Leaderboard

Popular Content

Showing content with the highest reputation on 12/10/21 in Posts

-

Thinking about a perfect finish here's an interesting PDF to read. A Quick Evaluation of Surface Finish of Pivots.pdf6 points

-

The staff isn't original, it's a hokey homemade one. The upper pivot appears a bit sketchy, but who knows maybe it works? The spring doesn't look too bad. You can put it on the cock (install the stud in the cock) upside down and manipulate it so the collet is centered over the hole jewel, and get it parallel with the cock surface, then when you install it it will be very close to true.3 points

-

I guess we need to define what exactly are you using the multi meter for? In the early days of mechanical watches amusing problems occurred when electric watches came out. Somebody wrote a really nice book on how to service the Hamilton watch. So nice that Hamilton bought the rights to the book so you can actually buy it in two versions of basically identical one published by Hamilton one by the other publisher. Elgin gave at least one class to a group of watchmakers on their electric watch. But Bulova had a different problem tuning fork watch doesn't quite look like your normal mechanical watch does it? So what Bulova did was came out with day to day class and unlike other classes in the day? Yes long time ago the manufacturers used to have classes and go into the field and help the professional watchmaker and have classes they were all really pretty friendly and easy but not the Bulova one. A very intense 2 day eight hour class with a test and if you past you got a nifty certificate. the whole reason because tuning fork watches aren't like a regular watch. There's all sorts of interesting challenges and now it gets even more interesting because they were never meant to run on silver cells but they can be phased to run on silver cells just fine. You just have to follow a slightly different procedure and it would be really nice to have a variable voltage power supply when doing this. Which is why the normal Bulova meter doesn't cut it anymore but still is a really nice beater for looking at the microamps it just doesn't have the variable voltage part. The first link explains about phasing with silver cells. You'll notice the variable voltage power supply aspect so Need a variable supply that you can vary at the voltage between 1 to 2 v. Then the ability to measure current very tiny quantities of current is an absolute must if you want to be successful. This is where your typical analog multi meter just isn't going to cut it The first link covers your phasing with the new silver cells second link shows a multi meter? Oh dear maybe it will cut it except look carefully what's the range at the lowest setting? By the way these will occasionally show up on eBay but they usually snatched really fast. The lowest range goes to 12 µA blessed as the adapter for the quartz watch with the capacitor to even out the reading C get the correct reading. Just need the variable voltage power supply third link interesting information Fourth flank if you're not in the building your own verbal voltage power supply you can modify one yes Bulova did have their own variable voltage power supply at one time all the watch companies well a lot of them at their own stuff at one time. Fifth link interesting page of Seiko tests enough if you scroll down you'll get to S-831 - Multitester This is basically the citizen made a same 12 µA scale it works really really nice meter. It's what I'm currently using the camera word picked it up a long long time ago works really nicely. Then if you scroll down even farther Seiko had a variety of digital meters The S-840 - Digital Multi Tester (Multi-meter) Will work for tuning fork watches I would still prefer an analog meter though it makes it much easier to see a trend. The rest of my don't know if the work were not a lot of times things designed for quartz watches don't like tuning fork watches. Sitting on my bench it work is a very expensive witschi meter nice liquid crystal screen for doing quartz watches even times mechanical watches but it really doesn't know what to do with a tuning fork watch at all. Then if you spend some time on eBay you can find micro amp meters they're getting much much harder to find. But they're still out there and if you get a big enough 50 µA it will still work but it's not as nice as getting a 25 µA or 20. Then a course the other way to do it is Bulova used the higher current meter and then they made an amplifier for their use in the factory somewhere out there have a very poor schematic of the thing. Device specific to the 218 sort of? Index wheel cleaning it can be interesting if you don't have the index wheel holder which I assume you do not. This means you can put it back in between the plates when you run the plates through the cleaning machine. Yes it really will clean the pivots etc. Just make sure the jewels of the index fingers art back up against the index wheel when you do that. The 218 you have to really really pay attention or you can bend or destroy the one index finger? I'll skip over how I know that from personal experience. So for instance you disassembling to get the fork out you have to rotate the finger then you can take the fork out. You want to put the screws back in that held the fork in place there is usually spacing washers underneath their color-coded you do not want to mix them up to put the screws back in. But the index wheel back in but remember to rotate the finger back because now it's out and if you put the plate down well I did warn you. Now you can run it through the cleaning machine never run the tuning forks through the cleaning machine or anything magnetic typically on an electric watch because they pick up all the magnetic particles in your cleaning bath and it's a big pain in the asked to clean the magnets off again. But as we stated above microscope is really essential to see what you're doing. Variable voltage power supply if you want a phase for silver cell and you definitely need a meter that can measure microamps. Preferably analogue but you could do with a digital meter. http://members.iinet.net.au/~fotoplot/accphs.htm https://www.ofrei.com/page256.html http://members.iinet.net.au/~fotoplot/acc.htm http://members.iinet.net.au/~fotoplot/accps.htm https://www.plus9time.com/seiko-tools#S-5002 points

