Leaderboard

Popular Content

Showing content with the highest reputation on 04/04/22 in Posts

-

Buy a set of feeler gauges from Amazon and the pick one that has the same thickness and start cutting with a dremel tool and drill out the hole first. Then get out the files.2 points

-

To get the old stem out follow the arrow where it says "push". Then push while pulling the stem out. I've never done this movement so I'm not 100 % sure. You can get a new stem from CousinsUK.com. To push in the new stem you will possibly have to push where it says "push" again while you wiggle the stem to fit into the square section of the sliding pinion. To salvage the crown it could be that you'll find the following thread useful. Good luck! EDIT: You will also have to cut (and preferably file) the new stem to get the correct length. You probably also want some thread locking glue that isn't too strong. I use Loctite 222 but perhaps Loctite 243 would be even better.2 points

-

The balance looks fine in the vids. Your positional rates seem to be pretty much in spec from John's document. These little movements can be a bear to get closer than that (some just naturally do have better rates). A big reason is the proportions change so much- there's a limit to how much sideshake you can eliminate and how small you can get the pivots when reducing movement size. Another big thing is the hairspring collet, these are proportionally very large on these little movements, which moves the hairspring center far from the balance center and has a very real effect on timing. Something that will bite you if you are going for a closer positional rate is- the condition of the hairspring! It really has to be perfect, flat and centered at the collet, and definitely flat and centered in general, and definitely centered in the regulating pins. The last one can cause rates that look like a serious out of poise condition or bent pivot. In the verticals, at a lower amplitude and with gravity acting on the spring, if not really perfectly centered in the pins and the pins at the proper size gap (very small), you can have instances where the spring remains in contact with a pin in a certain position, but barely make contact or even no contact with either in others. This will show up as a large rate difference. Another thing on mass produced pieces, especially older ones, is the lock on the escapement can be quite large. This also has a more serious effect on vertical rates (and amplitude). Your vertical amplitude seems good though. Considering what the hairspring has been through I think you should be proud of how well it's running now!2 points

-

Correct. It's used for examination not general work, you hold the workpiece in hand and move it closer to establish the correct focal distance, angle the piece around so it takes the better lighting. For the others you need to be sitting so that work is about armpits high, elbows standing by the sides, great lighting be it natural, artificial or mixed, and you can focus looking slightly down. Many people which are short sighted can so work without any lens, but if you need one try all magnifications power until you find the one that suits you better, it can be more than one for different work. This is the first and most important advice written in the good old books, but that you won't see even mentioned in videos.2 points

-

Hello thanks for accepting me I am looking and not having much luck at it for a rotor axle pinion part no: 72205501429 for an Omega 565 movement, the rotor is touching the case I would really appreciate if someone could point me in the right direction as to sourcing one Thanks1 point

-

Hello , I'm a former yacht mechanic who's now landlocked and have been watching a bunch of watch repair videos over on the 'tube. I have a few old watches lying around, and have thought about maybe giving the hobby a try since I love mechanical things. I have a Rementoir 10 Rubis pocketwatch that's in pretty sad shape that I might have a go at. I saw that someone on this site had posted a .pdf walkthrough, but it is no longer hosted. I have a question about magnification. What do some of you use? I have a 'watch repair set' coming just to see if I can do it. I don't want to dump a bunch of money into tools just yet, and I also want to get a few pocket watches to try my hand at.1 point

-

Hi, I'm Robin from Scotland in the UK I've ended up here having watched a you tube video - or 40 just looking at the possibility of watch repair being a hobby, though having just braved the strange world of replacing a battery I'll admit I'm a little out of depth! I'm a bit of a Casio fan but looking to change that and move to a mechanical at some point soon.1 point

