Leaderboard

Popular Content

Showing content with the highest reputation on 11/07/21 in all areas

-

Look at the suspect wheel with good magnification it could be a bent tooth.3 points

-

My name is Randy. I'm a retired Aerospace manager ( Boeing ). My father was a graduate of the Bulova school after WWII, and left a lasting impression on me in regards to the wonders of watches and watch repair, and shared some tips. I still have and use some of his tools. Years after he passed, I started taking online courses and adding to my collection of tools and methods. For a short while, I was repairing watches for friends, and a few other clients,..but now that I'm retired, it's mainly for myself. I live in the US..Eastern Washington state. I also play music - professionally. Best regards to you all, I'm looking forward to sharing with all of you. I've added a picture of my bench. Built it using IKEA parts2 points

-

Just found this one as well. It does not have a stunningly finished movement like other pocket watches that I have seen, on here mostly, but this is Australia. Is this worth picking up? This would be for me. https://www.gumtree.com.au/s-ad/epping/antiques/silver-full-hunter-pocket-watch-1907-working/12844028681 point

-

One of the underlying problems is the mindset of the watch buying public implying that a watch part made on a Japanese machine in Switzerland is better than a watch part made on a Japanese machine in China, USA, England, Australia, France, Germany or anywhere else in the world that has the machinery. The major watch factories in Switzerland offer a public perception that their watches are made by Swiss watchmakers who, by virtue of birth, are better suited to make quality watches. This is great salesmanship on their part but, in truth, their watches are designed with Cad/Cam software, made with stamping presses, CNC lathes, milling machines and wire EDM machines. Watch factories require designers, engineers, CNC programmers, set up technicitions, tool and die makers, assemblers and polishers. The one thing watch factories have the least need for are watchmakers. The point is, watch parts can be made almost anywhere to precise dimensions and tolerances. There is a video on YouTube showing a technician at the Patek Phillippe factory making a watch pivot on a WW Watchmaker lathe. They want the public to believe that this guy can crank out 65,000 plus watch pivots a year using a graver. This is sales fluff. Watch pivots are made on CNC lathes fed by a huge roll of pivot wire. The pivots are designed by engineers, the CNC machine is programmed by a CNC programmer and the lathe is set up by a CNC set up technician. In the end a watch gear, a lever, stem, pivot or any other part on a watch can be made in Switzerland or outside of Switzerland. If the watch buying public could realize this the Swiss watch factories would choke on their own greed. david1 point

-

I am pretty sure you gentls be regular customers once you try Coca Cola as penetrant fluid, Soak works better than just penetrating oil as it reaches every point where no pentrating oil has gone before.1 point

-

These screws snap only when glued, rusted solid, or force turned in the wrong direction. A broken screw in a barrel is particularly nasty to have, and must be avoided by all means, because unlike others it can't be grabbed at both ends with an extractor.1 point

-

Hi Have you recently dismantled it/serviced it , If not as clockboy said look for a damaged wheel or some dirt jammed in a pinion causing a bind .1 point

-

I had warned before, the motor looked toasted already and had to be treated and tested with care and some knowledge. Anyway if you measure it and can find a new one, that will cost you much less than repair. Electrical motor rebuilding is another almost trade, no surprise as skilled labor is charged gbp 50 to the customer, goods that used to cost equivalent of a month of salary are now available for a small fraction of that.1 point

-

Never seen any Rolex avertising which propels this notion, actually the message carried seems to be different one to me. Note I don't care a bit about Rolex or for that matter the entire Swiss industry. Incidentally, with all the admiration for independant watchmakers, I find them to be a bit out of place when diverting from their specific field of knowledge, but that would be digressing. Again, I don't think that anybody doubts that the for large volumes, production (as in making parts) is entirely automatic. However, do you have knowledge if the assembly is automated with robots as well? E.g. Seiko is known to do that for all the entry level mov.ts, but not for the Grand Seiko, and these sell in not so small quantities. I wrote about about vintage Rolex, as in 60 years old or more. Of course ready balance staffs are immediately available for current and recent models to any official service center, the watch doesn't need to go to Switzerland for that kind of repair. Then if a Swiss or anybody else lies and charges an eye for an official repair or service of a watch or other product, is of course dishonest, but not unknown. And to be blunt is not that I feel for the rich gold Rolex owner either. Anyway, what I am trying to say I that I find ridiculous to say that like of AP, PP, VC, and in their own segment Rolex, Omega, and another Swiss 100 brands or so do not hire excellent watchmakers, of which a good many could make a complete mov.t by himself. But they all work for the profit of the employer, which like it or not, comes abundant.1 point

