; a fork I had freshly re-shellacced would lose its shellac much more quickly than a lot of older ones, but really old forks might lose it as fast as freshly applied. One thing that simply hasn't been an issue over 25 years of doing this is pallet stones just falling out after the shellac is removed (intentionally or accidentally). In fact, if I really have to dig in to an escapement adjustment the first thing I do is remove all shellac, make my adjustments, including running the watch, then re-apply when I'm happy with it. I understand there are some forks out there that are loose on the stones, but I haven't seen one.1 point

-

I quite like the look of that tool and may get one to modify. I’m still surprised at the number of people who are paranoid about deforming hairsprings by suspending the balance wheel by the spring. In my experience, there are few balances which are heavy enough to cause damage if you handle them carefully.1 point

-

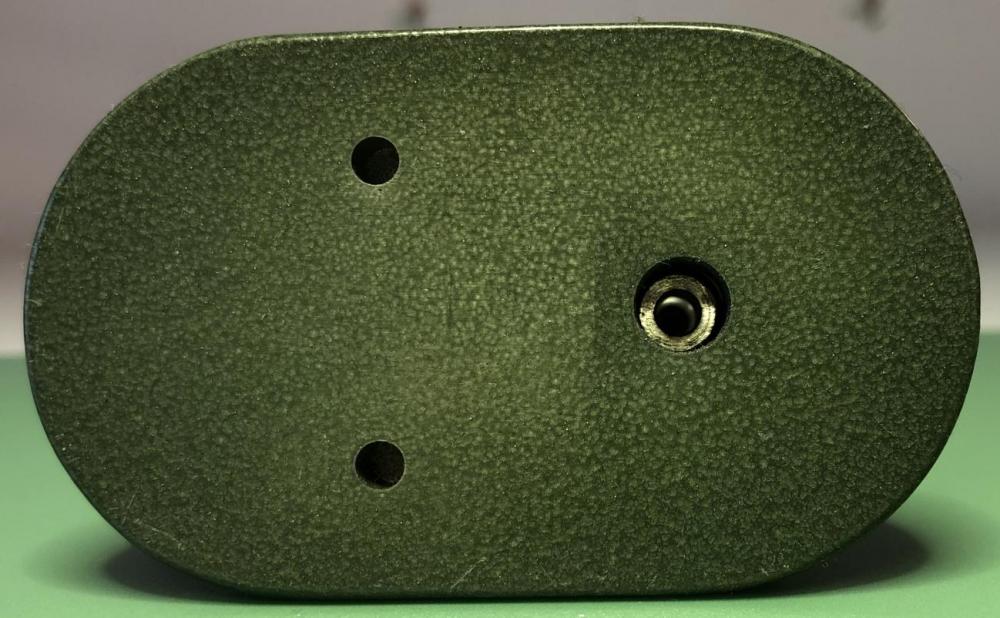

A couple of weeks ago, or so, I got my AliExpress Chinese Horia jeweling tool clone having 24 pushers and 24 anvils. So, it took approx. a month for the package to arrive. That's a lot less than I had expected. Another pleasant surprise was that it wasn't delivered from China but from the Netherlands (another EU state), so no additional fees had to be paid. Yippee! Anyway, it wasn't until today I had a chance to take a really close look and give it a try. Here're some pictures... (Click to zoom in!) Unlike the Seitz jeweling tool this tool does not have a "threaded cup" to catch the jewels pressed out all the way Anvil bottom-side Anvil top-side Pump pusher Pump pusher bottom-side (spring held in by screw having a slot) Pump pusher bottom side (spring held in by a hexagonal screw) Overall, I must say everything feels very well made and exceeded my expectations by a margin. Why some pump pushers uses a normal screw and some a hexagonal screw I have no idea, and I didn't try to remove any of them. The screws look like they could be made of plastic and they don't look all that nice. I don't know what the original Horia pump pushers look like, but the Seitz pump pushers are, is this respect, of a much better design. I measured the diameter of five randomly selected pump pushers and they all had the given diameter minus approx. 5/100 mm, which of course is necessary to make them pass through the holes for the jewels in the plates and bridges. I also measure the foot of a few randomly selected anvils and they all came in at 3.99 mm. So, as an added bonus the anvils and the pump pushers fit perfectly (near zero shake) in my Seitz jeweling tool (and in the clone tool) as well. Nevertheless, after having adjusted just a few jewels I already prefer this type of jeweling tool. With the Seitz tool you must always assert pressure on the handle, but since the Horia type uses a screw it frees up one hand and makes the operation feel both more precise and safe. The only drawback, of course, is that the Horia jeweling tool can't be used for reaming, so for that reason I'll be keeping my Seitz. Using my caliper I also measured the distance between the anvil and the pump pusher, then rotated the screw 360 degrees (1.00 mm) and measured again. The difference between the first and second measurement was just a few hundreds of a millimetre (minus the added millimetre of course) and my caliper is naturally not as exact as my Bergeon micrometre. So, it would seem the Chinese got the threading on the screw just right as well! Conclusively I must say that my very first AliExpress buy of a watch tool was a (somewhat unexpected) success and I wouldn't hesitate one bit to recommend this tool. The finish is not up there with the Swiss (Seitz and I would expect Horia), but it does what it's supposed to and it does it well. And, considering the price difference between the original tool and this clone, I'd say this is a no brainer, especially if you're a hobbyist.1 point

-

Mark Lovick teaches on the Unitas 6497, and for good reasons. Purchasing and following his Hi-Res training is the best way to learn1 point

-

If you want to get into manual watch repairing I always suggest you start with a pocket watch, they’re a lot bigger than a standard manual watch movement, you learn how to take it to pieces and put it back, you don’t need to bother about repairing it just practice, this will help you in using your screwdrivers and tweezers. Get to know what the parts are called. Do not work on fusee pocket watches, as those are completely different to manual watches1 point

-

I recently bought a watch cleaning machine from a retired watchmaker, when I collected the machine the jars already contained solution, the watchmaker told me the rinse jars contained isopropanol. I did ask him what effect on the shellac holding the pallet jewels would the isopropanol have, saying I would be worried that it would dissolve. He said he had used it since Benzine had been unavailable to use, and as long as I rinsed for no more than 15min in each wash there would not be a problem. He also said it was very quick to evaporate in the drying stage and left no residue. I have ordered new cleaning solution and rinse solution from Quadralene and intend to use these. I have though cleaned 4 watches last week in the solutions in the machine and have not had a problem. Today I decided to test and see how long it took to actually dissolve the shellac, The image above shows 3 Russian and one Swiss set of pallets and the shellac can clearly be seen. I have been using the solution for 15min each rinse and have not had a problem so I put the pallets in a isopropanol rinse for 1hr to see what effect it had On the Russian pallets it has greatly degraded the shellac and almost totally washed it away on one, but on the Swiss pallets it has not even touched the shellac on those. I will not use isopropanol again in a cleaning machine and intend to try a similar test with the Quadralene rinse to see how shellac friendly that is because the data sheet doesn't specify what ingredients are in it, but quadralene did tell me they have many watchmakers who buy their rinse and have not had any problems.1 point

__23-02-1963_.jpg.72708d274459c26493849b9a34f02006.jpg)