-

1 point

-

Hello everyone. I am retired (from being in the software business for 40 years) and started to study watch repair in the past few months as a hobby. I found it both relaxing and focusing. I have traditionally also been a woodworker and general do-it-all but watch repair and restoration is sooooo much cleaner and does not require a huge space, big machinery, or overalls I started with 2 pocket watches that belonged to my grandfather. Neither worked. So lots to do on those.1 point

-

Hi all, I just subscribed to the forum. Because I would love to repair watches myself. Until now always had it done, but I enjoy all technical things, e.g. repairing my own car, repairing my bike, kind of inspired by a book called "zen and the art of motorcycle maintenance" by Robert Pirsig. Thanks, Hans1 point

-

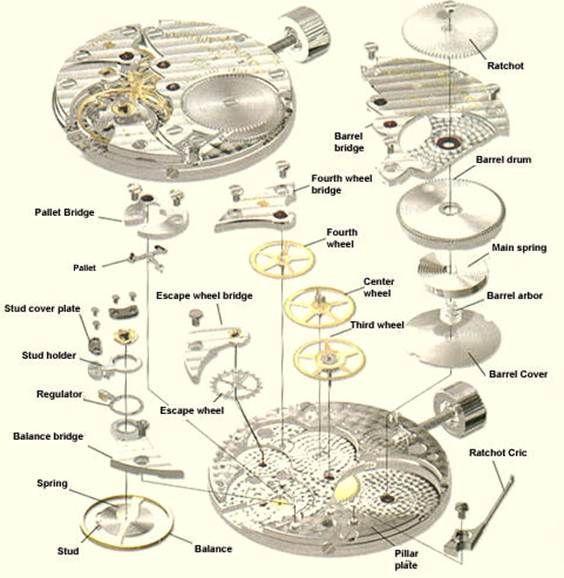

Disassembly sequence here (Please sort by name in ascending order) Assembly sequence here (Please sort by name in ascending order) The watch is an Enicar Star Jewels Ocean Pearl from the 1970s A bit of background I bought this watch on tradera.com (Swedish eBay) listed in the category "Klockor/Renoveringsobjekt" ("Watches / Renovation items"). It was listed as "working" despite lacking the winding stem. I bought it for three reasons. I wanted to try my hands on an inexpensive watch in visual need of renovation. I was curious of the Enicar brand and their in-house movements, and I thought the blue dial with its applied indices had potential. It was clear that the watch needed a new winding stem, crown, and armoured crystal. I found an original stem on eBay from Spain for less than €10 including shipping (a bit of a bargain I think). I bought a bunch of inexpensive waterproof crowns from CousinsUK.com so that I could select the most comfortable and at least somewhat nice looking. I also bought a couple of inexpensive Sternkreutz armoured glasses from CousinsUK.com Overall the movement looked pretty OK except for a third wheel pivot that was rusty. Removing the rust (using vinegar essence) the pivot became Coca Cola bottle shaped so I burnished it and in the process had to remove approx. 2 to 3/100 mm. This in turn created too much side-shake so I replaced the jewel as well. The mainspring looked pretty OK too so I kept it. The cannon pinion also needed a bit of tightening. I guess the friction between the centre wheel arbor and the cannon pinion really can't last forever when a watch is being used for many, many years, perhaps even for decades (looking at the case back of this watch it has seen massive use). Anyway, to tighten the cannon pinion I first tried with my Seitz jewelling pusher and stake for lanterning cannon pinions, but it feels like the edges of the pusher and stake are somehow too blunt or perhaps not designed for wrist watch movements?! So, I resorted to my cannon pinion tightening tool (Bergeon 4733) which is really a bit scary to use but works very well once you've destroyed your first two or three cannon pinions learning how to use it. The trick is not to alter the position of the screw (unscrew it) once it reaches the inside of the handle. As soon as the screw touches the inside of the handle it's time to press. That will usually tighten the cannon pinion the required 1-3/100 mm (I would guess). To give back some of the luster to the dial and hands I simply used a Dial & Hand Cleaning Pen from CousinsUK.com. It worked better than I had expected. The old lume was partly missing and what was left was completely crusty so I simply scratched the remains off and didn't bother to replace it (the blue colour shining through the hands looked pretty great and I don't care much for lume anyway) Despite throwing everything in my arsenal of collected knowledge and experience on the this watch I couldn't get it to run perfectly. The amplitude (as well as the rate) in the horizontal positions fluctuates between 260 and 280 degrees but mostly stays around 260 degrees. I did adjust the curb pin as the hairspring was pinched between the boot and the curb pin and made sure it bounced evenly between the two, but the effect was only marginal. I suspect that the hairspring touches the lower part of the boot. Anyway, I decided to wait with further investigations, put it together, wear it and enjoy it. Despite this shortcoming it performs very well as a daily wearer, only varying in rate between about +1 and -1 seconds per day.1 point

