Leaderboard

Popular Content

Showing content with the highest reputation on 03/02/21 in all areas

-

If it were me (and you're not, nor should you be), I think I'd take a file/emery stick to the top of the new cam. Original parts are only original once, but new parts can be sourced. You're forced into a new minute counter by nature of the repair, but the others are still original. That seems like the lowest impact and most cautious approach you could take. That said, I'm a dummy, and someone else will be along shortly to prove it.2 points

-

2 points

-

In my experience (some seven years now, and a few professional level courses at AWCI in Ohio) there is no simple solution to the mainspring winder problem. I've owned and used the K&D 128. Not very friendly, but useable for most American PW sizes. Wouldn't count it for wristwatches -- barrel sizes generally too large. Also used K&D WW size winders (set of three with variable "barrel" sizes). These are easier to use and quite useful for older WW calibers, particularly American. What many folks starting out won't understand is that the winder has to fit a number of different dimensions: Winder barrel must be just smaller in diameter than spring barrel. Winder core must be just larger in diameter than spring eye (to assure secure grip without permanently distorting eye.) Height of winder barrel wall must be close to width (height) of mainspring -- if too high, spring will uncoil inside the winder barrel creating unholy mess and destroying mainspring (ask how I know!) Understand that modern automatic mainsprings are completely different animal than old PW or vintage WW springs. They are much longer (meaning larger diameter when fully wound), much narrower, and generally have much smaller eyes. Old American winders cannot be used on these without extensive modifications. Which brings me to solutions. Currently I'm using a set of generic Swiss winders sourced on E-bay for about $350. These are identical to current Bergeon set of 17 right-hand winders selling around $900. Also still using the K&D adjustable set of three. Finally, using new set of Chinese winders (similar to Swiss pattern, quality not bad) designated for various ETA calibers (also fits some Rolex). Even with all these options, creative modifications are called for -- reducing height of winder barrel wall by inserting small washer to take up space, turning tiny ferrule on lathe to allow use of ETA caliber winder in generic winder barrel, etc. Sorry to advise there is no simple solution. You will likely need several different winders before you're fully equipped. Best advice is to practice repeatedly with old mainsprings, preferably identical to the one you're replacing. Make modifications as required, and proceed with that expensive new mainspring only once you're fully confident you have the bugs worked out. Oh, and don't believe people who say you can do it all by hand . . . best of luck installing 60-hour power-reserve automatic spring by hand without destroying it. Simply won't happen . . . !2 points

-

Sound like the clicks in that wheel are sticky. How did you clean and lubricate that wheel?2 points

-

With the fork out, put the balance in and check its freedom. It should be totally free, to the point that just moving the movement holder gently will make it move. When that is OK, check with the pallet fork bridge and screws. Then put the fork back in. If you then have your original issue there is a problem with the interaction of the fork and balance. In the past I was assembling a small series of tourbillon watches for a client. I suddenly was having big issues with the running; at full wind 300+ degrees of amplitude, they ran great. Drop the power and go below 270 and they were terrible, and were almost like your case needing a good shove to get going. Turned out to be a micro burr at the corner of the fork slot and fork horn. Really tiny, barely visible at 30x magnification. Removed that and all was well. Another time I was working on an older piece, very nice LeCoultre. It had run pretty darn well prior to service; after service I had barely 180 degrees of amplitude. Now, I've been doing this for quite some time... I spent almost a day to discover that a tiny fiber was stuck under the barrel bridge and was absolutely invisible except at a certain angle with a certain light. That was the culprit.2 points

-

On a cross slide, I’d expect that thread to be carbon steel. Not that it makes a huge amount of difference. I’d use shock (tap with a light hammer) or heat (but only just too hot to touch so as not to adjust temper) to help loosen jammed parts.2 points

