Leaderboard

Popular Content

Showing content with the highest reputation on 02/16/21 in all areas

-

The first are countersinks. You can make oil sinks with them. Don't recognize the rest at the moment.2 points

-

1 point

-

1 point

-

Good point. As with any quartz watch there is no guarantee that just giving it power it will work. Perhaps one should attempt with a long exposure to strong light, or temporarily powering from a regular battery before spending for a new rechargable cell.1 point

-

Agree with both above. Also have you got a new cell yet? They are particularly pricey for the V157 / V158 (£50+)1 point

-

It's an M3, to make practice for a comparable, but non-standard size and pitch one that I need for an antique clock restoration. Slowly getting there and then I will tell its full story. This is what I've used, nothing to do with watch or clockmaking, but for various reasons it was the best purchase for me at this time.1 point

-

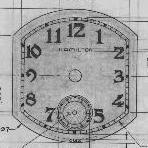

According to Rannft http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Hamilton_620 the Buren 1005 is the same. so I found these, attached Buren 1000, 1001, 1002, 1003.pdf1 point

-

Hi I found this one , Whether is close enough ? hamilton_626_627_628_629.pdf1 point

-

Ah haha you're right of course, 0.5. That's cool, it's very satisfying to make lathe cut threads!1 point

-

Yes, threading practice, tried some techniques like tool upside down and spindle in reverse, and cutting with compound set at an angle. BTW here where I live M3 is 0.5 pitch ?1 point

-

#2 is definitely an old-school pallet warmer. The #3 pliers are fascinating. There's a stop screw, domed guide, and cut out. I would (randomly) guess some sort of case tool or clock tool.1 point

-

Parts interchangeability is significant between Illinois 18 size models, as the image shows. Donor movements abound, and Dave's Watch Parts/Dashto has most of the specific parts you'd need for an 18s Illinois if you don't want a whole movement. The 6th model movements were made during a period of tighter, more precise manufacturing and finishing, so one of those would be an ideal donor movement if it has the parts you need. The 2nd models go back to the 1870s and are a bit rough.1 point

-

Take Longcase clocks (Grandfather Clocks) as an example made hundreds of years ago and still going strong, did you know some of these clocks still have never been rebushed or had parts replaced. This ships clock in about 20 years it will be worn out. It's down to quality of the material used, they can't afford to make things last because if they did they wouldn't make any money and employment would be much higher then it is. On a lighter note I like the song by Neil Young called Piece of Crap.1 point

-

Is 2 some kind of pallet warmer? It looks like it's used to hold something away from you while you heat it.1 point

-

Remove it and measure with vernier calipers. You will also need a crystal press. These are essential tools even for a beginner.1 point

-

I put it on a balance poiser and rolled it to find out which way it was bent. It was not a really bad bend...just bad enough. Then I noted the position of the roller jewel so that I could know when I was 180 degrees out of phase with the bend (the upward bend became a downward bend). Then in that position, I gently pressed down to correct it while holding the balance with my other finger. Once I thought I had made some progress, I took a triangular arkansas stone and rolled it along on the poiser on that pivot. It was crude and the stone was larger than I wanted, but I could not find a better solution in the bench. At the time, I did not know I had an equivalent Dumont #8. Installed the hairspring (180 degrees out of phase!!!!) and installed only to realize my mistake. Removed the hairspring and did it again right...close to right. After installing the balance, I could see I was still out of beat. So I removed it, put it on an anvil block, lifted the bridge while holding the balance and tweaked the hairspring collet. Installed again and voila. Lots of places along the way, I really need to channel either my dad or one of the experts on this forum, but I made it through. Like I said...this is a "learner" watch, so there was no down side to the exercise. I get incrementally better each time I work on one of these things. The watch is still running in static position on the bench.1 point

-

I have bought mainsprings, movement parts, and shock parts from Cousins UK. It is surprising what they carry. Some Russian calibers have unique shock springs, such as this Poljot 2409 from the 1960s. I suspect that some of the watches you bought were harvested for the balance settings and springs.1 point

