Leaderboard

Popular Content

Showing content with the highest reputation on 01/10/22 in Posts

-

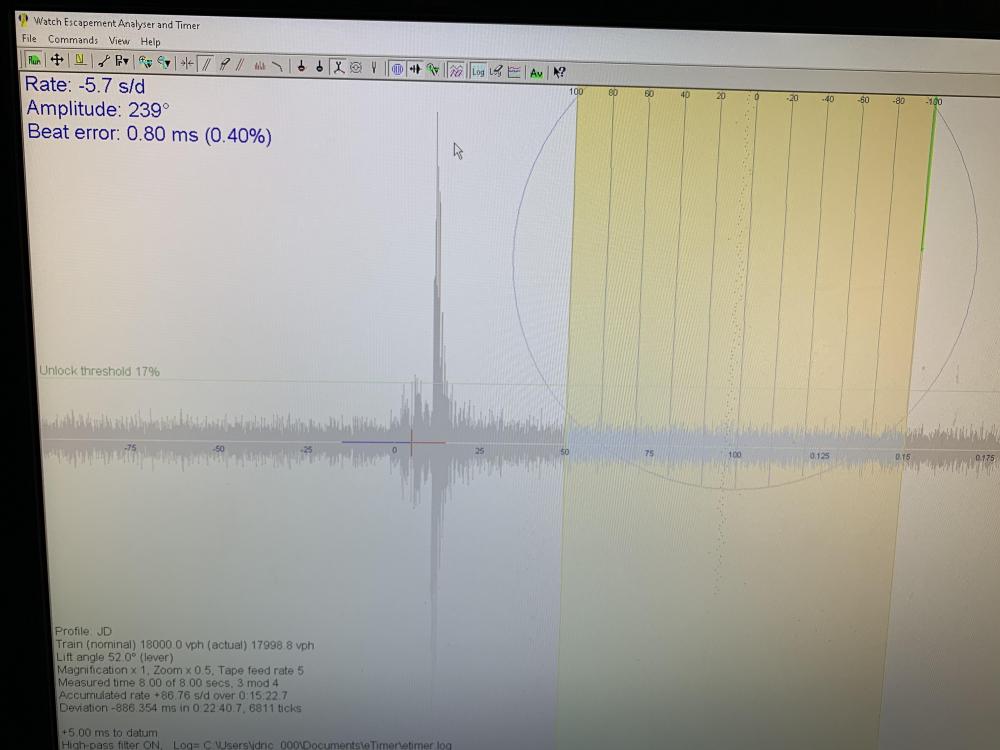

Magnetism in a watch is interesting because normally you would never see it? At least in modern times because the demagnetizer is right next to the timing machine normally. At least it was at school and that's what I was taught. Although I know watchmaker's today that will demagnetized before cleaning after clearing before timing after timing they get really obsessed so magnetize watches on the timing machine not likely to happen or be seen. A long time ago I was asked to evaluate a small collection of watches with the owners newfangled Chinese 1000 timing machine that I had recommended. He was confused with the reading he was getting. I timed his watches exactly as they were found no attempt to demagnetized clean etc. Then I was really excited about the opportunity to compare the Chinese 1000 with my witschi watch expert 2 machine. When evaluating timing machines to avoid complications it works out better if the various timing machines can look at the exact same watch at the exact same time. To understand what I mean there is a sample watch one of the other watches and you notice both microphones holding the watch in a way that you normally would not. Then the results may not always be exactly the same because you can't start both machines at the exact same time. They won't be of evaluating or averaging over the exact same part of the waveform they're always be some variations but this is the closest I can get to both machines at the same time. As you can see that interesting sine wave effect. It also shows a problem of liquid crystal screen timing machines versus the old paper tape or in this particular case software that simulates paper tape. Although I don't know why on the paper tape simulation there should be two lines and it looks like the watch visually is perfect in beat unless you look at the numbers? But in any case all three are showing the same thing an interesting sine wave which I had never seen before. As we see above once the magnetic field is gone the watch still desperately needs to be serviced but the beautiful sine wave is gone.3 points

-

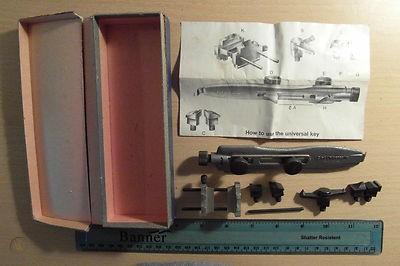

No 1 I think it’s to support watch hands. I own one which I got it in a job lot of horological tools a while ago and must admit I have never used it. No 2 is a mainspring hole punch. No 3 ???? No 4 Looks like an adjustable watch case opener. No 5 Might be a spring bar bending tool.2 points