-

Don't worry @MattyG, you can introduce yourself when and if you feel like it. More important then is to be an active member with lots of questions, info, and posts! After all, that's the best way to get to know each other. Please feel welcome by me (and many others I'm sure) without a formal introduction!2 points

-

Please do not post photos of dead animals as this can be up setting to members including me. This is a forum for horology not hunting.2 points

-

Be very careful with the index and pawl fingers. And don't hold the index wheel anywhere except by the arbor. Do you have an Accutron test meter?2 points

-

By my observation, virtually everything is known to cause cancer in California. CA has cornered the market on warning labels.1 point

-

1 point

-

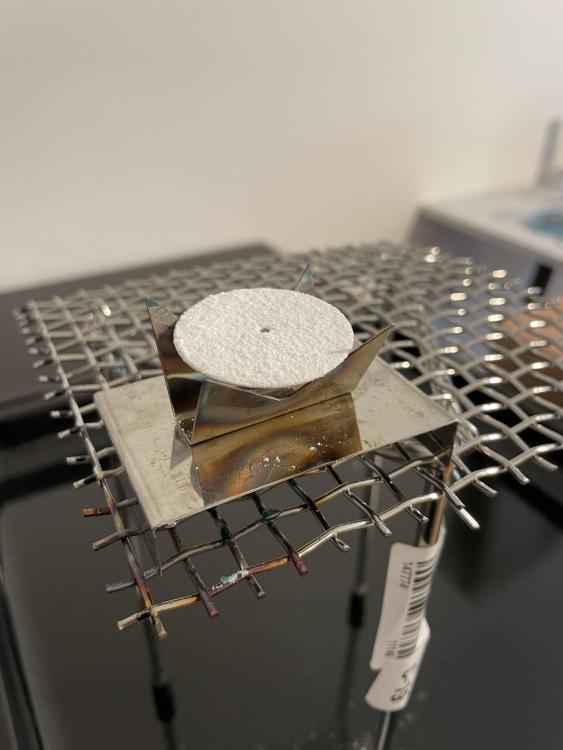

UV lamps lose intensity with use, I'm sure the one you had for photoresist would be fine but is maybe too old. We use a lamp for curing UV nail polish. Looks like the toaster oven my grandad had. Works great. If you search for lamps for nails I'm sure you'll find one.1 point

-

I remember Positiv 20. Real stinky stuff. I used to use backlight UV tubes for that and it takes forever to get a good exposure. Then I discovered 500W floodlamps. Those were awesome. I could get a good exposure in a couple of minutes. I too have Sternkreuz UV glue and bought 3 different LED UV lights for curing it. 2 of them don't work at all. The 3rd one is a 405nm LED light. But even that seems to give a rather weak cure. The glue doesn't seem to set very well. The best way I found was to leave it in the sun for 30 minutes. I hope other members can give you better advice.1 point

-

Go download a copy of the manual. You can find it on the internet. Also, read up on the theory of how a tuning fork watch works and how to index the watch correctly. There are some videos on YouTube on servicing tuning fork watches too. I remember I read everything I could find on the internet on the subject and watched every video on servicing tuning fork watches too. Then I put in on the back burner and let it stew for a few months. A tuning fork watch is totally different from mechanical and quartz watches, although background experience on working on other components like keyless works, motion works and calendar works would be a great help. A microscope of at least 20X magnification is essential. If you have an Accutron model 700 test meter, you won't need a variable power supply. But a normal multimeter isn't going to work. As for the watch that is humming, if the hands are not moving, it's better to remove the battery before the index wheel gets damaged. I'm no expert on Accutrons, but I'm here to help if you need it. Good luck.1 point

