Leaderboard

Popular Content

Showing content with the highest reputation on 01/04/22 in all areas

-

The upper (dial side) spring should be 170.02 and the lower (movement side) should be 172.02. Inca 170.02 is available on Cousins, I can't find 172.02 on there but 172.03 should be OK. Inca Interchangeability List.pdf2 points

-

2 points

-

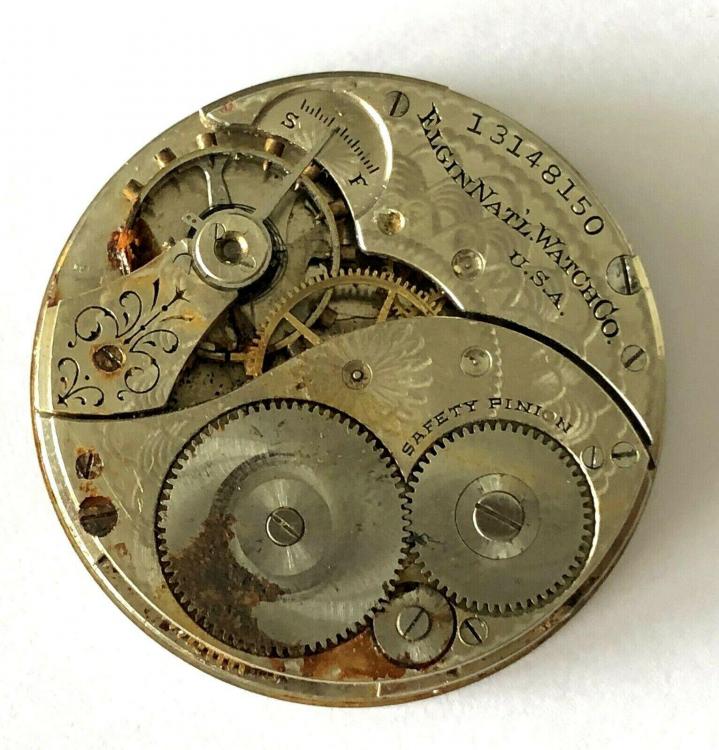

Hello, I'm Dan a new member, and a brand new watchmaker! I'm an Electrical Engineer professionally and an electronics designer/tinkerer/hobbyist for even longer. I've been obsessed with time and timekeeping forever. I've even built both a 60 kHz WWVB receiver and transmitter (that's the "atomic clock" radio station near Fort Collins, Colorado). Anyway, I inherited a couple of pocket watches: a Hamilton 992 railroad grade from my father about 10 years ago (it probably belonged to my great-grandfather) -- it had a broken crystal, wound tight, and wasn't running. Under a magnifier, I tweezed away the lint and hairs that were binding the hands and miraculously it began running! Ordered a couple of new-old-stock crystals and got it fitted. It's been sitting on the shelf since getting an occasional wind. More recently, I found a 1908 Elgin 12s 7-jewel grade 301 in a box that I inherited from my brother. Again no crystal, a broken hand, rusted case, and not running reliably -- looks like the second hand is rubbing against the dial hole. This prompted me to add on another hobby to my resume -- watchmaking, so I can properly service and repair this. Santa brought a nice wooden tool chest and a multitude of tools (some still on the way) and I ordered this mess of a movement off of ebay for learning: https://pocketwatchdatabase.com/collection/editdetails/131416/overview It was wound tight, rusted, and seized. Disassembled it and found two major issues: escape wheel's staff had corroded so much that it fused itself into the bridge, the balance had corroded too and "leaked" its rust onto the hairspring gluing it together. Good news is that the jewels are in good shape, and no broken staffs. Repaired what I could, cleaned it and now it runs, but not very well. I have another donor movement on its way. Thanks for reading this far and now to answer the question. Among the similarities are: require a strict attention to detail, working with small parts under magnification, share some common tools, and provide a great deal of mental stimulation. Best regards, Dan1 point