-

1 point

-

Beginners often ask about where to find this or that crystal, as it happens replacing is cheap and easy as long they are just flat round ones. But the crystal may not be found as generic, or can be expensive, or hard to find. So good old polishing is needed. Here again my technique key points: Crystal mounted on case, that will make it so much easier and safe to handle. Caseback removed, check below why. Jeweller's motor or other rotary tool with a fixed stand. You really want a screen like a carton box. Plastic roundel from a credit card as big as its size allows. 600 grit wet paper. No other grit is needed, as it will lose abrasiveness already after 20 seconds of use and become comparable to finer grades. Try to got directly over the deepest scratches, but without insisting too long (as in 5 seconds max) so to not dig valleys. Find the right compromise regarding the work angle, going flatly is good, but isn't even reasonable to try to sand the entire surface even. Look at the white streaks from inside the glass while working. You will see if you're getting right at the scratch or nick because if so the defect will show up in contrast Be patient with the paper stage. After a while it becomes hard to see if all scratches are gone, but you must remove them all before going to the next step. You should have made a mental note or drawing of where the defects are, rinse it up and observe at different angles. In difficult cases you may need to replace paper once or twice. Crystal will look now very foggy, that is normal Once happy refit caseback and crown, or rodico in the tube. The diamond paste is much more messy and you don't want that inside the case. Mount an hard felt wheel like 7 or even 10 cm dia, 2cm thick, place 1 cm of diamond paste (No. 10 or 14 good, but others work too) on the section toward you while keeping the crystal horizontal. Let the wheel grab the compound one bit a time, keep well pressed up and go over until all paste is used and you can present the entire surface to the wheel, rotate the watch and collect the past on the other side, place it on the crystal again on the other side. You can't do more than 30 - 40 seconds of work before adding fresh paste. Usually I do 4 or 5 passes like that. When working with paste is almost impossible to see the result with cleaning up. Clean with dishwasher detergent, dry it and observe well. Very likely you will notice some small defects, up to you if you want to go back to paper, concentrating on the spot only. Final polishing can be done switching to another wheel and finer paste, no less that 10 as these have no practical effect. Cerium oxide is another option but I didn't try it extensively so far. Below what I did today in about 20 minutes. The central scratch was quite deep. No final polishing or cleaning yet. After:1 point

-

My name is Terry and I have been following Marks You Tube Watch Repair Channel for some time. I have worn watches now for 55 years, since I was 10 in 1966. That is when my father gave me his new Timex "electric" watch that he was unhappy with because it would not keep running due to the severe vibration from the steering wheel in the Freightliner trucks he drove which caused the watch to stop running numerous times. I have been fascinated with time pieces ever since that first watch and it is one of my more enjoyable hobbies. I followed in my fathers footsteps and have been a truck driver now for 44 years and counting. Fortunately for me, todays trucks ride a lot smoother and watches are a lot more rugged. When I was 13 I picked out a Mondaine Dive watch at the local watchmakers store that was in a glass case with all the other rather mundane looking dress watches. That Diver had the requisite tough looking black dial marked Mondaine, 17 jewels, automatic, incabloc, "waterproof" 666 feet and real glow in the dark, "Radioactive" radium hands and markers and a date complication at the 6 that were under an acrylic bubble crystal. The bezel turned both directions. The back of the watch had the "speedo dude" a skin diver engraved in the center with 200 meters, automatic, stainless steel, antimagnetic, Swiss Made engraved around the circumference. And the most impressive thing to a 13 year old, a screw down crown. What more could a kid ask for? The acrylic bubble crystal would scratch yes, but every time Heinz Geisler the watchmaker who sold it to me got hold of it he would polish out the scratches with a cloth and I assume some fine rouge. I used to call the "time lady" at Bell to listen to her say "At the tone, the time will be" to keep track of how my watch was running. I could then tell Heinz if it was fast or slow a "few" second per day and he would exclaim 'But it's not supposed to be that accurate" but then he would put it on a vibrograph, open the back and tweak it a little, hand it back and say "see how it runs now". It was always better after he worked on it. I think that Mondaine had an ETA 2783 movement in it. Spent that summer of 69 body surfing at Huntington beach wearing that watch. I wore that watch for 10 years before i lost it. Wish i still had that one. Bought a Seiko quartz diver in 1980 for $180 because i could not swing the $250 for the 6309 automatic next to it in the case. I have worn various Seiko divers ever since. The latest is a 773 Turtle. Recently bought a couple of micro brand watches. One being a Vaer D5 Arctic diver with a Myota 9039 movement and the other a Dryden Chrono Diver with a Seiko VK63 mechaquartz movement. The Vaer with old radium tint super luminova reminds me of the early style Mondaine diver without crown guards and with a domed crystal. There are more stories about me working on or better yet "trying to work on" and in one case, murdering a watch but that's for another time.1 point