-

1 point

-

Before you take it further apart, please be advised of two important facts: What you have a cheap pin-lever mov.t. These were manufactured for low cost, not high precision. It could be that some "less than ideal" tolerance is there is since the beginning, making the train not running fluidly. Again to save cost, there is a single bridge for everything but the balance. That means that aligning all the pivots to put it back after cleaning can be not just difficult, but plainly frustrating especially for a beginner. And of course unless you have been able to identify and correct the problem above (something that is not guaranteed to be possible), it would behave exactly as it does now. So, from a practical point of view, the best way to rule out a matter of dried oils or general dirt would be to dip it in a degreaser, ideally petroleum ether, or other quick evaporation fluid, then let it dry in air. In conclusion, these "working class watches", just like their similar Ingeroll, Roskopf, Timex, etc are great to learn how a watch works and develop dexterity, but not that easy to manipulate or repair. Once again for anyone reading this, below our pinned topic about what mov.ts are indeed recommended to beginners.1 point

-

Best way to damage the wheel, esp. if you are unexperienced. Will surely be needed if you "just do it with a staking tool", rarely needed if you do it the correct way. I would recommend this. Ask and find one who does more than changing batteries and straps. Frank1 point

-

Hello Ross, Acts like there is a fault at third wheel or escapewheel's pinion leaves. Collect some data as you proceed with disassembly, I loosen screws to the big bridge( gears bridge) one at time, if it doesn't take off running, tighten that one back and try another screw. Once the bridge is off and you remove the gears your down to visual inspection. A clean and lube is usually all these movements need. If you have no ultrasonic yet, be careful cleaning pallet pins with a soft brush and your cleaning solution. Good luck.1 point

-

Do you have any background experience with tuning fork watches? In other words is this your first venture into electric watches and tuning fork watches or do you have prior experience? Yes test meter is nice along with a variable voltage power supply. Plus the service manual and microscope would be nice.1 point

-

Perhaps someone would like this - cheap, french and 100% for charity: https://www.ebay.co.uk/itm/James-Walker-Mantel-Clock-Laverstoke-Mills-Wedding-Present-Portal-Family-Gift-/185207888859?mkcid=16&mkevt=1&_trksid=p2349624.m46890.l49286&mkrid=710-127635-2958-01 point

-

Some off-topic postings have been split here. In addition, since these had images of dead game, these have been hidden for now. If possible, text content without the images will be restored. In all cases, when quoting a post with long text and images, please don't include these.1 point

