Leaderboard

Popular Content

Showing content with the highest reputation on 01/02/22 in all areas

-

We are back in India, visiting family, and my wife decided that we needed to modify a quilt for my nephew with some means of hanging it up. For that of course you need a sewing machine. There are actually three sewing machines in the house here, but they are all somewhat ancient. I thought I'd tackle the two hand cranked ones first. Not a problem I thought, how difficult can it be to get an old hand cranked sewing machine working. Well as it happens, quite difficult, since they have both been lying for many years having been put away with various ailments. I have them both purring away now like... well like a well oiled sewing machine obviously. The list of faults included gunked up lower bobbin case, rusted lower tensioner path, rusted upper tensioner, gunked up crank gears, sticky bobbin winder, stuck stitch length adjuster and of course the usual dried up oil we are all so familiar with. The two machines are both the archetypal "Merritt" model that you see in tailor's shops everywhere in India, and are remarkably similar to their Scottish built Singer counterparts. They are also equally bomb proof. There is a third machine with a treadle which I may take a crack at later, but I managed to make the hanging tube with one of the ones have fixed, so the third machine will need to wait till I am sufficiently bored by the latest current covid restrictions to be in need of some more ancient mechanical device restoration therapy.5 points

-

Not just Rolex watches is a lot of watches that people with relatively little experience should not work on. Either the parts are going to be impossible to get or going to be extremely expensive. Always something to consider when working on a watch that accidents can and do happen and they tend to happen more with less experience.3 points

-

2 points

-

2 points

-

1 point

-

Just a clarification so things are clear in my mind. Just to be clear on things you do know that the watch is not necessarily a self-starter. In other words I'm going to snip something out of the service manual for the 218. Notice the reference that you have to give it a start. So in other words it's not a 100% the watch will start with power it sometimes needs a little help and the manual was written with the thought of using a Mercury battery.1 point

-

Good idea K. Even if its broken, its length and other dimensions can be measured which helps choose a lower grade spring.1 point

-

Rolex prices are ridiculous, unless I win the lottery I'm staying well clear of them.1 point

-

Whichever pivot this end stone is suppose to cap, might now be pushed on by the cap as you have installed it, possibly retarding or fully stopping the pivot from turning. Another point worth mentioning is that I see all three cap jewels are off, unless marked or some how kept track of, how do you know which one goes back where, you inadvertantly have altered end shake all are three relevent arbours, thats not good watch repair. As you acquire more experience, you would want to check and adjust end shakes on all arbours for a smooth gear train. This is part of what makes watch repair an art as well as watchmaking. Regs1 point

-

We need some photos to say if the spring can be repaired. If so, it would be your best option.1 point

-

Pivot is suppose to somewhat protrude the jewel hole before reaching end stone. You now are likely to have the end stone touching cock jewel, hence have zero pivot protrusion, as a result pivot would easily jump out of the jewel hole in the event of a shock. If the end stone doesn't want to stay put, I try to slightly peen the hole for a tighter fit of the end stone. No glue whatsoever, I havev seen glued ones as scrap in lots I buy.1 point

-

I need a better picture of something? Then I think I asked a question which didn't get answered let me see and I will quote it? Now the reason I asked the question I did is in the 218 manual it says when removing the stem you should always do the following which is what? Notice when ever removing the stem from a 218 it must be in the setting position? The reason for this is if you don't do this you have the possibility of getting it in an interesting position of both running and setting at the same time. This means if it's in the running position and you turn the crown the gear train will spin it's very bad for the index wheel so I wouldn't try. I can't tell in the photograph but it looks to me like the little brass pin that is used to move the finger away looks like it's touching but it's really hard to tell in the photographs and it's not supposed to be touching when the watches running it should be a way just a little bit. But it may be a picture optical illusion. Then I should delete everything up above because I feel really stupid? But since I tend to feel stupid a lot I'm going to leave what I posted up above because it's still a good thing to remember. So why do I feel stupid because I wasn't paying attention to your pictures At least paying attention to the way we should have. I snipped out a couple more images and circled a mystery component I don't suppose you're missing any screws?1 point