-

1 point

-

Well it should do some research but the crystals that have a metal tension ring do not interchange with normal crystals. The word normal Crystal isn't even a proper term the non-tension ring round crystals. They tend to fit in the case differently the tension ring pushes in with a lot of friction the other one goes in a little differently there shaped differently. So in general they don't interchange a tension ring crystals never going to hold in a case that wasn't designed for it. Okay let's use the example of the 2486 again Both of your sites indicate this is the crystal PZ5000. Then the other site indicates that the discontinued and it's really this PZ5140. So both nomad tension rings both of them have numbers let's see what happens if I go to my site which isn't my personal site I does have access to it. Let's start off with this crystal PZ5140 Which is supposed to go into this case 2486. The crystal number comes up listed three separate times I'm copying and pasting the information for all three below. The site also offers me the opportunity to find out which watch this Crystal goes in and that's weird two pages of various cases and that case number I just get a paid search doesn't come up and I did make sure my page search works by searching for something on the page so according to my site that Crystal does not go in that case? The other thing you'll notice below is eyeglass? The first one doesn't have it the second And third do. GLASS PLEXI ST RING D29.62 H4.7 REF : 063PZ5140 063 DIAMETER D1 : 29.62 MM 063 EYEGLASS : WIHTOUT 063 HEIGHT TOTAL H1 : 4.70 MM 063 PROFILE : CONCAVE 063 SHAPE : ROUND 063 TYPE : ETANCHE GLASS PLEXI ST RING REF : 063PZ5140LC 063 DIAMETER D1 : 29.62 MM 063 EYEGLASS : WITH 063 HEIGHT TOTAL H1 : 4.70 MM 063 PROFILE : CONCAVE 063 SHAPE : ROUND 063 TYPE : ETANCHE GLASS PLEXI ST RING REF : 063PZ5140LR 063 DIAMETER D1 : 29.62 MM 063 EYEGLASS : WITH 063 HEIGHT TOTAL H1 : 4.70 MM 063 PROFILE : CONCAVE 063 SHAPE : ROUND 063 TYPE : ETANCHE Okay let's look at Crystal number and see what it comes up as PZ5000 Then the nice furniture of my browser is all just keep the same case number will see if it matches that case Things get interesting in that it comes up is two separate crystals one of which has a price and the other is price on demand which probably means it's discontinued and you have to order direct and ask for the price. Then this crystal was more popular it goes in three pages of cases none of which match your case or none of which match 2486. GLASS PLEXI ST RING D29.62 H4.3 REF : 063PZ5000 063 DIAMETER D1 : 29.62 MM 063 EYEGLASS : WIHTOUT 063 HEIGHT TOTAL H1 : 4.30 MM 063 PROFILE : CONCAVE 063 SHAPE : ROUND 063 TYPE : ETANCHE DIAM OF THE GLASS SEATING D2 : 29.50 MM GLASS PLEXI ST RING D29.62 H4.3 REF : 063PZ5000L 063 DIAMETER D1 : 29.62 MM 063 HEIGHT TOTAL H1 : 4.30 MM Sold Coeff Unit : 1.0 Who knows maybe I screwed up let's look up this case TNN and see what we get 2606. Notice it comes with what kind of a ring? It comes with an invisible ring or because it doesn't specify am assuming it comes with zero ring. GLASS PLEXI D31.60 H3.00 REF : 062PN0316 063 DIAMETER D1 : 31.60 MM 063 EYEGLASS : WIHTOUT 063 HEIGHT TOTAL H1 : 3.00 MM 063 PROFILE : CONCAVE 063 SHAPE : ROUND DIAM OF THE GLASS SEATING D2 : 31.20 MM Sold Coeff Unit : 1.0 So basically I don't know what to tell you if you like I can modify the numbers to have a ring but isn't that what you did already? Okay let's look at your part numbers Both numbers are interesting they come up with this I wonder what it means? No result found The best things still to do would be to take the crystal outs look at it and see what's in there and look at the edge of the case as to what kind of Crystal should go in there. Because I keep coming up with the same thing no ring none.1 point

