Leaderboard

Popular Content

Showing content with the highest reputation on 03/18/20 in all areas

-

Brand new in box, never worn, and with original guarantee and user manual, all for the heady sum of 0.99p plus postage, no other bidders. Admittedly it had been sitting around so long, unworn and unloved that the battery was flat, but never the less, I think this one more than qualifies for the 404 club.2 points

-

No worries, just wanted you to know that I’m experienced enough to know my limitations. Have serviced and ”repaired” up towards a 100 wrist watches of cheaper origin and age and know that unexpected things may happen any time concentration slips. Mainspring swap should be in my reach here but I’ll tread carefully. Sent from my iPad using Tapatalk2 points

-

This Bloody awful scourge has us all on the back foot and we all have to take it seriously , The attitude It wont happen to me, has got to go. If a company like BERGEON are taking it seriously so shall we all. Keep safe and well friends.2 points

-

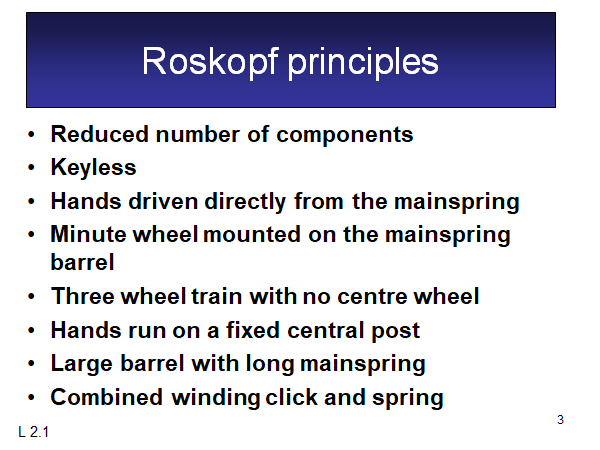

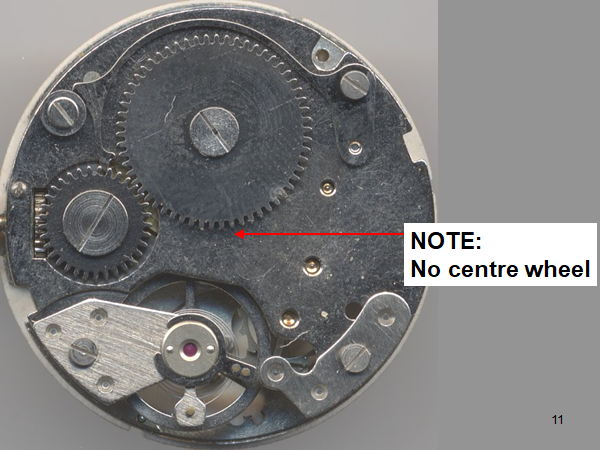

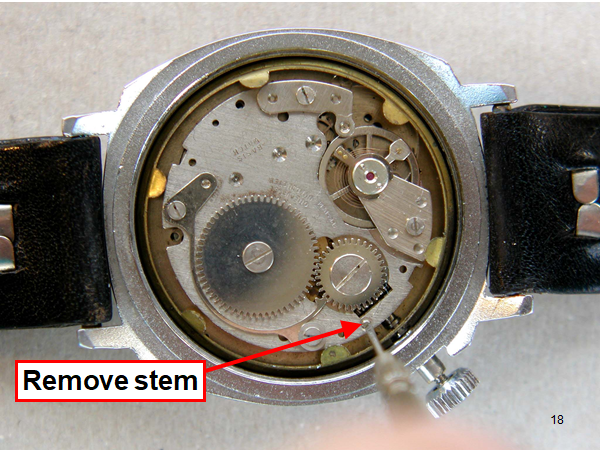

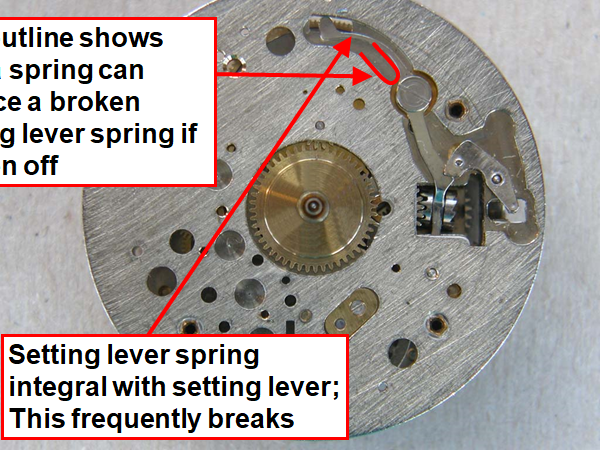

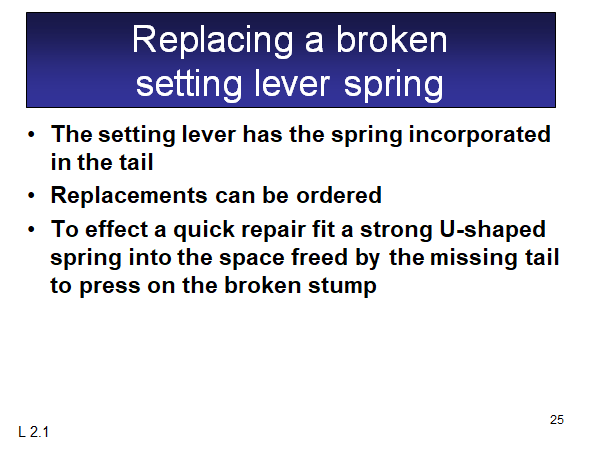

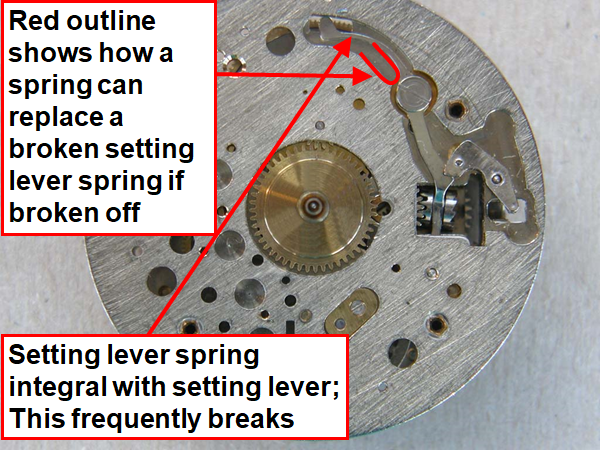

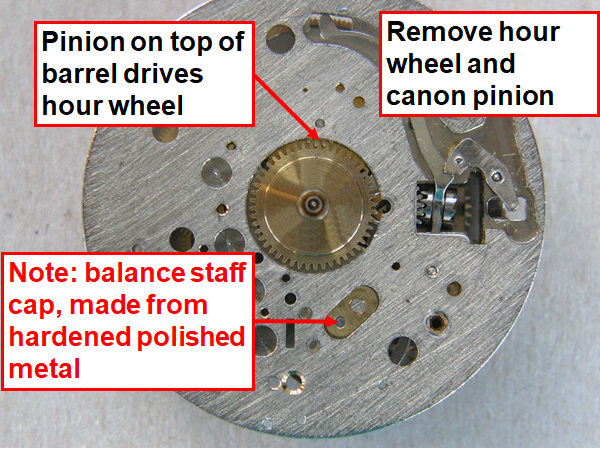

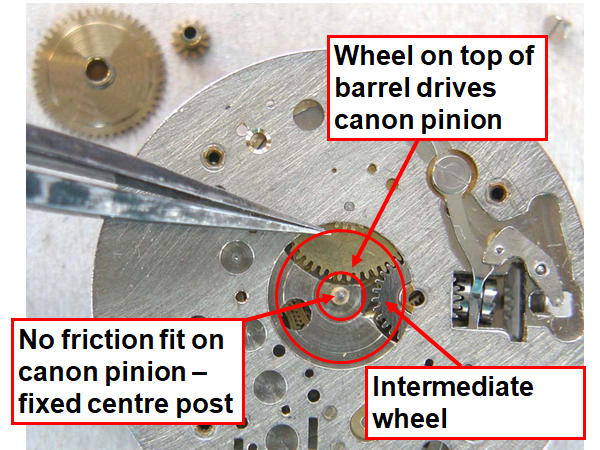

