Leaderboard

Popular Content

Showing content with the highest reputation on 07/27/20 in Posts

-

Hi I got another Wag on the Wall Clock (postmans clock) in a box its had a hard life. Its been duly cleaned and in doing so on of the pivots was almost gone, So out comes the lathe and after making a pivoting flag to fit the tool rest post, down to work drilling the arbour and fitting a new pivot. The end result was a working clock again now on the test stand awaiting the dial and surround fitting. I thought I had better post something in case you all think I dont do anything6 points

-

3 points

-

2 points

-

2 points

-

That movement is a rebadged A. Schild 2066. You should have no problems finding parts for it.2 points

-

Hey guys I just wanted to share with you my first project, an Omega Genève with the calibre 565. I saw it on Chrono24 for really cheap. It was sold as not working, but for the price I just couldn't say no to it and immediately bought it. When the watch arrived some days later, I opened the caseback to see if there is something obviously wrong with the movement what causes it to not run. A screw fell out and I noticed that it should keep the one missing caseclamp in place. I suspected that the clamp has made it's way into the train of wheels what causes the watch to stop. And indeed: a slight shake and it fell out and the watch started ticking, it wasn't running great at all but at least a sign of life so I hoped a service would recover it. Movement before service The movement was quite nasty, everything covered in small pieces of dirt and old oil. Stripping the movement down went quite smooth and I took photos of some parts to remember their location. I cleaned it in an ultrasonic cleaner with Elma Red and then rinsed it in distilled water and isopropanol. After all parts were dried I started to inspect them and I thought that they would all be fine, but that assumption turned out to be wrong later. All parts cleaned and dried (with expeption of the automatic assambly) When the movement was assambled again I was really happy to see it ticking again, but the joy only lasted for a short time, because it stopped after about a minute. I first inspected the balance again but it was moving freely so I assumed that the problem would be in the train of wheels, because the watch was running nice at first. When I checked the third wheel I noticed a small black dot between to teeth, barely visible even under magnification. I cleaned this spot and also all other wheels again and pegged out the pivot holes. After reassembly it was now running nicely. On the timegrapher the watch is running with around 240° in dial up and down position and around 220° in hanging positions. Beat error as well as positional error a quite low. I know that these results are far from perfect, but it's my first project and if I consider the condition it was in before I'm quite happy with the result The lession I've learned from this: spend more time on inspecting the parts, as it can save you a lot of time and nerves later I found a new original Omega Crystal for this case reference, now I just need to wait for it to arrive and it will be a nice watch again. I hope you enjoyed this short report and I wish you all a nice weekend1 point

-

I always wanted a carriage clock so took the plunge and bought this one for £40 at auction. The clock was a bit dirty so only cleaned with a cloth. A couple of the external screws have slight surface corrosion, a bit of dust inside the “cabinet” and the glass edges had grime build up. There is no name on the clock, as far as I can see. I bought the clock unsure if it was working however a couple of turns with the key and tick tick it worked ! I read a number of posts on here and was a surprised to learn of the Chinese interest in carriage clocks. Is my clock genuine ? Keeps good time too.1 point