-

1 point

-

Dots are well centered, but pictures taken from a slight angle can make them look as they aren't. This fake belongs to the so called superclone class, with the improving in tooling these are made to fool anyone and it take a real expert to tell, after looking at the mov.t as well. Have a look at the video below1 point

-

1 is a Watchmaker Hand Broaching Holding Pliers Number 3 is a watch bracelet cutter, I had one, it is for cutting the ends of the bracelet if it is to wide for the watch case. You put the end of the bracelet in one of the holes and squeeze the handles to cut. 4 is an adjustable case opener but it is missing parts. Here it is complete. 5 is for bending spring bars.1 point

-

This thread caused me to go educate myself on this topic. I read several papers and watch a couple of videos. Very interesting stuff. The old watch timers (Vibrograf) did not calculate amplitude. When did this become "a thing?" Maybe the old watchmakers did this visually. Re demagnetizing watches. I watch a video a while back...it was an interview with Fried back in '92. One thing he talked about was the issue of demagnetizing watches in the early days. Was not so simple as it is today!!1 point

-

Smaller lift angle means less time the balance is engaged with the escapement, which is a goal for good timekeeping. It's easier to achieve with larger movements as proportionally the various "plays" can be smaller. So pocketwatches are often around 40 degrees, wristwatches creep up closer to or above 50. 60 is odd on a pocketwatch but as seen above can happen (these are very old ones). Very small wristwatch movements are often above 55; JLC 101 and 104 are often at 60 and several other of their calibers are 56 or 58. The Swiss sort of standardized around 49-53 mid 20th century as it was found through practical experimentation that they got excellent results there- with an ease of produce-ability. There are exceptions, the Omega 321 for example is around 40, while its close cousin the 861 is 50. Also, with higher beat rates the geometry of the escapement changed, with 20 or 21 tooth escape wheels becoming common which lend themselves more to a 50ish degree angle.1 point

-

Interesting that there's such variability in lift angles among earlier watches. Any idea why that might be? I suppose if you're manufacturing everything in smaller scales, as well as at the beginnings of the mass production era, there would be less standardization, but I have to think there's a functional reason most modern watches are all in the neighborhood of 52°... What would be the advantages/disadvantages of 62° or 38.5° (the most extreme in the list from a quick glance) over the currently predominant 52°-ish.1 point

-

Lift angles https://watchguy.co.uk/cgi-bin/lift_angles https://www.watchmakingandme.com/watch-caliber-hand-sizes http://www.mcbroom.biz/forum/read.php?3,779311 point

-

Clockbox is on the money ! . watch hand broaching tool, 2 . Mainspring punch, 3 . ????? 4. Watch case remover both snap on ans screw 5. pocket watch bow bending pliers.1 point

-

I like my Weishi Nr. 1000 but on movements like the UMF 24, BFG 866, other pin-pallet 1 or 0 jewel, I wonder if they are just too noisy to get a good reading because they always look like a snow storm. And that makes me consider putting together something like this.1 point

-

Revision: On part number 574 for the Anacd there is no day changing finger. But on The 11 anacb there is. However, because of that extra finger it was causing the date to change twice. Once at 12 and again at 10:30 am as there is no dial spacer on the ANACD this was causing the extra changing of the date. So using a .5 mm flathead I broke off the small tab that changes the day. This seems to have fixed the problem. So can you use a 574 anacb on a 574 anacd yes you can if you break off the day changing tab. thanks for all your help.1 point

-

ok, i removed the train of wheels, canon pinion, hour wheel, and most of the calendar works and subjected them to an ammoniated detergent, water rinse, 99% ipa, heated drying, final rinse vm&p naphtha, and another heated drying stage. Then whittled down a bamboo toothpick until i could use it to peg the interior of the canon pinion with some one-dip. Also put the cog end of the center wheel into a hole in an anvil and pressed a one-dip soaked softer pegwood against the pivot body while rotating it. Then noted that the datasheet from AS specifies fine oil for all of that, and i had used D5 for some of it, so cleaned the main plate and the center wheel bridge and re-lubed everything with 9010 during reassembly. I no longer have an excessively stiff setting action so i guess i cleaned off whatever was causing the problem. i'll see if it runs without stopping now.1 point