-

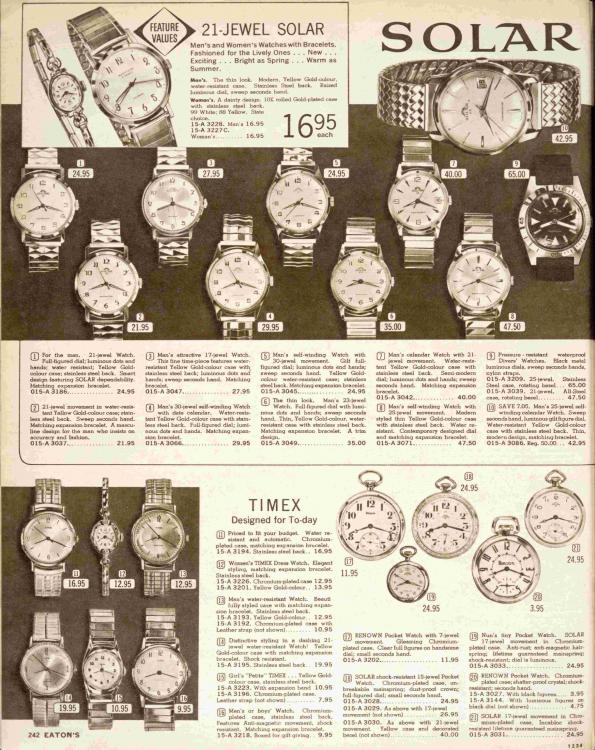

Hi all. I'm in western Canada. A year ago I found myself unceremoniously semi-retired before I really planned to be. Thanks Covid. Semi-retired = unemployed in your early 60s. So I started watching Mark's videos, then Retro Mike's videos and got really interested in watchmaking. (I'm a tinkerer; IT systems, Electronics (tube, solid state and microcontrollers), I build and repair guitars (acoustic and electric), I brew beer, design typefaces, and probably do a few other things.) So, yeah, tinkerer. But now a job found me, so I'm no longer living the frugal life. I can probably even afford some Mobeus oils and some Bergeon screwdrivers. I have a few old watches from my youth that need attention. Only one is automatic, so that's where I'll focus my time. It's a 23 jewel 'Solar' brand watch from about 1970. These were sold by the large Canadian department store chain called Eatons back then. Solar was an Eatons house brand. The watch was Swiss made and has an AS movement. It runs but barely. It needs a service. Time to get at it (after I gear up).1 point

-

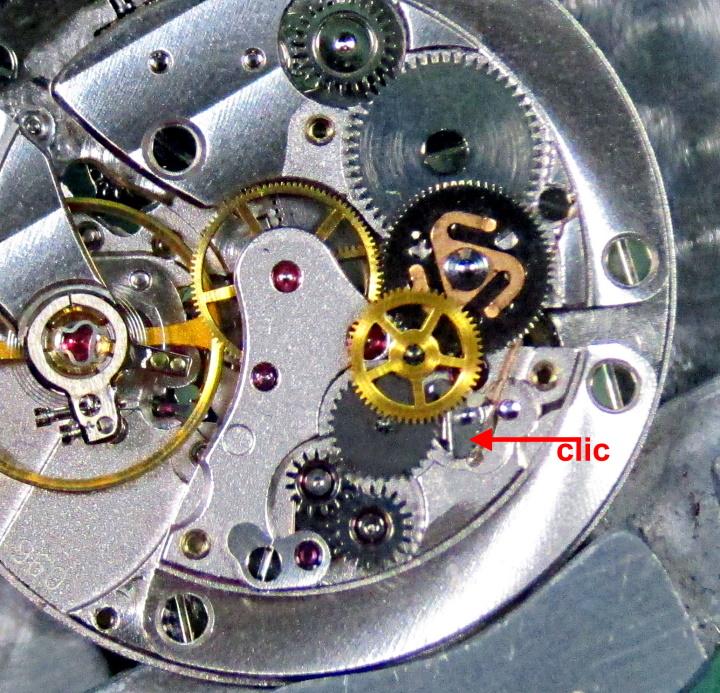

Splines are one way but simple interference between the two parts is sufficient. There are tables of interference fits for all sizes of shaft and holes. The overlap is measures in hundreds if a mm (can be measured with the JFK) Here is an example that I had to deal with recently - the drive wheel of the JLC Cal 960. The little gear wheel at the bottom drives directly the ratchet wheel and is an interferece fit (press fit if you like) onto the arbor. The pivot is 0.3mm the arbor 0.53mm and the gear wheel outer diameter 1.34mm. The gear wheel takes all of the force needed to fully wind the mainspring. An astonishing design for a top end movement that is used in several fancy watches such as the JLC Reverso. Sometimes the gear splits and as it also holds the mainspring back through the automatic system to the only clic in the movement, when it fails even manual winding is out. But straight interference works most of the time for all of those JLC and IWC watches using the Cal 960.1 point

-

1 point

-

N9 sounds like a Bulova/Caravelle date code, 1979. AFAIK, Buolva didn't mark any case or movement codes on the outside of the watch. Just a serial number, and no one knows what those mean if anything, and the date code. There will be a caliber code on the movement, like "10AX". The watch itself is now ID'ed by some name that was found in vintage advertisements, those being the only records remaining. There is no source of replacement NOS case parts. You'll have to find a matching watch somewhere, e.g. ebay, to take the bezel from. The lack of a code on the outside of the watch, unlike e.g. Seiko, means most sellers won't know what to call it, making searching far more trouble since you have little more search for than, "vintage Caravelle".1 point

-

It's highly unlikely I will ever be in a position to make practical use of what you show there, but it's a pleasure to watch you work all the same.1 point