-

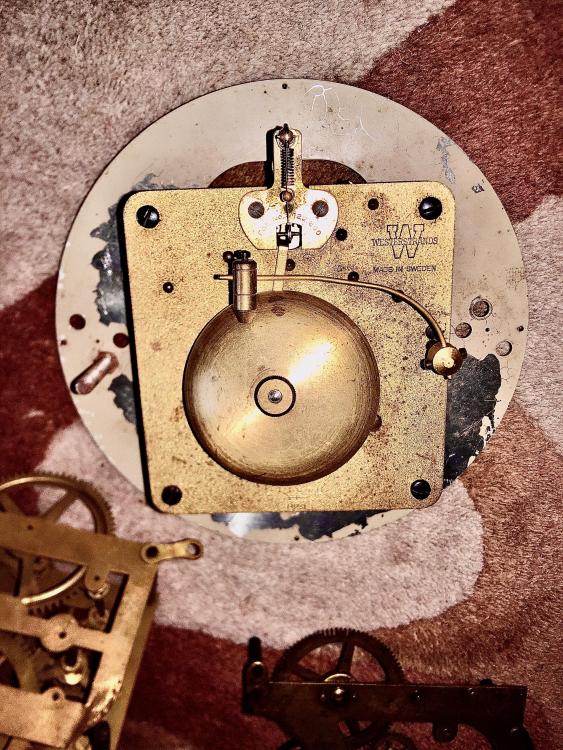

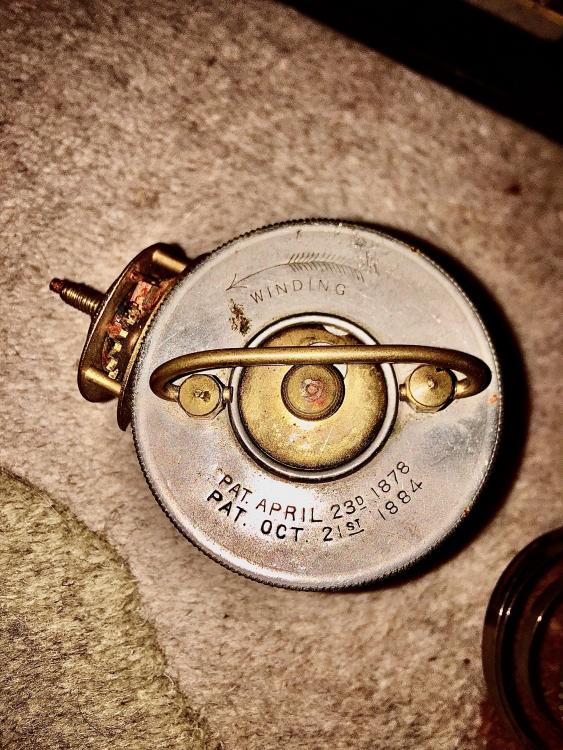

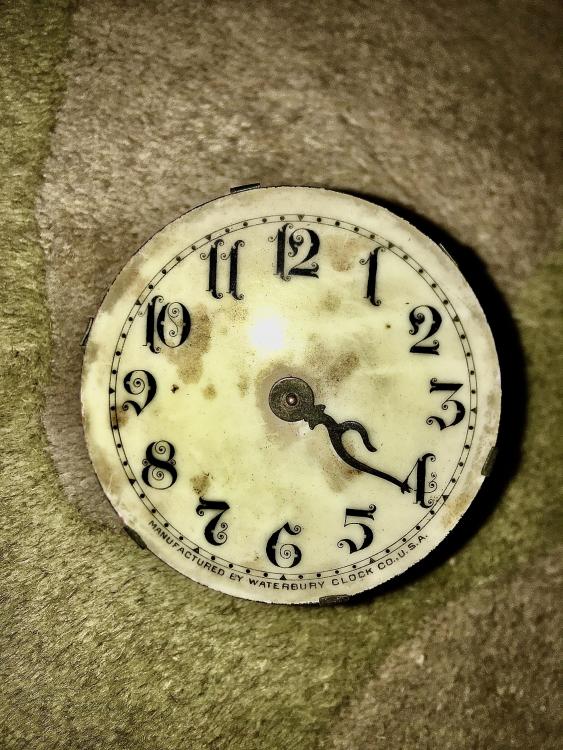

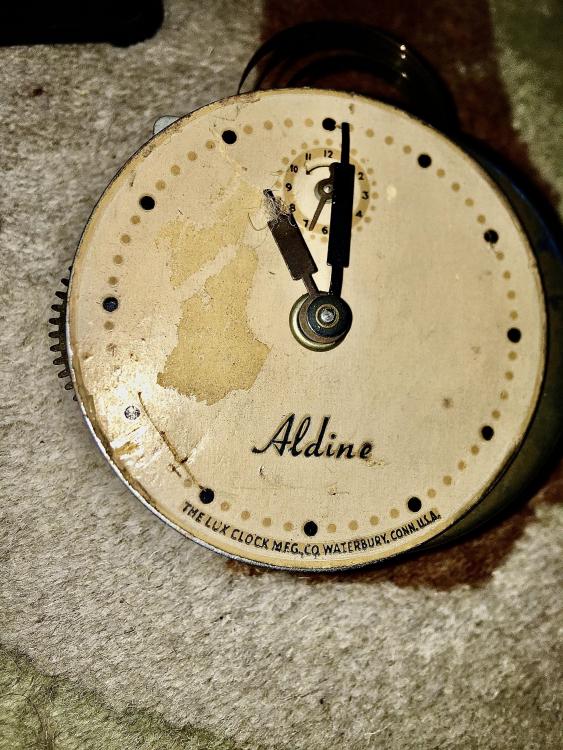

Someone gave me a bunch of clock parts for free that they were about to throw out. Knowing some of the history and value these might have I took them all! :) All of these parts and pieces seem to be broken in some way. There seems to be some really old parts in here. I was wondering if anyone on the forum could help ID some of the better, more valuable pieces and parts? I know some of these are worth keeping or selling, but I do not have much of a knowledge of vintage/antique clocks. (BTW please forgive the blurry pictures, my cell phone camera is dying and I discovered it while taking these photos)1 point

-

I'm new to this forum but some of the forum members are very much familiar to me!! how ?? I was secretly following and learning watch repairing techniques from you guys (thanks to Mark and others who put lot of freebies on YouTube and other forums). here are few watches from my collection https://www.instagram.com/crudecaliber/?hl=en why I only collect old and simple watches !!?? because purely I cannot afford new and complicated one's.1 point

-

1 point

-

I am not sure how to say this, AS 2066 used parts or watches might be sourced from India for less than the asking price of a scrap elsewhere, we are not sure if you need parts for it. Watchweasol is very right, lets find out why the dude doesn't run first.1 point

-

No, you're right. It's veneer. Veneer usually comes in two flavors: book matched and rotary cut (I said rolled above). The former involves cutting thin slices off a log, and lining them up side by side, typically accordion style so that the lines meet up and form a nice pattern. The latter involves taking a long and putting it on a giant spit with a giant apple peeler-like cutting device, and the veneer is peeled off in one large sheet. It occurred to me when you used the word manufactured (not that it has anything to do with it, that's