Leaderboard

Popular Content

Showing content with the highest reputation on 09/30/20 in Posts

-

I suggest you put it on first to check the direction of the wheel before gluing it on or closing the hole. You wouldn't want a backward face escape wheel.4 points

-

It could be fun! I had a new quartz clock from work they were throwing out because it ran backwards. I set it up in my basement studio and you could read it perfectly in the control room window reflection.3 points

-

Yeah, this one was well glued- nothing worked correctly. Seems okay now.2 points

-

Hi all, hope your having a good day! I have finally got back to restoring a Landeron movement, a personal project I started a while back. I believe it is an early cal. 48 although it may be a 47? The balance was one of the many issues with the watch. With a broken pivot on the staff and the balance spring beyond fixing, without buying professional tools finding a complete balance would be the easiest way for me to fix the issue. I am at a complete loss as to what balance I need; I know its a non-incabloc, possibly made by either Barbell or Renata but I'm not sure what I should be looking for, or where to find one. There are many variants and I'm not sure if any of the calibers of Landeron house the same balance that I might be able to utilise? I've attached a picture of the movement before I disassembled if it's to any use? Any help is very much appreciated! Many thanks1 point

-

Hi everyone, I discover mechanical watch 1 year ago, and since then has been a ride.. bought my first Chrono Longines L688 in the beginning of the year, pass a few months I bought a couple of Seikos, CWC, and lately I moved to vintage watches.. i own now a tissot antimagnetique cal 27 from 1948, and 1 week ago (my birthday) I bought an amazing lecoultre Powermatic 481 from 1948. my wife bought me an hobbyist kit, with all the necessary tools to service a watch, together with an broken tissot cal 27. I’m loving it, I’m still in the process of finishing the cleaning and oil of it. i love Mark’s videos, they are great inspiration. nice you meet you all1 point

-

Looks like an AS 554. Compare http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&AS_5541 point