-

Apologies for the delay but have been reviewing all the great information you posted which lead me to others and others and others and so on LOL and then the pinned topics, etc. I appreciate the input and think for now I'll stick with tools to just do basic disassembly and reassembly and not worry with mainsprings or crystal presses. Then if I still enjoy it and after I do this a lot, then I'll order some oils and oilers and eventually then work my way up as I start branching out like crystal presses, mainspring winders, etc. I will splurge just a little to get a good set of screwdrivers and one set of #2 tweezers as I can find uses for these with my electronics hobby, but the rest of the basics I am planning to get won't be the top of the line but will be good quality. I went ahead and sold some of my older computer equipment that was just sitting around for years not getting used so figured worse case I rather have tools than could be used vs. computer stuff that isn't being used. I joined the Watchmakers Helping Watchmakers as that seemed to be the most popular but plan to spend most of my time here. For parts\tools that aren't new, I'll just keep an eye out on eBay and maybe get lucky. Thanks so much and appreciate your patience with my beginner questions. I'm picking up the knowledge pretty quick, a lot to digest, but still excited to try this out. This was perfect and glad to see I'm not alone. Looks like some of the less expensive tools are of decent quality and do the job. I have no problem going this route for tools that are used every once and a while and then hopefully finding a deal on eBay or other Watchmakers who are upgrading and willing to part with their older tools. This was very helpful and I have been keeping my eye out on a lot of these suggestions and plan to get one as soon as the price is right. I spoke with a friend and he asked me what my latest hobby I was into and when I mentioned watch repair, he said he had 3 old pocket watches that were just sitting in a drawer and I was welcome to see if I can get them going or just tinker with them with no expectations. Yeah as the more I read and watch videos, it seems the whole washing machine is more of a convenience and time saver vs. a significant amount of better cleaning. Don't get me wrong, they do a great job but those I've watched doing ultrasonic cleaning gets just as good results, but just takes a little longer due to multiple cycles and having to remove parts and put them in different jars\solutions. Thanks again so much JDM for all the help. Thanks Nucejoe, looking forward to learning so much more, getting experience and finding and exploring a lot of history through watches. While I have removed a decent amount of items (oilers, oils, extra tweezers, etc.), my current plan is to get the following to allow me to practice disassembly and assembly: Watch Casing Cushion Rodico Bench Mat Watch Case Opening Ball Dumont #2 Tweezers Pegwood Dust Cover with Tray (Generic) Horotec 10x Loupe Generic Brass Tweezers (#3 and #5) Horotec Micro Ball Bearing 8 Piece Screwdriver Set (splurge item) Bergeon 4x Loupe (I have a visor that goes up to 4x) so not sure if loupes work better? Bergeon Loupe Headband Horotec Lever Hand Removers (kinda splurge) Bergeon Case Knife Bergeon 4040 Movement Holder Bergeon Set of 3 Hand Setting Tools with Stand (splurge) Air Duster Bergeon Cannon Pinion Remover (splurge but feel it's worth it to make this task easier) Well that's about all I got for now, I truly appreciate everyone's help, feedback, tips and advice. Stay safe everyone1 point

-

That's the spirit! Although I would strongly recommend you practice on a few scrap movements, one or two fully working Unitas 6497/6498 movements or clones (pocket watch), and a few Vostok 2409/2414s movement first. It takes time and practice to master this micro mechanic universe well enough that you can make a mechanical watch tick reasonably well. Good luck!1 point

-

We say Loctite and probably we mean generic Cyanoacrylate / superglue, but in fact Loctite makes so many adhesives for mechanical use. https://www.henkel-adhesives.com/us/en/search.html?filterType=Products&facetedSearch.productcategory=Instant Adhesives Then choosing the "best one" is a first world problem I suppose.1 point

-

If your seconds hand bought for a 28xx is .25, then is too large for a NH3x with a .21 pivot. You can try closing its tube a little with a pin vice, but no guarantee that will come out well.1 point

-

On this type the top plate only holds partially, the battery is held by the tab on the plastic casing ring - if you don't have one you will have to improvise something else. That is done to facilitate battery replacement, however Miyota and other makers don't do the same.1 point

-

1 point

-

As far as the friction issue goes, (and now I am harking back to my trade but the product is still available), is Beltgrip a possibility?I presume that the friction material inside the bush would be cork or felt. Could be completely wrong on that though. Beltgrip is really good at stopping slipping V-belts on a car. Another option is to put one side of the bush on a solid face like a vice and then tap the other side with a hammer to close the bush down a bit . Sort of make it an oval. Bit crude, but might work. Another method that could be used is a centre punch at four places around the bush. 12, 3, 6 & 9. Centre punching would cause a bump on the other side of the bush and tighten the friction face of the bush to the friction material. Any metal that 'grows' around where you centre punch could be filed back so you would just have four neat little indentations.1 point