just what triggered the thought), there's been a trend in recent years toward stacking a billion layers of plywood on top of one another to form a continuous face of plywood sides. I'm sure there's a name for it, but I don't know what it is. This may be a veneer version of that aesthetic. Hard to tell from the photos though. I googled a little, and there is also rift and quarter sawn veneer. The latter is not common, and while it sounds like it's usually oak, this isn't that. Might be rift sawn though, as that would account for the grain being so straight and regular. I've never seen a product like that at any of the local suppliers, but wood is a pretty regional thing, and I don't look at sheet goods very often so it would have been easy for me to miss. My money is on the rift sawn oak veneer. Looks really good with the trim. The strong horizontal lines give it a bit of a modern vibe.1 point

-

Its quite a nice looking watch and at $3 and being a mechanical watch this might be your route into the Horological hobby as at $3 its worth having a look to see whats worng. Then post if you want further help, of which there is plenty on this site. Have go1 point

-

1 point

-

1 point

-

Looks fake to me. Compare that "Omaga" (above) with for example these images (below). The tooling is far more precise, and the finish is streets ahead. I call FAUX-MEEEEGA!! Having said all that, there are some very good fakes around, so you need to be pretty careful. If it seems too good to be true, then it almost certainly is. Also always compare with lots of examples of the watch it claims to be, from sites like dealerships and the manufacturer. Some watches (TAG for example) produce so many variations and variants of variations, that this can be difficult, but Omega and to some extent non pimped Rolexes come in fewer variants, and you can almost always find a matching or close match to the watch that is for sale. If in doubt, ask for more and better pictures. Actually in my opinion, if in doubt, run away, since mistakes can be very costly.1 point