-

Hi, I'm trying to learn watch making from Christian Lass' videos on his website. I collect watches, non-Omega and Rolex grail level for now, and am trying to learn how to repair them.1 point

-

1 point

-

I have to do a little commercial for a youtube channel called "In The Metal". Here is more than 50 hours of talk about watches. Johnny McElherron of The Watch Press, and former lead guitar legend with Anthrax and present-day US Master Watchmaker Dan Spitz. Invites in each section an independent watchmaker in the studio and the talk goes far and wide! https://www.youtube.com/c/InTheMetal/videos1 point

-

Hi @PostwarO27 - glad I could help. Hope this parts match up works out; sounds like you've sourced a bargain so not much to lose.1 point

-

1 point

-

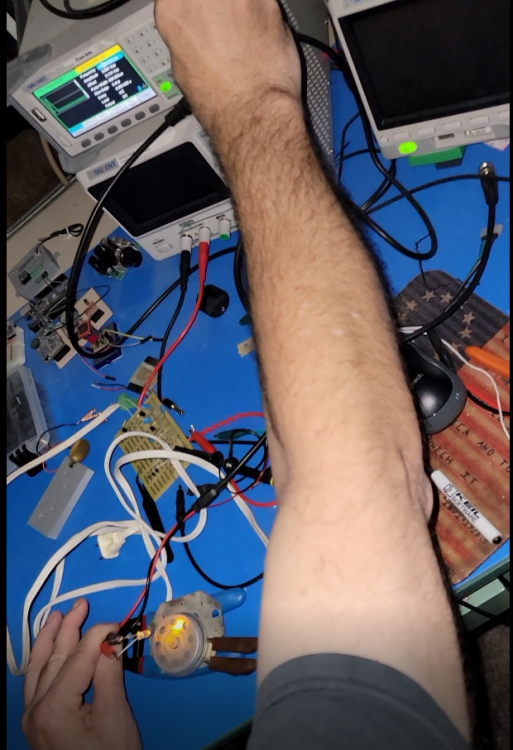

I need a working motor for a Seth Thomas electric. The bad motor is a sangamo that runs (I think) at 7.5 RPS. So I am buying motors on ebay in hopes of coming up with a retrofit. But I need to measure the speed. Aha!! I wired an LED to my arbitrary waveform generator and used it as a strobe. Dial up the frequency until the rotor stops! This one is 12 RPS. Voila!!1 point

-

As requested, a little bit about myself. When I was younger, I only had cheap watches. They needed frequent battery changes. A real bother when you had 3 or more watches. As soon as you had one battery changed, there was the next one to change. In 2020, I donated them all. Since them, I've been buying lots of Seiko watches; Kinetics, Automatics, Solars They have a lot fewer battery/capacitor changes. A lot better quality too. Now I like watches with big hands with lots of contrast, that you can read from six feet away. A number of diver style watches. Lots of fun1 point