-

That will work, but is should be burnished into the setting; but your technique will work.1 point

-

1 point

-

I don't know, but my, and I'm sure your impression, is that the jewel shouldn't normally separate from the holder. Let's see what the pros have to say about it.1 point

-

I'm refering to electronic components like the transistor, resistor and capacitor. I'm sure solder joints age too. Most electronic components nowadays are only designed to last about 10 years. Those in tuning fork watches are half a century old.1 point

-

WOS does adjust the gain automatically unless you've selected "Adjust threshold level manually" in the "Settings" window.1 point

-

1 point

-

Loupes are always needed for general work unless your eyes are able to work without. A microscope is just an extra for when a strong lens won't do. Don't pull through, start with the part near and pull away like 30cm in 2 or 3 secs.1 point

-

1 point

-

Well, I'm about to do it. I've had advice from many members. Marks second course is to be my purchase tomorrow. Even got the offer of a reduced fee. What more can I say. Thank you folks. Incidentally, I'd like to prove to you that your advice was correct. I let my head rule my heart. I saw a course for 1/3 of Marks course and enrolled. 30 minutes later I asked for a refund and was fortunate to have my money returned. I had originally, on the chat line for the site, asked it the course was good for a novice on learning watch repair. Oh yes. Paid my money, opened the first introduction. It was the whole course, 59 minutes of video, made in 1997 on a camcorder, 24 years ago. Hand held zoom. I've learned my lesson. Will I listen to you and heed your advice? Oh yes. Regards to all Ross1 point

-

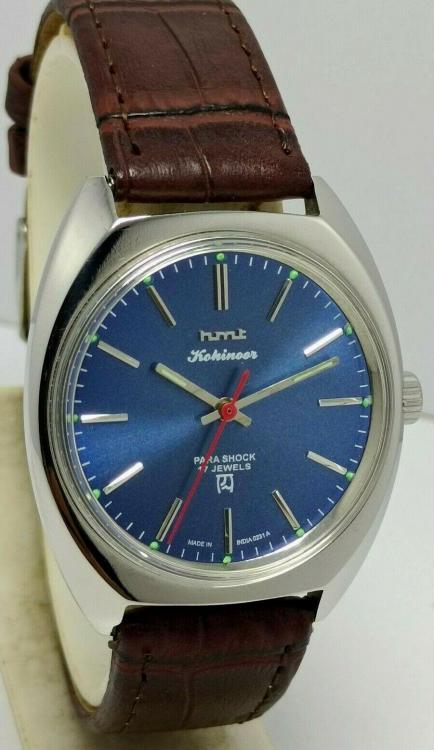

Must be citizen addicted just bought another version of this watch with blue highlights and ss case but missing the crown doh1 point

-

Nothing horological for today, unless a bit of covid lockdown, cabin fever related "time" wasting counts. Our young mildly dinosaur obsessed nephew in the US asked us to do some "homework". "Draw a picture of an Edmontosaurus in stripey pyjamas, asleep under a tree by a river and.. a picture of whatever you can think of." A penguin? I suggested.. "Oh yes please." Enjoy, and remember, you can't get down off an elephant, but you can get down off a duck. ?1 point

-

I feel like a bit of a barbarian, when I superglue an M10 nut (other sizes will also work) to the back of some particularly gunked up, cross threaded, corroded or mauled case back, but it does work, and if you take care when removing the nut/glue with acetone, the case will be none the worse for the experience. I do have a couple of case back removal tools, but sometimes you are up against damaged notches or so much corrosion that you fear the tool may slip, or something will break. Don't try the superglue and nut trick on soft precious metals or some forms of plating, as it may not end well. Stick to stainless backs. One other obvious advantage is that you get a helluva lot of M10 nuts for £2,0001 point

-

It's almost certainly that the guard pin is too far from the roller*. This could be because it is bent, but also due to excessive play between the pivots of the pallet fork, balance wheel, or both in their jewels- or a combination of all of the above. The adjustment of a vertical guard pin to roller table is much touchier than with a double roller and more modern horizontal guard pin.0 points