-

1 point

-

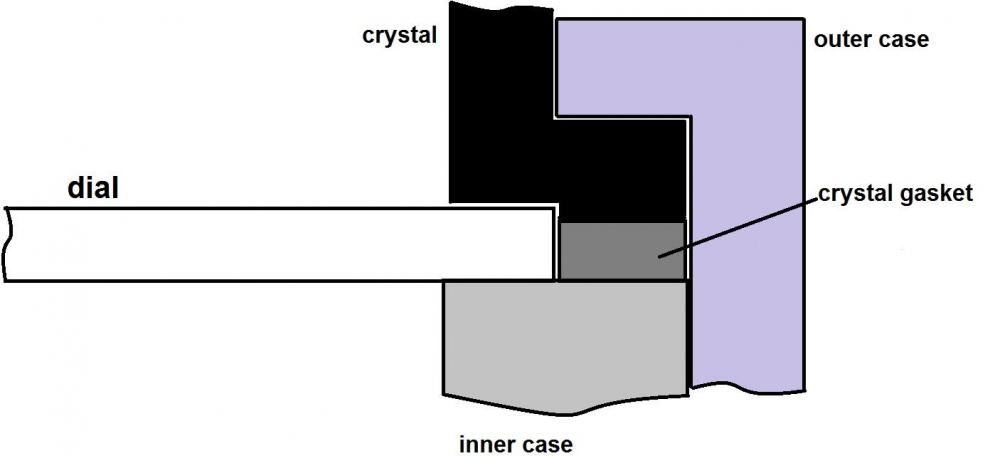

It is an English gold case. The case numbers often don't show anything for the crystal. My guess would be sternkreuz ATG or ATGR 316. We, and other wholesalers, stock these crystals. You need to take the old crystal out first and check/measure to be sure. Measure the diameter. Then check the gold tension ring on the under side, if it has a tiny cut out/step to make room for the dial then you need ATGR, if not then a normal ATG is fine. If yopu haven't replaced a crystal before I would take it to someone that has as it is easy to do a lot of damage and you don't want to do this to a gold Omega. Luke. (seen hundreds, maybe thousands of omegas for crystals over the years at work).1 point

-

If somebody had looked at the part numbers I had the second number doesn't have a tension ring. Doesn't even mention a color of a ring maybe it's invisible? Looking carefully at the case and its 18 karat gold I'm guessing it doesn't have a ring. Yes definitely before destroying something it would be nice to make sure we get it right. I wonder what a replacement 18 karat gold case costs?1 point

-

I'm assuming you made a clerical error as that's not reference number? It really should be 147.08. The decimal point really is important. Then if you had access to the newer reference listings the actual number would be 147.0008 you really can't do the search without all of the digits it just won't come up. Then there's the other problem? A lot of times the reference number will come back to a variety of cases with a variety of materials. So whatever I'm looking at now says it's stainless steel ring and yours doesn't look stainless steel? So this requires a slight modifications the part number. 063PZ5184 | GLASS PLEXI ST RING D33.12 . It also has a discrepancy with your dimension because here it's listing it is 33.12. If you change the number to 063PX5184 Then you get the gold ring. But I am concerned about the size discrepancy it's bigger than whatever you think it is. It's also for a watch that has this movement 861.1 point

-

In similar situations I have made a well around the screw with Rodico or blue tack to contain the alum solution. If dipping part of the main plate - don't forget the dial screws, like I did !1 point

-

1 point

-

The movement looks like a Baumgartner 582 'digital: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&69&2uswk&Baumgartner_582_DIG Onto the second watch ... should be interpreted as 'Diantus' rather than 'Diantvs'. If you there google something like diantus watch history you should have more luck. For some case openings I have a normal screwdriver (with a good quality approx. 4mm steel blade) I filed down to thin the blade but still keep it's width. This is ideal for then putting in the opening recess and then a twist of the handle easily pries the case back off. I find this more reliable and controllable for where there is an opening recess than a more traditional case knife that can slip or not apply such even pressure.1 point

-

1 point

-

1 point

-

Thanks for letting me know, A drop of naphta, deisel fuel, avgas etc on jewels, temporarily frees the pivots which may be stuck in dried oil. I recommend making a habbit of its use to anytime we suspect a lubricant issue. I also recommend finding and fixing as many faults as we can, prior to final clean, But I am self though so not all my techniques may agree with scholastic teachings. Regards1 point

-

I found this Summit on ebay going for not much £ - just loved the look of it. The hands are beautifully blued. A clean+oil, new mainspring and strap, it's running well and looks great The movement is a 17J A Schild 1130, which would date it to 1955-60, but it looks more modern to me. Anyone heard of Summit ?1 point