-

Hi! I've been fascinated by things that go tick for as long as I can remember, starting with a clock I made as a school project with dubious wooden gears divided by pencil and compass and which jammed with great regularity. Since then I have become slightly more competent with machine tools and made parts for watches and clocks although it has never been my profession (I am a mathematician by trade as it were). I've made most of the usual things - balance staffs, stems, pallet staffs, pallet jewels, wheels, pinions, regulators mostly working on an 8mm lathe with some assistance from a high speed drill and a jig borer. But I confess I've never made a spring detent for a chronometer and I'd like to do that some day (although I am sure it will turn out to be an exercise in extreme frustration) and my biggest problem is that the finish I achieve never quite attains the level that I would ideally like - even on something as simple as a screw, so plenty to work towards (and I have read many articles on finishing). Also I'm very slow - really amazed that people manage to do these jobs economically! Alan1 point

-

Hello all, Complete noob here and after going from never even wearing a watch, to finding an interest in old watches to now looking at restoring vintage watches as part of a hobby to get me away from work/TV etc. I fix telecoms equipment for a living and have done for 30 plus years (it is now pretty much swaptronics and the skill level is nothing like it used to be). I'm slowly going through fleamarkets, 2nd hand and antique stores looking for watches i can at least take apart and put back together, even if I don't get it working. I'll be lurking around the site for many months looking for ideas and info. Thanks for the add.1 point

-

Very new to watch repair, stumbled on this new hobby/potential part time employment by accident when researching a friend's grandma's watch (It was an Eaton's Solar 1970s ladies watch as it turns out). Well the nerd in me kept looking further into vintage ladies watches and couldn't quit. Love the look of the earlier 1900s art deco ones the best. The computer/electronic repair part of me started wondering if maybe I could try cleaning, restoring and repairing some less expensive ladies watches to collect or possibly resell and I've got my first handful of purchases slowly coming in this week. So exciting to actually hold them in my hands. Found this site quite by accident when clicking on something else entirely. Can't wait to see what all is here, looks like a tonne of great info. Cheers Michelle1 point

-

Hi all, I found this forum after I subscribed to Mark's online watch repair course. I have been devouring the episodes and can't wait to get started. So please excuse any daft questions for the first few months or so I have had a fascination with watches for as long as I can remember and am very much looking forward to breathing new life into some old pieces. Thank you. Rich1 point

-

I am currently trying to help fix my friend's seiko watch with an 7S36c movement. I have come to this forum for much needed help in fixing the watch as it is my first ever fix. Please help me!1 point

-

1 point

-

Hello everyone! I'm not new to collecting watches. I tinker a little, mainly crystal, gasket replacement, batteries and bracelets. I'm gaining more confidence and wanting to get into servicing my own mechanical watches. For instance, my 6309-7040. While I do appreciate everyone's excellent work, I'm interested in giving it a try. We shall see how this goes. Cheers!1 point

-

Hello everyone , my name is Ian and i love watches. I have always liked watches since my father gave me my first Timex military style watch as a lad in the mid 70's. I am sure i still have it , and it will turn up one of these days ... I bought a Hamilton khaki a few years ago that reminded me of it a lot. I dont have any real vintage watches yet , I only really have old watches at the moment ... including one or two that need a bit of love to hopefully get them running again... and a couple of slightly newer ones, Breitling Aerospace and Omega Speedmaster Moonwatch that have tempted me over the years ... dont you just love interest free credit I wish that i had paid more attention to my fathers tinkering and repairing watches for his friends and friends of friends when i was younger, I guess now i'll have to try and learn the hard way I dont have any aspirations to being a watchmaker , i'm just an aircraft engineer in my late 50's who would like to be able to take apart and rebuild some simple watches to running order for my own pleasure and to give the old grey matter something else to think about ... and if i could maybe create a watch from an old case with a homemade / designed dial and hands i would like that a lot. I like leather straps as opposed to bracelets , I dont like gold watches , and i dont like outrageous flashy anything ... I am a simple creature. Not much else to tell you at the moment , I shall surely be posting a few cries for help soon as i stumble along trying to diy it, or more likely "biy" it ... until i can justify / afford to do Marks watch repair course ... I already have my basic toolkit that i bought a good few years ago ,and its had far too easy a life so far and is almost as new so now its time has come ... lets see how many of the tools are worth using and what needs replacing first .... Thank you all for listening to my ramblings Ian1 point