-

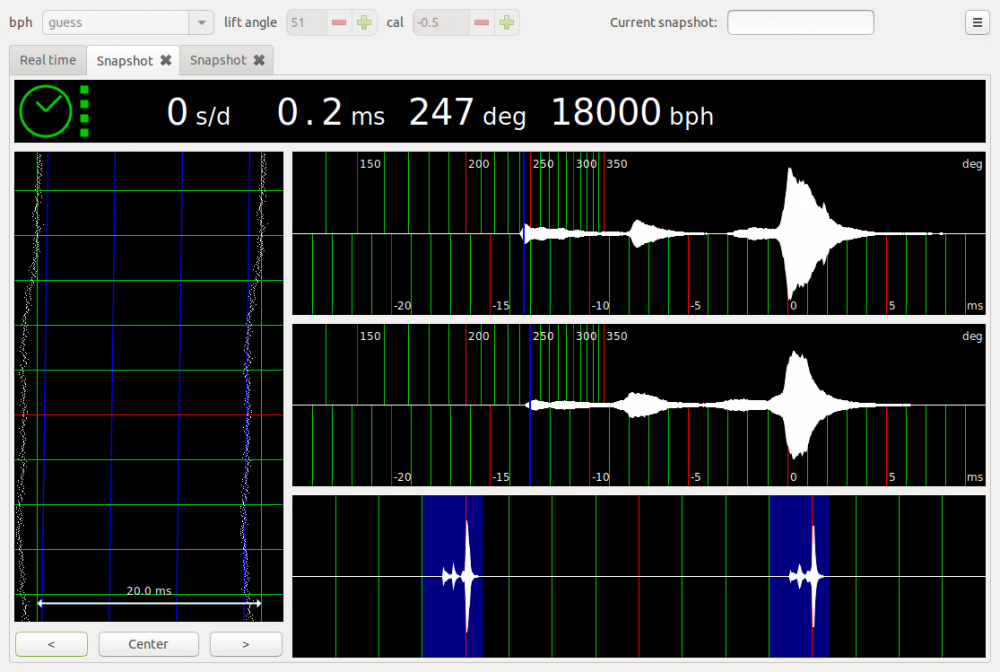

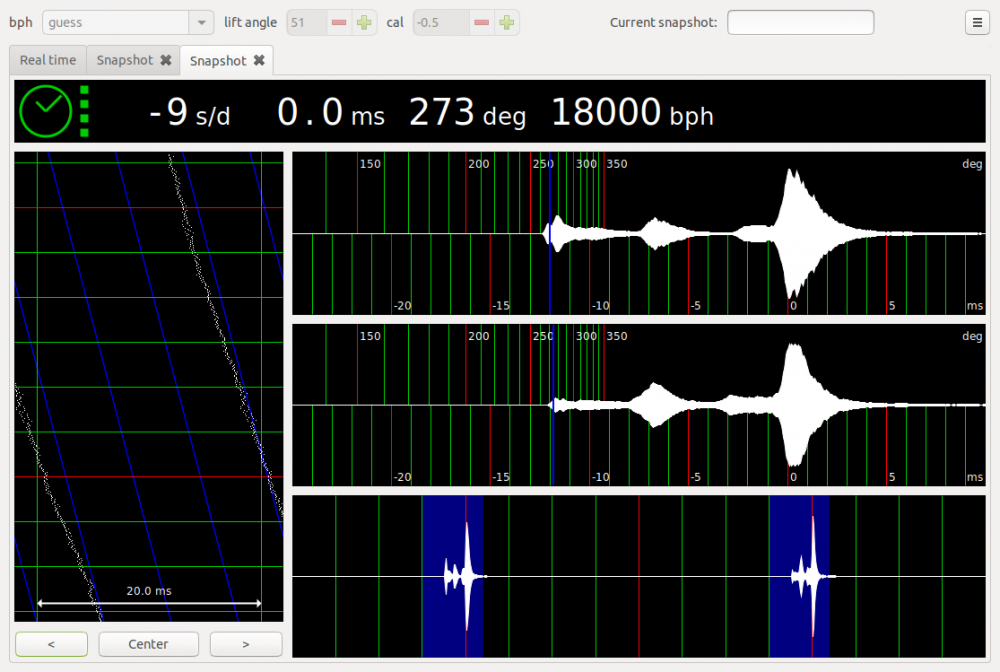

I've been wearing one of my recent 404 club watches quite a lot recently. The Sekonda on the left in this picture. Some might suggest I'm drawn to it because the big numerals are easy for my old man eyes to deal with. I couldn't possibly comment on that. However the real reason I've been keen to wear it is because I decided to torture lubricate it with my witches brew of fragrance free baby oil and neatsfoot oil. I have tried this on a couple of Timex mechanicals, and nothing exploded, so I thought I would risk it on a "real" jewelled piece. Now I am most certainly not recommending this experimental concoction in place of oils from a recognised manufacturer, however I am curious to know how well it stands up to the rigours of actual wear. Given that the formulation I chose is only a guestimate of what is actually in genuine watch oils, the result could well turn out to be disastrous, but so far it seems to be doing remarkably well. When the poor victim arrived, it was completely gummed up and wouldn't run, so it was treated to a fairly conventional strip and clean service, followed by lubrication with my "special formula'. Here is the result after 24 hrs on the wrist. For comparison here is the result of re-winding the watch and letting it settle for a minute or so, before testing once more. So I guess I must be at least in the correct ball park with the viscosity, as I have been wearing it for about a week and the performance has been consistent. So far nothing has migrated to places it shouldn't have, and the warmth of my wrist and the relative chill at night don't seem to have made any measurable difference to its performance. Of course the real test will be to see if it is still going strong in a years time or so.1 point

-

Hi Both bench mats and desk top benches come in all types see below. The options bench mat Bergeon around the £20 mark but a lot of people use craft mats (cutting mats) like from Hobby Craft. The desk top options are as below The DIY option at low cost but very practical solution to restricted space and the ready made one from H.S.Walsh. Even the ready made one can be a DIY project. On both counts the options are numerous its just a question of cost against time for DIY.1 point