-

definitely looks like a Baumgartner! 844 seems to be missing that horseshoe shaped cutout in the main plate though. @guidovelasquez has a very good implicit point here, that the mainspring you found in the barrel isn't necessarily the correct spring for that movement. The 844 is listed with a very different mainspring than the one you describe, 1.40 x 9.0 x 0.11 x 260mm (works out to 1.40 x .11 x 260 x 8 Non-Automatic GR3696 on Cousins) which is a lot more reasonable in length than what you had (but also thicker and narrower).2 points

-

2 points

-

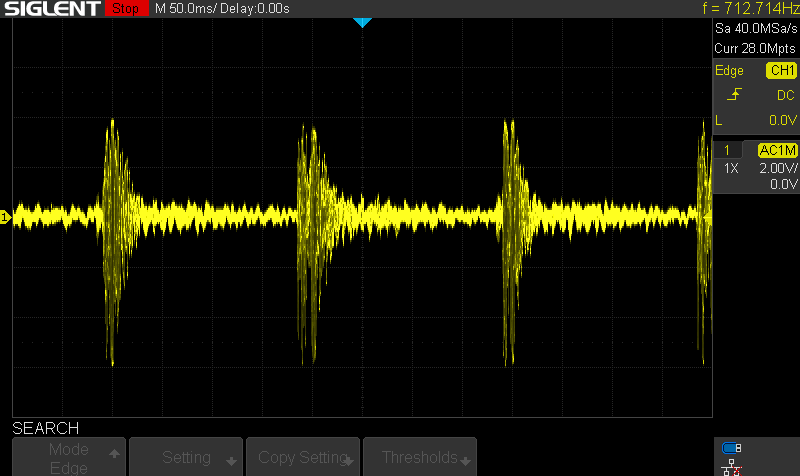

I listened to them...sounds like the 27mm is saturating...at any rate, it is a greater amplitude--what I would expect with the larger vs. smaller. I am not using the timing software, just looking at the output on my oscilloscope. Can you show the waveforms for these to cases? I think watch-o-scope will do that. Another thing that one would expect. When I modify the way I mount the piezo, I can change the sensitivity. Less cantilever...lower amplitude. This makes sense to me anyway. Interesting stuff. I will add an emitter follower and attenuate the output so that I can record it with my Tascam...on another day.1 point

-

Silly me I had forgotten about this. Where the hing is sometimes that holds the movement in the case so by removing the pin in the hing the movement might be removed. Your other question I will help tomorrow. It's bed time for me.1 point

-

Smaller ones seem to produce a "cleaner" and more accurate sound. Any size will work perfectly with TG or Watch-O-Scope but my goal was to get the best sound. As for the question of whether it's more sensitive? I'm not sure! I think the main takeaway from my testing is that if the disk is larger than the diameter of the surface that's making contact with the watch crown, you will pick up additional (unwanted) noise. The 'pin' on my timing stand is ~6mm so I'd want to have something closer than that rather than overhang it with a 27mm disk. Here are several recordings that compare 12mm and 27mm from two different watches. The pre-amp, and high-pass filter are the same on all files. I have not yet tried the method that Guido uses with a resistor and transistor. I think it will include even less static/noise. https://mega.nz/file/dtYHXQqK#0cVkxw02t1NSl4VE3B0tn4pOoGLmTn3NAo5_Xx162N01 point

-

I'll second that it's a good practice to replace just the balance complete prior to assembly so you can get a good look at the hairspring. After doing that, you can add the pallet fork and bridge to see how the fork and jewel interact.1 point

-

Agree with the above comments but also check the escape wheel teeth, just one tooth being a touch out of shape will cause the stops.1 point

-

Observe the coil from side view of the balance while running, a close up video of balance looking streight down on the bridge and side view showing the coil helps. Coil should be flat, level with concentric circles and not foul itself. Judging from the previous video, amplitude seems good which is a sign of hairspring free from rubbing, however you give the balance plenty of swing when you nudge it, instead gently move the wheel see if it picks up and go at some point. (I think the balance is out of beat) I always put just the balance complete and bridge back( no other part) on the mainplate for final adjustment leveling etc. it will give you almost 330 access to the HS around the balance wheel What happens if you turn a gear, third or center ?1 point

