Leaderboard

Popular Content

Showing content with the highest reputation on 09/27/21 in all areas

-

If you find you start doing escapement work an electric heater is definitely more convenient than an alcohol lamp. There is of course the very expensive Bergeon heating plate with electronic temp control, but if you scour Ebay you can find small lab heating plates surplus for less. You can definitely get it to zero just by manipulating the collet. I do some vintage after sales service for a big brand, pieces often from the 1920s up to 60s; they expect the beat error to be under 1ms in all positions. It's not easy or fun to do on a tiny delicate movement, but definitely doable.4 points

-

For pinning at the collet, in school we modified a pair of #5 tweezers, blunting them somewhat and then shortening one tip; this allows the long tip to push while the short one still has some purchase on the collet, leaving the hole free. It would be hard to make a slotted tweezer that would work at that dimension, but they could be useful elsewhere nonetheless. I have pliers I have modified as such for removing and replacing pins on clock movements.3 points

-

I have a recipe that was published by Gruen, I think it was during the war for "getting things done". It's not that different from the Finnish recipe I use for clocks. Gruen recipe: 1 ounce oleic acid 2 ounces acetone 4 ounces 22% ammonia 25 ounces distilled water The oleic acid and ammonia combine to form a soap*. Oleic and oxalic are quite different; oleic is essentially pure fat and liquid, where oxalic is from my experience crystalline, that is perhaps why the addition of some soap in the above recipe. Rinse in distilled water 2x and finish in isopropyl alcohol, dry in warm air. *The most traditional soap is some kind of fat mixed with sodium hydroxide, or lye, a very strong base. Ammonia is less basic than lye, but works great and also has its own cleaning action.3 points

-

2 points

-

I hated science. The teacher I had always kept hitting me on my head with books because I was always messing about.2 points

-

Just had a look on ebay there are several pinions for the 610 1250 and 1250B so worth having a look1 point

-

Hi what you have got is a broken mainspring or it come away or broken off the the anchor point in the barrel. Either way the watch needs stripping down and the spring replacing and the watch serviced whilst in pieces.1 point

-

From what I have seen on the sheets 1250 1250b 1250d look very much alike as the definition is not too good, there must be some reason there are three versions. Could be height, shaft diameter, Checked up and found . 1250D height = 5.99mm parts restricted by manufacturer 1250B height = 5.69mm obsolete. so in either case its a case of finding NOS parts.1 point

-

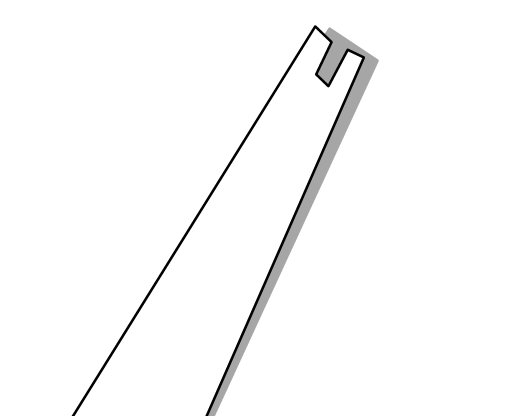

Many thanks again for the help on this one! In the spirit of learning I'll keep going in both directions, trying to source a part while I make a replacement. The references above are great - clearly I need to keep working on identification and cross-referencing skills with the catalogs and various other sources. Looks like a chance to revive the old army identification skills with those decks of cards that showed silhouettes of planes and tanks (now adapted to watch parts). A rough-in of the replacement is shown below. I've filed and shaped it a bit more but may start over to give it another try. Quick summary of the process: Started with metal from a feeler gauge Punched the screw hole Attached the broken part to the steel with Shoo Goo Roughed in the shape (very slowly) using a cutoff wheel on a Dremel Shifted over to various files for the final shaping Will keep everyone posted on the outcome!1 point

-

1 point

-

I found a modified tweezer among my Dad's tools. I will post a picture of it later today if I can...or tomorrow. It may well be what he used for this task.1 point

-

It can be. I just 3d printed in resin a movement holder for a 6498 and it was a perfect fit, with no shrinkage. No post finishing required. Another option is to print it slightly oversized and then, if you have a lathe or mill, machine it to final dimensions. Much less work than machine everything in metal. And with the advances in metal printing, you can 3d print things directly in 316L stainless steel. I am looking for this service but it is still expensive for printing watch cases.1 point

-

Your idea is perfect, however, Nickelsilver said it better than I can. A DIY is hard. I think there must be something suitable produced at sometime, I just haven't seen one. Regs1 point

-

I use a cheap regulare pair of tweezers to tighten the pin, one prong pushing on unsharpened end of the pin , other prong on the other side of the stud. Hold your tweezers a bit unlevel so you wont obstruct the sharpened end. Regs1 point

-

You completely missed the point of my post The O/P was asking about a low cost solution. And believe it or not water and dish soap does a very good job of removing oils and grease, it's what dish soap was designed to do. It not be used by any watch maker professional or not that you know of, that does not make it any less good at removing oils and grease, I bet the average frying pan is far dirtier than your average watch. I agree it my not be the best and it may not generally be used by watch makers, but that does not make it any less effective at doing what it was designed to do and at a low cost which was the point of the O/P I will step away now. Bye1 point