-

Yes ,the original bracelet. That type of construction is called "case integrated" and is not a good choice if like to change to a strap or anything else.1 point

-

I think you'd still want to remove the bezel to polish; the gold is most likely TiN and it will require some effort to remove... If you do it in place, you may lose a lot of case before you are done with the bezel. If it IS gold, it will come off easily. But Seiko is known for pioneering TiN coating so that's where I'm betting. I'd chuck the bezel in the lathe and polish it that way.1 point

-

1 point

-

1 point

-

O1 or 1095 would be good choices. It's available in numerous thicknesses, generally with 1095 having more options in the thin sizes, you'd have to check suppliers in your area to see what they offer. It's quite hard to find it in the very thin thicknesses useful for watch parts, except in the already heat treated state. You can anneal it though, which would make working it far easier. Just a quick look and I found these guys, https://springsteelstock.co.uk/ they say that they are "the small order specialists" which sounds very encouraging, and they offer 1095 from 0.1mm to over 1.5mm in thickness- I'd try them out. They say it's generally offered in heat treated state but that implies that they can sell it annealed as well. For watch work 0.3mm and 0.4mm would cover 90% of what you might want to make. I would stay away from hacksaw blades, they are often a mix of HSS and carbon steel, I don't think it would anneal very well and would be a bear to heat treat.1 point

-

Cut a piece of thin aluminm foil, like 1.5mm by 3mm, warp it aroumd a screwdrive about the diameter of canon pinion, role as you would a cigarrete, you are making a tube of aluminum, place the tube on the CANON pinion, you have increased diameter of the canon pinion by the tube's thickness, the tool grabs the bigger diameter. It works. Good luck.1 point

-

Seiko 5 bezels can be removed but that requires a good press and precise dies. If the OP's intention is just to change its color he can simply polish it well without removing it. That requires a rotary tool or even better a bench polisher, and the proper felt wheels and compounds.1 point

-

And the case up. It’s a bit unnerving casing this up. I feel like I’m “jamming” the thing together. But I did a little cleaning of the case, jammed the movement in, and it’s still running! Bonus: the mysterious keyless works, works. The stem soaking in oil seems to have done the trick. Once back together, I can move from winding to setting abs back again with no issue at all. Hands are not perfect but beautiful blue regardless. I caught the color nicely in at least one shot. We’ll see how it’s running tomorrow. Hopefully good enough.1 point

-

Hacksaw blades are good source of steel but I've never tried a set lever bridge. Thought about it and if I had no other option I would 1. Mark out the piece on the hacksaw blade stock. 2. Drill the holes and triple check that they are correct (this includes the bit which 'clicks' when you pull the crown). 3. Drill the inside corners. 4. Drill holes along the perimeter so that you can cut between them. 5. Rough shape using a dremel and Hand-file to finished shape. 6. Thin down to correct size. Good luck and share if you've managed to maked one! Anil1 point

-

Normally you should peen the hole to get a good grip when you reinsert the arbour on staking set. Do not attempt this without the tool as you are sure to bend/ damage the wheel. It works if glued, clean, put the wheel on top of a scrap hour wheel to refit the arbour( you are using the hour wheel as an anvil) you can grab the arbour's upper section(not the pivot) in tweezers to avoid damage to the pinion. refit, apply the smallest bit of glue to the pinion shoulder, try not to get any glue on the pinion. This wouldn't get approval from any master watchmaker, just that works . The glue specially if super glue will in the long run chemically react/rust l and weld the two parts bonded permanently. In case of mishap when gluing ,immediately soak in acetone and brush the glue off. Good luck.1 point

-

Let’s get some good close ups of the bezel straight on, and at side angles. It probably can be removed...1 point