-

I don't think that the "SHIELD" on the dial refers to the movement maker at all but is simply one of the many tiny microbrands that came and went, possibly a sub-brand of one of the bigger watch companies. Also it would be a little unusual to put the calibre on the case back, but not impossible, after all Seiko does it. Until the back is removed and we can actually see what's inside any attempt at ID-ing it is just speculation, however, if I were to hazzard a guess I would go for a Peseux 3xx, 30xx, or 70xx movement. These were used in a lot of lower end dress watches through the '60's and '70's as they were inexpensive and quite thin. They're actually quite nice little movements. There is even a Peseux 7001 which is 2 hand plus sub seconds manual winder. All that said we need a good picture of the movement before anyone can provide any practical help.1 point

-

1 point

-

I would say the movement has been changed that does not have a day facility. This is one I found in the net. https://www.dayclox.com/4003-day-time-clock-movement-kit.html1 point

-

I recommend that you stop right there and give it to a reputable professional, just provide a picture with the back removed if you want. Below our pinned topic about repairers, be aware that to have it repaired the cost may surpass many times the material value of the watch.1 point

-

1 point

-

The watch in the picture could be genuine but what you receive might not be. Is it a reputable website?1 point

-

Random thought I assume you demagnetized it? The nice thing about the graphical display is the meaning hasn't changed since the first machine spit out paper. Although some of the timing machine manuals you wonder about the mental state of the people who Were interpreting the results. The one I'm attaching is pretty straightforward. Then I snipped out an image of what it probably is. Then unless you verified the lift angle your lift angle is probably wrong. But that's not going to change the graphical display output only the amplitude. Timing-Machine-Charts.PDF1 point

-

1 point

-

1 point

-

LittleWatchShop: Wow, you should consider yourself lucky to still have that vintage diver. I've thought about buying a vintage Mondaine like mine but there are several minor variations in the ones to be found if you search vintage Mondaine dive watch. I'm not sure if i have seen them all yet. Funny the link you put up is the exact picture i have bookmarked to show friends an example of what mine looked like with some small differences. I'm almost certain mine had 660 ft. not 20 ATM as most images i can find show. There is one variation that has 50 meters but it is a hand wound piece, not automatic. Some images show the watch with a cyclops. Mine had no cyclops and if i even knew what that was back then, 13 year old/new eyes did not need it! One day when i was 14 it quit running. I know this sounds crude but using dads only pair of needle nose pliers and with the watch held firmly down on Ma's carpet, i unscrewed the back. I may have touched the tips of the pliers up on a stone before hand so they were square. With great care, even pressure and luck i did not mar or scratch the case back. What I found were two tiny screws and the self wind rotor & bridge assembly adrift. I knew dad had a small tube of locktite and a set of jewelers screwdrivers in his big tool box and so i very carefully put what i thought was a "small" amount on the tip of each screw and put the bridge back in its place and tightened the screws. Screwed the back on and she ran! Next day, watch stopped again. I probably went back in and seeing no loose parts had to tell Pops "we need to go see Heinz" After I told Heinz what I had done, He furrowed his brow and in his wonderful German accent told me "Sonny, locktite is not made for zee vatches! You stay out of zem when zay stop. Bring zem to me FIRST next time". I guess he had to disassemble the works and clean out locktite. I told him it was only a "tiny" amount and he insisted "any" was too much! His shop was a delight for me to visit with my Dad. I remember he let me see his bench in the back and specifically his vibrograph. More wonderful small tools than i had ever seen up to that time. My folks bought a floor standing grandfather clock from him about that time and I remember him delivering the clock in the back of his Volkswagon square back with back seats folded down and the how careful he was unloading and setting it up in our living room. That clock is still in my brothers house keeping time and chiming. Tempus Fugit!1 point

-

There have been several Timex forums over the years, the current incarnation is here - The New Timex Forum This is a general forum, not specific to repair. The owner (Mel) is battling ill health at the moment. Since the forum is set for moderator approval of new posts, it can take some time for them to appear. I am sharing some Timex documents, including repair manuals, here - Timex Documents As far as sharing repair/restoration info,tips,and tricks, right here might be the best place that I know of, just ask!1 point