-

Found a way to override the system . Just write for example 6309-7040 Jules borel in the search window . Jules borel old pages comes up . Then it works as before. Still out there but it's harder to find.1 point

-

Thanks @Graziano for the good wishes and I hope you are all doing well too. We are lucky enough to be double vaccinated, and so far have escaped the dreaded C19.1 point

-

1 point

-

The arm thats got little screw on it is called stud carrier or beat adjustor. The one with no screw is the regulator arm. When moving the regulator arm , the other arm should not move at all, but sometimes tend to. Good luck1 point

-

Oh no, I always though it was India Pale Ale. I guess this explains the sticky hairsprings. Oh well, you learn something new every day!1 point

-

I have a tool that moves the roller table in very precise increments for fine tuning the beat error. I only used it on one caliber I used to do for a small manufacturer, it's not terribly practical for everyday use. It has a table with a collet in the center that clamps on the roller table, then a finger clamp that holds the balance rim. The table turns around the collet, with index marks so you know how far you went. You can very easily turn the roller table a fraction of a degree, and then go back exactly the same if you want. For every day work, from the smallest ladies movements to marine chonometer, I set the balance with the cock on a bench block so the roller table is in a hole, balance on the block. Lift up the cock and move it over- not flipping it, just moving laterally, until I can see the slot in the hairspring collet, get in there and adjust (for tiny watches this is usually with an oiler, larger, a small screwdriver). Go back in the watch and check on the machine. If you have no idea which way to move, like when you are very close and the fork looks perfectly centered, you can check like this: let off all power, hold the balance rim, then nudge the center wheel so an escape tooth contact a pallet stone. See where it contacts. Rotate balance so an escape tooth can contact the other pallet stone, observe. This is with zero power on the watch so the balance really truly finds its neutral position. If, for example, a tooth hits the front part of the entry stone, and the last part of the exit stone, you can rotate the balance to see which way it needs to go (here the balance need to turn counter-clockwise from its rest state, so the hairspring needs to go clockwise).1 point

-

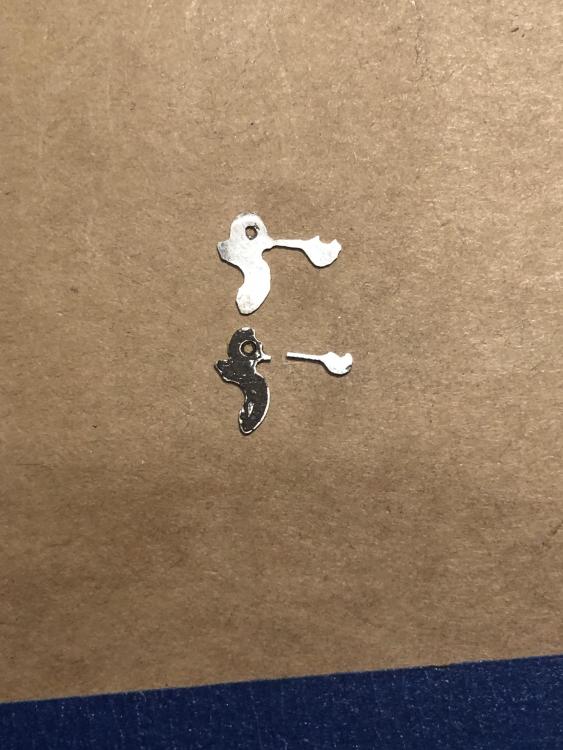

I believe so. They will tell you, "it's matter of practice, you can't expect to master it quickly", which is true of course, but the fact is, not everybody gets to the same level, some people is naturally more talented. I'm myself on the mid of the scale at best. Once again the key concept is: practice on something that has zero value, or for which you have replacements at no cost. For me, ruining some of the balances below at Euro 15 a piece was a sobering experience. Which was a good call. Which is what we tell all the time, but some beginners really think they know better. Recently one (not you) attacked a ladies hairloom because "he had reasons to do that". We never heard again how that ended.1 point

-

I think we have become overly OCD about beat error. Before the invention of timegraphers, what did watchmakers do? They just line up the balance jewel with the pallet fork by sight and that was it. I think the error could be out by 1.0ms.1 point

-

1 point

-

A Raketa CCCP mystery watch - possibly a 2609HA - The Dial reads CCCP - гласность This translates to USSR - Glasnost. The crystal looks cracked, and it is missing its crown, and possibly its stem, but hopefully I have suitable replacements. It should look a bit like this. It should also make a fine 404 club member and a good companion piece for the Slava 21 jewel 2414 - Перестройка (Perestroika) mechanical above.1 point

-

1 point

-

1 point

-

Ok, I had to replace the wiring in my old Elma when I got it a can remember the weird fourth wire. That was a while ago so is a bit hazy but if I remember right you have the live from the plug which goes up to the control head at the top of the column where it connects to the motor switch. It also connects to the heater switch. The other side of the heater switch the cable then goes back down the column and through the heater. When it comes out of the heater it goes to the neutral on the plug. The neutral side of the motor switch goes through the speed controller then back down the column to the plug. So I think that what you have is 1 earth, 1 live, and 2 neutrals to connect to the plug. That way the power for the motor and the heater are independent of each other. It should be possible to verify this with a meter if you have one. Unfortunately I can't remember which colour was which.1 point

-

1 point