-

This has a lot of indicators the Bracelet the links appear solid on original Omega watches each link is made from multiple parts, the back is engraved "Escapement Co-Axial" it should be "Co-Axial Escapement " in that order with a circled Omega symbol preceding the engraving, the movement is chinese in origin "Swiss Omega Made" . The Omega movements have the calibre number on the rotor under a Omega symbol on the earlier calibre's or just the Omega symbol.1 point

-

Wristwatches aren't my forté. May I ask, what are some of the indicators that this is not a genuine Omega? This is something I would like to learn. Omega has been around a long time and I'm starting to get interested in them also.1 point

-

1 point

-

I fixed a friends watch and I bought a used fork plus MS for $21, looked like new fork but seller who said it was used had half a pound of psrts to the caliber. A new fork is far superior to old ones since pallet jewels are new on it. Anyway if you happen to see outrageous prices out there, I'll be happy to do what I can.1 point

-

Thanks for everyone who is giving the app a spin! I really appreciate it. It’s cool to meet another watch enthusiast who is also a developer. I built this using NodeJS (written in TypeScript) with MongoDB for data storage. The front end makes use of all the latest JavaScript web standards I could get my hands on so I didn’t have to touch any of the popular frameworks or even have a single build step in place — something I’ve been wanting to experiment with but couldn’t with my day job because of browser support limitations, etc1 point

-

I think those numbers refers to the system EBAUCHES SA tried to introduce a while ago. ETA has change their system a bit and do not always use these reference numbers nowadays. The older tech sheets still do so I attach an old document describing the different parts and their referens number. Dictionnaire Technologique-EBAUCHES SA.pdf1 point

-

a problem with this particular numbering system is that the numbers represent a part. Such as a stem is referred to part number 401. But part 401 without the movement number could refer to literally hundreds of different stems. So it's kind of a two-part system the number as opposed to the word stem bike 401 and then the movement number. Otherwise ordering a 401 all by itself it isn't going to fit. helpful when looking for parts is the third link where you can see the differences of the watches you're looking for they appear to be in the same family. Then the first in the second plank are the parts. If you click on the part number in each of the listings it give you the cross reference the parts. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_2773 http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_2783 http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_27831 point

-

SOLVED: I put a lot of Moebius HP1300 between the two parts and let it rest for 1-2 hours. Afterwards I removed the superfluous lubricants and installed everything back together. Turning the crown initially needed some torque but then the cannon pinion became loose and turntable. Setting the time is possible again. Thanks for the encouragement and the other tipps!1 point

-

Did you by any chance use an ultrasonic cleaner to clean this? Parts in close contact should not be placed in an ultrasound, such as scissors, pliers, ball bearings, etc. Especially items under spring tension. The parts vibrating against one another will cause indentations in the metal surface. This type of damage is called Brinelling ( named after the Brinell hardness test guy ).1 point