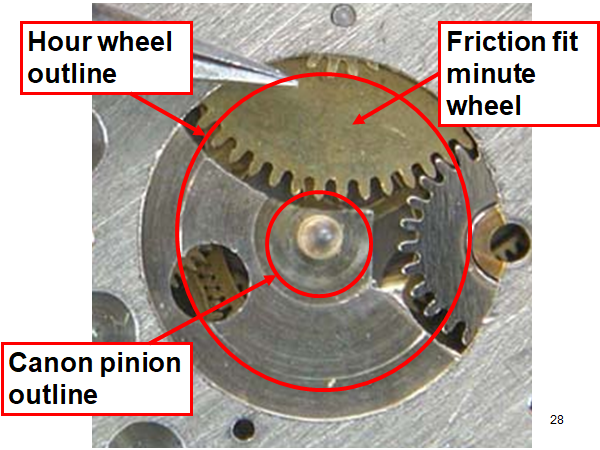

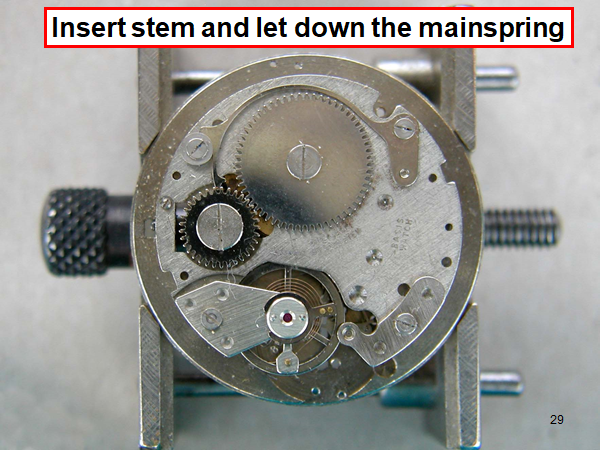

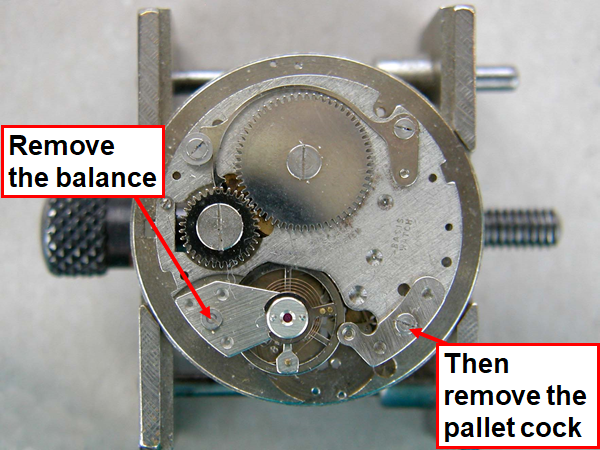

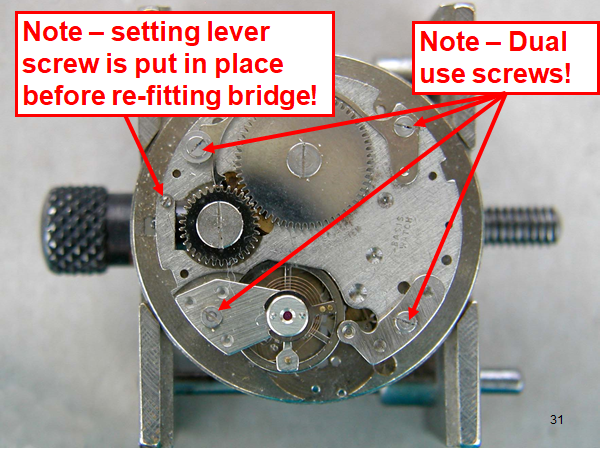

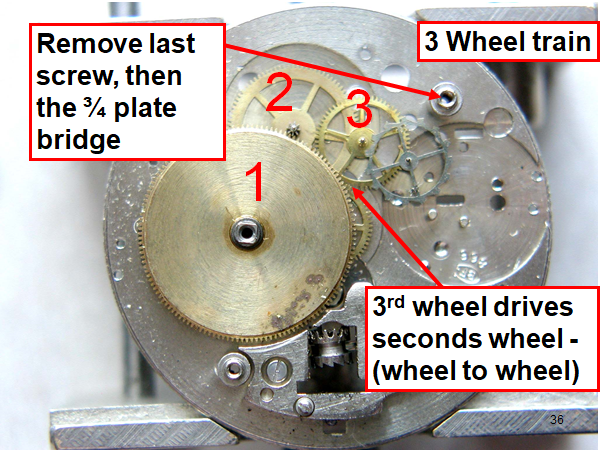

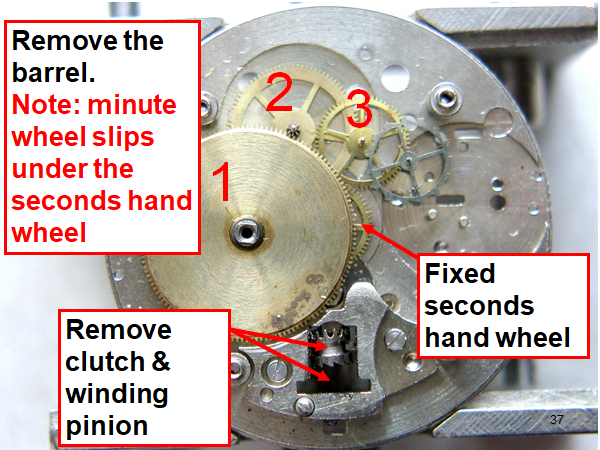

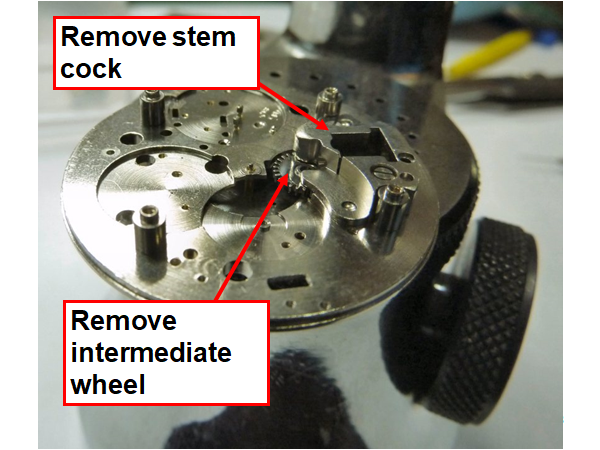

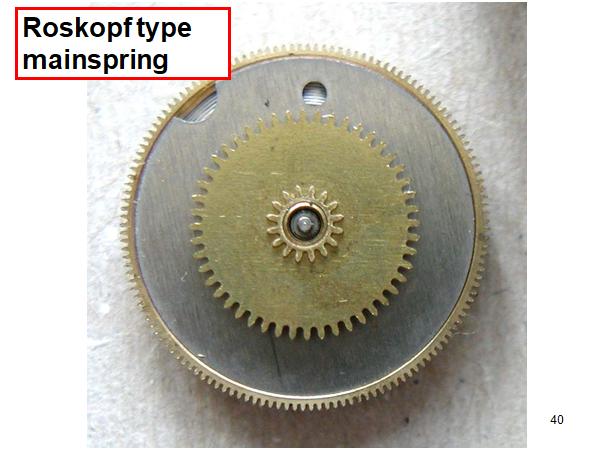

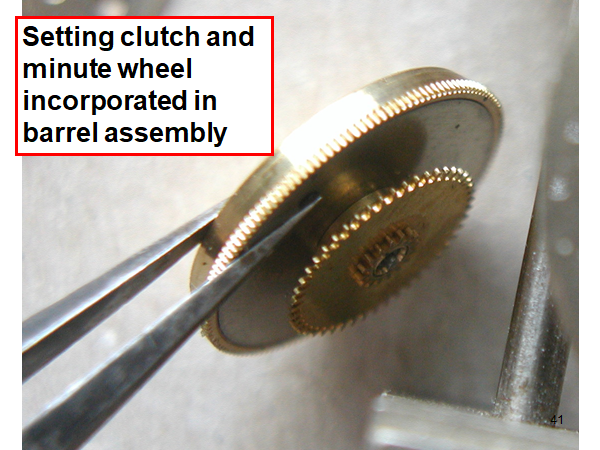

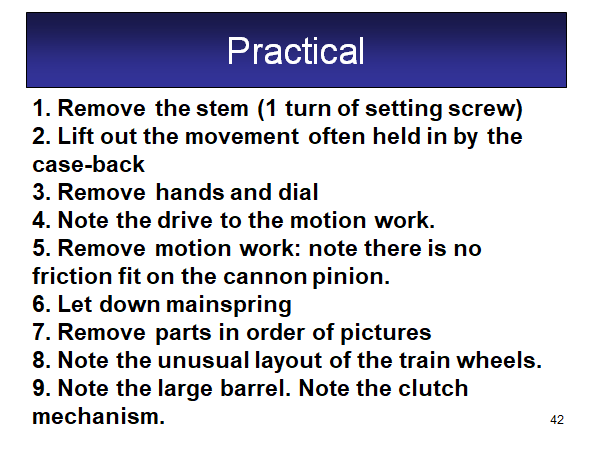

Hi, I teach watchmaking to complete beginners at Epping Forest Horology Centre, close to Epping and this is one of the lessons on the BFG 866. I wanted to show my class a classic pin pallet (Roskopf) movement and how to service it, as many watchmakers won't touch these watches as they hold no monetary value. Turn the setting lever screw 1 to 1 and a half turns to release the winding stem A piece of watch paper or small plastic jiffy bag to protect the dial, whilst removing the hands The driving pinion is part of the friction fitted minute wheel on top of the barrel. This work in a similar way to a friction fitted canon pinion to set the watch hands Remove the keyless work: setting lever, held in place by the setting lever screw, screwed from the other side of the mainplate, then the yoke, which sits on top of the clutch (castle) and also the winding pinion. I have three other lessons on this movement that cover bringing the watch 'into