-

A heat gun is a bit it too much i think If you can keep the heat localised ok that's why we recommend the soldering iron as you can place it on the screw head and the screw gets the heat. good luck1 point

-

The case looks good. A good bees wax polish to feed the wood should be all that is needed. Those synthetic polishes like Mr. Sheen I wouldn’t recommend them.1 point

-

The search result appears conclusive but I have seen now enough mov.ts where the ratchet wheel screw is left handed, and with a single slot. The reason, I believe, is that saved one tool switch operation at manufacturing, when the thread is as the crown wheel. So after applying penetrating oil and bit of heat, which won't hurt anyway, I suggest the OP to try a gente twist clockwise also.1 point

-

But given that the legal profession is the most corrupt immoral profession going I would suggest it's quite likely. Just look at the politicians that have a legal background.1 point

-

You're singing my song! I [i]hate[/i] that sort of chauvinism... I almost didn't buy a BMW once because of it. Porsches are worse though... Not every Porsche owner pronounces it like the thing attached to the front of your house, but [i]way[/i] too many of them do... It's the same in watchdom. My mind goes to the ETA 2824-2 (and copies/derivatives) in every damn watch for sale it seems. Or better yet an ETA 7750. I knew a guy who had a $45K gold Breitling. He was so proud that he spent $45K on it, and I had a hard time keeping my face in check... That's a REALLY expensive 7750... I think IWC is another brand that sells pretty boring movements at really not-boring prices. Then there's the same flavor of nose angling over Sellita movements being somehow inferior to ETA... Sellita [i]MADE[/i] ETA's movements! A 2824-2 is zero percent better than a SW200, and it's probably the other way around (doesn't the SW200 have an extra jewel? I'm too lazy to look it up for the hypothetical argument with no one). They're machines. If we're honest, they're not even very good ones since a $1 quartz movement will blow most of them out of the water. Admittedly, I will say I prefer your typical Swiss movements over your typical Japanese movements, BUT that's because of the finishing. I fully acknowledge it's an aesthetic thing, and I'd probably still take a better spec'd Japanese movement over a lower spec Swiss movement...1 point

-

Are you turning the screw the right way? Ratchet wheel screws can be left or right handed, and not all manufacturers are considerate enough to mark their left handed screws so that you know which way to turn it. You may have to try some careful experimentation to work it out. On the other hand if you can identify the movement, and maybe post some pics, somebody here may have already worked it out on another watch and can pass that info on.1 point

-

This is a Swiss movement of usually questionable quality meant to look kind of like high grade American railroad watches. Finding out the maker is usually tricky, as they didn't want anyone to know! There are collectors of the "Swiss fakes", I would imagine asking at the NAWCC forums might bring some of those guys out of the woodwork. I am guessing there's an engraving of a locomotive or something on the case back?1 point

-

OK that's great. If what you've got is what I think it is then you want the Sternkreuz ST, Domed Top range which you order by outer/inner diameter. Check out here. The idea is that the crystal is sandwiched between the inner diameter of the bezel and the outer diameter of the case, making a very secure and water tight fit. With this type of crystal no press or crystal lift tool is of any use at all unles you get the bezel off first, and then the crystal should simply push off the case.1 point