-

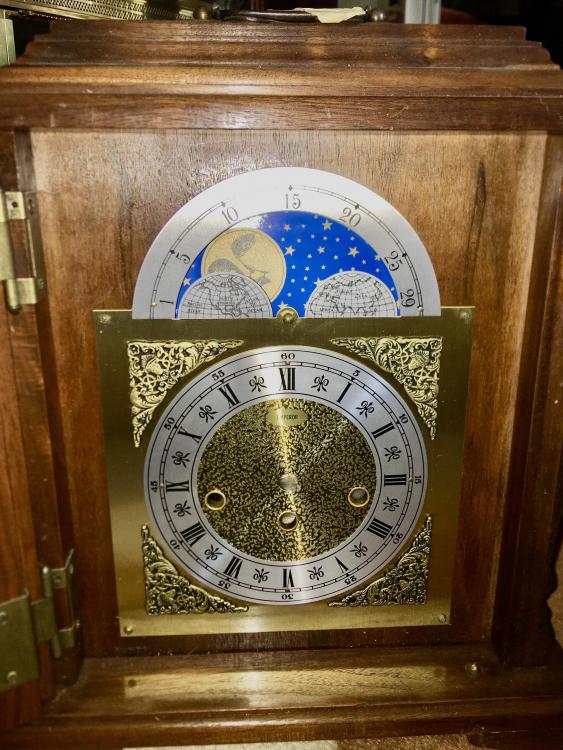

Many thanks wls for your reply, much appreciated. The clock does need a clean, particularly the dust inside the cabinet. I’ve only had the clock a few days and over a twelve hour period she gained eight minutes, the “time lever” for setting the “time accuracy” being set to F. At the time I took the photograph I had set the lever to S and over a further twelve hour period she correspondingly lost approximately six minutes. Today I have the lever set at the mid point so will be interesting to see the outcome. When you mention the “cylinder platform needs a service” is that the mechanism at the top of the clock which I have been adjusting via the lever ? The glass appears to be original, heavy but dirty around the edges. I suspected my carriage clock to be at the cheaper end of those produced but it does have a look of quality. Maybe that says something about it’s age. Nevertheless it’s nice to know that it is an original piece - many thanks for your time. I’ve attached of a photo of my previous favourite mechanical clock but the carriage clock is the one I look at first !1 point

-

May be the patent application was for the lock? And where is the key? Then they may have spent the related fee in at the pub instead? Difficult questions, I know. I know the model, he's my watchmaking mentor, portraied 30 years ago.1 point

-

A stereo microscope is incredibly useful, I did not know that before I got mine. Check this post out: pivot holes I took me months to figure out whats wrong and the microscope helped me with this. I must say that my lack of experience was also responsible here, probably I could have noticed this with just using a lupe and having a good look at the pivot holes. As Andy said check the pivot holes and all the pivots too. I had a balance pivot with a mushroom effect, it was so bad that i had to use some kind of a force to pull the pivot out from the pivot hole and the watch actually run in certain positions.1 point

-

Got a job lot of 16 in the post last week, £63 + £5.20 postage, so £4.26 each all in, how that is eventually amortised over the bunch remains to be seen! One of them at least is probably beyond saving (the squareish one is missing crystal and it would be uneconomic if not impossible to get a replacement) They are all 70’s ish Swiss, I’ve taken the back off a few and they are all budget, built down to a price with pressed components and most are only 1 jewel. If nothing else I may repurpose the cases for a couple of them to house better orphaned movements. First one I tackled was this Trafalgar 2 hander with a Baumgartner BFG 866, Interesting little movement, it sort of has a keyless works bridge, everything else is on one plate so getting everything in the train lined back up on reassembly was a bit of a challenge (no jewels doesn’t help here either, the tiny holes are difficult to spot!) the pallet fork is an unconventional ‘sideways’ design with metal pin pallets. Seems this movement was also available with seconds hand, day and day/date variants as well as being used in some jump hour watches. This one wasn’t running at all but otherwise in decent cosmetic shape, just needed a good clean to get it going. Now runs solidly with decent amplitude (260+) dial up/down, but positional error is dreadful crown down/up/right/left, amplitude drops below 200 and timekeeping goes from +/- 10s to -400s! Beat error goes up too. Not sure if this is just a symptom of a worn cheap movement or whether I could improve it at all. I’m pretty inexperienced still and positional error seems to be my nemesis on the few watches I’ve tackled! Not really sure where to look, if it was a fully jewelled movement I would check for damaged jewels but here I just have holes, so maybe that is partially to blame? Will update on the others as I work through them!1 point

-

I forgot a contribution to this club. Got a bunch of watches in a lot I bought a while ago, think the average price was about 3£ a piece, sometimes one just need one part and end up with a bunch of classic watches, like this which I’m quite sure is the pride of some eastern country watchmaking. Let me introduce the 39-Day calendar watch! With this one all your vacations becomes a little bit longer0 points