-

1 point

-

1 point

-

Watchweasol is correct. Because of the zinc in brass, it tends to burn rather than melt under many heating conditions. Better to solder it or use copper. I've had one of those Chinese rigs for a while and really found it useful for the price paid. I could take in repairs that some other jewelers around here couldn't. I just needed a little more control and found a great deal so I scooped up the Orion. I'm excited to see just what its limits are. Because you can tailor the ramp of energy, you can supposedly get stronger welds because it allows the metal to cool slightly slower. That doesn't help with this application, but for prong replacements near heat sensitive stones and costume jewelry repairs it will be a godsend. So as I understand it, the machine you refer to building is a resistance heating unit. This Orion has a function like that. I'm just going to find an old scrapper or two in my basement and do some experiments. If I find no success I'll build one of those. I guess that's the best way to learn in the end anyway.1 point

-

Brasswire doesnt work well at all. Most if not all dial feet are copper which is the best. I have done several dials using a machine I build similar to the Fassbender machine and never had a problem with dial face marking. as stated the machine cost around £20 to make and it works. Not rocket science.1 point

-

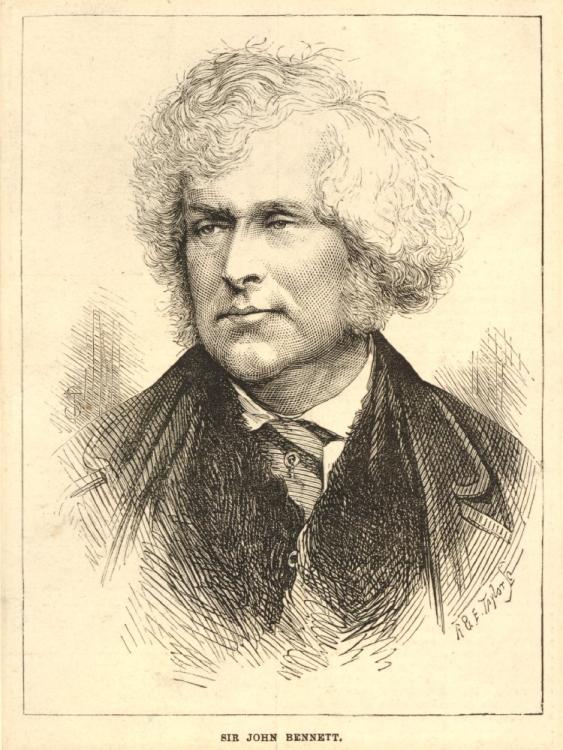

Have done a little bit of digging into the history of John Bennett. Trained as a watch maker under his father and moved to Cheapside sometime between 1839 and 1847 He had 10 kids, 3 with his wife and 7 with his mistress! He became the Sheriff of London and Middlesex in 1871 and Sir John Bennett in 1872 In 1889 the business became a Limited Company and it was around this time that John ceased to have any dealings with the company. The shop was dismantled in 1920 and parts of the shop front are still standing in the Henry Ford Museum in the US including two statues of Gog and Magog. lots of info here https://www.google.co.uk/amp/s/londonstreetviews.wordpress.com/2013/08/08/john-bennett-clock-and-watchmaker/amp/ interesting to know the history of the makers.1 point

-

Mine came with a small bottle of ink for that machine. You would be surprised how little ink that machine will use.1 point

-

That's why you open another checking account in the same bank solely for use with on-line transactions. You can transfer in and out electronically, but the potential loss is severely limited and always in your control. They impose no limits on how much must be in the account...1 point

-

That's awesome. In non-power delivery gearing, often you can get by with some serious leeway as long as nothing binds. A friend of mine worked at Breguet around 2000, he had an 80s vintage watch come in with two brass pins in the minute wheel where teeth had stripped off. His boss said ,"if it works, leave it", which he did and promptly quit haha (Breguet has massively improved in that time btw).1 point