-

Hello everyone. I fell down the watch rabbit hole during covid lockdowns, then promptly got me into modding watches and now I find myself staring at too many tools and watches that I have assembled for friends and family. I would like to see how deep this hole goes. I think the next step is to do Mark's 3 courses. I know that in the FAQ he mentioned that the movement to get to follow along is the Unitas 6498 or Seagull 3620. Can anyone let me know if it matters that I get the 6497 instead? Thinking after the practice, i can make a nice little gift for one of my god children.1 point

-

Great channel. The one where he restores a watch at the bequest of his "accountant" is epic. Love his channel. Matt1 point

-

1 point

-

You're absolutely right - one eye seems to work just fine. I was worried about depth perception but having now torn apart an Elgin 313 I've had no trouble finding and removing screws.1 point

-

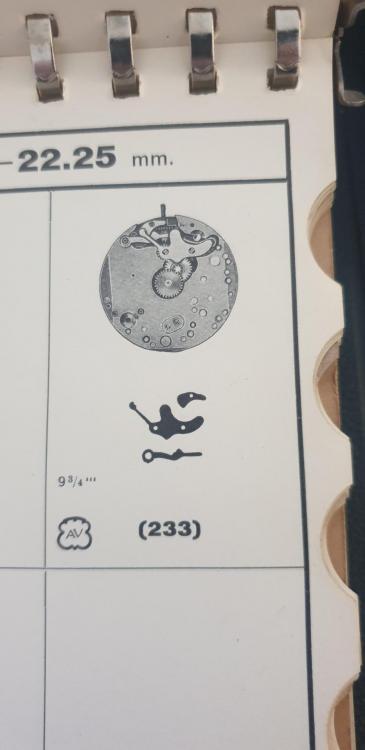

Hi What you will find highlighted by the push indication is a small lever, you push it down and this releases the stem. Have a close look with the loupe. I have had a look or the sheet for the 172A there are non listed in cousins esslingers or the SCWF lists the closest is the V182A which is a close cousin did not get a hit with Ranfft either. I have attached the Seiko V182A in the hpe there are enough similarities to be helpful. Seiko V182A (1).pdf1 point

-

1 point

-

It's handy to fix the broken part onto your steel stock and use it as the guide when grinding/filing/sawing it out. You can use super glue, but sometimes the part de-glues right at the wrong time. You can soft solder it and it will be more secure; an excellent solder for this is Tix, along with Tix flux. It has a low melting point but is very strong. Feeler gage is a great source of material, though you might find it's too hard to drill without carbide drills, and will resist a jeweler's saw blade, but will grind and file fine.1 point

-

Thanks Endeavor! Really heart-warming! Yes, I put a lot of time and effort into trying to make these walkthroughs easy to follow and understand so your kind words feel truly encouraging Oh yes, the Junkers 3133 chronograph. Well, I've been putting it off as it would be such a great experience to do my first chronograph while following @Mark's chronograph course on watchfix.com. Unfortunately, it feels like we've been waiting forever for it to be published (or is it just me being too impatient!?). It's not that I lack the confidence to take on my first chronograph, but doing it while following along Mark's course would be so much fun. As a patron I do have access to the watchfix.com chronograph course development videos - which in my opinion are world class both technically and pedagogically - but as the videos are being gradually replaced and I can't follow along in real time, I've been waiting for the finished course so that I can take it from start to finish in its entirety. So, if anyone (perhaps even Mark?) can give us an update on the progress and when we perhaps can expect the course to be finished, it would be much appreciated. There are some other chronograph courses out there and I might take one of them in the meantime, but what I really look forward to is Mark's course and I will enrol to it when published either way.1 point