-

That is a clever design help, perhaps it was added to alleviate the constraining trap of removing only from the setting position - something unheard on most other mov.ts, Seiko to begin with. Anyway, personally I don't follow the practice of the shaped hole. I just trust my able hand to push just enough for the stem to come out being gently pulled by the other. Which has not failed me yet.1 point

-

Thank you @VWatchiethis is a helpful tip. I gave the plastic film in the movement holder a try. And it's definitely better than what I was doing.1 point

-

Sometimes unfortunately hard to find because sometimes the wording is incorrect. But always worth a look may be somebody else has asked your question before. Here's a link with a nice picture which explains what I was trying to say . https://www.watchrepairtalk.com/topic/9981-stem-removal-on-sellita-sw200-1/1 point

-

1 point

-

A bit strange is the OP wanting to replace it, which suggest it is badly scratched, that shouldn't happen with sapphire. Just like any other modern Seiko, it uses a nylon gasket, P/N 86580100. Anyway as it happens in these cases of "in search of Seiko crystal" is always good to openly tell how this information is gathered, whicj is hardly a secret. Parts numbers for a given reference can be found from a variety of online sources like the ones mentioned by watchweasol above, plus Boley.de and Seiko Australia. Of course, the fact that a part is listed doesn't mean that is available, or convenient to buy. And here attached the Seiko document that allows to decode, to an extent, crystal codes. Crystal Codes.pdf1 point

-

It should be 290A02SN02. From that number we can tell it's Ø29.0 mm, glued in, sapphire, no-coating, and transparent. Can't tell how thick it is unless there was a list that said how thick serial number "02" was for this crystal. You don't need to remove the crystal to measure the thickness, which will be harder to get back in because it's doesn't look like it's press fit with a gasket. Just put something inside the case that sticks out enough so that you can get calipers on the crystal and whatever is in there. Maybe a plastic bottle cap?1 point

-

Well done and nice find. That looks great, and the new bracelet makes a big difference. Enjoy it.1 point

-

I bought a slightly modded Seiko SKX007 off of eBay, about which in general a more experienced man than I here aptly quoted Obi Wan Kenobi: "you will never find a more wretched hive of scum and villainy." LOL. To be fair, the watch was accurately described cosmetically, more or less, but I didn't take the time to read the description. One thing that wasn't entirely accurate was the representation that the watch "works well." Well, it did run, but not to expectations. The amplitude was low, the beat error high and the rotor felt sluggish. So what's a newby to do? Well, a full service of the 7S26 is still a bit beyond my skill set. So I replaced the movement with an NH36, which meant removing the hands and dial from the 7S26 and mounting them on the new movement. I also discovered (last to know) that the crown and stem were not a clean "switch over" between the two movements so I measured, cut, and filed the new stem that came with the NH36 movement and epoxied the crown on to it. Now I know that this hardly qualifies as watchmaking, but I have to admit feeling a bit proud that the watch is now better regulated, that I managed not to bend or lose the hands, that the epoxy is only on the intended part and that the thing is back together with no extra bits sitting in the tray. Or, more precisely, you have to celebrate your small triumphs along the way to some level of actual competence. Remember that feeling when you first got parts to play well together to resemble a functioning timepiece? Well it's been a pretty good morning so far. My family appears to be tolerating this with an air of bemusement, as in, "I wonder what crazy scheme Dad's up to now?" But you all will get it. Happy Wednesday . . .1 point

-

Purchased some tweezers recently just for hairspring work. However I have been very disapointed with them although they grip the hairspring the slightest touch and the coil slips. Wishing I had purchased more Dumont tweezers I searched the internet to see if I could make them at least work better. Many sites talked about dressing tweezers and when I found this vid I realised I was not dressing them correctly. Just another one for that big learning curve.1 point