-

Part 3 is a sort of redemption, or at least some lessons learned. The donor arrived about six weeks later (thank you Covid) and I quickly transferred the balance complete. The wavy traces quickly returned. So I stripped the movement again, paying close attention to the barrel arbor bearings. Looking closely, I could see that the barrel had actually been scraping the bottom of the barrel bridge. Manipulating the barrel with the bridge on and the train removed, I could also see that, under torque, the barrel would foul both the bridge and possibly the mainplate. Swapping in the donor movement bridge, the wavy traces continued. The free running of the train was okay with the pallets removed, but, turning my attention to the mainplate barrel arbor bushing, I could see this was slightly out of round. Under torque, the barrel would still hit the bridge. So that was it. I could not close the barrel arbor bearing hole, so after repeated reassemblies and inspections, I became convinced that the original movement was a goner. Thankfully, I had the donor, which I decided to service and install in the watch. In truth, the donor looked to have very little wear - I am unsure what kielbosched it in the first place. I serviced the donor and prepared to install the balance complete. Here tragedy struck again, as it appears that one of the problems in the donor was that the regulator arm was improperly seated in the balance cock, or the pins were just too short. Closing the regulator pins, the hairspring caught the closing arm and became kinked in the terminal curve. Here I finally did Mark's video justice, carefully massaging the hairspring until it was again smooth throughout the curve. A final hurdle: the balance on the donor movement had no endshake - none at all. Having watched Mark's video on unexpected endshake problems, I looked for a shim under the balance cock. Sure enough, Minsk Watch Factory had indeed made a shim under the cock, near the screw, which I had flattened as I had rubbed the tarnished mainplate with pegwood. So I got my screwdriver, and made a painful jab into my newly-cleaned donor movement. Reinstalling the cock, it ran strongly! Hurrah. Here are the results, positive and negative. On the positive, the watch runs strongly and relatively straight in all positions. There is also relatively little positional error (maybe 5-10 seconds a day, but I can live with that). But here's the heartbreaking thing. This donor, this seemingly babied donor with no major signs of wear, has exactly the same problem of wavy traces and variable amplitude as the original movement! It's less pronounced, sure, but it's there - a 15-20 degree variability in amplitude at seemingly random intervals, with the associated wavy lines. A reflection on that below. Battle-ready once again, but not without difficulty. Another charm(?) of the Luch is that the dial does not sit flush with the movement, so you need to be extremely careful when seating the hands to make sure they won't hit the dial. And back on my wrist, at long last. So, a summary. Why should you, an absolute beginner, try to diagnose and fix a battered Russian watch that hasn't been opened since Gorbachev? Well, first, you won't break the bank. These are plentiful, and if you get a plain dial they are cheap as chips. Second, you will use a lot of Mark's lessons. Not just chapter 2, but 3 as well. I watched every single video repeatedly, and tried to apply them all. If not for his video on barrel arbor bearing wear, I would never have found the problem. Last, I practiced a lot - a lot - of skills. I'm still bad, but getting this Luch back on my wrist has made me feel like I'm on the road to being a real watchmaker, whatever that means. And why should you avoid articles like this? One reason: poor, inconsistent build quality. From the shim, to the regulator pins of incorrect length, to the badly-seated dial, it doesn't take a George Daniels to see that these things were absolutely slapped together. This makes them hard to work on and diagnose. And even when you find a good donor that was seemingly retired after only a few years in service, you may find that it has the same fundamental problems as the donor you thought was deeply, unusually defective. So just live with it, and know when good is good enough. Don't make perfect the enemy of the acceptable, because they sure didn't when they built these things in the first place. So that's it. If you're exceptionally patient or you didn't have anything better to do tonight, thanks for reading this far. And thanks to the people on this forum for helping me out with this project - I am very glad I joined. Cheers!1 point

-

Hi as you have already found out lubrication of watches is a minefield every one has there own ideas and theories. As jdm remarked some of the products mentioned on the sheets have been superceeded by more modern products. I have attached the moebius book and the rules of lubrication (omega) so by reading both and making an informed choice. cheers moebius-specsbook.pdf 1472711985_8645_WI_40_rulesforlubricationcousinsuk (1).pdf1 point