-

Hi When assembling the watch, as in your case the train wheels and bridge, at that piont check for rotation. Then fit the barrel and bridge and check again, then when fitting the pallet/fork put a ouple of turns on the spring and check that the fork snaps back between the banking pins smartly. That way you have verified the freedom of the movement at each stage of the rebuild. What you have got is like Hector said a bent pivot or a trapped/broken one . so its dismantle and chech it all again.1 point

-

I don't have enough experience to say for sure either way, sorry. The fact it doesn't occur in the vertical would apparently rule out a bent pivot as the cause though. I would not consider the amount of wobble you are showing in your videos as a problem in itself. Still it's interesting to speculate why it is only occuring dial down. Maybe too much endshake combined with a tapered pivot, or a not perfectly flat cap stone? I think in my previous post I answered a question you weren't asking, with a description of a very specific set of circumstances which may or may not be present! From your description of the current performance, and the information John provided on Omega's specifications, your watch seems to be running fine now. If you still have concerns then I'd like to see the timegrapher traces in six positions.1 point

-

1 point

-

9504 would be better is 9501 with an additive of a high-pressure boron lubricant. With the added bonus it comes in slightly smaller 5 mL bottle I believe which makes the cost slightly cheaper1 point

-

I am a newbie, but it seems like 9501 is a good grease for keyless works that costs a whole lot of money, and you could sub another good grease that isn't near as expensive like molykote 44. or Nye PML Stem Grease, available from otto frei and some other supply houses.1 point

-

1 point

-

1 point

-

Yes but you need to follow certain specifications on that? And understand I'm going to snip something out like fully wind is not fully wind tight you need to let it run for a little bit of time so you have a window were you doing this. The same as at the end 24 hours and usually the watch companies get more excited about things at 24 hours. We tend to get really obsessed on this group with minimum amplitudes on a fully wound up tight but the watch companies are more concerned with timekeeping and stuff at 24 hours.1 point

-

1 point

-

That does not surprise me. For the crown logo to be aligned with the stem joint it would be needed that the stem thread is positioned precisely while the crown is at the correct distance at the same time, perhaps with tiny shims inside? Maybe they where able to do that at the factory, maybe not all the time, maybe the crown has been removed already, who knows.1 point

-

Radium like asbestos needs to be treated with respect, but both seem to garner a lot of fear mongering. I dabble in antique radio restoration and a lot of radios used asbestos cloth sheets for heat control. the subject of what to do comes up a lot.just like the subject of radioactive paint from days gone by. With asbestos as with the paint, if you leave it alone there is no risk. Only if you start cutting grinding or scraping will you release particles into the air. That is the hazard. With asbestos in radios just leave it alone. or if you feel strongly about it you can spray it with water remove it to a plastic bag seal the bag and be done with it. As clockboy states finger cots a dust mask and store in a sealed container and all is good. If you are not sure if the watch you are working on is radioactive and you do not wish to assume the risk, what little there is, while taking the proper precautions, then pass such work on to some one else. For me, i will probably never work on a radium watch. But if I do, at least I have a clear understanding of what I am up against and how to handle the situation to minimize the risk to myself and others around me. That is the beauty of forums like this with learned members, being informed goes a long way to being safe. Thanks for posting and the heads up... Ron1 point

-

Radium has a half life of 10,000 years probably more. Madam Curie is in a heavy lead & concrete coffin. All the bed side clocks & most watches had radium dials when I was a kid. I'm still alive. We used to take under our blankets and play army. Just be careful & you'll be OK1 point

-

More than one time I saw requests for mainspring sizes. There are rules, how to calculate the optimum mainspring for a given barrel. I packed them into a tiny windows app: just enter the barrel diameter and the optimum spring will appear. App attached for download (unpack the zip file). Frank Mainspring.zip1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)