-

It's called grey market and exist in any trade. Authorized business do the purchase, also because they have to keep a certain inventory as manufacturer mandates, and then resell. It may have happened now or decades ago, and the goods may have changed hands various times. But if no seller has the part that you need, your only choice is to give the watch to an authorized service center.1 point

-

1 point

-

Hi What JohnR725 has explained is spot on, without any prior experience the removal of the movement and re fitting of the hands without the equired skill level is frought with problems and as its an omega expensive ones and therefore best left to some one with experience. Again pictures of the movement and any numbers are always informative. cheers1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

I think we need a clarification so I quoted something no skills to repair a watch correct? Is this an easy watch to fix may be but it requires skills. It's a Omega watch and as you noted finding a nice clean perfect older Omega watch is a challenge or maybe it's impossible? Having the problems you're having makes you wonder if the watch was really serviced at all. Sellers typically on eBay exaggerate the reality of the situation and usually don't backed up or guarantee what they've sold. Because if it had been recently serviced it should have a warranty and it should go back to wherever it came from. If you've never done watch repair learning on an Omega watch is not a good watch to learn on. You need to find somebody who knows how to work on a watch and have them fix the problem. Otherwise things are going to really expensive really fast. Because there are not a lot of Omega parts out there. So to help us what is your watch repair skill level experience? Then can we get a picture of the inside of the watch in other words take the back off?1 point

-

I agree with JDM here. I think it is best to begin with the simple aspects of the work, and get used to using our more basic tools, before investing in some very expensive equipment. Myself, I am so near-sighted that I often just take my glasses off to do watch work, and I do not generally need any aids for the more common tasks, as I can see and count the threads on a screw which holds in a screw-mount jewel with my naked eye. I will choose a loupe sometimes to look at the side-shake on a pivot as a watch runs, or some other thing that I wish to see in greatest detail. And I have a microscope for inspecting jewels for cracks, and inspecting parts for wear or metal fatigue. For aching backs, what the others say is about the best advice we can give: raise your work surface up closer to your eyes, rather than lowering your face to the work surface. A watchmaker's bench has a higher work surface than most for that reason. It may feel strange to you at first if you are used to working at an ordinary table, but you will soon adapt and realize the benefit. Your back will thank you. I went one step further and purchased a kneeling chair to go with my desk and aid my posture. It is wonderful. When I knew I was ready to do the work that would require them, I bought the loupes. When I knew I would be ready to replace jewels, I brought in my microscope. "Jumping in with both feet" is very expensive (unless you are wealthy) and wasteful if this becomes a passing fancy. But given the enthusiasm I am reading between the lines of your post, I think you may be well on your way. This watch of yours is a size 12s, somewhat larger than most wrist watches, and you know your eyes - if you need a headband-mounted loupe, I'd get one. But most things should be undertaken more easily by just raising your work up toward your eyes.1 point

-

I received a set of 2 Arkansas stone (M and F) like yours and I ordered the 3D printing, will be done this week. I also added a small design for a 20mmx20mmx50mm block to file the blade edge perpendicular to the stone to finish it that the 3D printer designed for free. Made from nylon as it's most durable. I will post pictures when I pick the parts.1 point

-

timing machines are interesting devices which can tell you all sorts of wonderful information. for instance I'm attaching a PDF tells it all kinds of nifty information. But reality is the timing machine points you in the direction like this watch needs servicing. Or another way to think about timing machines like interpreting a crystal ball some interpretation is required and if everyone on this group looked at your timing machine like a crystal ball we would all have possibly different interpretations perhaps. In other words it's not always an exact science. then the power fluctuations like that things like the mainspring if there's sticky grease old grease that results in uneven power that will give you fluctuations. yyou will notice in the PDF is that it's for a paper tape machine. Everything should be more or less the same except if you're looking for gear train problems it's hard to see on a liquid crystal screen it's much better if your machine is spinning out paper.. Or you get an entirely different machine there's better ways to look for gear train problems unfortunately the machine I'm thinking of is really expensive so that's no help at all in this discussion. So they are simplistic is it points general direction of your watch looks bad servicing is probably required especially if it hasn't been serviced in a long time. Then when using your machine it helps to establish a procedure. Like you wind the watch up wait about 1530 minutes then time and usually dial up or dial down and for crown/pendant positions allowing time when changing positions for the thing to settle down then try not to get obsessed with all those positions it just a good way of looking for problems. But don't get obsessed about your watch keeping time to one second all positions.. Timing-Machine-Charts.PDF1 point