Leaderboard

Popular Content

Showing content with the highest reputation on 02/22/22 in all areas

-

2 points

-

2 points

-

1 point

-

1 point

-

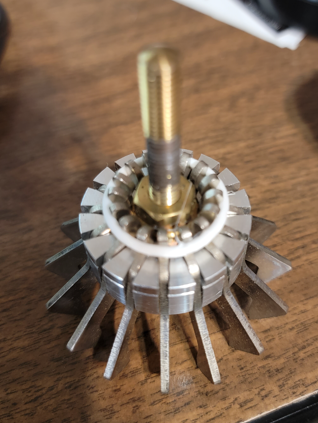

Thanks, Nucejoe. I rechecked the movement on timegrapher and realized that every 5 minutes it was still jumping minutes fast per day. So I decided to take a better look at the train and found some slightly damaged teeth on third wheel and fourth wheel pinion where they meet. I counted teeth and pinion and luckily had spare parts so I went ahead and changed all train wheels except for center wheel and now the watch is staying running steady and strong. This time I left it on timegrapher for 20 minutes and no problems.amplitude also improved some. I figured this information may help someone else with this.1 point

-

Lets keep this a secret, I did the same, thats all Chinese ones are good for.1 point

-

As said its a front loader, you would find a seam around the bezel, crack the bezel open to uncase the movement. Is that a portion of the stem still attached to the crown? it might just unscrew , alum disolves steel in case a piece of the crown doesn't want to come out of the crown. So if you plan to attack from the dial side, remove the hands, dial plate to expose the keyless. There is also an aproach from the barrel side, release the barrel power through the click, remove ratchet wheel and barrel bridge then barrel should just fall out underneath which is the keyless mech. Take plenty of pix as you dismantle, help with reassembly. Good luck.1 point

-

1 point

-

1 point

-

1 point

-

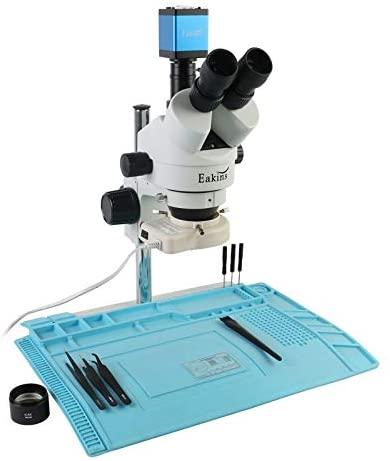

I was thinking about this statement and I think you don't have a true stereo microscope. A true stereo microscope has two separate optical pathways, with two separate objective lenses side by side, to give stereoscopic vision. From your description, if it shares a single objective lens, it would be impossible to give stereoscopic vision.1 point

-

Supply houses carry a replacement rubber band for like $8 which seems a bit high. I stole the coiled spring from a chinese crystal lift for my vintage Vigor as well.1 point

-

1 point

-

Off to redo this one. I'm going to mark a tray with a correct spots for each screw type. I have a feeling I've done the same thing before on a Seiko 6309. The screw involved takes some serious study to see the difference. The last time I did one of these, I put each screw, in order, on a strip of rodico. This time I put all the screws in one container to clean. Mostly as a lesson to learn to sort and identify them. I need more practice with this. I started with a non moving, dirty, slightly rusted movement. It is running pretty well now. I did my best to peg the jewels but the old oil was crusted on well. This gives me another shot at getting everything even cleaner.1 point

-

The 'B' in a triangle by the ratchet wheel click indicates the movement is by Buser. The dial says 16 rubis (jewels) but is that a 15 or 16 under the crown wheel?!1 point

-

Hi Joe I have somthing similar for close inspection work, I does the job. not tried to work under it as its a bit close to thhands and looking at the screen and working a bit disorientating. Not got the required surgical technique.1 point

-

You will come across all sorts of stupid stuff that others have done. One I remember was some idiot used a file to make the winding holes and center wheel hole bigger because the screws that held the movement were not fixed tight in the case so he moved the movement which made it out of line with the key holes and the center wheel for the hands He didn't bother to fill the old screw holes. So it ended up with these bloody great holes in the dial.1 point

-

1 point

-

How far apart is " sporatic" perhaps your observation on TG hadn't been long enough to see a period of occurance. I make a habbit of checking how the movement runs on TG before and after installing the dial and hands. Regs1 point

-

Welcome to the forum. Enjoy. Best of luck with everything that you are hoping to do. I think much the same and you. Who is gin to pass on their smart watch to their kids. Chances are that they will certainly bo out of date software wise and will switch on, but that's it. I grew up in a place where a watchmaking course was just not available. I wish I had followed up to find out what I could have done and had chased after that. Best of luck to you.1 point

-

Welcome to the forum. Enjoy. I love old stuff as well. I just hope that other people where I live feel the same way.1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

I use this microscope. AmScope SM-1TSZZ-144S-3M Generally very happy with it. It takes a bit of practice to actually "work" on a movement under the scope. I use this for removing cap jewels and oiling pivots. Also very handy for inspecting various components. My only gripe is that I need to remove my eyeglasses before I can look through the scope. I believe there are special eye cups available that may solve this problem.1 point