-

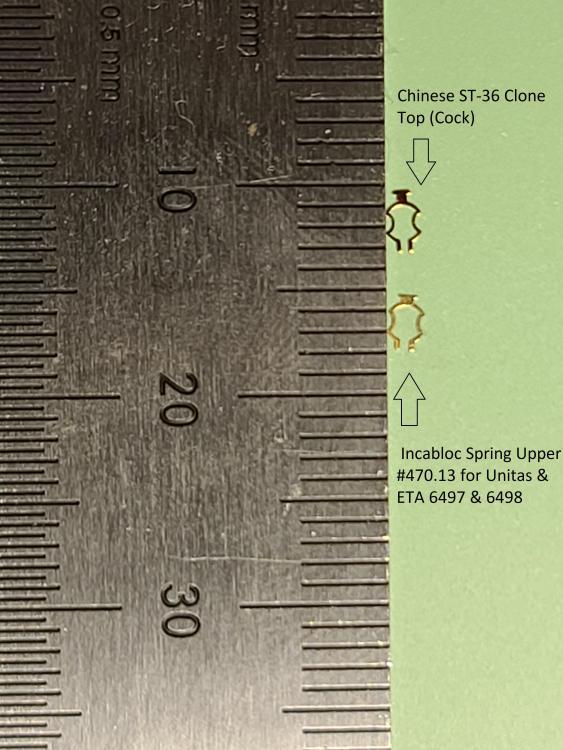

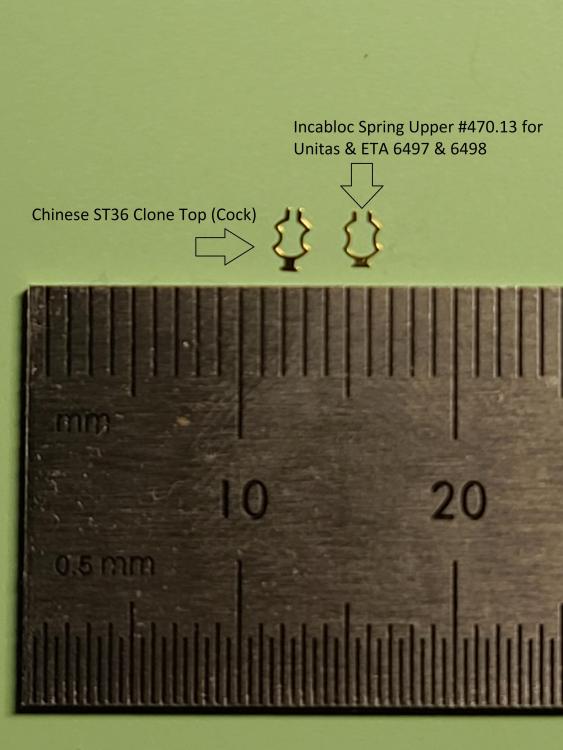

Hey All, Got the replacement I ordered from Ofrei. As one can see, it measures much different than the original Chinese clone one. Wanted to make sure I posted this here so anyone else with the same issue can check it out. I haven't had time to try to install the original incabloc (which I ended up finding). Will report back when I do that. Thanks for all the help thus far!1 point

-

1 point

-

Always start with he really simple and common stuff: how does the barrel and centre wheel sideshake look with the power let-down? Rubbing hairspring coils tend to cause very noticeable rate changes which are obvious. Improperly adjusted escapements are more common on older watches in my experience, say <1950's.1 point

-

Please read the Watch cleaning section especially page 8 it's good practice to also peg fork of pallet taking care of guard pin and impulse jewel surface, I have done this combined with burnishing fork with ladies mainspring wired to pegwood,with great results. 20 to 40 degrees difference. This article on cleaning will recharge your approach to cleaning and amplitude. Obviously mechanical issues sorted first. Graziano 626914013_December2012(1).pdf1 point

-

Here’s some pictures on a movement (ETA 2000-1) I was working on to illustrate: place a tiny piece of rodico in the gap using a sharp tool (tweezers, or a rounded pin in a piece of wood) nudge the middle part of the shock spring slightly until it pops out; repeat the process on the other leg of the shock spring After removing the cap jewel, using tweezers close the shock spring back into the setting. Then remove the rodico. When repeating the process after cleaning to reinsert the balance jewels, it can be significantly harder to open the shock spring legs from an empty shock block. You need really sharp tweezers, using the flat at the end as a blade to “twist” up the shock spring from its catch, because the balance jewels are not there to stop the shock spring legs from downwards movement.1 point