beat' as well as taking apart the friction fitted minute wheel from the barrel, lubricating and staking back on to achieve the correct friction setting and finally how to remove the centre seconds wheel safely and refit using a staking set. Many people leave the friction fitted minute wheel on top of the barrel, not realising the amount of old grease that can't be cleaned out from it, as well as not removing the wheel of the centre seconds arbor and again not cleaning out the pipe which has old grease inside. Hope you enjoyed the tutorial? More to come....1 point

-

1 point

-

Exactly. If the collet is centered, the spring will touch the regulator pin. Probably this hairspring was changed in the past. Frank1 point

-

First; 80 degrees can't be right. Second; 209 is very low as well ...... are you sure you did set the lifting angle to 42 degrees?1 point

-

Haha don't worry I had a million "dumb" questions when I was starting out! Also somtimes you overthink things and come out with questions that can only be thought of as dumb dumb, unless the teacher understands. Having been on both sides I understand!1 point

-

Help and welcome. This specific forum is strictly for introductions and we try to enforce that rule to encourage a smooth flow of posts. In regards to your dilemma, it can be fixed given a few criteria. 1: Value and scarcity of the watch 2: material that the watch is made from 3: finding someone with the appropriate skills to perform this repair. 4: An understanding of the cost of the repair VS the value of the watch. That said, it may just be cheaper to replace the watch altogether rather than shell out the cost of repairing it. I hate to break it to you, but your watch is more or less a fashion watch and generally speaking doesn't have much actual value other than personal. I'm not sure what that exact watch cost new, but I found more than one for under $80 on eBay. Good luck my friend.1 point

-

Hi Dadistic you will have to be carefull, some other lathe sneaked in and that's the result although if it happens again it could be profitable. You will have to find the father !!!!!!!!?.1 point

-

1 point

-

The movement number appears to be a serial number.. American pocket watches for instance the serial number will usually reveal a model number.. Then from the model number you get a list of parts. Other ways to identify watches not just pocket watches the diameter of the movement and picture of the setting parts found under the dial. The setting parts of watches form what's known as a fingerprint system there are various old catalogs showing those pictures you can identify movements. Or there is the second website link below you can enter in parameters somewhere in the site to help you narrow it down or in my case I just guessed. There is not many watches listed by this company there. Then you do want to compare your photos with the site below just to make sure I guessed correctly.. Then parts from this company for the most part nonexistent. The real question is whether they went with a custom mainspring or whether that was off the shelf? The only way you're going to know is you'll have to disassemble and measure the mainspring if you're lucky may be an off the shelf spring will fit. Then the first link need more information about this watch they will look in their archives for you for a fee. https://www.patek.com/en/retail-service/extract-from-the-archives http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Patek-Philippe_18H51 point

-

1 point

-

1 point

-

How are you holding the screw for polishing? Typically it would be held in a tripod tool if going for a flat polish. I would recommend a couple of paper steps before polishing, I typically use 20 micron for serious flattening then 12 micron and go straight from there (after cleaning) to diamond paste, Aluminum is not a good substrate for polishing, the surface oxidizes in minutes and that is as hard as ruby. If you don't want to find or make a tin or zinc plate, thick plexiglass works well. Roughen the surface with a clean file before using.1 point