-

1 point

-

OK, I will have to attenuate the output to line levels and then capture it with my Tascam recorder. Give me a day or so...distracted by other shiny objects!1 point

-

1 point

-

Given that it is visually “in beat”, I would get it into its fault state (potentially repeatedly) and give it a slight wind and see if there is anything obvious going on which stops it from automatically starting. It could be excessive depth of lock which is difficult to overcome from static. I’m guessing these watches have adjustable banking pins (or equivalent).1 point

-

1 point

-

1 point

-

http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&2&2uswk&Baumgartner_8441 point

-

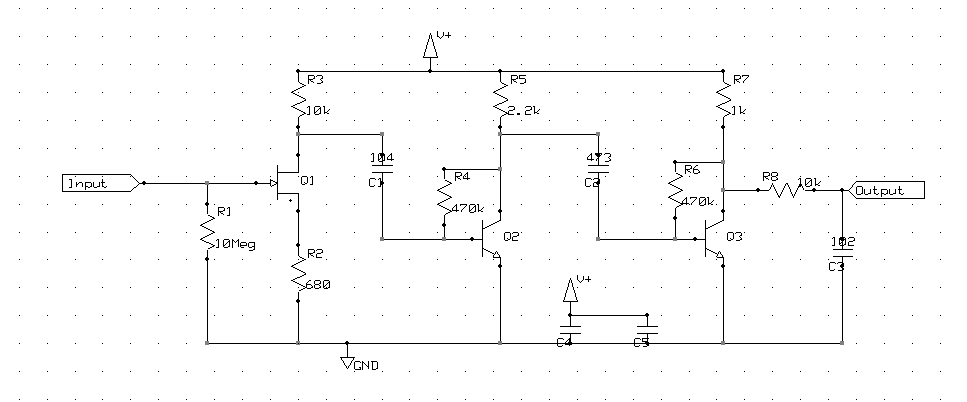

This may be a "tired" thread, but I still keep playing around with my sensor. I did not have any decent piezos in my lab (hard to believe...I have everything else!), so I ordered some. The two-transistor circuit needed a high impedance, so I added a JFET front end. Had WAY too much gain, so I dialed the last two stages down. May need to reduce it a little more. Nice result. Now, no background audio noise sensed (like with the electret), but guess what? It senses me walking across a carpeted floor!! I even have the sensor sitting on a rubber pad.1 point

-

I don't think ebay care these days jdm. I have reported loads of fake clocks and they don't bother. So I have given up.1 point

-

Oh no, ETA has removed all "Technical Communication". I should have downloaded these documents before they were removed. I'm going to service my first ETA 2836-2 and I really enjoyed reading (but not always agreeing with) ETAs advice. Anyone aware if these documents are available elsewhere? Checked with Cousins, and they have outdated versions. Perhaps just a matter of time before ETA forces Cousins to mark these documents as restricted. ? This really sucks! ?1 point

-

So that everyone who grasps what were talking about I have a link. It looks like there is no reference to them anywhere but they may still be functional if someone had flash player still installed. Somebody had suggested to me the way to do this is to get a portable version of a browser and then portable flash player so it can run on a USB drive or somewhere it's not installed that might work but I haven't got around to try yet. Then I suspect with the current Swiss attitude towards anyone touching their precious watches that there will never be an update for these. The above posting needed to be more clear perhaps? Or not talking about the tech sheets were talking about four separate webpages that had the assembly disassembly of four different movements. Then there was also the dynamic dictionary at all of these required a web browser with the flash plug-in. Cousins Has the technical stuff at least the older stuff. The newer stuff still exists it just isn't available for normal download. https://www.eta.ch/swisslab/7750/7750.html1 point

-

1 point

.thumb.jpg.e1737221d1bb91b37331a627546ff250.jpg)